Patents

Literature

43results about How to "Small error in temperature measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature field measuring instrument of CCD image sensor

InactiveCN101566503AImprove practicalitySmall error in temperature measurementRadiation pyrometryMeasuring instrumentImage acquisition

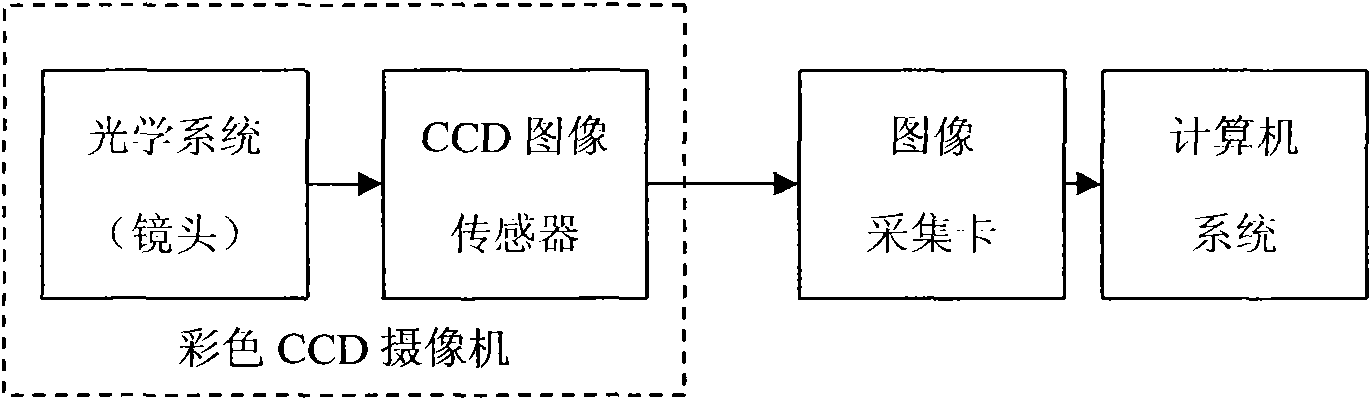

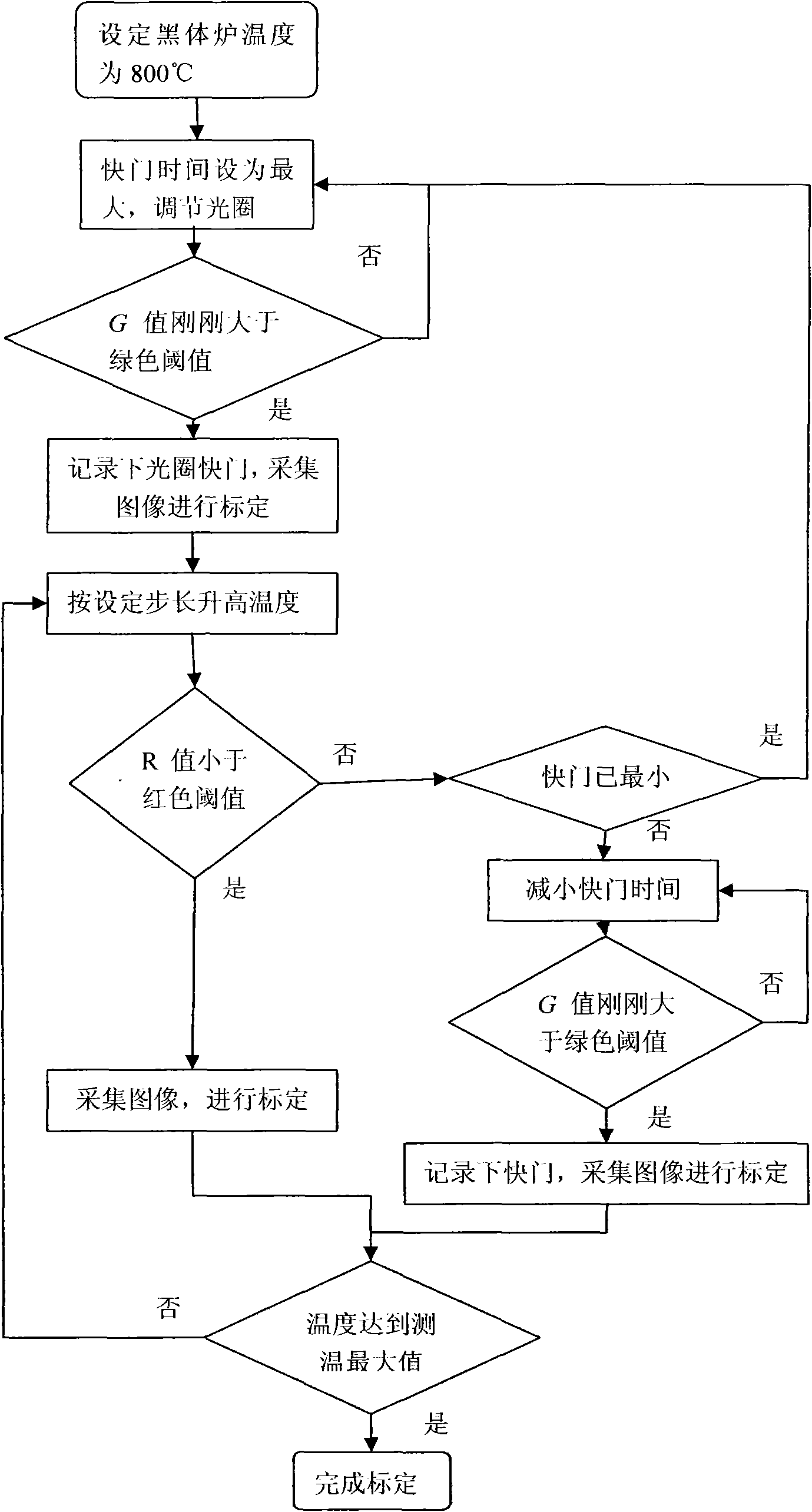

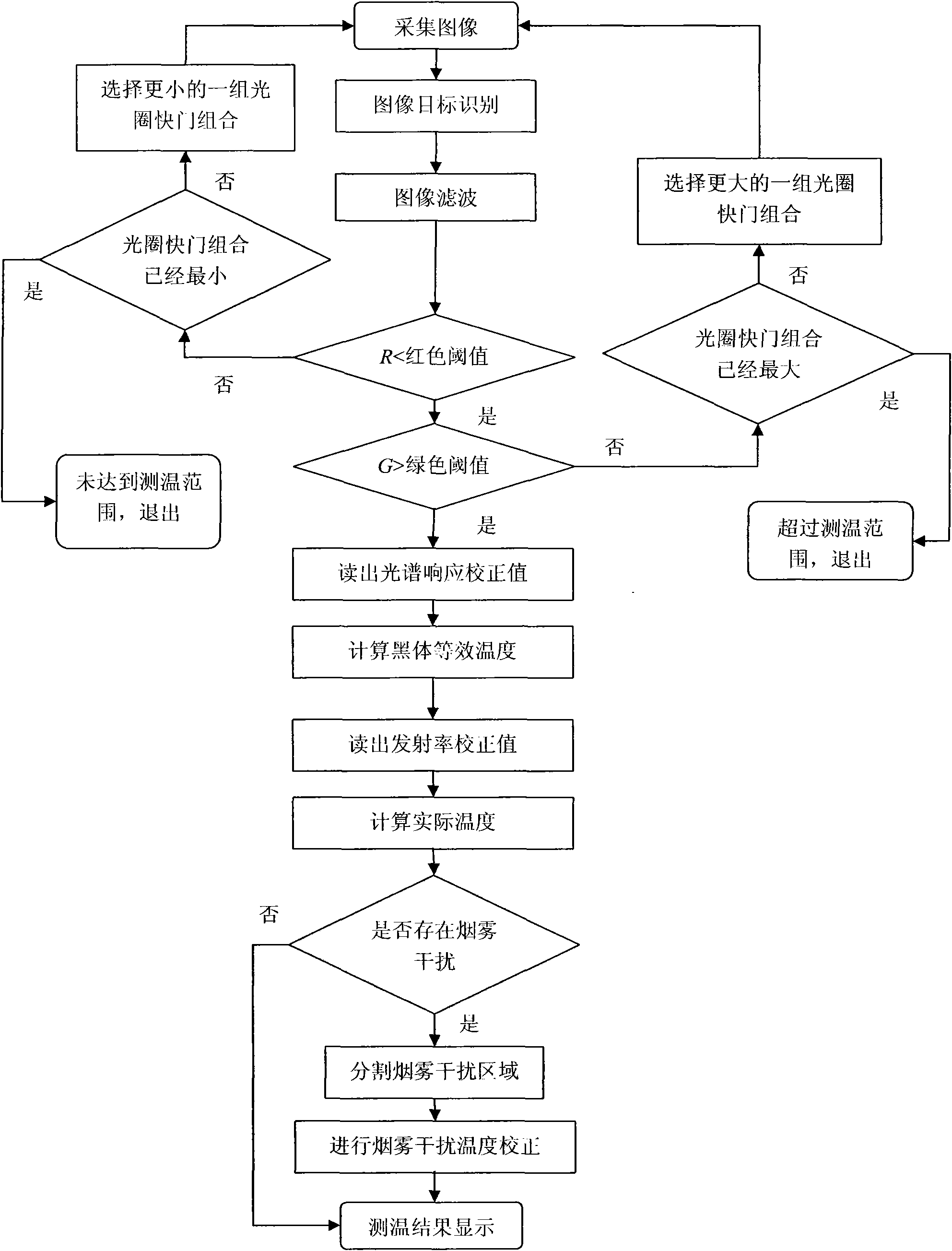

The invention relates to a high-temperature field non-contact type measuring instrument based on a color CCD image sensor. The measuring instrument consists of the CCD image sensor, an image acquisition card, a computer system and a corresponding measuring software. A calibration experiment is implemented for correcting temperature-measuring results, and the CCD is guaranteed to work in a linear area all the time by automatically adjusting the inlet light quantity. The high-temperature radiator images acquired by the CCD are preprocessed to obtain red and green base-color values; a soft measuring model is used for calculating the surface temperature field of a radiator; and a smoke attenuation radiation energy compensator is used for compensating and correcting the temperature-measuring results. The pseudo-color display is conducted on the final calculation results of the temperature field.

Owner:彭小奇 +2

Temperature measuring system based on image sensor

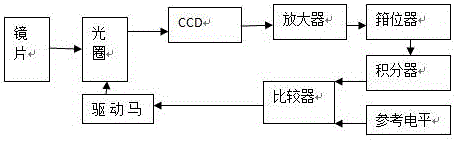

InactiveCN106017694AReduce grayscale variationSmall error in temperature measurementImage enhancementRadiation pyrometryCamera lensLuminous flux

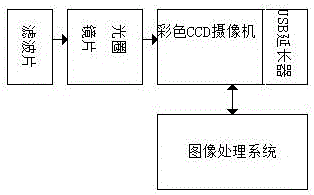

The invention discloses a temperature measurement system based on an image sensor, which is characterized in that: it includes an imaging system, an image sensing system and an image processing system; the imaging system includes a filter and a lens, and the lens includes a lens and an aperture for The thermal radiation signal of the measured object is gathered on the photosensitive surface of the CCD, and the passing luminous flux is controlled at the same time; the image sensing system includes a color CCD camera and a USB extender, and the color CCD camera is used for photoelectric conversion, outputting temperature information RGB signal and USB extension are used to realize remote control and remote high-speed transmission of data; the image processing system is used for temperature calculation, temperature field display and analysis and processing data. The three-primary-color temperature measurement method of the invention reduces the temperature measurement error caused by factors such as the gray scale change of the heat radiator and the non-ideality of the CCD response wavelength bandwidth, and the image segmentation method can quickly and accurately segment the target image.

Owner:CHENGDU DESHANNENG TECH CO LTD

Double-wavelength single receiving channel-based rotation Raman temperature measurement laser radar

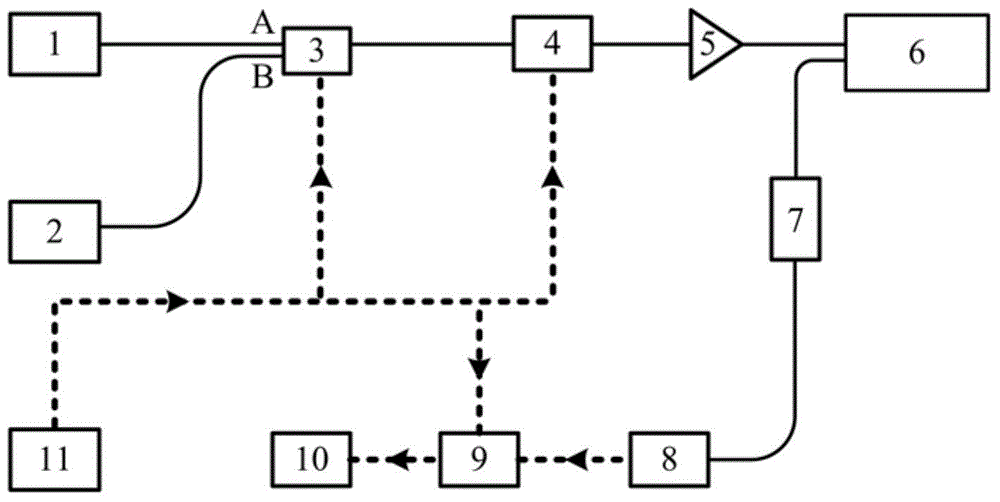

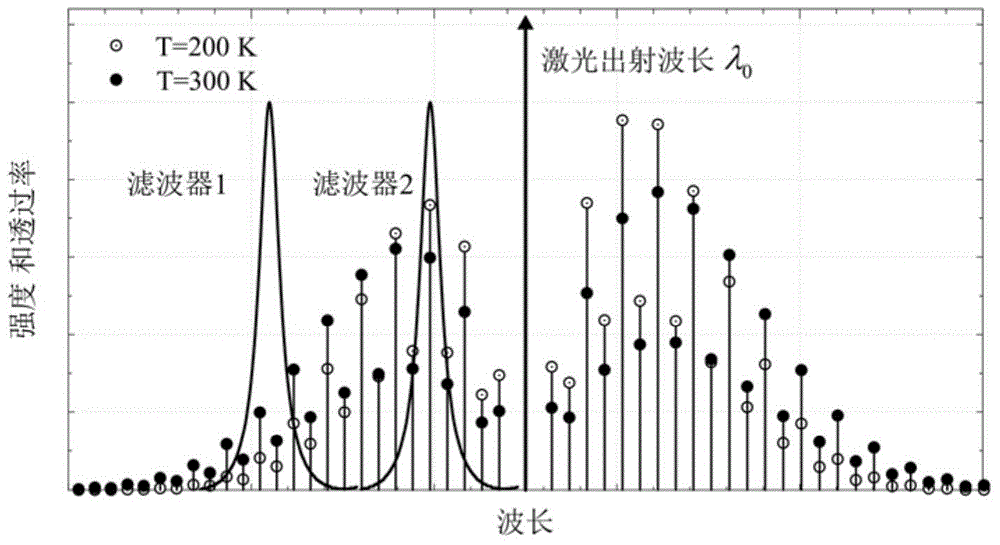

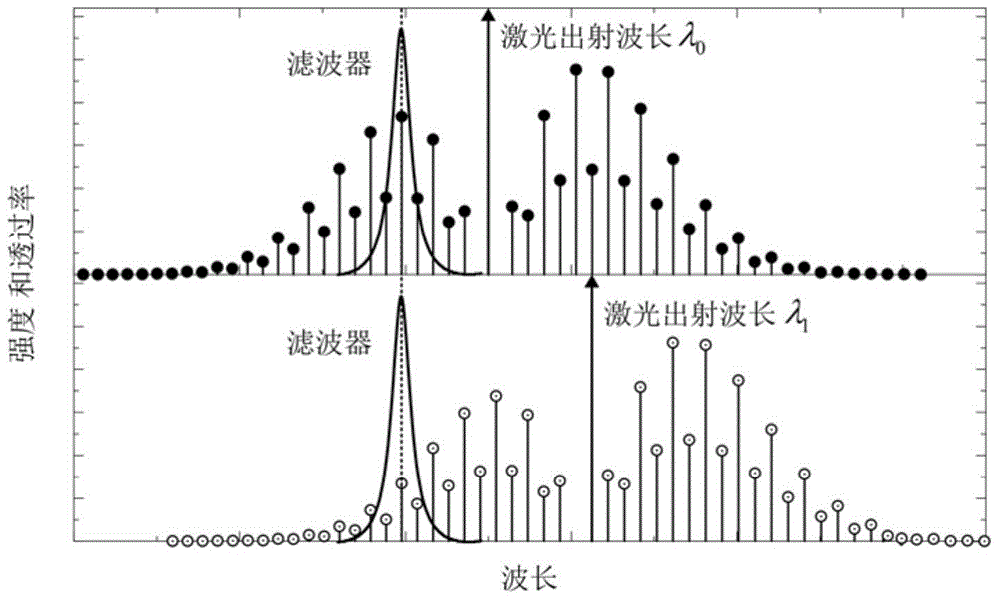

ActiveCN105182365AReduce the difficulty of adjustmentAvoid job performance varianceElectromagnetic wave reradiationICT adaptationAtmospheric temperatureRaman lidar

The invention discloses a double-wavelength single receiving channel-based rotation Raman temperature measurement laser radar. The laser radar is based on two working wavelengths and a single receiving channel. The two working wavelengths of the laser radar are respectively composed of odd number pulses and even number pulses. The low-quantum-number rotation Raman signals of one working wavelength and the high-quantum-number rotation Raman signals of the other working wavelength are extracted by the receiving channel of the laser radar. The laser radar is operated alternately at the two working wavelengths in the time division multiplexing manner. The atmospheric temperature is calculated based on the ratio of high-quantum-number rotation Raman signals to low-quantum-number rotation Raman signals. According to the technical scheme of the invention, the rotation Raman temperature measurement is realized only by means of a single filter, a single detector and a single acquisition card. Compared with a single-wavelength double receiving channel-based rotation Raman temperature measurement laser radar, the above laser radar is compact in structure, wherein the difficulty of optical path adjustment and the difficulty of system parameter calibration are lowered. Meanwhile, the double-wavelength single receiving channel-based rotation Raman temperature measurement laser radar is low in cost. The working performance difference between the filter and the detector caused by the inconsistence of working environments can be avoided. Moreover, the detection accuracy, the system stability and the environmental adaptability are improved.

