High-temperature sensor for metal tubular black body hollow cavity

A technology of temperature sensor and blackbody cavity, which is applied in the field of temperature sensor for high temperature measurement, can solve the problems of lack of temperature measurement means, etc., and achieve the effect of high temperature resistance, reliable performance, and small comprehensive temperature measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

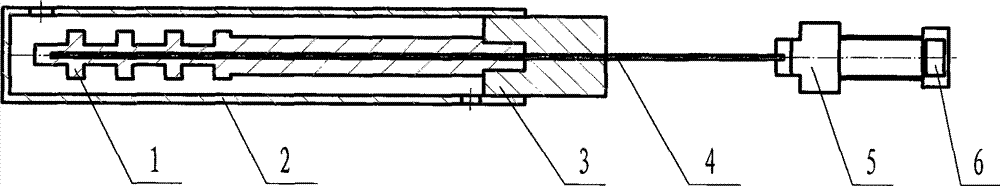

[0027] Metal tubular blackbody cavity high temperature temperature sensor, including blackbody cavity 1, shielding cover 2, coupler 3, transmission fiber 4, spectroscopic detection system 5 and data processing system 6; between blackbody cavity 1 and coupler 3, shielding cover 2 and coupler 3 are connected by thread, and the outer surface of the thread connection is coated with high-temperature sealant to ensure that the thread connection does not rotate in the circumferential direction, and at the same time avoid light leakage;

[0028] Both the black body cavity 1 and the shielding cover 2 are made of metal iridium. Before forming, the metal iridium needs to be forged and hot-rolled to improve its comprehensive mechanical properties. The direction of the tissue fibers after pressure processing is parallel to the direction of the normal stress;

[0029] The head of the outer surface of the black body cavity 1 is designed as a fin structure, and the number of fins is 3 to enhan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com