Multipoint temperature measuring interface device of vacuum furnace

A technology of interface device and vacuum furnace, which is applied in the direction of measuring device, electric device, thermometer, etc., can solve problems such as measurement error, and achieve the effect of reducing temperature measurement error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

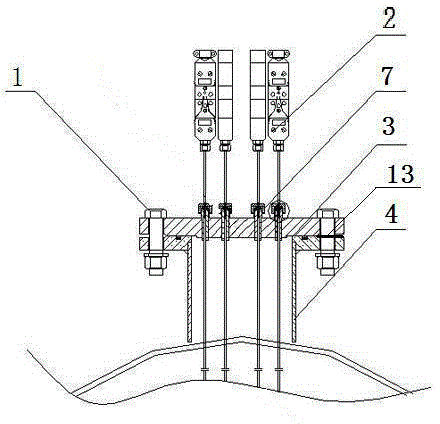

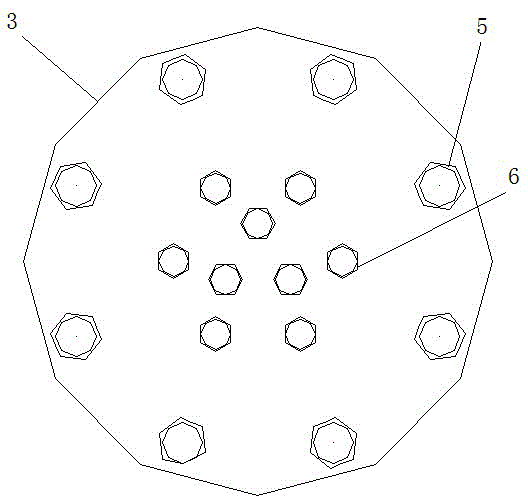

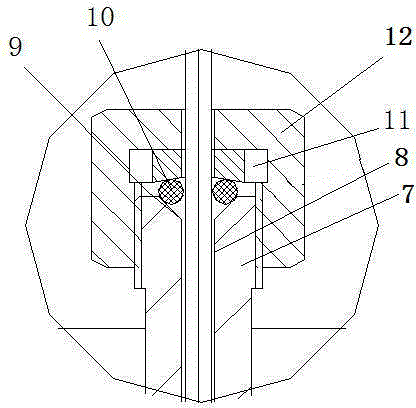

[0011] Such as figure 1 A multi-point temperature measurement interface device for a vacuum furnace is shown, including a flange lock nut 1, a temperature measurement thermocouple 2, a flange cover 3, and a multi-point temperature measurement tube 4. The flange cover includes an outer hole 5 and an inner hole Hole 6, the multi-point temperature measuring tube 4 is connected to the outer hole 5 at the bottom of the flange cover 3, and penetrates the flange lock nut 1 for fixing, and the temperature measuring thermocouple 2 is connected to the flange cover 3 In the inner hole 6, the temperature measuring thermocouple 2 is equipped with an inductor 14, the inner hole 6 is equipped with a fixing seat 7, and the outer side of the fixing seat 7 has a locking thread, which is fixedly connected with the inner hole 6, The center of the fixing seat 7 is a hollow circular tube 8, the hollow circular tube 8 is connected with a temperature measuring thermocouple 2, the inner side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com