Owner:UNIV OF SCI & TECH OF CHINA

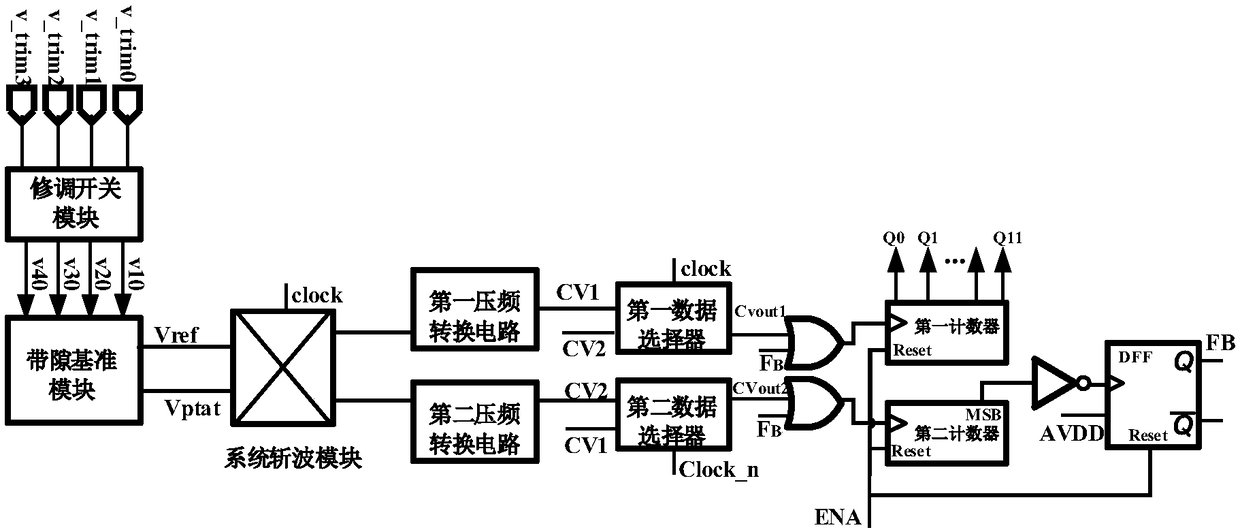

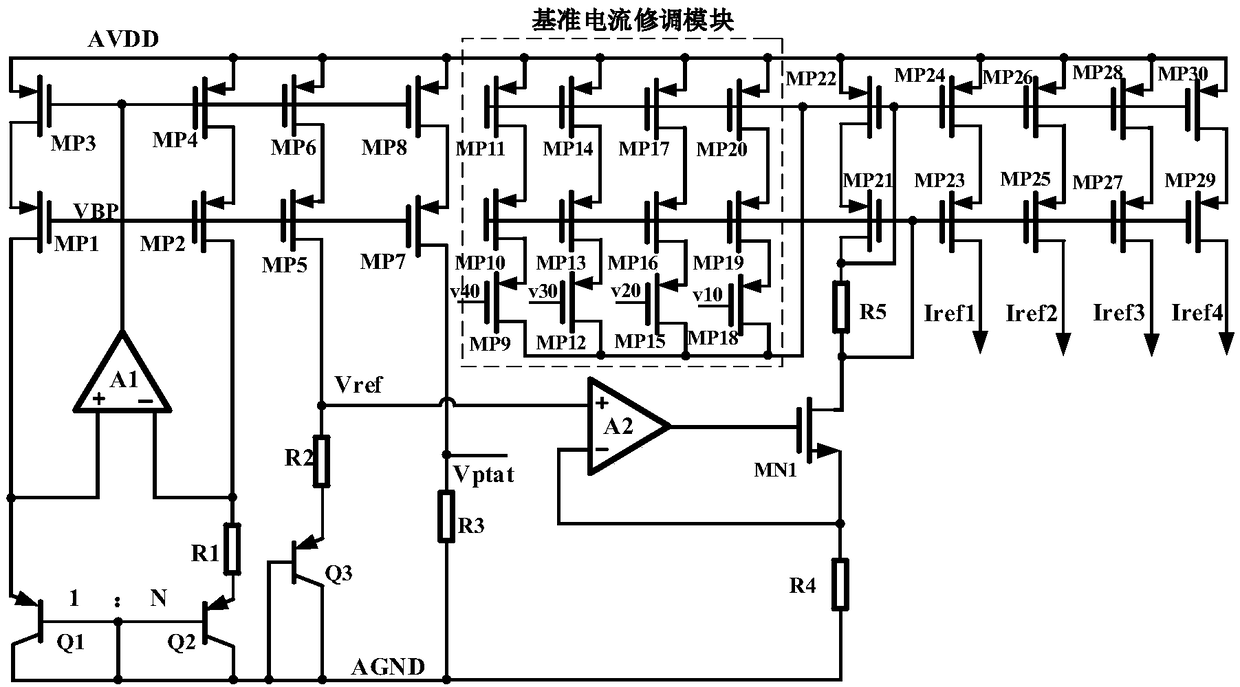

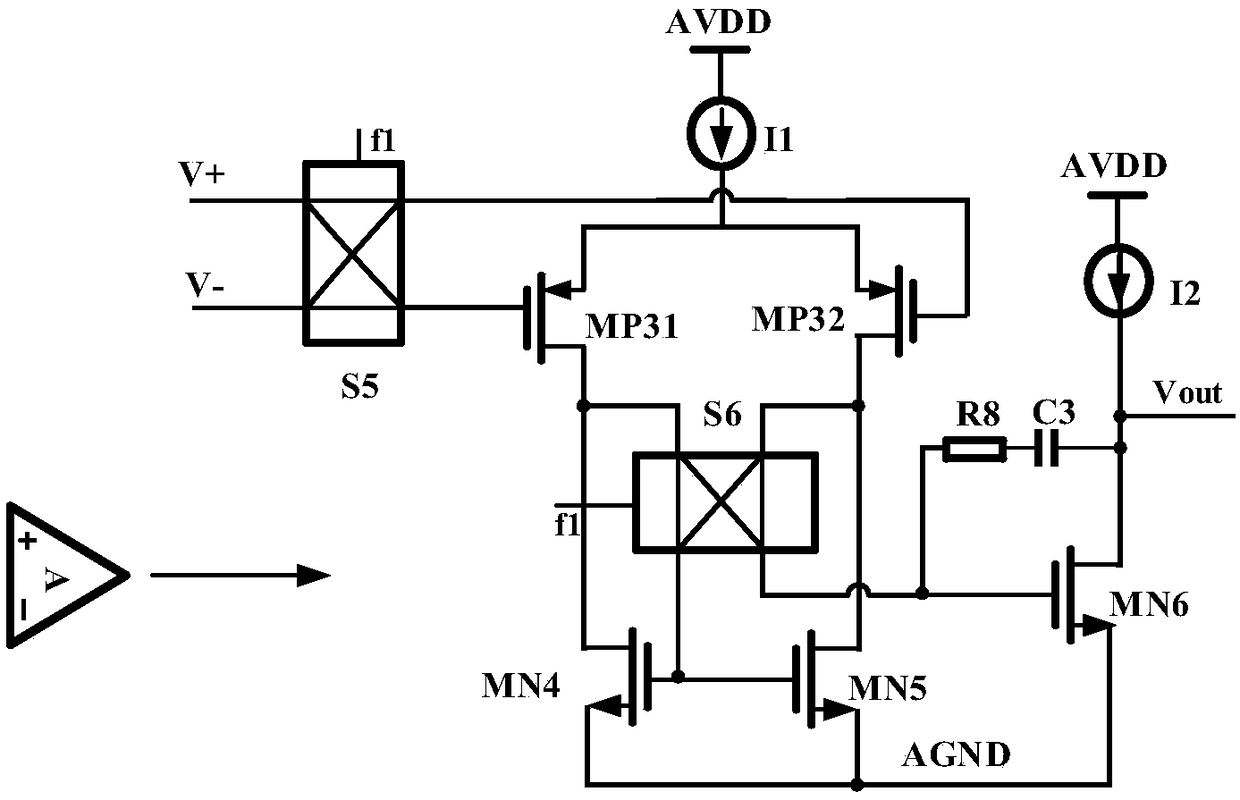

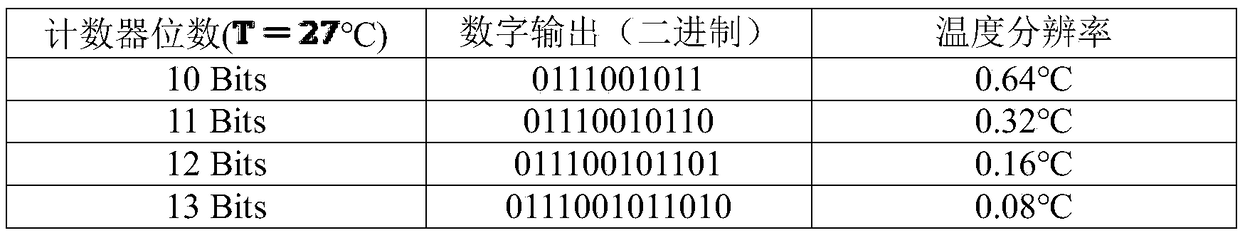

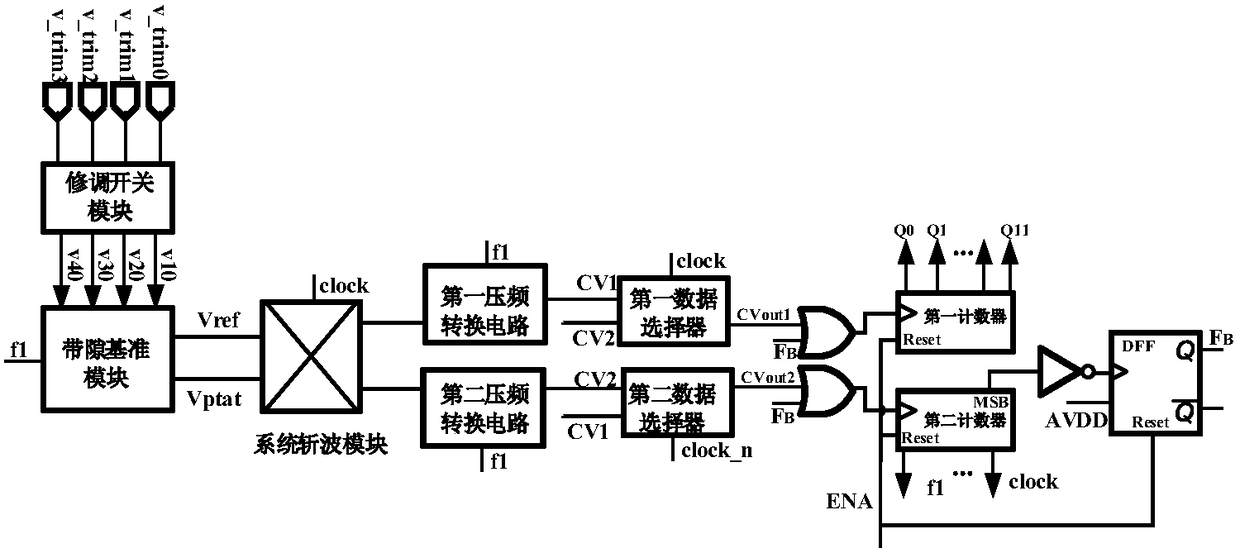

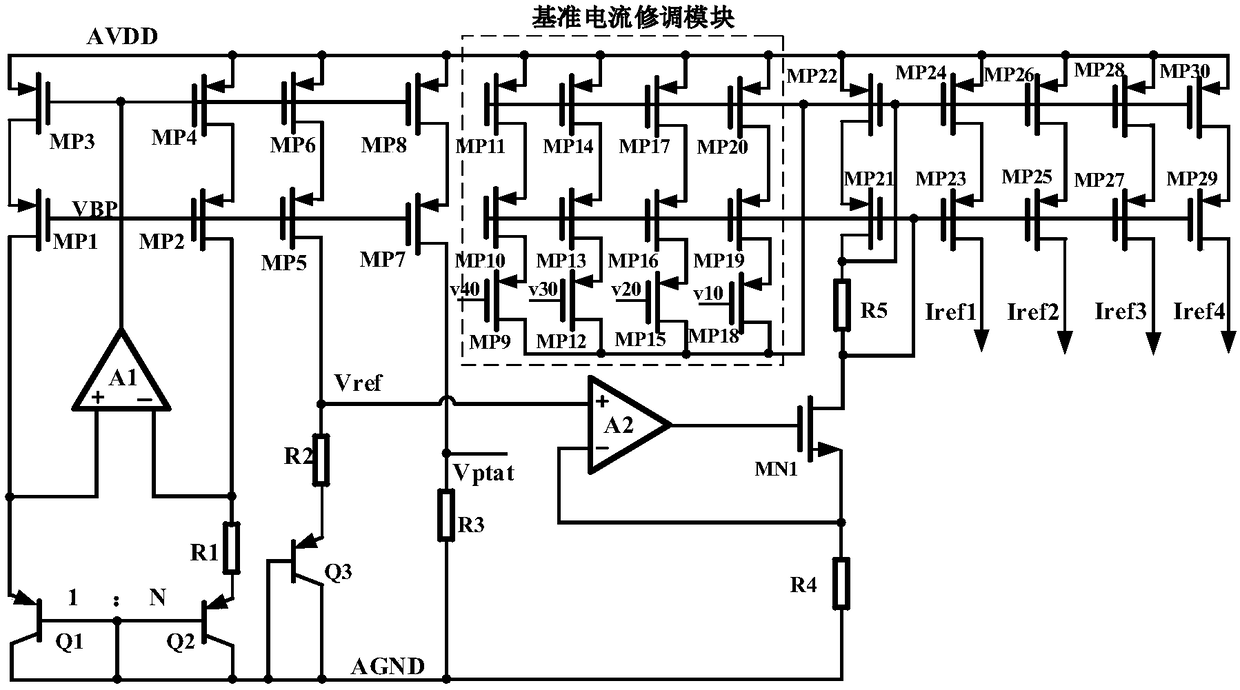

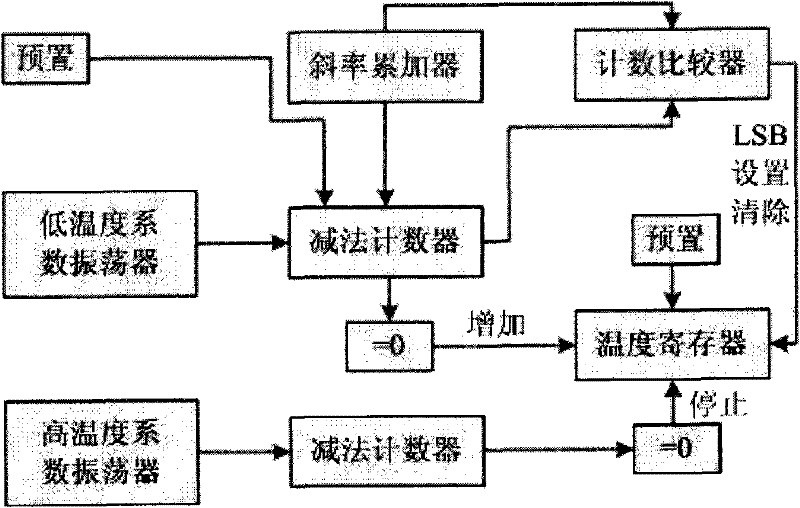

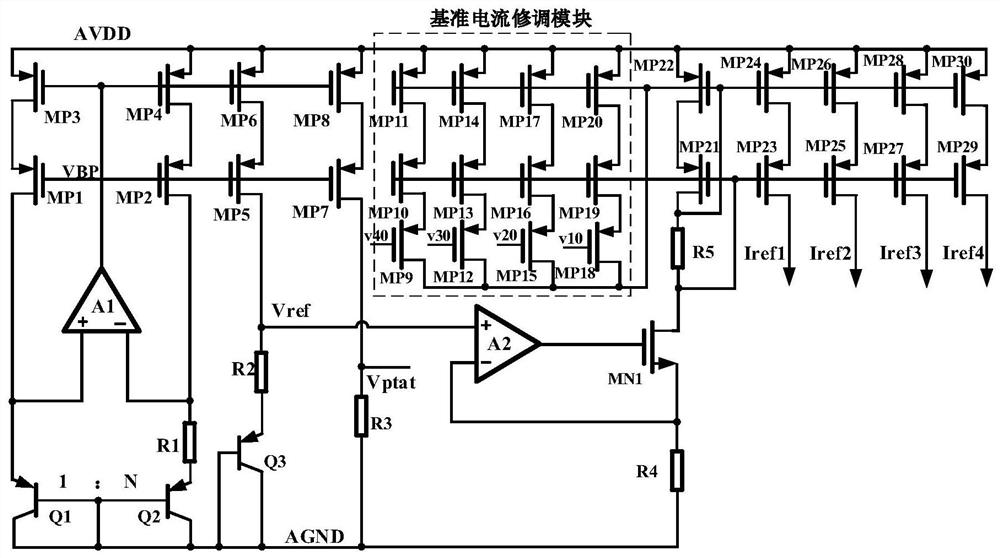

High-precision temperature sensor circuit

ActiveCN108562373ASimple structureReduce power consumptionThermometers using electric/magnetic elementsUsing electrical meansFrequency conversionHemt circuits

The invention discloses a high-precision temperature sensor circuit and belongs to the technical field of electronic circuits. Firstly, a bandgap reference module is utilized to generate a bandgap reference voltage and a positive temperature coefficient voltage; then, two identical voltage-to-frequency conversion circuits are used to convert the positive temperature coefficient voltage and the bandgap reference voltage into a positive temperature coefficient voltage frequency and a bandgap reference voltage frequency, respectively; finally, two counters are used to count; and after a second counter is full, the first counter stops counting by a feedback signal, and a temperature value is obtained by obtaining a ratio of the positive temperature coefficient voltage to the bandgap referencevoltage. The designed temperature sensor has a simple structure and can realize low power consumption; a chopper operational amplifier is used in the bandgap reference module to eliminate an error caused by offset of an operational amplifier; a system chopper module is added behind the bandgap reference module to reduce a temperature detection error caused by a comparator offset voltage; and the high-precision temperature sensor circuit provided by the invention has the advantages of simple structure, low power consumption and small temperature measurement error.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

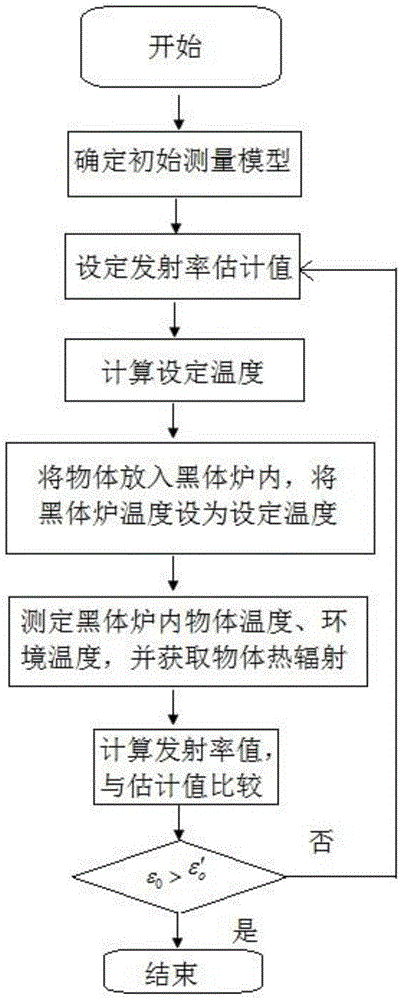

Emissivity measurement method

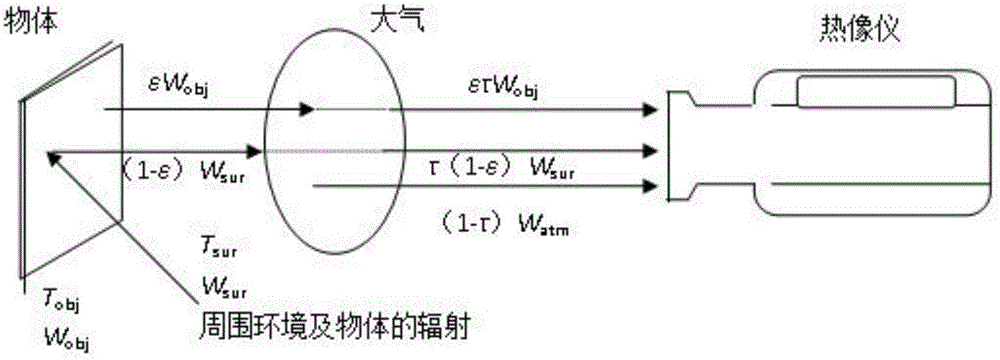

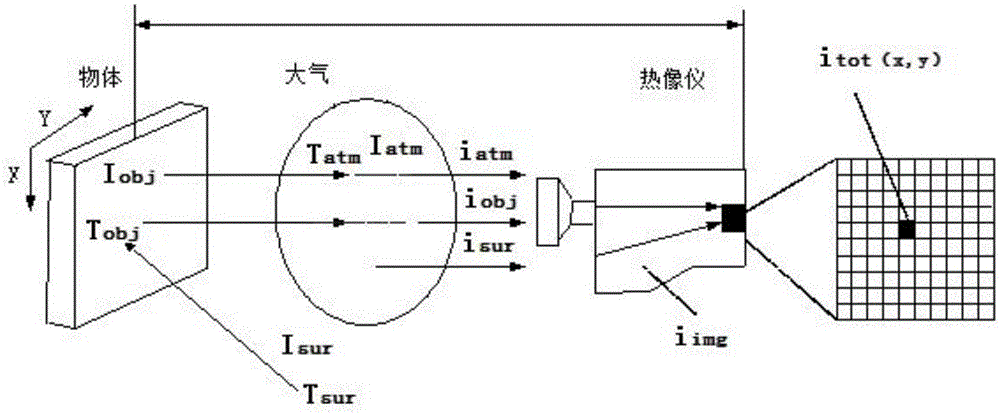

InactiveCN105004754AOptimizing the emissivity measurement modelSimple and fast emissivity measurement modelMaterial heat developmentThermal radiationRadiation

The invention discloses an emissivity measurement method. The method comprises the processes of establishing an optimized emissivity measurement model, and measuring the emissivity of an object to be measured through using the optimized emissivity measurement model. The optimized emissivity measurement model establishing process concretely comprises the following steps: establishing an initial emissivity measurement model, selecting an object having a same material with the object to be measured as an experiment object, setting an emissivity estimation value epsilon'o, and calculating the set temperature T''obj of the experiment object; putting the experiment object in a blackbody furnace, setting the temperature of the blackbody furnace to be T''obj, and calculating the temperature Tobj of the experiment object in the blackbody furnace and the ambient temperature Tsur outside the blackbody furnace after stable reading; capturing heat radiation itot of the experiment body by using an infrared thermal imager; substituting the itot, the Tobj and the Tsur into the emissivity measurement model, calculating to obtain the emissivity epsilono of the experiment object, comparing the epsilono with the epsilon'o, and ending optimization if the epsilono is greater than the epsilon'o; and resetting the epsilon'o if the epsilono is smaller than the epsilon'o, and re-optimizing until the epsilono is greater than the epsilon'o. The method is simple and fast; and when the optimized emissivity measurement model is used to measure the emissivity of the object, the measurement result is accurate.

