Interior temperature measuring equipment for material bed of belt-type sinterer

A technology of internal temperature and measuring devices, which is applied to measuring devices, thermometers, measuring heat, etc., can solve the problems of increased cost, trolley damage, high cost of infrared temperature measuring devices, etc., and achieves improved measurement accuracy, fast response, and temperature measurement. small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

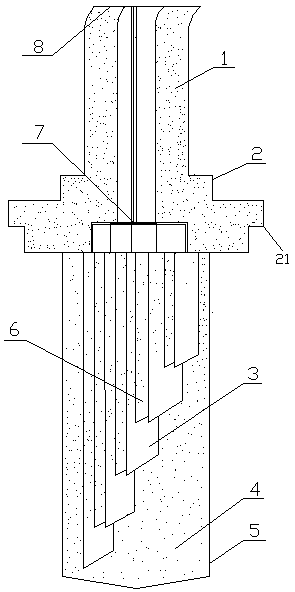

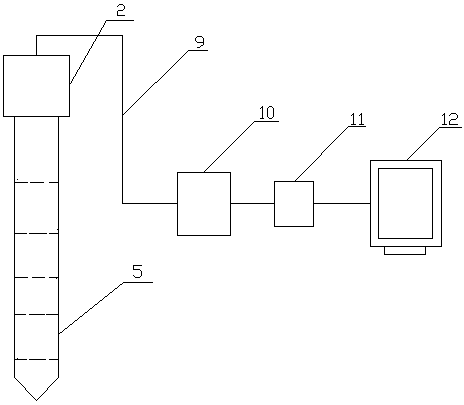

[0017] like figure 1 As shown, a belt type sintering machine material layer internal temperature measurement device, including refractory tube 2, thermocouple group 3, protective sleeve 5 and data line connector 7, refractory tube 2 is a double-layer refractory tube, the top of refractory tube 2 The movable connection is provided with a protective cover 8 for easy disassembly and assembly. The protective cover 8 is made of high temperature resistant material; The couple group 3 is installed in the protective sleeve 5. The thermocouple group 3 is composed of a plurality of thermocouples arranged. The top of the thermocouple is connected to the data line connector 7, and the bottom of the thermocouple is stepped, so that it can be realized in the height direction of the sintered material layer. Multi-point synchronous temperature measurement work; a shielding electrical insulating fiber sheet 6 is arranged between two adjacent thermocouples, and the shielding electrical insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com