Full-automatic small-size alternating current and direct current control aluminum groove ice making machine

A DC control, small size technology, used in ice making, ice making, ice storage/distribution, etc., can solve the needs of ice making that cannot meet small size and high efficiency, the strength of the aluminum tank ice machine is not enough, and the increase of access Refrigerator cost and other issues, to achieve the effect of low noise, low cost and stable transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

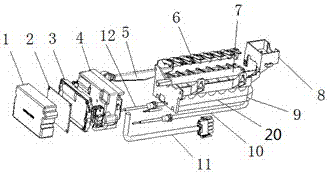

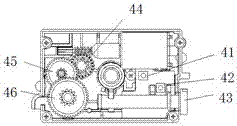

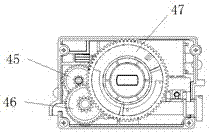

[0024] The fully automatic small-sized AC and DC controlled aluminum tank ice machine of the present invention includes an aluminum alloy ice making tank 9, and the left end of the aluminum alloy ice making tank 9 is fixedly connected with a gear box assembly 4 through screws, so that A micro switch K141 and a micro switch K242 are respectively installed on the left side of the inner cavity of the gear transmission control box assembly 4, and a control rod 43 is connected through the lower part of the right side of the gear transmission assembly 4, and the control rod 43 One end is connected to the outer side of the gear C346 through a connecting rod, the central shaft of the gear C346 is meshed with a gear C447, the outer side of the gear C346 is meshed with the central shaft of the gear C245, and the outer side of the gear C245 is meshed with the gear C144 One side of the gear transmission assembly 4 is provided with an ice probe 5, the other side of the gear transmission ass...

Embodiment 2

[0029] For the special case where the freezing degree is very thick and the adhesion is very strong, the hot air flow can be filled into the cold runner for cyclic preheating, and then the preliminary deicing and deicing effect can be performed on the surroundings of the aluminum alloy ice making tank 9, which is better Meet the actual use needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com