Owner:XI'AN POLYTECHNIC UNIVERSITY

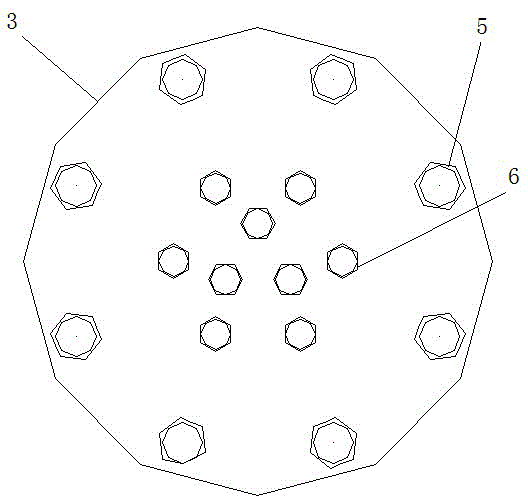

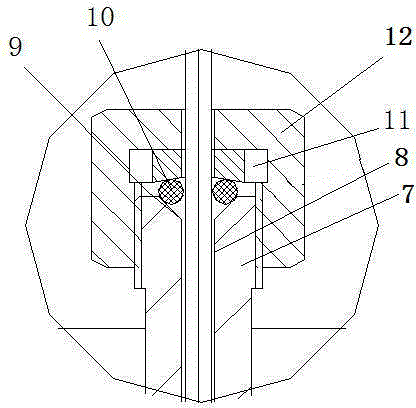

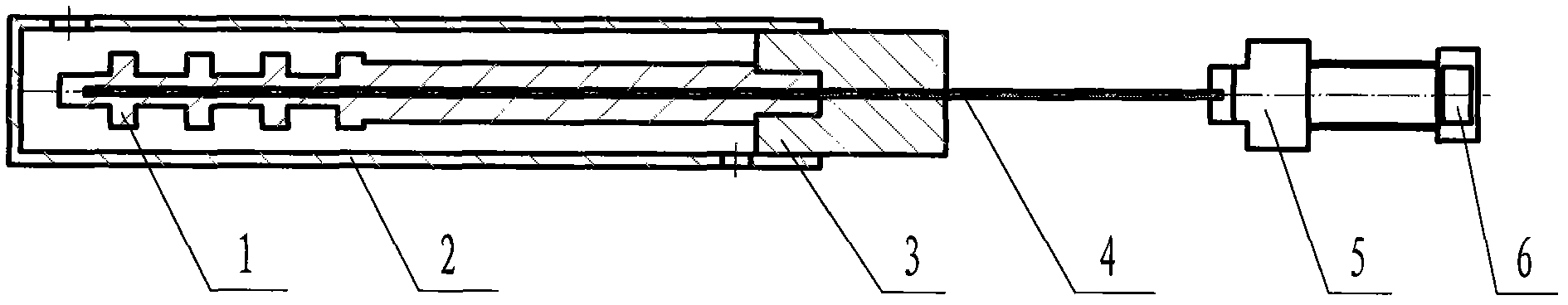

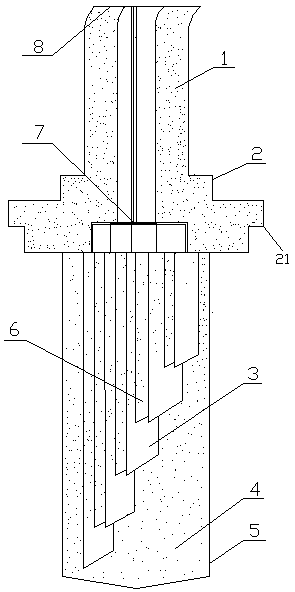

Multipoint temperature measuring interface device of vacuum furnace

InactiveCN103913248ASmall error in temperature measurementThermometer detailsThermometers using electric/magnetic elementsRubber ringInductor

The invention relates to a multipoint temperature measuring interface device of a vacuum furnace. The interface device comprises flange locknuts, temperature measuring thermocouples, a flange cover and multipoint temperature measuring pipes. The flange cover is provided with outer holes and inner holes, the multipoint temperature measuring pipes are connected to the outer holes in the bottom of the flange cover and penetrate into the flange locknuts to be fixed, the temperature measuring thermocouple are connected into the inner holes in the flange cover and provided with inductors, fixing bases are installed at the inner holes, locking threads are arranged on the outer sides of the fixing bases and fixedly connected with the inner holes, hollow round pipes are arranged in the centers of the fixing bases, the temperature measuring thermocouples are connected with the insides of the hollow round pipes, oblique openings are formed in the inner sides of the pipe openings of the hollow round pipes, O-shaped sealing rubber rings are placed in the oblique openings, spacers are installed at the top ends of the fixing bases and are fixedly sealed through sealing lock nuts, gaps between the temperature measuring thermocouples and the flange cover can be well fixedly sealed through the fixing bases, and the effect of reducing temperature measuring errors is achieved.

Owner:WUJIANG YATAI VACUUM EQUIP TECH

High-temperature temperature sensor based on surface-modified tungsten-rhenium thermocouple

ActiveCN102095517APrevent changes in thermoelectric propertiesEasy to useThermometers using electric/magnetic elementsUsing electrical meansRheniumComposite ceramic

The invention belongs to a temperature sensor for high temperature measurement, and relates to a high-temperature temperature sensor based on a surface-modified tungsten-rhenium thermocouple for short-time temperature measurement below 2600 K. In the invention, a composite ceramic material is used as the protection film of the tungsten-rhenium thermocouple to prevent the change in the thermoelectric characteristics of the tungsten-rhenium thermocouple due to the erosion of oxidative gas. Through the film coating treatment, a composite high-temperature-resistant and anti-oxidant ceramic material grows on the surface of the tungsten-rhenium thermocouple to ensure the normal use of the thermocouple wire. Meanwhile, a special protection sleeve material is used to ensure a less comprehensive temperature measurement error during the temperature measurement of high-temperature air flow through theoretical analysis and numerical calculation. Therefore, the high-temperature temperature sensor is applicable to the high-temperature air flow environment and can keep the enough thermal strength to ensure the temperature measurement accuracy with the aid of a proper structure. In addition, the high-temperature temperature sensor has the advantages of high temperature resistance, high oxidation resistance, quick response and the like.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

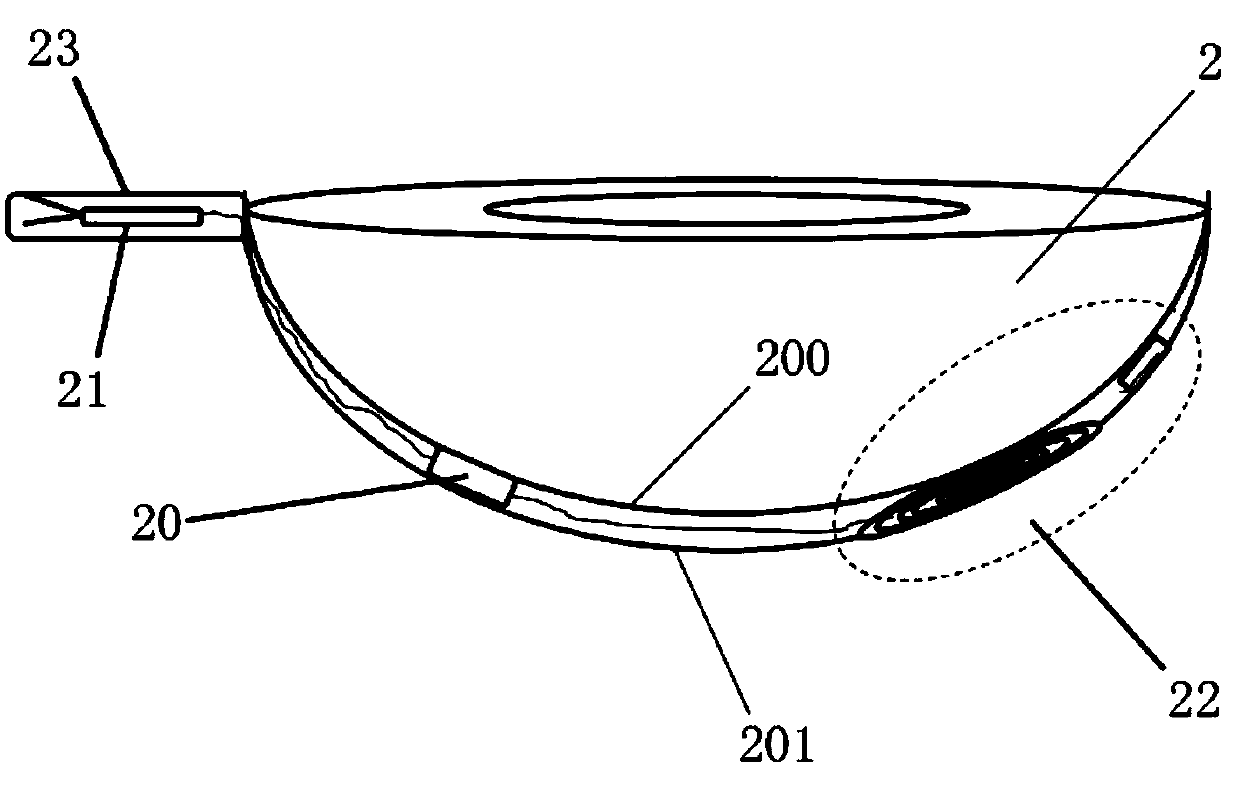

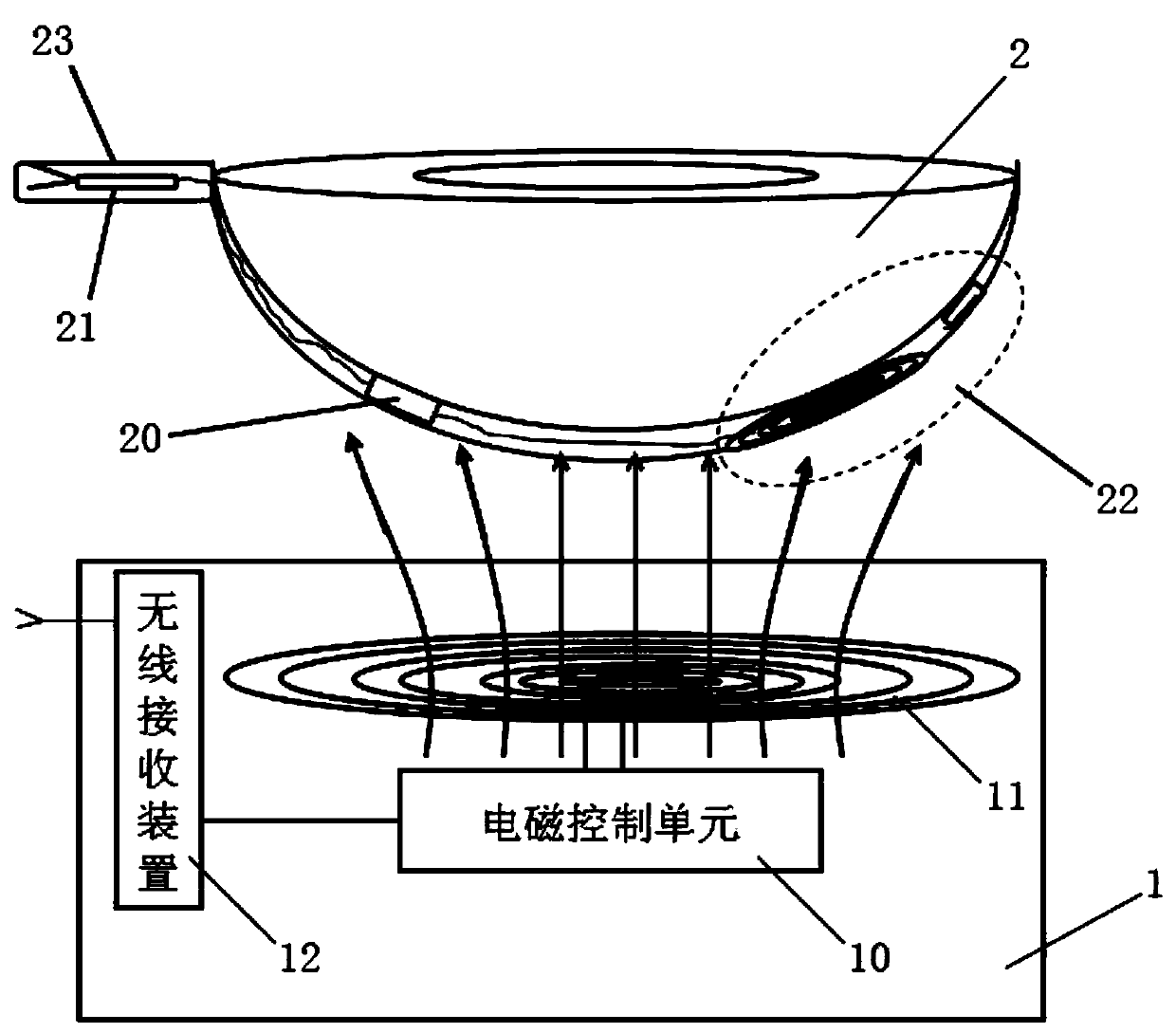

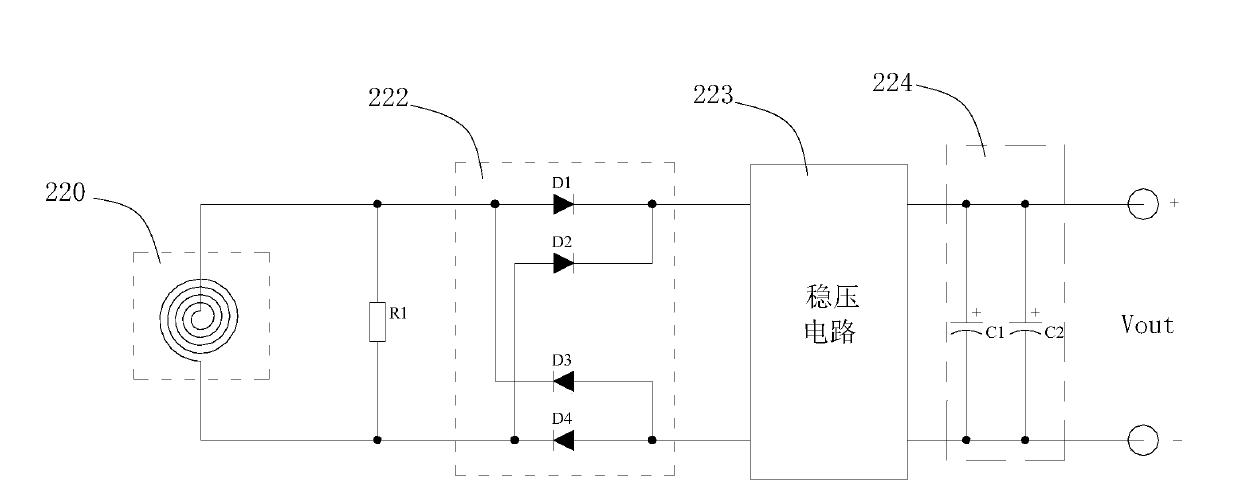

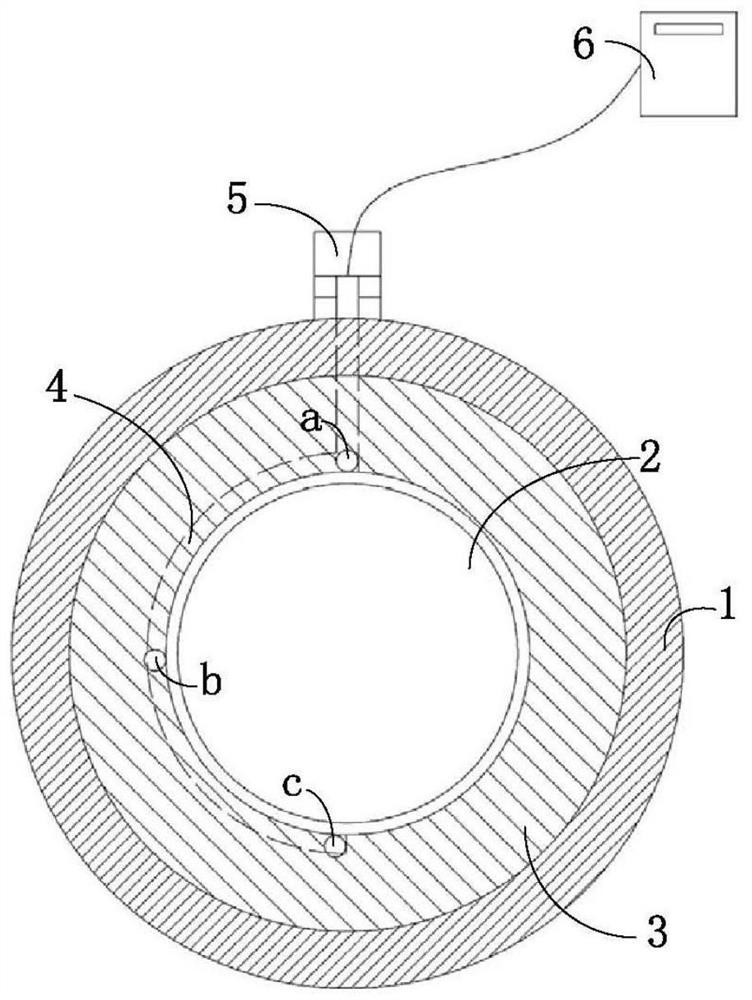

Wireless temperature measurement type wok, induction cooker and wireless temperature measurement method

InactiveCN105496173AAvoid hysteresisSensing temperature quicklyDomestic stoves or rangesLighting and heating apparatusEngineeringWireless signal

The invention discloses a wireless temperature measurement type wok. The wireless temperature measurement type wok comprises a wok body, a temperature detection circuit, a first wireless transceiving device and a wireless power supply device, wherein the wok body comprises an inner wok surface and an outer wok surface, the temperature detection circuit is arranged in a cavity formed between the inner wok surface and the outer wok surface and is used for detecting the temperature of the wok body, the first wireless transceiving device is electrically connected with the temperature detection circuit and is used for sending temperature data detected by the temperature detection circuit in a wireless signal manner, and the wireless power supply device arranged in the cavity is used for generating electric energy by magnetically coupling with an alternating field and supplying electricity to the temperature detection circuit and the first wireless transceiving device through the electric energy. An induction cooker with the wireless temperature measurement type wok has the beneficial effects of rapidity in temperature sensing, small temperature measurement error and capability of detecting the temperature of the wok in real time.

