A high water pressure resistant fiber grating temperature sensor and assembly method

A technology of temperature sensor and fiber grating, applied in the direction of thermometers, thermometers, thermometer parts, etc. with physical/chemical changes, can solve the problems of inability to apply, complex manufacturing process, complex structure, etc. Processing difficulty, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

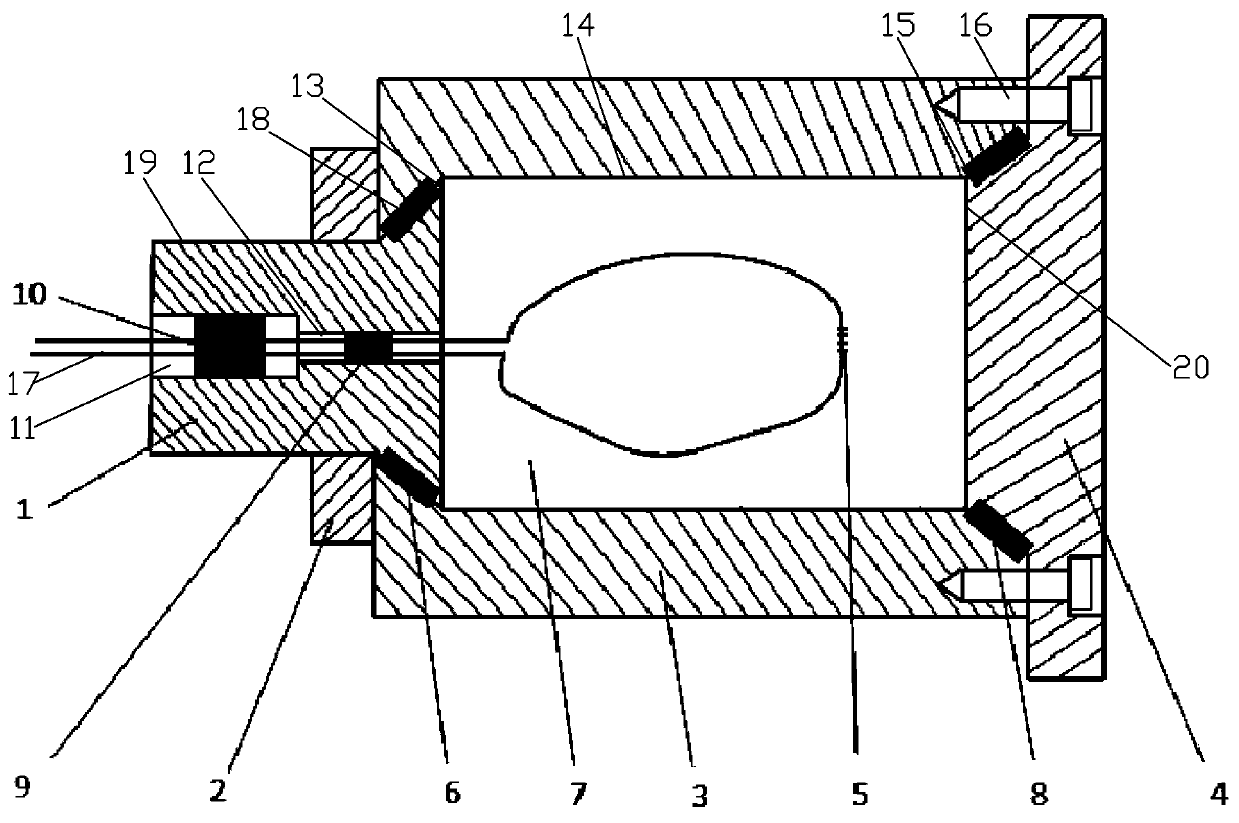

[0033] like figure 1 , a fiber grating temperature sensor resistant to high water pressure, it includes a housing 3, the inside of the housing 3 is provided with an inner cavity 14, the inside of the inner cavity 14 is provided with a fiber grating 5, the fiber grating 5 The optical fiber lead-out line 17 passes through the upper cover 1 and leads out of the housing 3, the upper cover 1 is fixedly installed on one end of the outer housing 3 and seals one side of the inner cavity 14; the end of the outer housing 3 opposite to the upper cover 1 A lower cover 4 for sealing the other side of the inner cavity 14 is installed. By adopting the fiber grating temperature sensor with the above structure, since it is in use, the fiber grating 5 is inside the completely airtight inner cavity 14, and the fiber grating is in a bending and relaxing state in the airtight working cavity, and it will not be compressed nor It will be stretched, avoiding the influence of fiber grating tensile st...

Embodiment 2

[0043] The assembly method of the high water pressure resistant fiber grating temperature sensor described in any one is characterized in that comprising the following steps:

[0044] The first step is to pass the fiber lead-out wire 17 of the fiber grating 5 through the first center hole 12 and the second center hole 11 of the upper cover 1, and make the fiber grating 5 inside the inner cavity 14 in a state of free bending and relaxation After the optical fiber lead-out line 17 is led out of the upper cover 1, the first central hole 12 is dispensed and filled to form the first sealant 9, and the second central hole 11 is dispensed and filled to form the second sealant 10, and the upper cover is ensured 1 sealing of the center hole;

[0045] In the second step, the first sealing ring 6 is installed on the first frustum section 18 of the upper cover 1, and the upper cover 1 with the fiber grating 5 enters the working cavity 7 inside the outer shell 3 through the lower surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com