Cooling-free type high temperature sensor based on composite material

A high-temperature sensor and composite material technology, which is used in thermometers, instruments, thermometers and other directions that use electrical/magnetic components directly sensitive to heat. Longer life, increased continuity, and less temperature measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

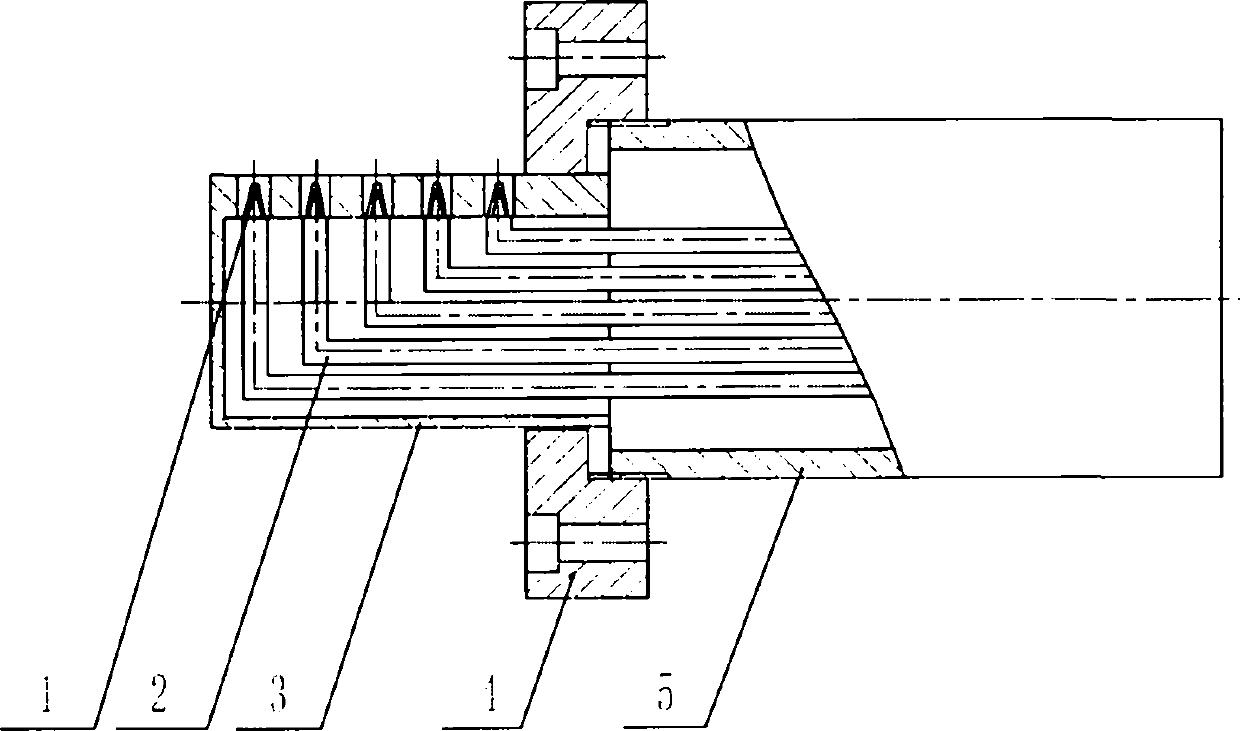

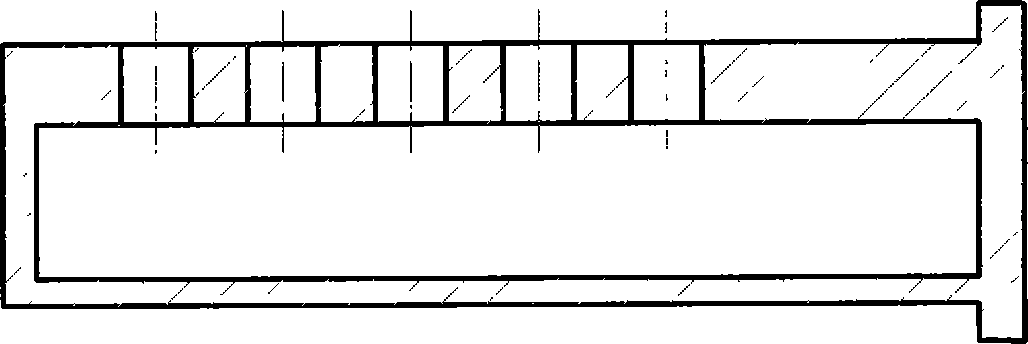

[0025] A non-cooling high temperature sensor based on composite materials, including a thermocouple wire 1, an insulating porcelain tube 2, a casing 3, a mounting flange 4 and a plug 5; the casing 3 is made of C / SiC composite material, and the preparation method of the casing 3 is as follows :

[0026] Step 1. Weave a skeleton of the desired shape with C fibers to obtain a C fiber skeleton;

[0027] Step 2, growing SiC on the C fiber skeleton by means of chemical vapor deposition or chemical liquid phase deposition to complete the generation of the basic structure of the shell 3;

[0028] Step 3: Sinter the basic structure of the shell 3 described in step 2 in a sintering furnace. The basic structure of the shell 3 described in step 2 is sintered in a sintering furnace at a sintering temperature of 1850K.

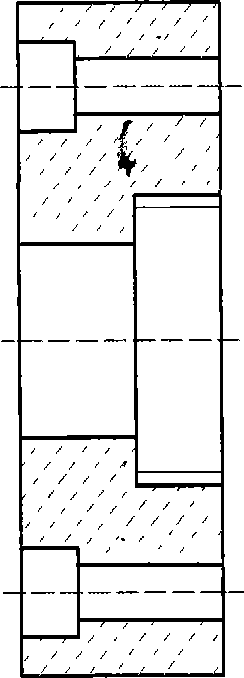

[0029] The connection relationship of the high temperature sensor is as follows: the shell 3 is a hollow structure with a blind end, and a step is designed at the non-blin...

Embodiment 2

[0036] A non-cooling high temperature sensor based on composite materials, including a thermocouple wire 1, an insulating porcelain tube 2, a casing 3, a mounting flange 4 and a plug 5; the casing 3 is made of C / SiC composite material, and the preparation method of the casing 3 is as follows :

[0037] Step 1. Weave a skeleton of the desired shape with C fibers to obtain a C fiber skeleton;

[0038] Step 2, growing SiC on the C fiber skeleton by means of chemical vapor deposition or chemical liquid phase deposition to complete the generation of the basic structure of the shell 3;

[0039] Step 3: Sinter the basic structure of the shell 3 obtained in Step 2 in a sintering furnace at a sintering temperature of 1800K. For a thin-walled hollow shell 3 with a wall thickness of less than 2 mm, graphite is required to be used as a mandrel during weaving, and C fibers are woven on the graphite mandrel, and the graphite mandrel is removed after SiC growth is completed.

[0040]The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com