Owner:广东易爱云厨科技股份有限公司

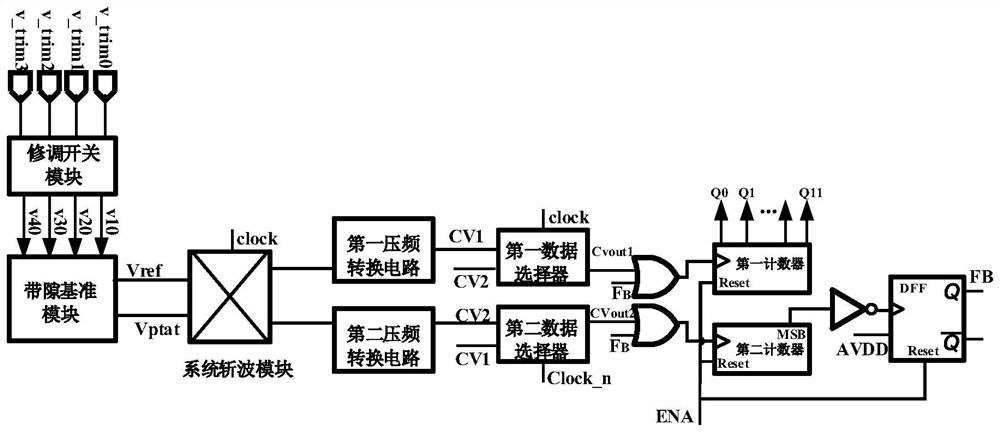

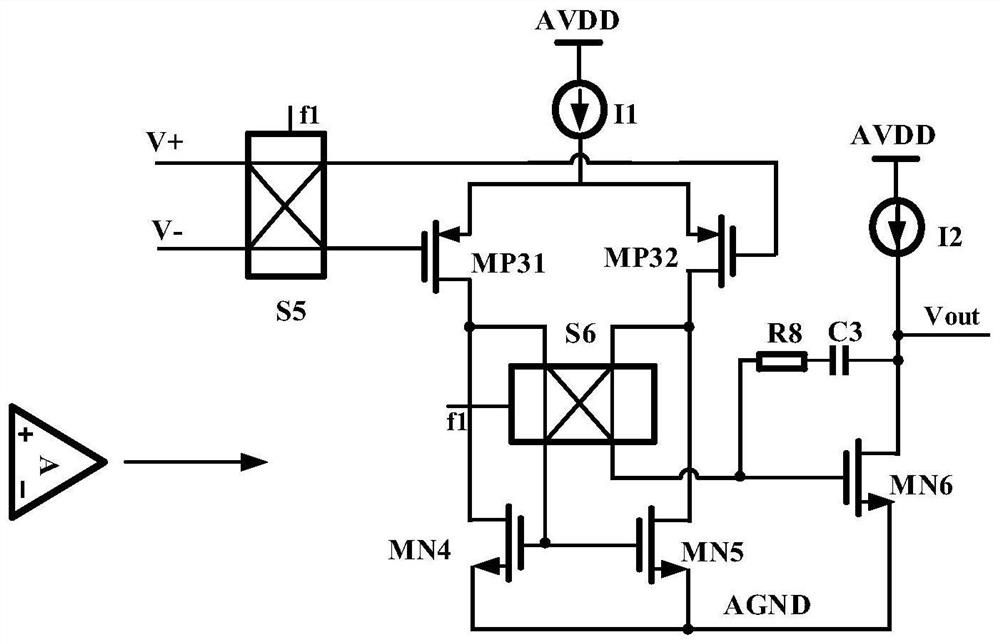

Temperature sensor circuit with built-in clock

ActiveCN108572034ASimple structureReduce power consumptionThermometer detailsThermometer testing/calibrationClock rateFrequency conversion

The invention discloses a temperature sensor circuit with a built-in clock, which belongs to the technical field of electronic circuits. Firstly, a band-gap reference module is used to generate band-gap reference voltage and positive temperature coefficient voltage; then, two identical voltage frequency conversion circuits are used for converting the positive temperature coefficient voltage and the band-gap reference voltage to a positive temperature coefficient voltage frequency and a band-gap reference voltage frequency; and finally, counting is carried out through two counters, after full counting of the second counter, the first counter stops counting through feedback signals, and the size of a temperature value is acquired through acquiring the ratio of the positive temperature coefficient voltage to the band-gap reference voltage. The designed temperature sensor has a simple structure, and low power consumption can be achieved; a chopper operational amplifier is used in the band-gap reference module for eliminating errors caused by operational amplifier maladjustment, a system chopper module is added behind the band-gap reference module for reducing errors of comparator maladjustment voltage on temperature detection, the second counter generates first clock signal and second clock signal, and advantages of a wide frequency range, adjustable clock frequency and the like are achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-temperature sensor for metal tubular black body hollow cavity

ActiveCN103162840AImprove accuracyCompact structureRadiation pyrometryData processing systemBlack body

The invention relates to a high-temperature sensor for a metal tubular black body hollow cavity and belongs to the technical field of temperature sensors for measurement of high temperatures. The high-temperature sensor for the metal tubular black body hollow cavity comprises the black body hollow cavity, a shielding cover, a coupler, transmission optical fibers, a light splitting detection system and a data processing system, wherein the head portion of the outer surface of the black body hollow cavity is arranged to be in a rib-piece type structure according to the design, and the black body hollow cavity is arranged to be in a blind hole form according to the design. The black body hollow cavity made of high-temperature resistant metal materials is used as a to-be-sensed portion of the high-temperature sensor, the silica optical fibers are used for transmitting signals, a double silicon detector is used for splitting light and conducting photoelectric conversion, and therefore the high-temperature sensor for the metal tubular black body hollow cavity is compact in structure and reliable in performance. In addition, the shielding cover is arranged outside the black body hollow cavity according to the design; and combined with the special-shaped structure of the black body hollow cavity and through theoretical analysis and numerical calculation, the high-temperature sensor for the metal tubular black body hollow cavity has the advantages of being good in high-temperature resistance, oxidation resistant, high in accuracy and the like, and can solve the high-temperature measuring problem which cannot be solved at present.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

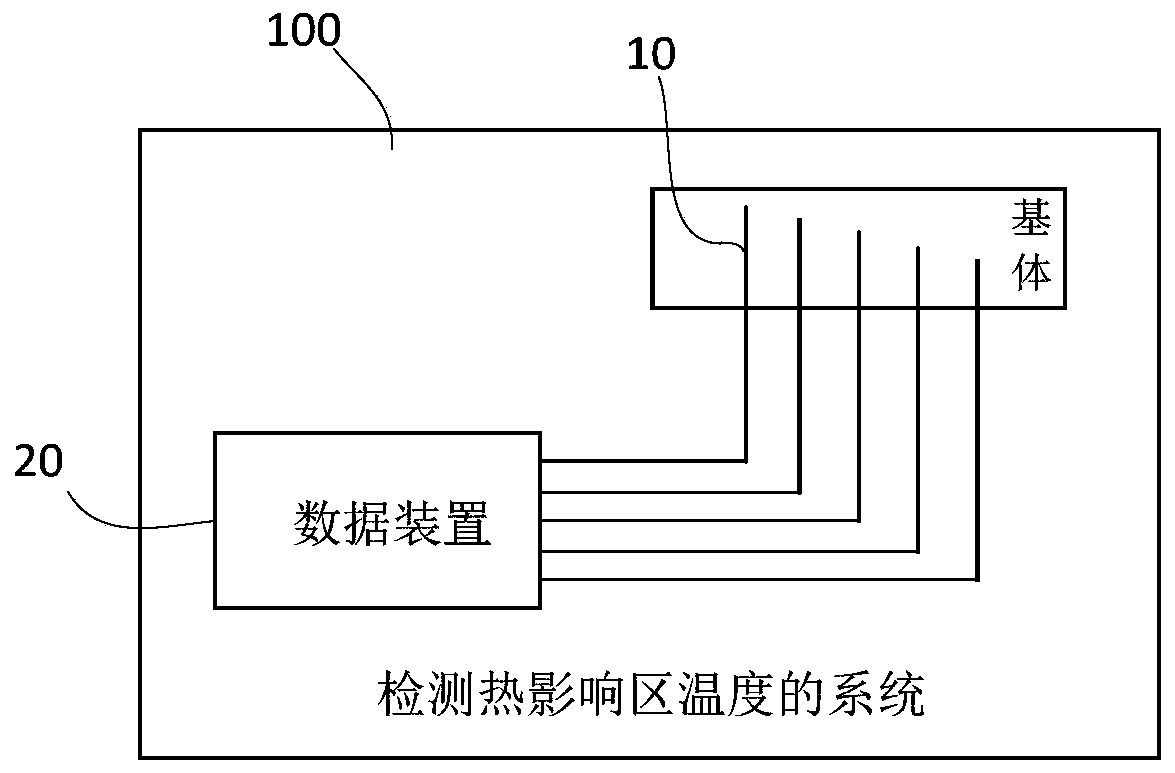

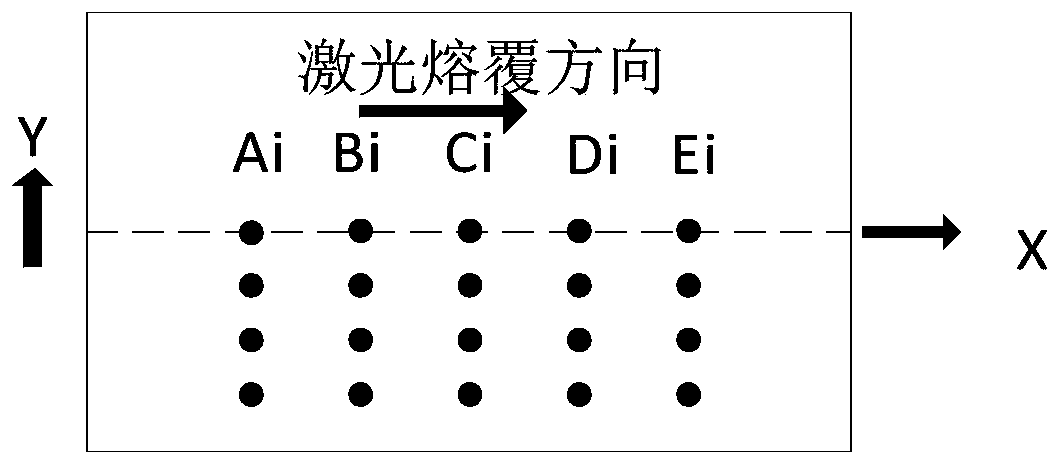

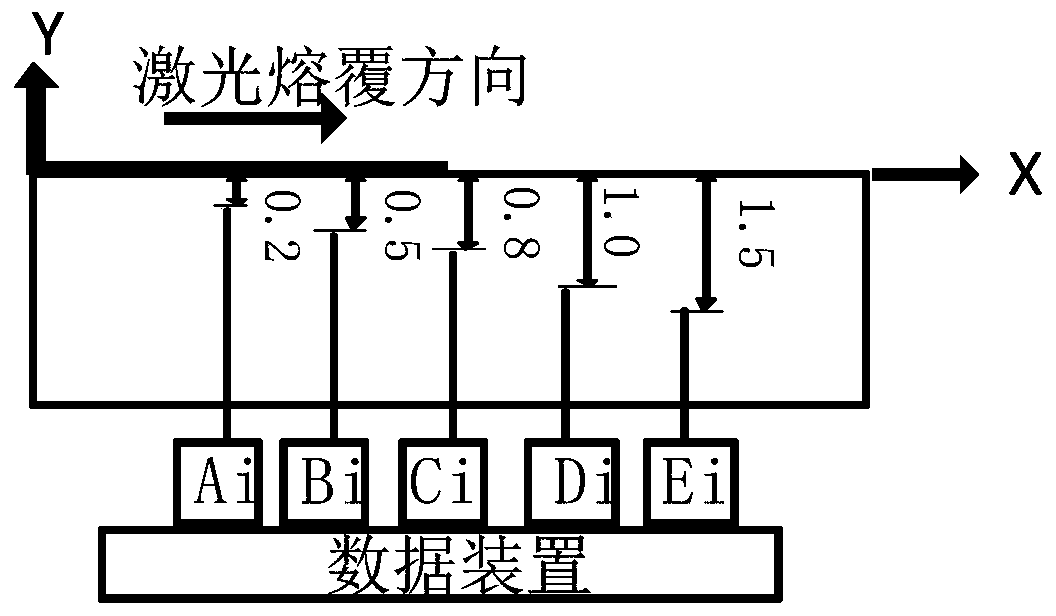

System and method for detecting heat affected zone temperature and storage medium

ActiveCN111256859AOverall Temperature ParametersComplete Temperature ParametersThermometers using electric/magnetic elementsUsing electrical meansThermodynamicsHeat-affected zone

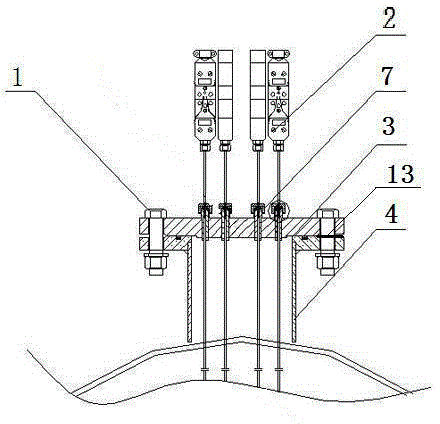

The invention provides a system and method for detecting the temperature of a heat affected zone and a storage medium. The method is characterized in that a plurality of temperature measuring points with different depths are arranged at different positions of an estimated heat affected zone of a matrix, laser cladding of the matrix is carried out through a laser, and the system comprises a plurality of temperature sensors which are arranged in one-to-one correspondence with a plurality of temperature measuring points and are used for detecting the temperature of the corresponding temperature measuring points, and a data device used for acquiring temperature detection data, the cladding time is recorded, a temperature time curve of each temperature measuring point in the cladding directionis obtained according to the temperature detection data and the cladding time, the temperature time curves at different moments are converted into temperature space distribution of the heat affected zone at the same moment according to the cladding speed, and temperature data of the heat affected zone are obtained according to the temperature space distribution. The method is advantaged in that accurate and reliable temperature parameters can be obtained through direct measurement, and a data basis is provided for researching structural gradient and mechanical property evolution of materials.

Owner:TSINGHUA UNIV

Double-screen air suction type sapphire optical fiber high temperature sensor

InactiveCN105333974ACompact structureReliable performanceThermometers using physical/chemical changesAirflowSapphire

The invention belongs to temperature sensors for high temperature measurement, and relates to a double-screen air suction type sapphire optical fiber high temperature sensor. The double-screen air suction type sapphire optical fiber high temperature sensor is suitable for measuring airflow temperature in the temperature zone of 1,300 K to 2,000 K. The high temperature sensor is composed of sapphire optical fibers with black cavities, a precious metal shielding cover, single-core multi-mode silica optical fibers, a photovoltaic conversion and data processing system and the like. In order to guarantee the accuracy of high temperature airflow temperature measurement, the precious metal shielding cover is designed to be of a double-screen air suction type structure to reduce heat transfer errors and speed errors. The advantages of being accurate in temperature measurement, fast in response, high in anti-electromagnetic interference capacity and the like are achieved, and the aim of high temperature measurement under the high-temperature high-speed airflow environment in the temperature zone of 1,300 K to 2,000 K can be achieved.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

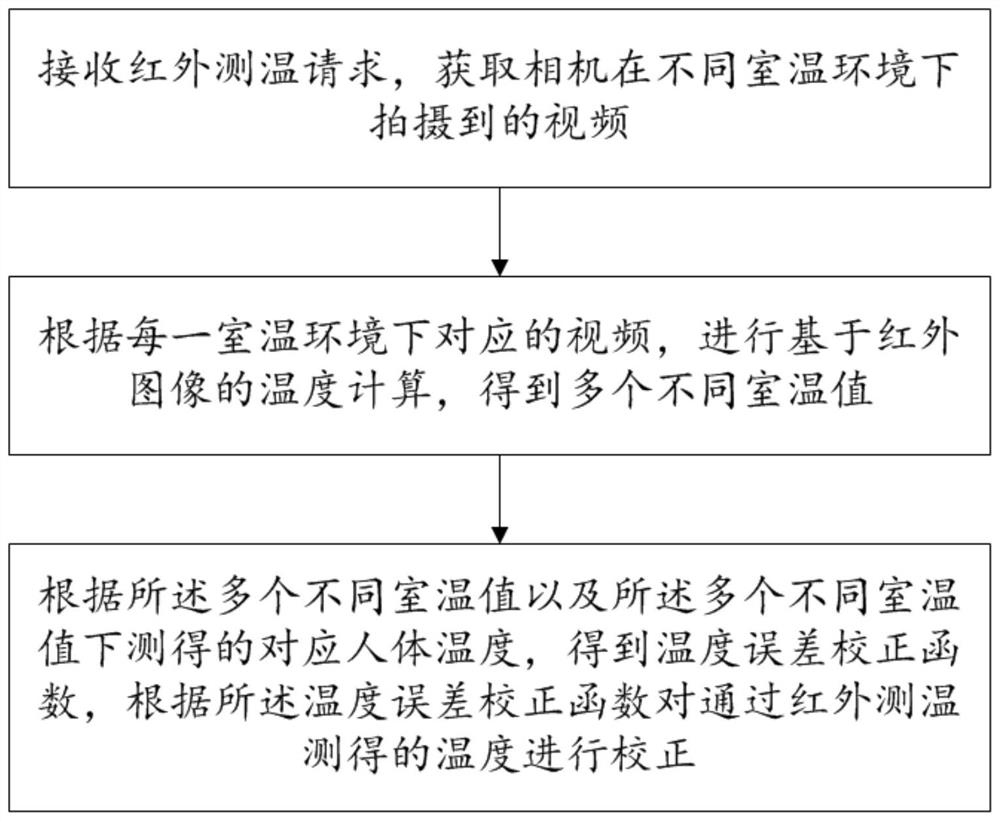

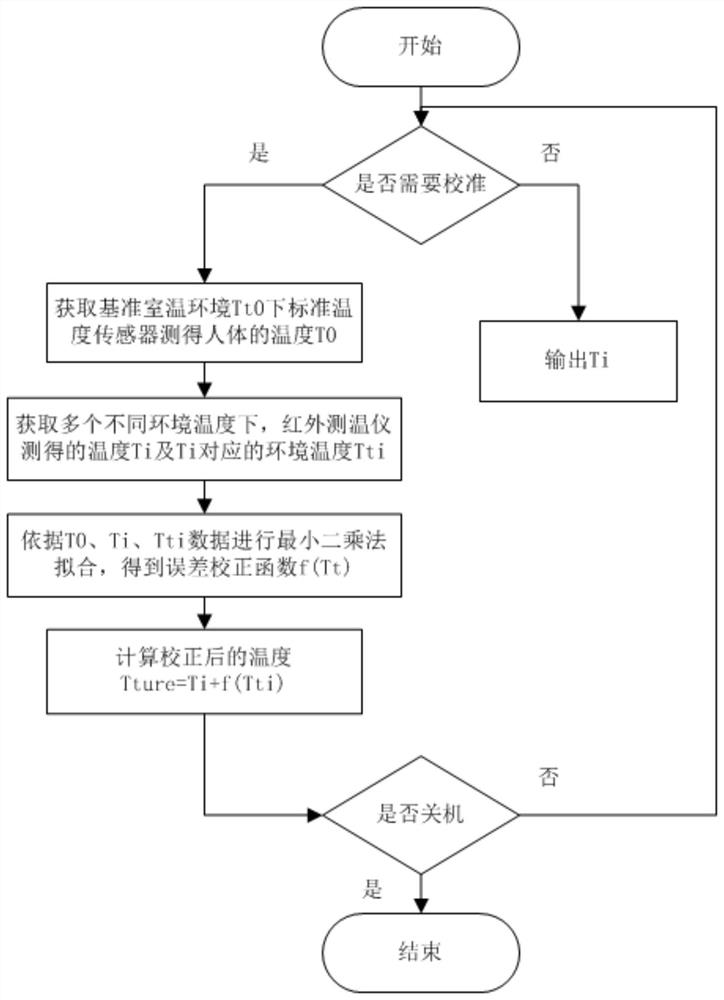

Infrared temperature measurement correction method based on infrared images and terminal

ActiveCN112525359AAccurate measurementHigh precisionSensing radiation from moving bodiesRoom temperatureImage pair

The invention discloses an infrared temperature measurement correction method based on infrared images and a terminal, and the method comprises the steps of: acquiring videos shot by a camera in different room temperature environments when an infrared temperature measurement request is received, and carrying out temperature calculation based on the infrared images according to a video image framecorresponding to each room temperature environment to obtain a plurality of different room temperature values, acquiring a plurality of different room temperature values and the temperatures measuredat the plurality of different room temperature values to obtain a temperature error correction function, and correcting the temperature measured through infrared temperature measurement according to the temperature error correction function. The temperature of each image frame is calculated through the infrared images, the indoor temperature can be precisely measured, the temperature error correction function can precisely obtained, and the temperature measured through infrared temperature measurement is corrected through the temperature error correction function, therefore the high-precisionhuman body temperature is obtained. The room temperature is calculated by using the infrared images, and the temperature measurement precision can be ensured while the calculated amount is small, so that the influence of an environment temperature factor on the human body temperature measurement precision is reduced.

Owner:SHENZHEN HIGHGREAT TECH DEV CO LTD

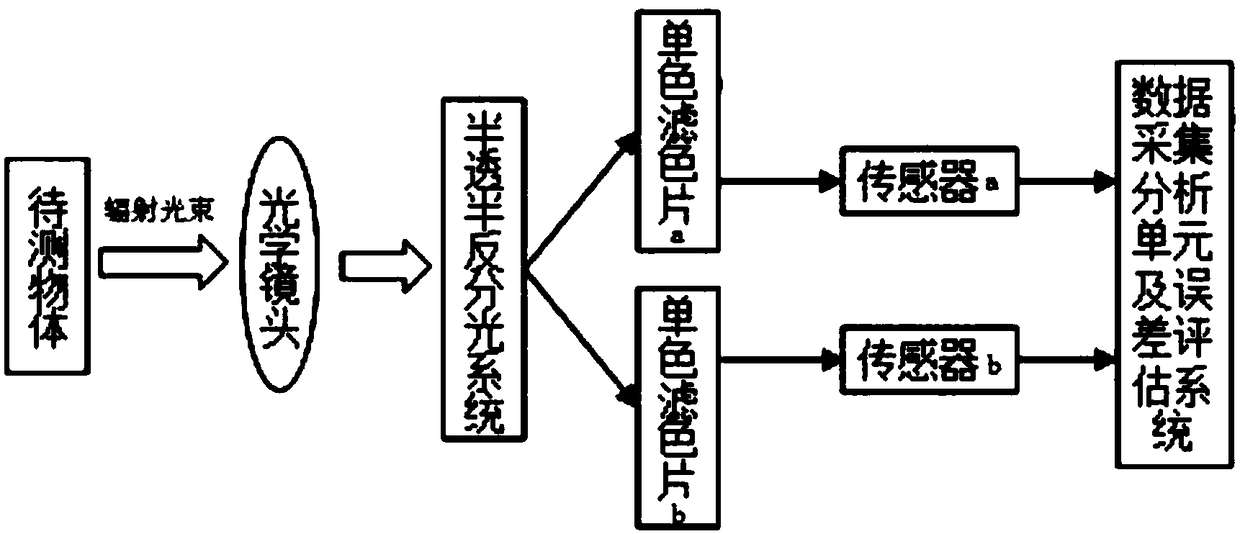

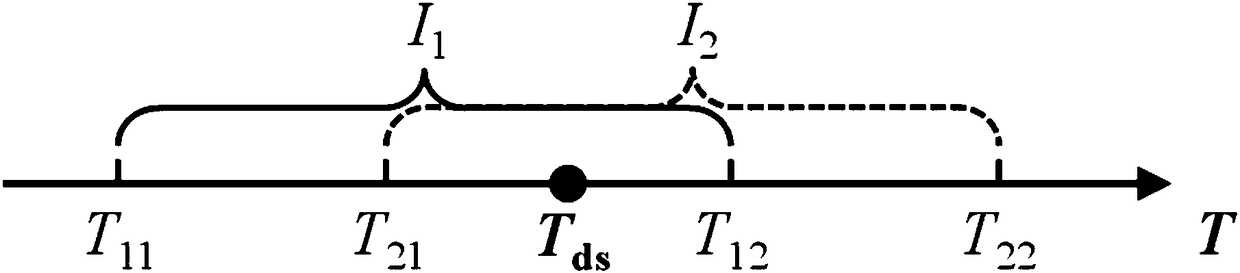

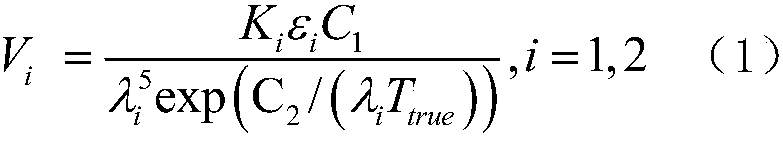

Dual-wavelength radiation temperature measurement device and method

ActiveCN108254079AFacilitate error assessment predictionsSmall error in temperature measurementRadiation pyrometryOptical radiationMeasurement device

The invention discloses a dual-wavelength radiation temperature measurement device and method. The device comprises an optical lens used for focusing radiation light beams of a to-be-measured object on a semi-transmitting semi-reflecting beam splitting system. The semi-transmitting semi-reflecting beam splitting system comprises a semi-transmitting semi-reflecting beam splitting piece used for splitting the radiation light beams into transmitting light beams and reflecting light beams, the transmitting light beams and the reflecting light beams are received by sensors, and optical radiation measuring signals are generated. A data acquisition and analysis unit and an error evaluation system calculate the temperature value of the to-be-measured object according to the optical radiation measuring signals, and the temperature value error is predicted and evaluated. The method includes the following steps that looseness approach is carried out to acquire a corrected dual-wavelength temperature; single-color probability approach is carried out to acquire a single-color probability average temperature; averaging is carried out to acquire the average of the corrected dual-wave-length temperature and the single-color probability average temperature. High-precision measurement of gray body surface or non-gray surface temperatures is achieved under the condition that emissivity behaviorsare unknown, and the error can be conveniently evaluated and predicted based on the measured temperatures.

Owner:CHINA UNIV OF MINING & TECH

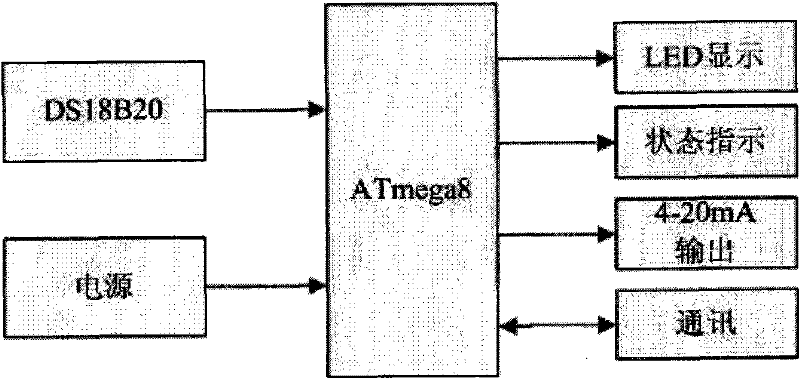

Intelligent indoor temperature acquirer

InactiveCN102680121AEfficient use ofSmall error in temperature measurementThermometer detailsCommunication unitDisplay device

An intelligent indoor temperature acquirer is a temperature measurer for indicating indoor temperature. A temperature sensor acquires and processes temperature signals, the temperature signals are transmitted to a signal processor to be processed and calculated, and results are displayed on a display device or transmitted to other equipment via a communication unit. Nonlinear errors are reduced by a DS18B20 temperature measuring principle, linear errors are reduced by piecewise linearity and a least square method, and temperature measurement accuracy is improved. A low-power-consumption element is adopted, and the intelligent indoor temperature acquirer is powered by a lithium battery which is charged by solar energy.

Owner:BEIJING JUNHE SHENGSHI ENVIRONMENTAL PROTECTION TECH

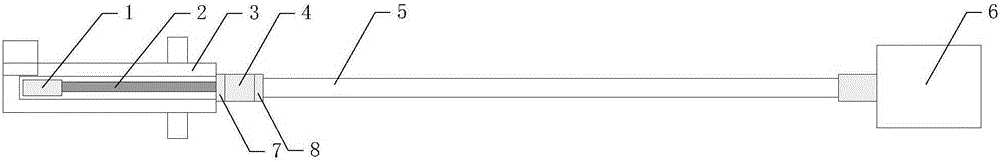

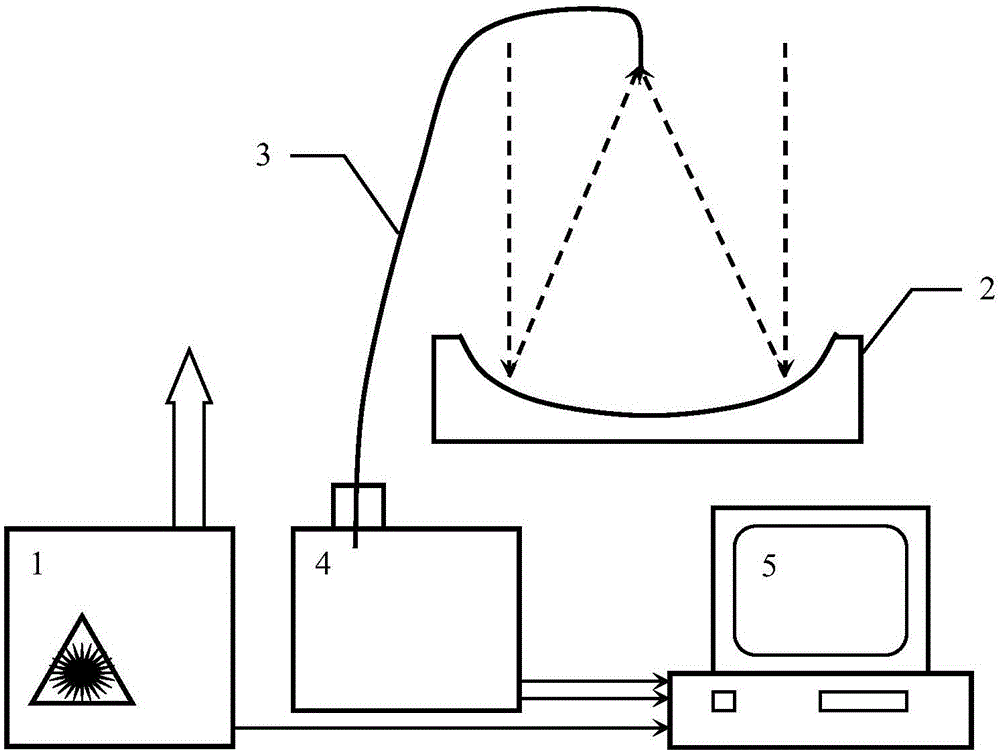

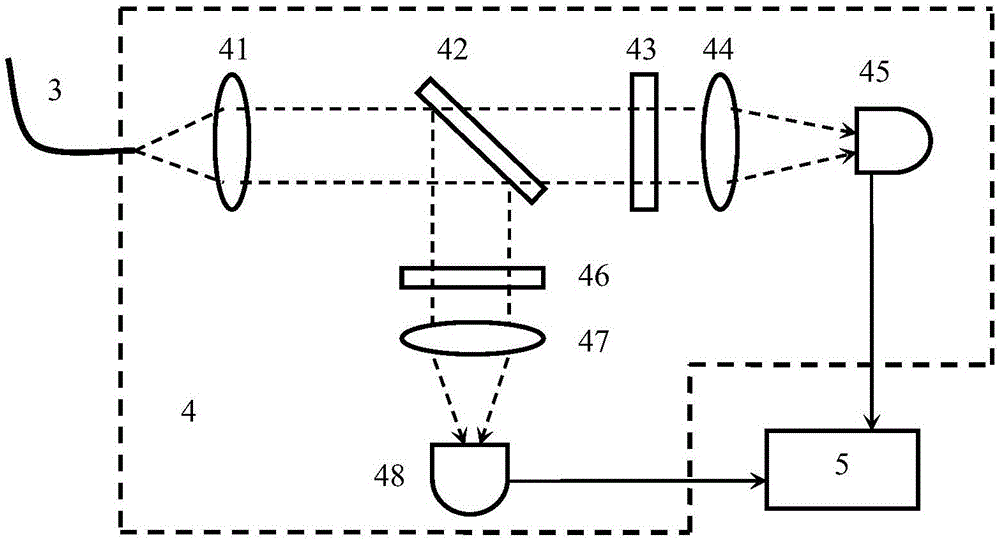

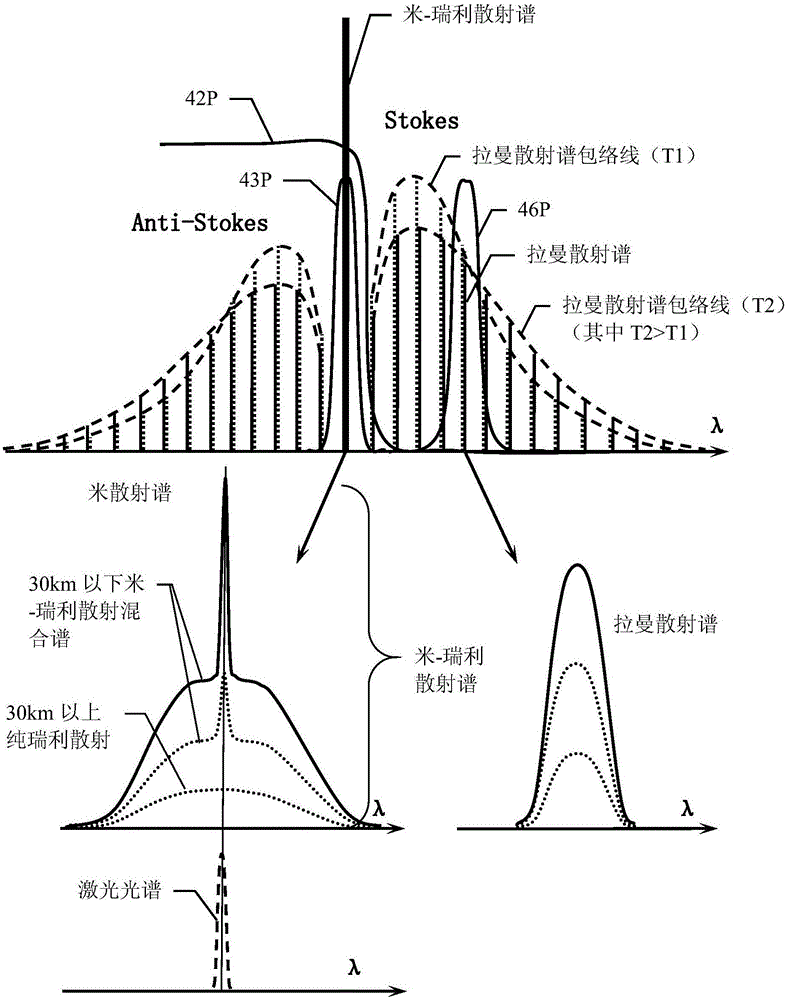

Atmospheric Raman-Rayleigh scattering temperature measurement laser radar and inversion method

ActiveCN106483531AEliminate the effects ofExpand the range of temperature measurement spaceElectromagnetic wave reradiationICT adaptationRayleigh scatteringEcho intensity

The invention discloses an atmospheric Raman-Rayleigh scattering temperature measurement laser radar and an inversion method. The laser radar comprises a laser transmitting unit (1), a receiving telescope (2), a receiving optical fiber (3), a signal detecting unit (4) and a signal processing unit (5). A high-resolution spectrum detection method is adopted to measure Rayleigh scattering spectral signals generated on atmospheric molecules by laser higher than 30km or above and Raman scattering spectral signals generated on atmospheric molecules by laser lower than 30km; and inversion is carried out to obtain the temperature of atmosphere at 30km, or above or below can be obtained based on a characteristic that the Raman scattering spectrum is in direct proportion to the Rayleigh scattering spectrum in echo intensity, and therefore, the temperature measurement space range of the Rayleigh scattering temperature measurement laser radar can be expanded. The atmospheric Raman-Rayleigh scattering temperature measurement laser radar has the advantages of wide temperature measurement height range and small temperature measurement error.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

Full-automatic small-size alternating current and direct current control aluminum groove ice making machine

PendingCN107345722AAvoid the defect of large water injection time errorContinuous motionLighting and heating apparatusIce productionAlternating currentUltimate tensile strength

The invention discloses a full-automatic small-size alternating current and direct current control aluminum groove ice making machine. The full-automatic small-size alternating current and direct current control aluminum groove ice making machine comprises an aluminum alloy ice making groove connected with a gear transmission assembly. A temperature sensor and a heater are arranged at the bottom of the aluminum alloy ice making groove. The side wall of the aluminum alloy ice making groove is further provided with a corrugation type cold runner. Electric heating blocks are arranged at the four bevel positions of the corrugation type cold runner. The corrugation type cold runner comprises a temperature compensation chamber, a cold runner inlet and a cold runner outlet are formed in the outer side of the temperature compensation chamber, and a condensation agent inlet is further formed in the cold runner inlet. A concave arc cooling groove is formed in the bottom of the temperature compensation chamber, a temperature induction medium and an induced draft fan set are further arranged in the temperature compensation chamber, and the concave arc cooling groove is filled with a condensation agent. According to the full-automatic small-size alternating current and direct current control aluminum groove ice making machine, the beneficial effects that the control efficiency is high, the size is small, the occupied refrigerator volume is small, and energy consumption is low are achieved; and the ice making strength of the aluminum groove ice making machine can be improved, ice disengaging is easy, and the actual using requirement is met.

Owner:CHUZHOU FLURIDA MACHINERY ELECTRONICS

Wireless passive temperature measurement monitoring method for substation high-voltage switch cabinets

InactiveCN110220601AGuaranteed operational safetyNo maintenance costsThermometer detailsThermometer applicationsData acquisitionPower grid

The invention discloses a wireless passive temperature measurement monitoring method for substation high-voltage switch cabinets. The method comprises the steps of: (1) integrating UHF electronic tagson temperature measurement sensors, mounting the temperature measurement sensors in the high-voltage switch cabinets by watch pocket type structures, and mounting temperature measurement data acquisition devices communicated with the UHF electronic tags in the high-voltage switch cabinets; (2) by the temperature measurement data acquisition devices, acquiring data measured by each temperature measurement sensor, and uploading the data to a station side management display screen for display; and (3) uploading the data to a remote online monitoring terminal by the station side management display screen, and carrying out centralized monitoring on a temperature condition of each substation high-voltage switch cabinet in a region which needs to be monitored. According to the invention, later maintenance cost of batteries and the sensors is avoided; the wireless passive temperature measurement monitoring method is energy-saving and environmental-friendly; a power supply wire and a data transmission cable are completely omitted; maintenance-free temperature measurement of high-voltage switch equipment can be implemented; power grid accidents are reduced; a trip-out rate of a power grid is reduced; and reliable operation of the power grid is greatly improved.

Owner:GUIZHOU POWER GRID CO LTD

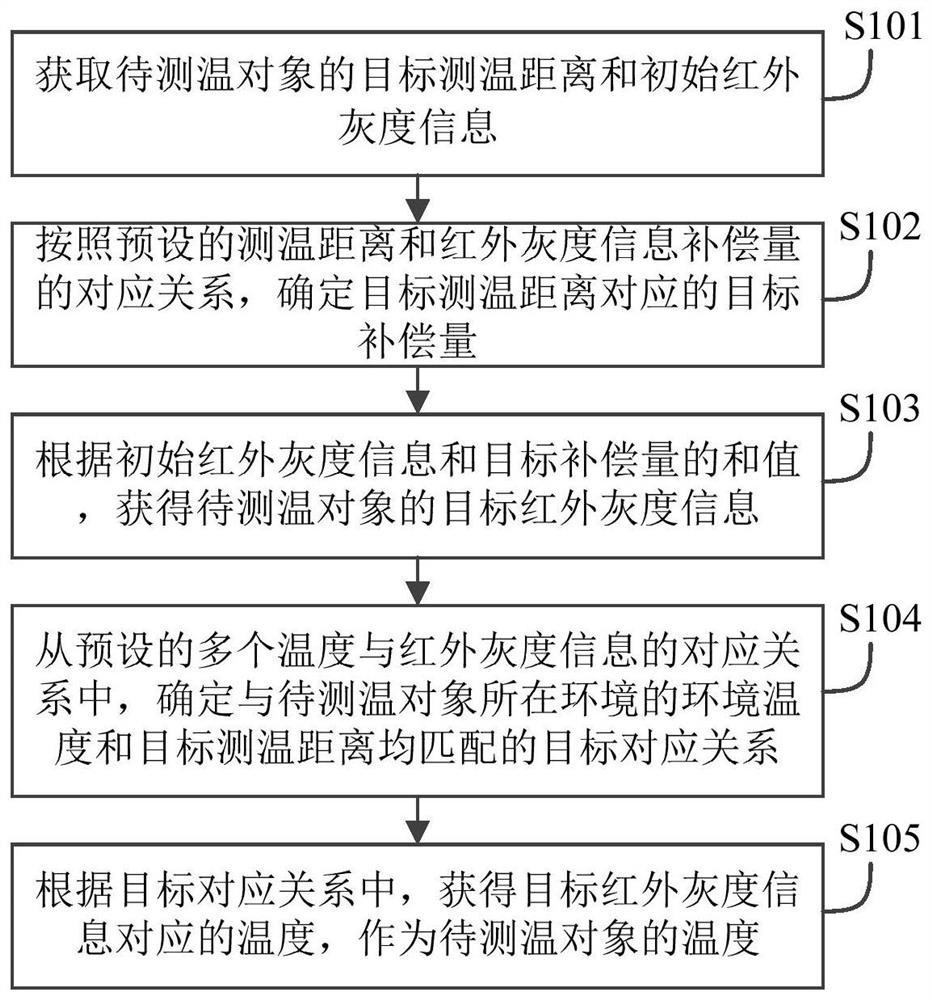

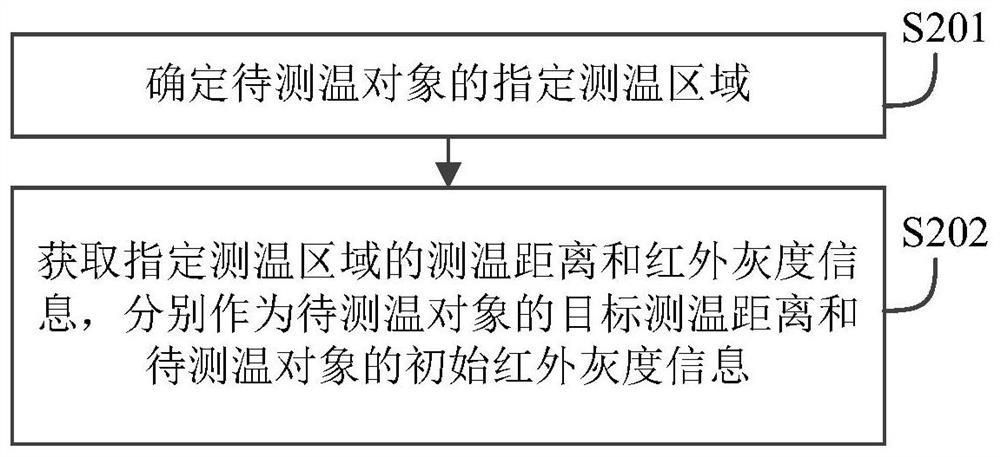

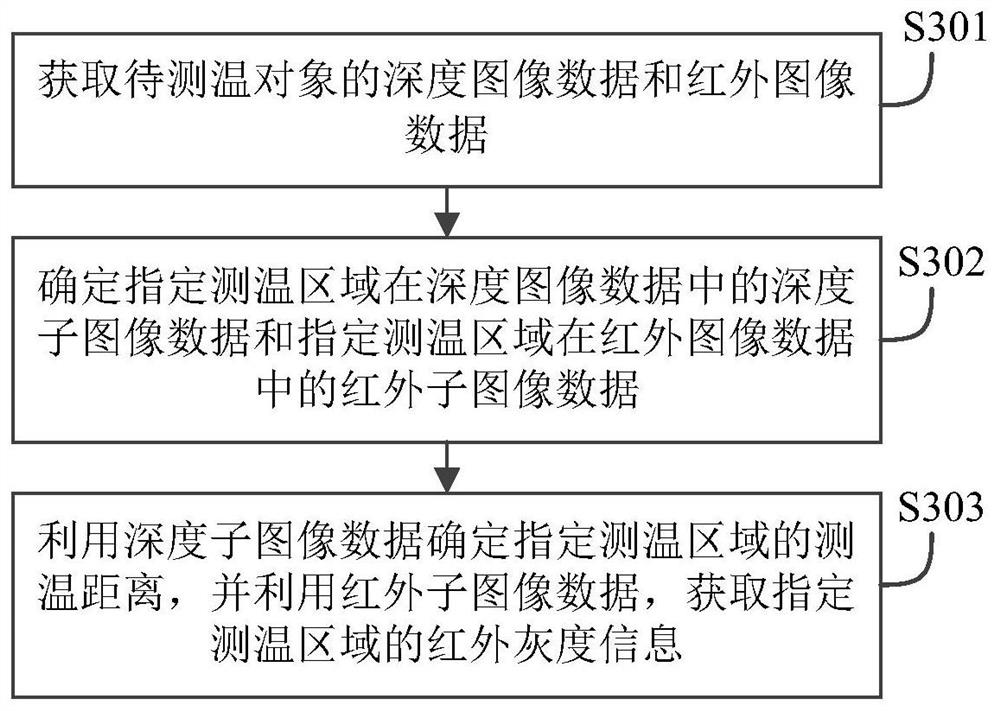

Temperature measurement method, electronic equipment and storage medium

ActiveCN113358226AReduce the impact of accuracySmall error in temperature measurementRadiation pyrometryEngineeringPhysics

An embodiment of the invention provides a temperature measurement method, electronic equipment and a storage medium. The method comprises the following steps of: acquiring a target temperature measurement distance and initial infrared gray scale information of an object to be subjected to temperature measurement; determining a target compensation amount corresponding to the target temperature measurement distance according to a preset corresponding relation between a temperature measurement distance and an infrared gray information compensation amount; acquiring target infrared gray information of the object to be subjected to temperature measurement according to the initial infrared gray information and the target compensation amount; determining a target corresponding relationship matched with the environment temperature and the target temperature measurement distance of the environment where the object to be subjected to temperature measurement is located from a plurality of preset corresponding relationships between temperatures and infrared gray scale information; and acquiring the temperature corresponding to target infrared gray scale information according to the target corresponding relationship, and taking the temperature as the temperature of the object to be subjected to temperature measurement. Compared with the prior art, by applying the temperature measurement method provided by the embodiment of the invention, the influence of the environment temperature and the temperature measurement distance on the non-contact temperature measurement mode can be reduced, and the temperature measurement precision of the non-contact temperature measurement mode is improved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

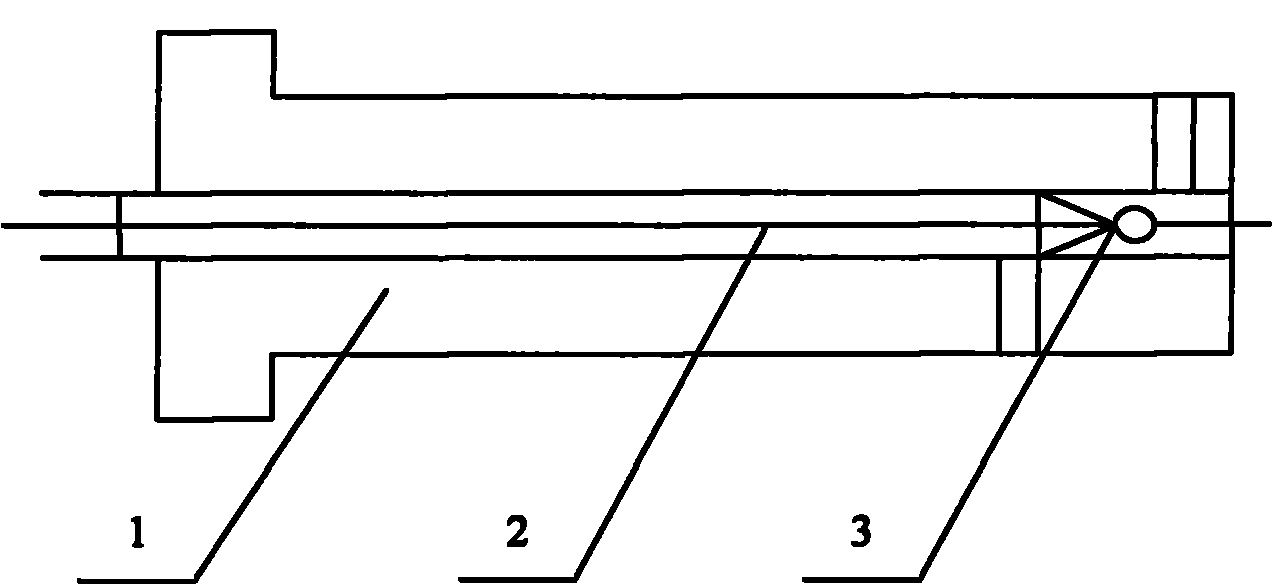

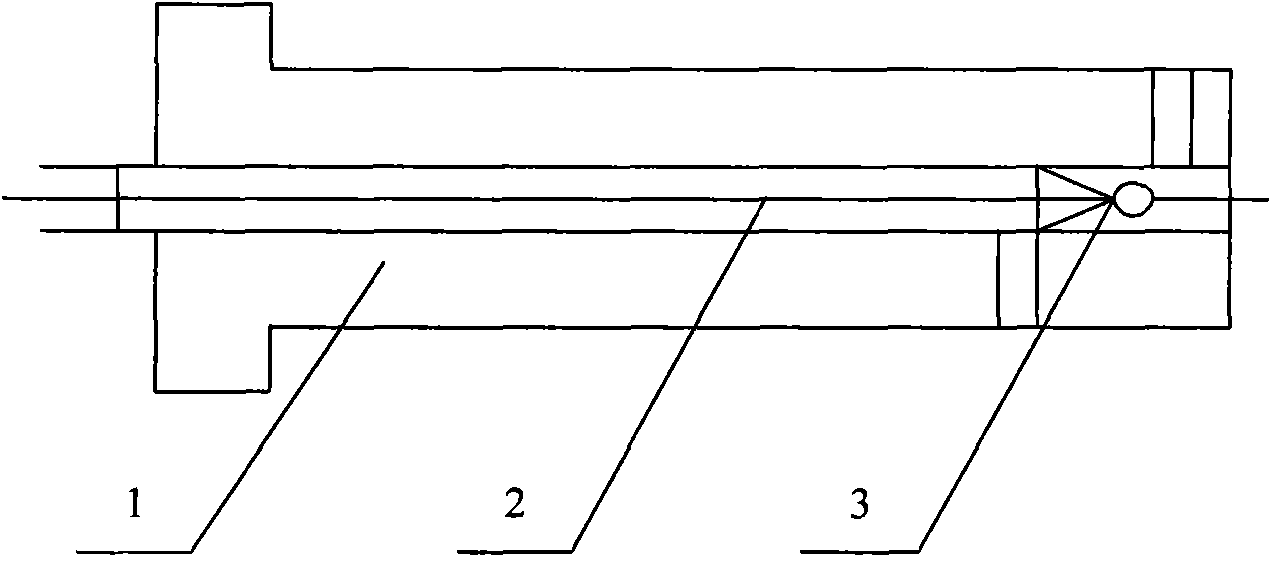

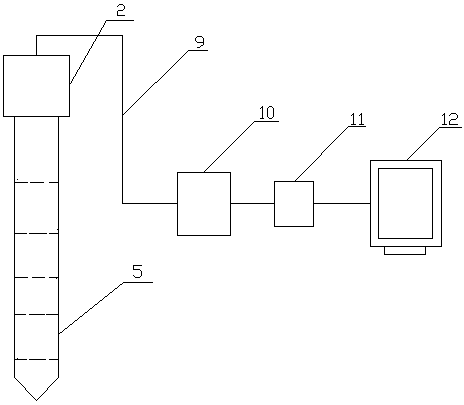

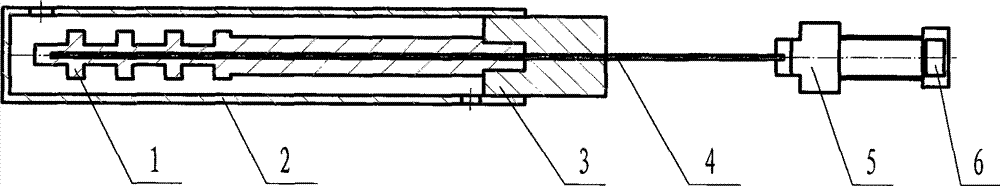

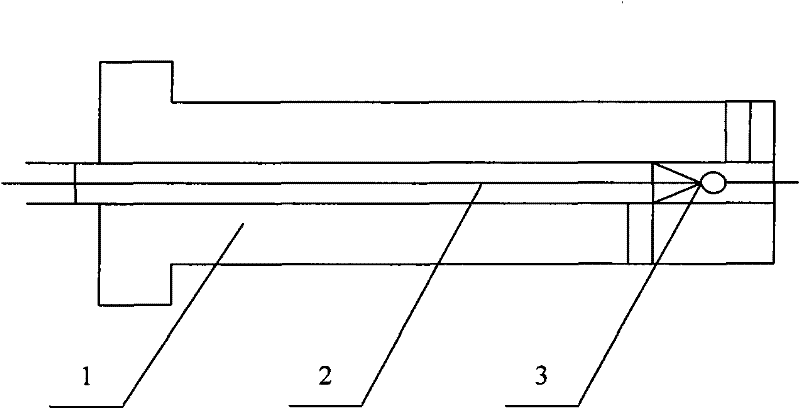

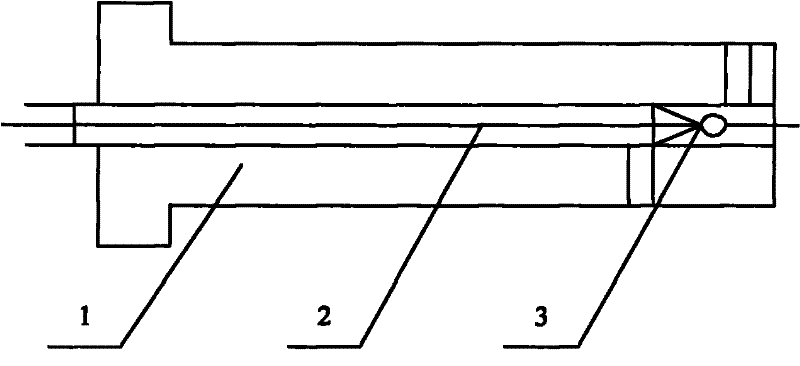

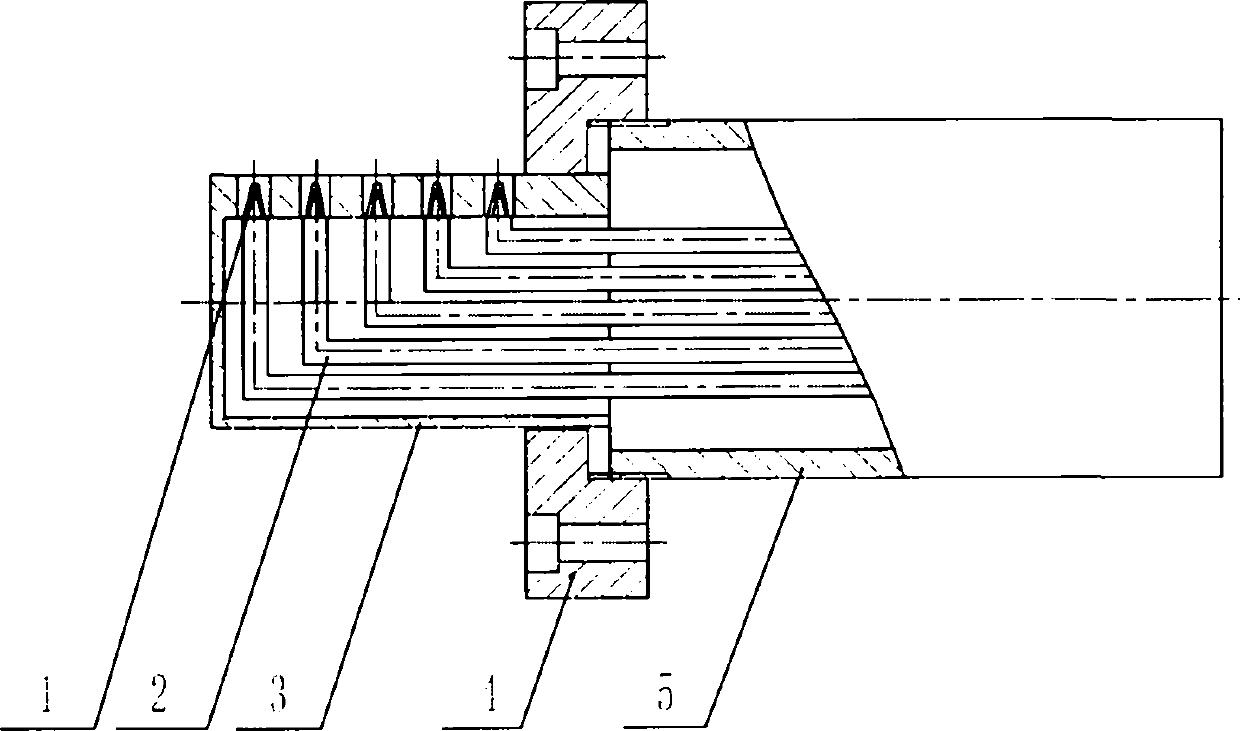

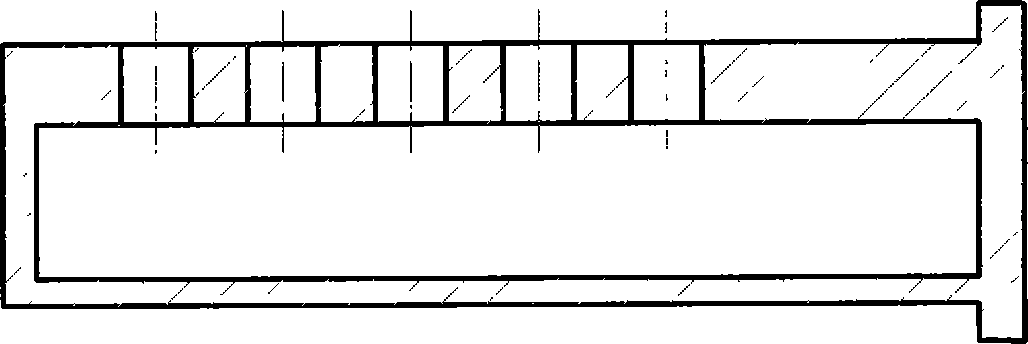

Interior temperature measuring equipment for material bed of belt-type sinterer

ActiveCN102840926BAvoid enteringQuick responseThermometers using electric/magnetic elementsUsing electrical meansFiberIron ore sintering

The invention relates to the field of iron ore sintering equipment, in particular to interior temperature measuring equipment for a material bed of a belt-type sinterer. The interior temperature measuring equipment for the material bed of the belt-type sinterer comprises a fire-resistant tube, a thermocouple set, a protective sleeve and a dataline joint. The protective sleeve is fixedly connected with the fire-resistant tube. The dataline joint is installed in the fire-resistant tube. The thermocouple set is installed in the protective sleeve and is formed by arranging a plurality of thermocouples. The tops of the thermocouples are connected with the dataline joint. The bottoms of the thermocouples are stair-stepping. A slice for shielding an electrical insulating fiber body is arranged between two adjacent thermocouples. The gap in the fire-resistant tube is filled by high temperature resistant asbestos, and the gap in the protective sleeve is filled by high temperature resistant insulating particles. According to the interior temperature measuring equipment for the material bed of the belt-type sinterer provided by the invention, the temperature instantaneous values at different positions in the height direction in the sintering material bed can be tested with rapid response speed and small temperature measuring error. The interior temperature measuring equipment for the material bed of the belt-type sinterer can work in a comparatively severe environment in the production process. A bump is arranged on the fire-resistant tube, so that the measuring precision is further improved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

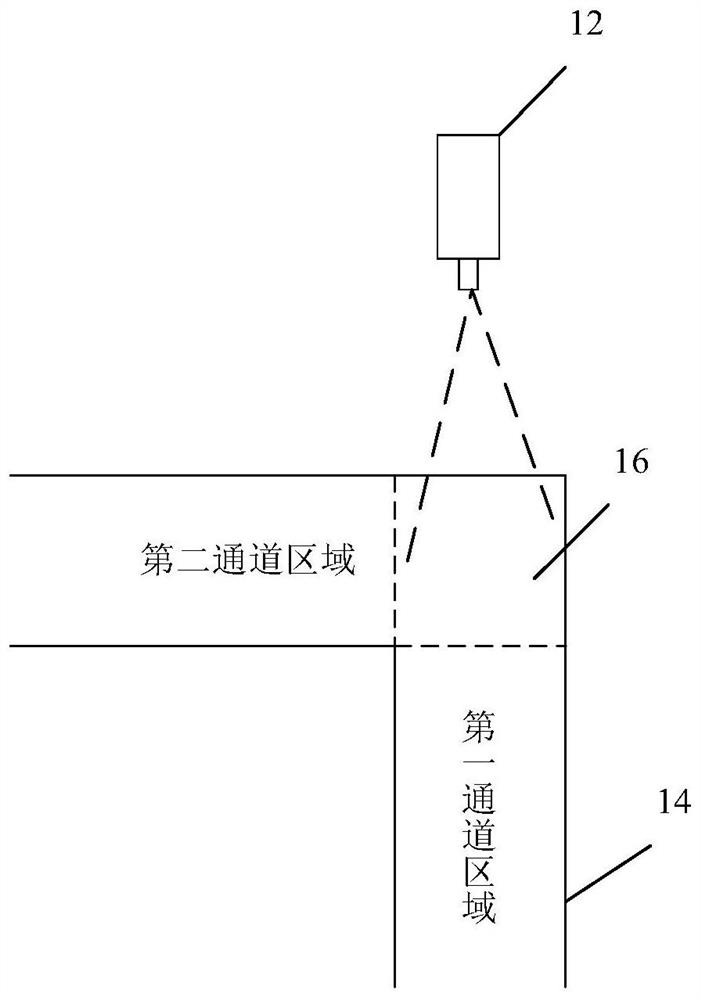

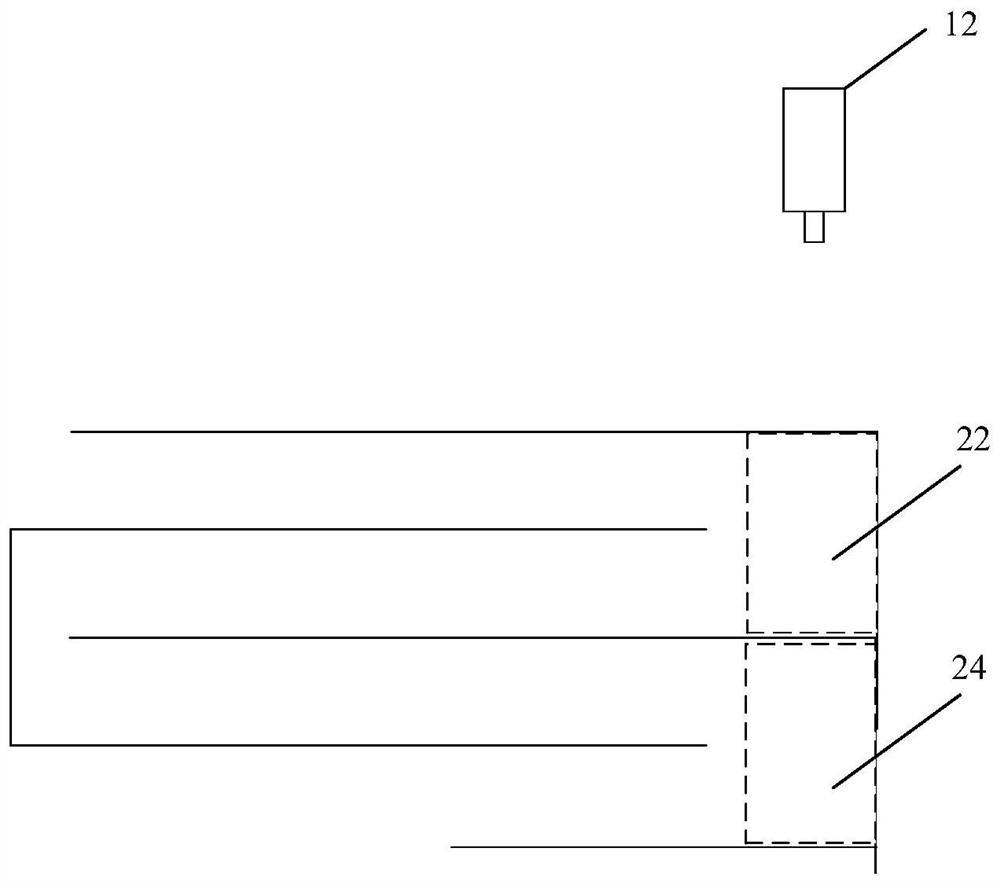

Temperature measurement system and method

ActiveCN112798113BSmall error in temperature measurementSensing radiation from moving bodiesRadiation thermographyMechanical engineeringMechanics

The present application relates to a temperature measurement system and method. The temperature measurement system includes a temperature measurement device for measuring the temperature of an object to be measured and a flow guide device. The flow guide device is formed to include a flow guide channel, and the flow guide channel includes a first channel region and In the second channel area, the object to be temperature-measured moves from the first channel area to the second channel area, and changes the moving direction along the second channel area; the temperature measurement device is arranged toward the second channel area, so that its temperature measurement area is at least partially It covers the second passage area, reducing the impact of crowd gathering on the body temperature of the tested person, and reducing the temperature measurement error of the tested person.

Owner:浙江华感科技有限公司

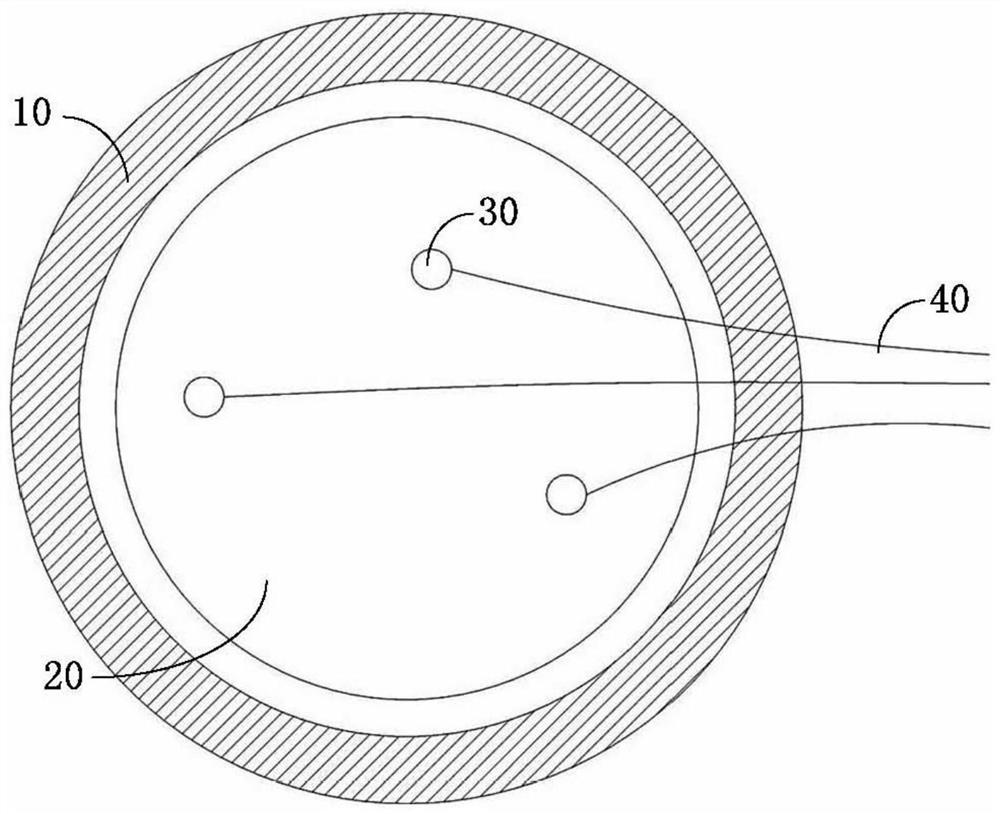

A high water pressure resistant fiber grating temperature sensor and assembly method

ActiveCN110186589BImprove stabilityAvoid the influence of tensile stress and deformationThermometer detailsThermometers using physical/chemical changesFiberEngineering

The patent of the present invention relates to a fiber grating temperature sensor with high water pressure resistance and an assembly method, which includes a casing, an inner cavity is arranged inside the casing, an optical fiber grating is arranged inside the inner cavity, and an optical fiber grating is arranged inside the optical fiber grating. The optical fiber lead-out line passes through the upper cover and leads out of the shell. The upper cover is fixedly installed on one end of the shell and seals one side of the inner cavity; Lower cover sealed on one side. It is a fiber grating temperature sensor that is easy to use, simple to connect, has strong protection strength, and can respond quickly to the ambient temperature and withstand high water pressure, so as to solve the problem that the conventional fiber grating temperature sensor has complex structure and complicated manufacturing process, which cannot be applied in High water pressure is a particular problem in harsh environments.

Owner:国能大渡河猴子岩发电有限公司

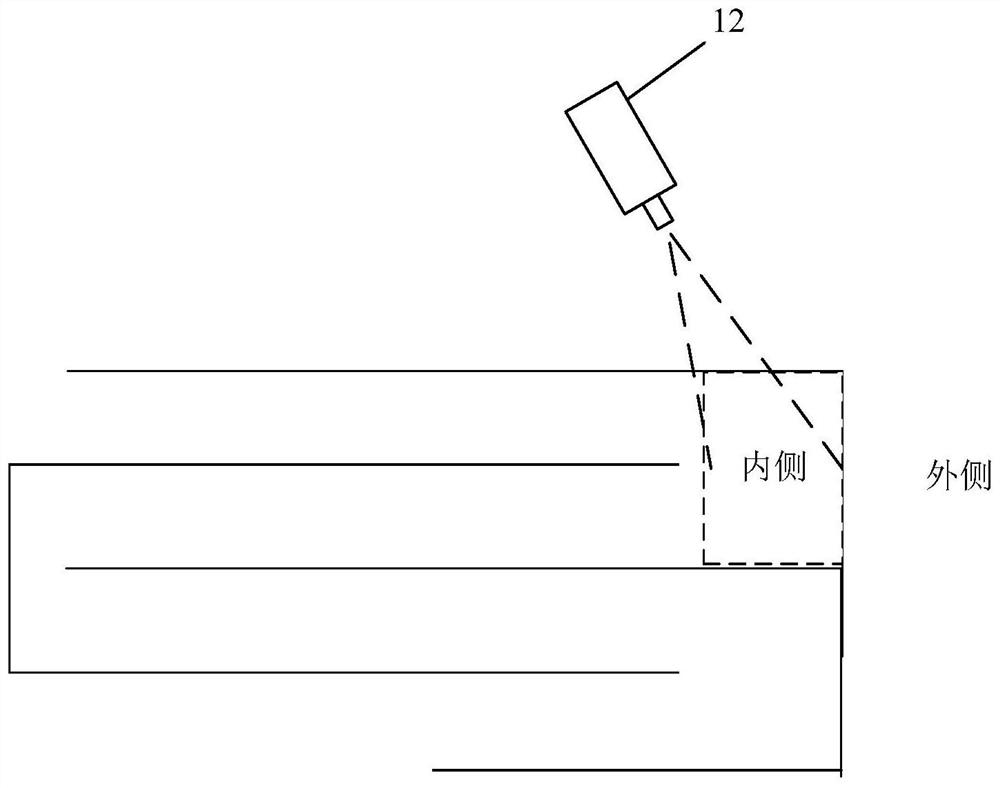

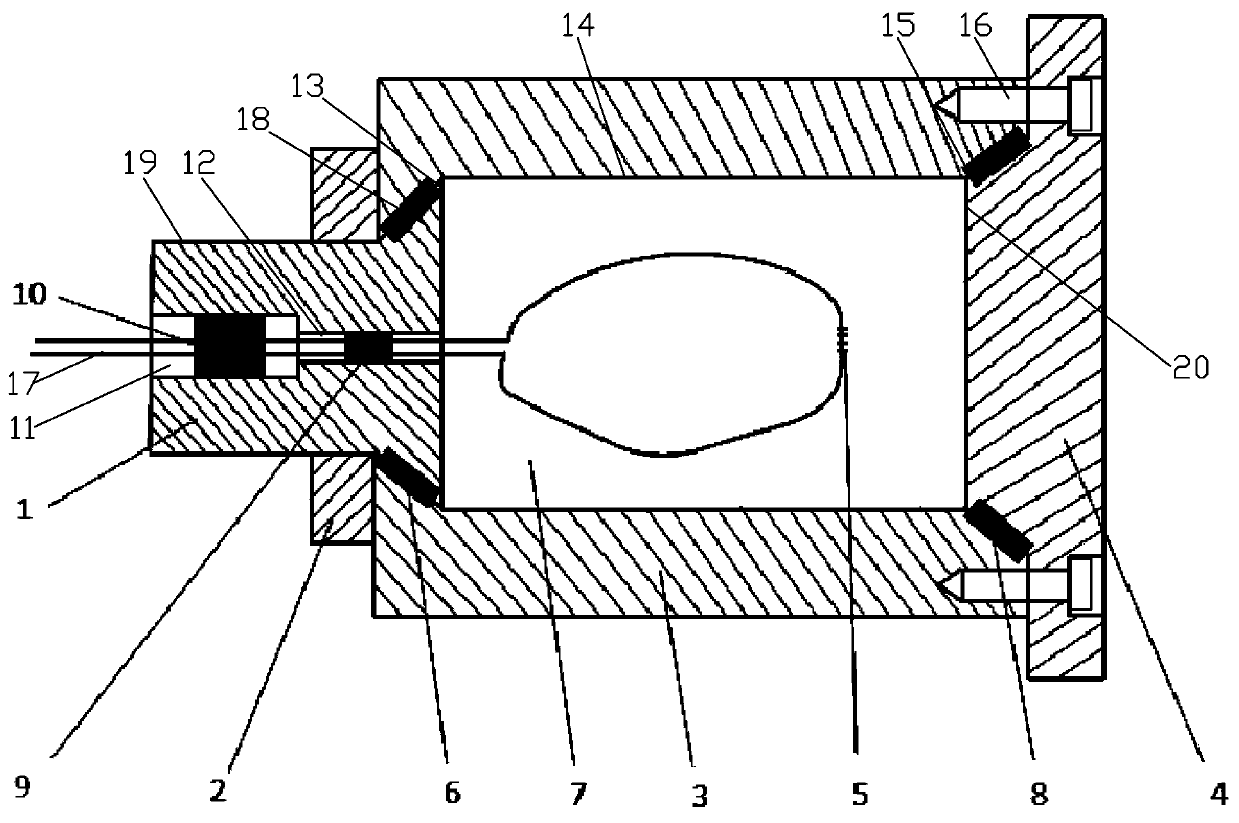

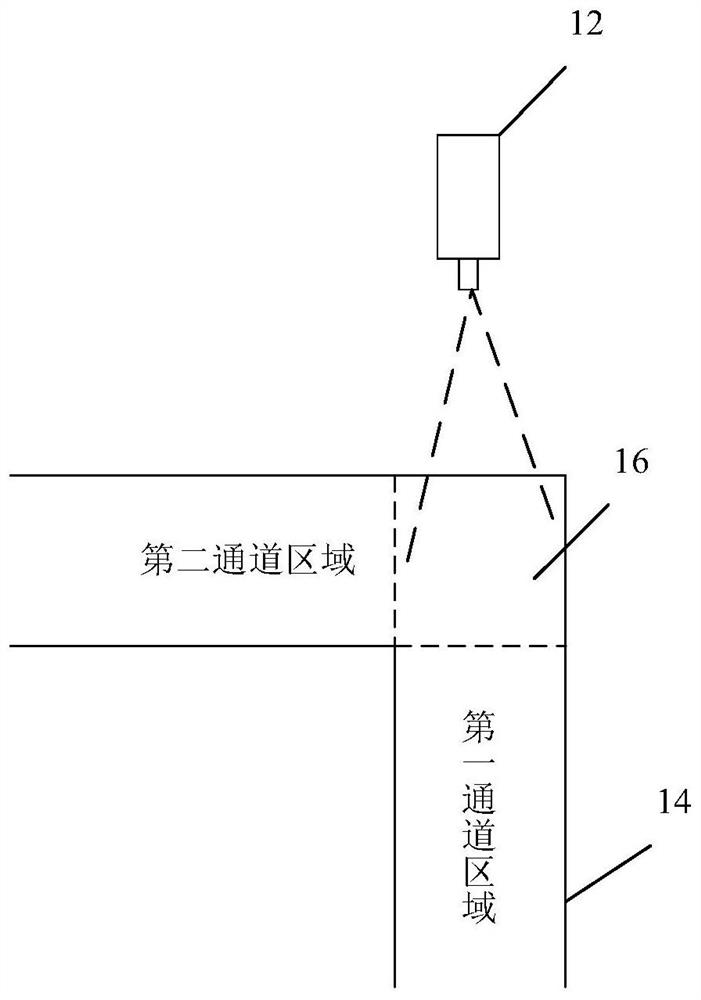

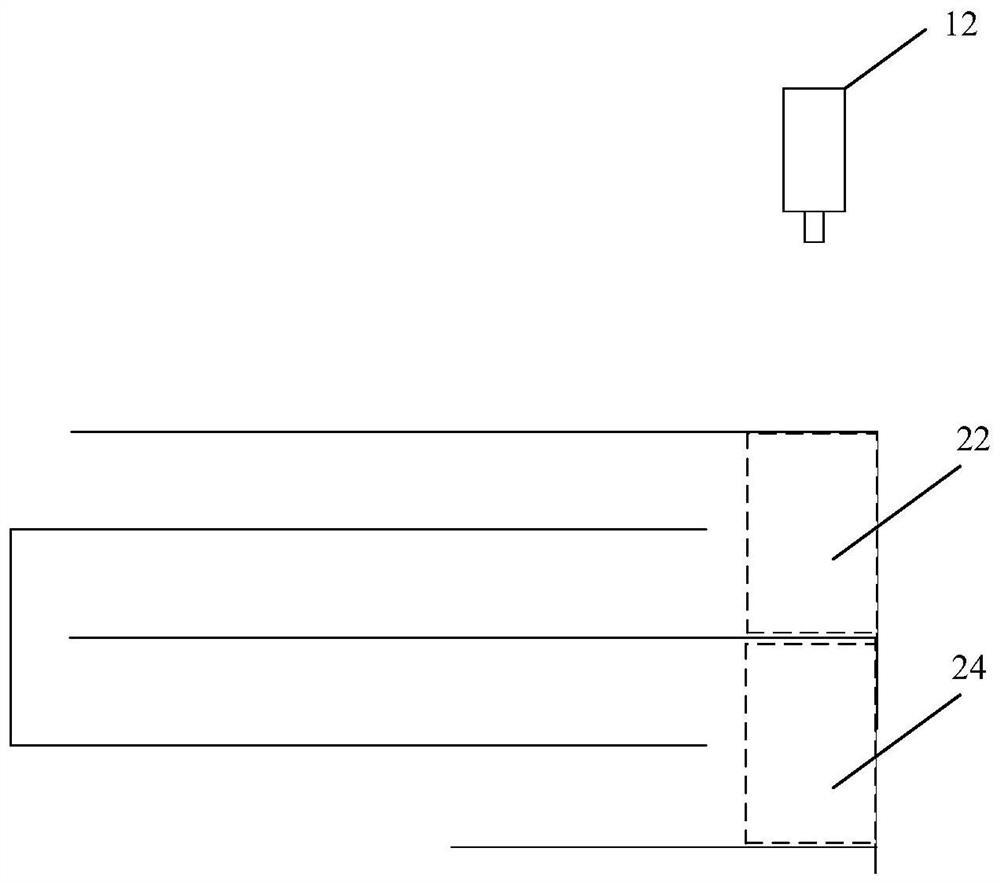

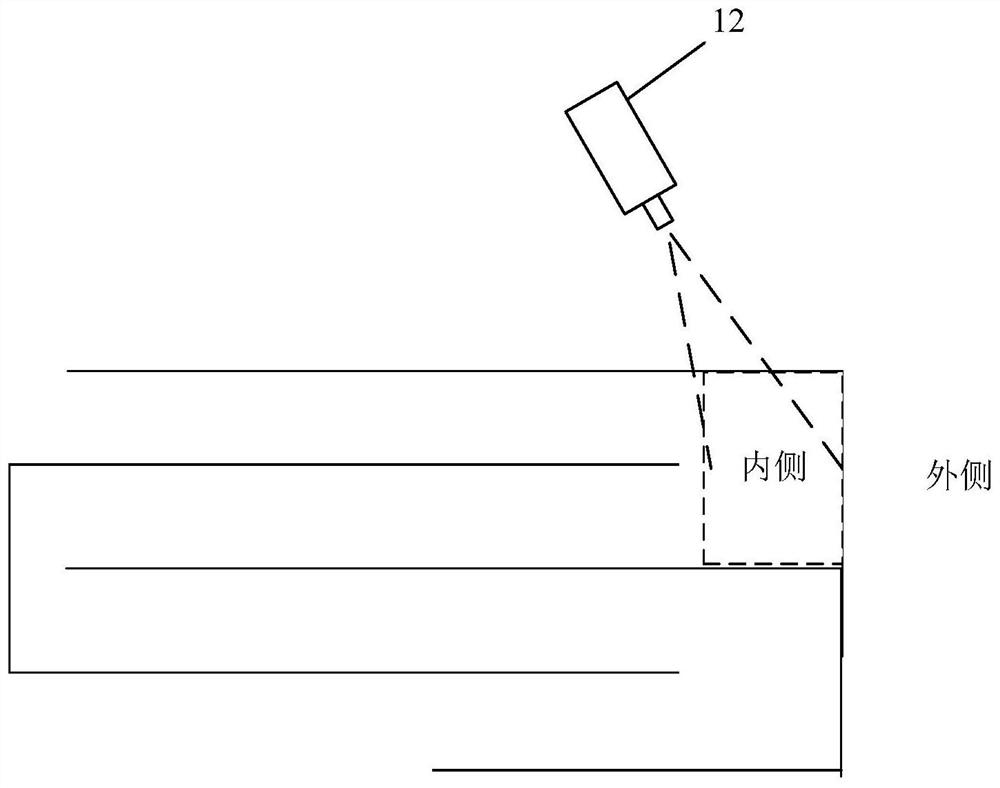

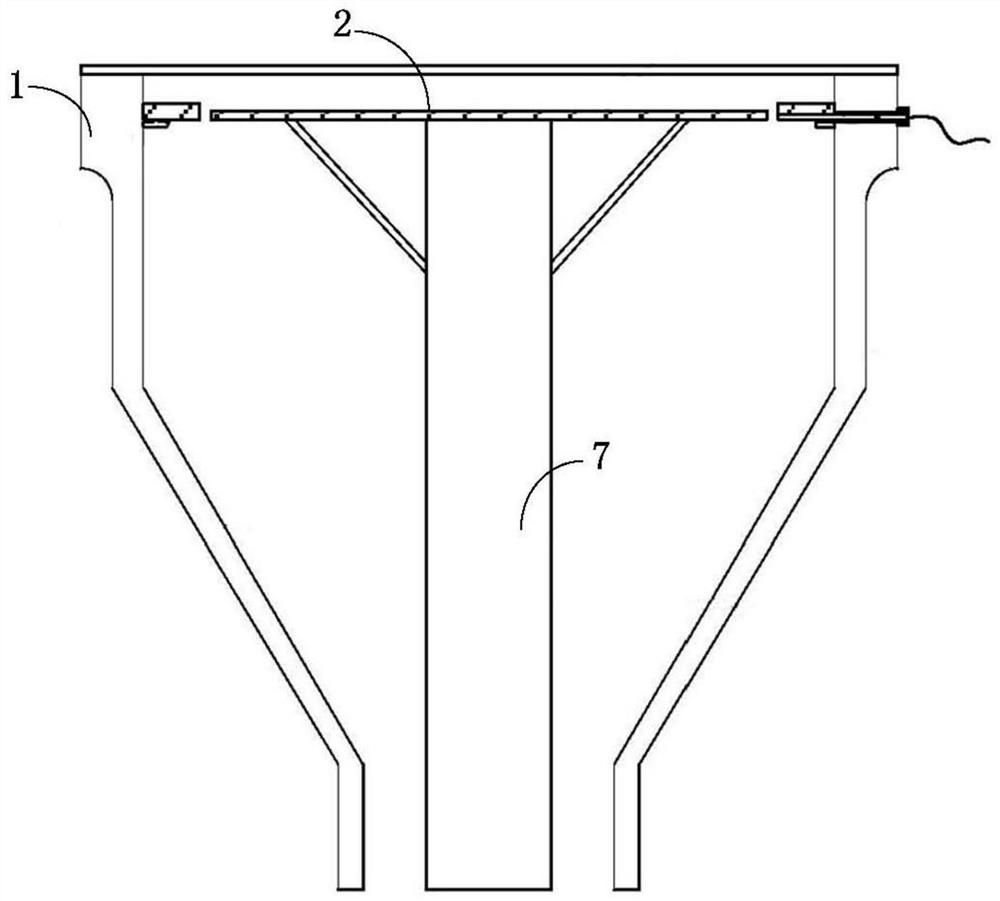

Temperature measurement system and method

ActiveCN112798113ASmall error in temperature measurementReduce the impactSensing radiation from moving bodiesIndividual entry/exit registersEngineeringMechanical engineering

The invention relates to a temperature measurement system and method. The temperature measurement system comprises temperature measurement equipment used for measuring the temperature of an object to be subjected to temperature measurement and flow guide equipment; the flow guide equipment comprises a flow guide channel; the flow guide channel comprises a first channel area and a second channel area; the object to be subjected to temperature measurement can move from the first channel area to the second channel area, and can change the direction of movement along the second channel area; and the temperature measuring equipment is arranged towards the second channel area, so that the temperature measuring area of the temperature measuring equipment at least partially covers the second channel area, and therefore, the influence of people gathering on the body temperature of a measured person is reduced, and the temperature measuring error of the measured person is reduced.

Owner:浙江华感科技有限公司

A high precision temperature sensor circuit

ActiveCN108562373BSimple structureReduce power consumptionThermometers using electric/magnetic elementsUsing electrical meansFrequency conversionHemt circuits

A high-precision temperature sensor circuit belongs to the technical field of electronic circuits. First, use the bandgap reference module to generate a bandgap reference voltage and a positive temperature coefficient voltage, and then use two identical voltage-frequency conversion circuits to convert the positive temperature coefficient voltage and the bandgap reference voltage into positive temperature coefficient voltage frequency and bandgap The reference voltage frequency is finally counted by two counters. When the second counter is full, the first counter stops counting through the feedback signal. The temperature value is obtained by obtaining the ratio of the positive temperature coefficient voltage to the bandgap reference voltage. The designed temperature The sensor structure is simple and can achieve low power consumption; the chopper op amp is used in the bandgap reference module to eliminate the error caused by the offset of the op amp, and a system chopper module is added after the bandgap reference module to reduce the comparator offset voltage Error in temperature detection. The invention has the advantages of simple structure, low power consumption and small temperature measurement error.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-temperature sensor for metal tubular black body hollow cavity

ActiveCN103162840BImprove accuracyCompact structureRadiation pyrometryData processing systemBlack body

The invention relates to a high-temperature sensor for a metal tubular black body hollow cavity and belongs to the technical field of temperature sensors for measurement of high temperatures. The high-temperature sensor for the metal tubular black body hollow cavity comprises the black body hollow cavity, a shielding cover, a coupler, transmission optical fibers, a light splitting detection system and a data processing system, wherein the head portion of the outer surface of the black body hollow cavity is arranged to be in a rib-piece type structure according to the design, and the black body hollow cavity is arranged to be in a blind hole form according to the design. The black body hollow cavity made of high-temperature resistant metal materials is used as a to-be-sensed portion of the high-temperature sensor, the silica optical fibers are used for transmitting signals, a double silicon detector is used for splitting light and conducting photoelectric conversion, and therefore the high-temperature sensor for the metal tubular black body hollow cavity is compact in structure and reliable in performance. In addition, the shielding cover is arranged outside the black body hollow cavity according to the design; and combined with the special-shaped structure of the black body hollow cavity and through theoretical analysis and numerical calculation, the high-temperature sensor for the metal tubular black body hollow cavity has the advantages of being good in high-temperature resistance, oxidation resistant, high in accuracy and the like, and can solve the high-temperature measuring problem which cannot be solved at present.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Reaction cavity, semiconductor process equipment and base temperature control method

ActiveCN113186520ASmall error in temperature measurementImprove temperature measurement accuracySemiconductor/solid-state device manufacturingChemical vapor deposition coatingPhysicsEngineering

The invention provides a reaction cavity, semiconductor processing equipment and a base temperature control method. The reaction cavity comprises a cavity body, a base and a preheating ring, wherein the preheating ring is connected with the inner circumferential wall of the cavity body and surrounds the periphery of the base, the reaction cavity further comprises a temperature measuring assembly, the temperature measuring assembly comprises an arc-shaped detection pipe and a temperature measuring element arranged in the arc-shaped detection pipe, the arc-shaped detection pipe is arranged at the position, close to the inner circumferential edge of the preheating ring, of the bottom of the preheating ring and extends in the circumferential direction of the base; one end of the detection pipe is provided with an extension part, and the extension part penetrates through the cavity body and extends to the outside of the cavity body; the temperature measuring element is used for detecting the temperature of a plurality of temperature measuring points which are distributed at intervals in the extension direction of the arc-shaped detection pipe, and is used as an edge temperature value of the base, and wires of the temperature measuring element are led out of the cavity body through the extension part. According to the reaction cavity, the semiconductor processing equipment and the base temperature control method, the temperature of the base is detected in real time in the process state of the cavity, and the cavity does not need to be opened and the temperature measuring assembly does not need to be dismantled before the formal process is started.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

High-temperature temperature sensor based on surface-modified tungsten-rhenium thermocouple

ActiveCN102095517BPrevent changes in thermoelectric propertiesEasy to useThermometers using electric/magnetic elementsUsing electrical meansRheniumComposite ceramic

The invention belongs to a temperature sensor for high temperature measurement, and relates to a high-temperature temperature sensor based on a surface-modified tungsten-rhenium thermocouple for short-time temperature measurement below 2600 K. In the invention, a composite ceramic material is used as the protection film of the tungsten-rhenium thermocouple to prevent the change in the thermoelectric characteristics of the tungsten-rhenium thermocouple due to the erosion of oxidative gas. Through the film coating treatment, a composite high-temperature-resistant and anti-oxidant ceramic material grows on the surface of the tungsten-rhenium thermocouple to ensure the normal use of the thermocouple wire. Meanwhile, a special protection sleeve material is used to ensure a less comprehensive temperature measurement error during the temperature measurement of high-temperature air flow through theoretical analysis and numerical calculation. Therefore, the high-temperature temperature sensor is applicable to the high-temperature air flow environment and can keep the enough thermal strength to ensure the temperature measurement accuracy with the aid of a proper structure. In addition, the high-temperature temperature sensor has the advantages of high temperature resistance, high oxidation resistance, quick response and the like.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Cooling-free type high temperature sensor based on composite material

ActiveCN102944320BSmall thermal errorSmall error in temperature measurementThermometers using electric/magnetic elementsUsing electrical meansFiberGraphite

The invention belongs to high temperature sensors for high temperature measurement, relates to a composite material-based cooling-free type high temperature sensor which is applicable to the temperature measurement of high temperature air flow under 2100K, and belongs to the field of temperature testing. The cooling-free type high temperature sensor comprises a thermalcouple wire, an insulating porcelain tube, a shell, an installing flange and a plug, wherein the shell (partially or completely) is made from a C / SiC composite material; firstly, a framework of a required shape is woven by using C-fibers; secondly, SiC can grow on the C-fiber framework in a chemical gas deposition or chemical liquid deposition mode so as to accomplish the growth of a basic shell structure; subsequently, the shell is sintered in a sintering furnace, wherein the sintering temperature is 1770-1870K; and for a thin-wall hollow shell of which the wall thickness is less than 2mm, graphite is used as a core die when the thin-wall hollow shell is woven, the C-fibers are woven on the graphite core die, and the graphite core die is eliminated after the growth of the SiC. By utilizing the cooling-free type high temperature sensor, the temperature measurement error is reduced, the continuity of the shell material is increased, and the use performance of the temperature senor is improved and the service life of the temperature senor is prolonged.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

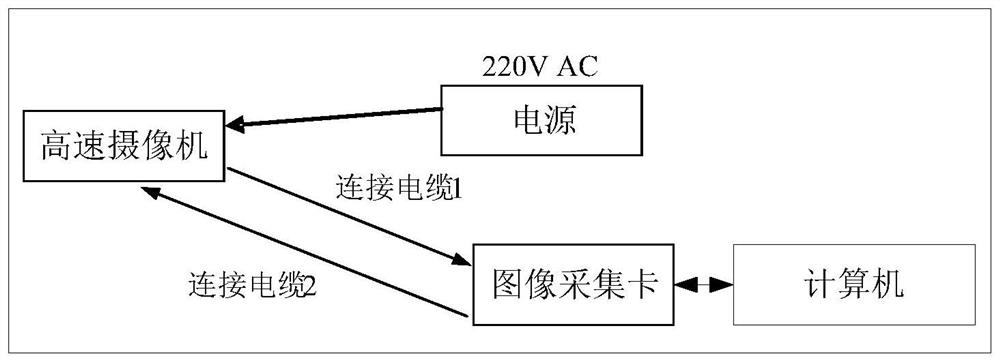

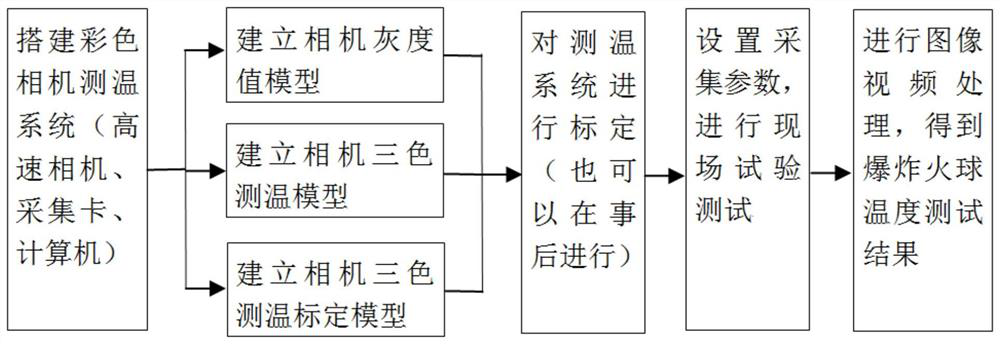

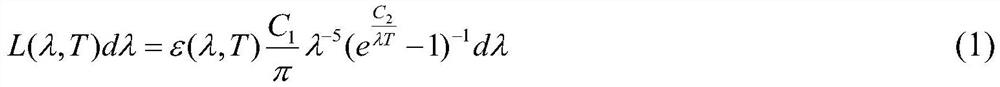

A kind of temperature testing method based on RGB three primary colors

ActiveCN111397759BAdapt to temperature testFast dynamic responseThermometers using physical/chemical changesTarget surfaceEngineering

The invention provides a temperature testing method based on the three primary colors of RGB. According to the relationship between the imaging gray value of the photosensitive target surface of the high-speed camera and the wavelength, the gray value of the R, G, and B primary colors output by the color high-speed camera is used to measure the temperature. The invention adopts the theory of thermal radiation and establishes a non-contact measurement method, which is suitable for testing the fireball temperature of an explosion field composed of complex materials with high pressure and high-speed airflow under complex and harsh working conditions; the dynamic response is fast, and it is suitable for high temperature of the fireball, extremely fast change, continuous The characteristics of short time; it is suitable for the actual test of the fireball temperature of the warhead, ammunition, thermobaric bombs and other explosive fields in the field test environment.

Owner:中国人民解放军63871部队

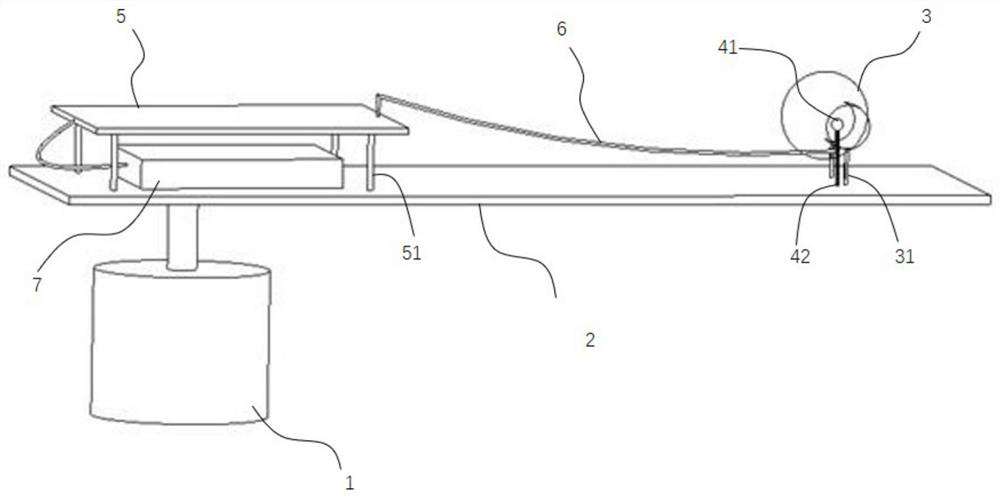

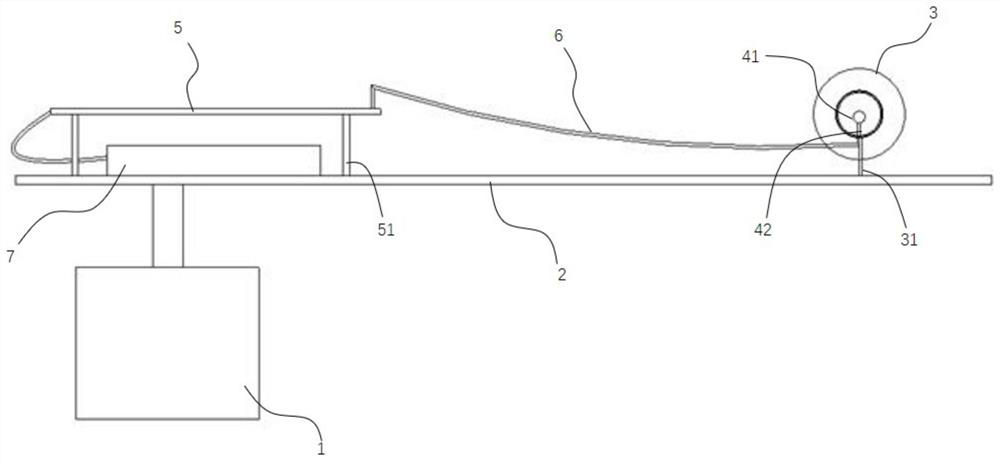

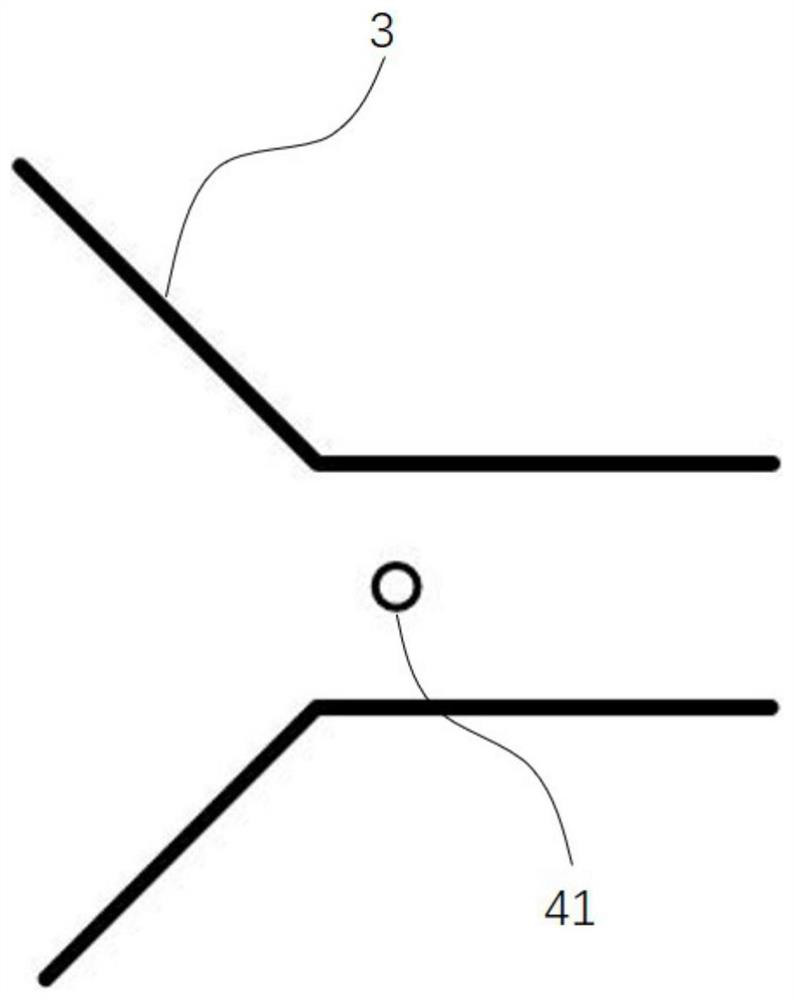

A kind of forced ventilation radiation shield with flow guide device

ActiveCN111521294BStrong ventilationScientific and reasonable structureThermometer detailsTemperature measurement of flowing materialsDrive shaftElectric machinery

The invention discloses a forced ventilation radiation shield with a deflector, which comprises a motor, a support plate, a deflector, a support column and a temperature sensor probe; Rotation; the support plate is set horizontally, one end is fixed on the drive shaft of the motor, and the motor can drive the support plate to rotate in the horizontal plane; the shroud is a trumpet-shaped structure with both ends penetrated; the shroud is fixed on the other end of the support plate through the support column The upper surface of the support plate rotates with the support plate, and the shroud is arranged in a direction perpendicular to the radius of rotation; the temperature sensor probe is fixed in the middle of the shroud; the motor drives the support plate to rotate, and the shroud located at the outer end of the support plate and the inside of the shroud The temperature sensor probe moves accordingly. The invention has the advantages of scientific and reasonable structure, strong ventilation, small temperature measurement error and the like.

Owner:江苏佐都数字科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com