High-temperature temperature sensor based on surface-modified tungsten-rhenium thermocouple

A temperature sensor and surface modification technology, used in thermometers, thermometers, instruments, etc., which are directly sensitive to heat-sensitive electrical/magnetic components, can solve the problem of lack of temperature measurement methods, and achieve guaranteed accuracy, high temperature resistance, The effect of small comprehensive temperature measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

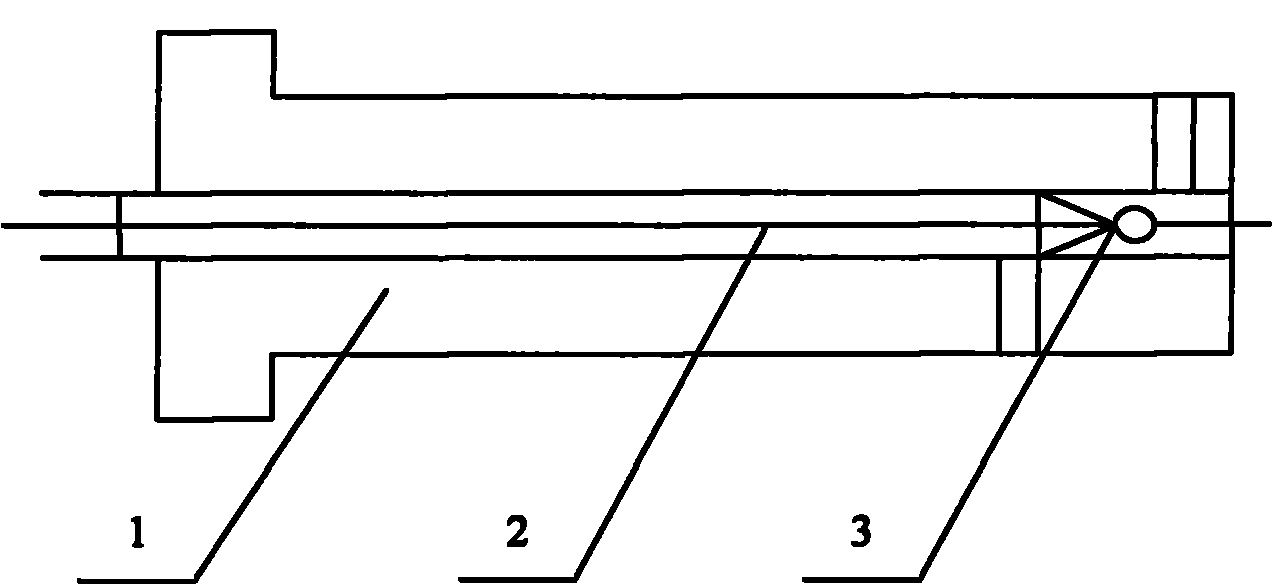

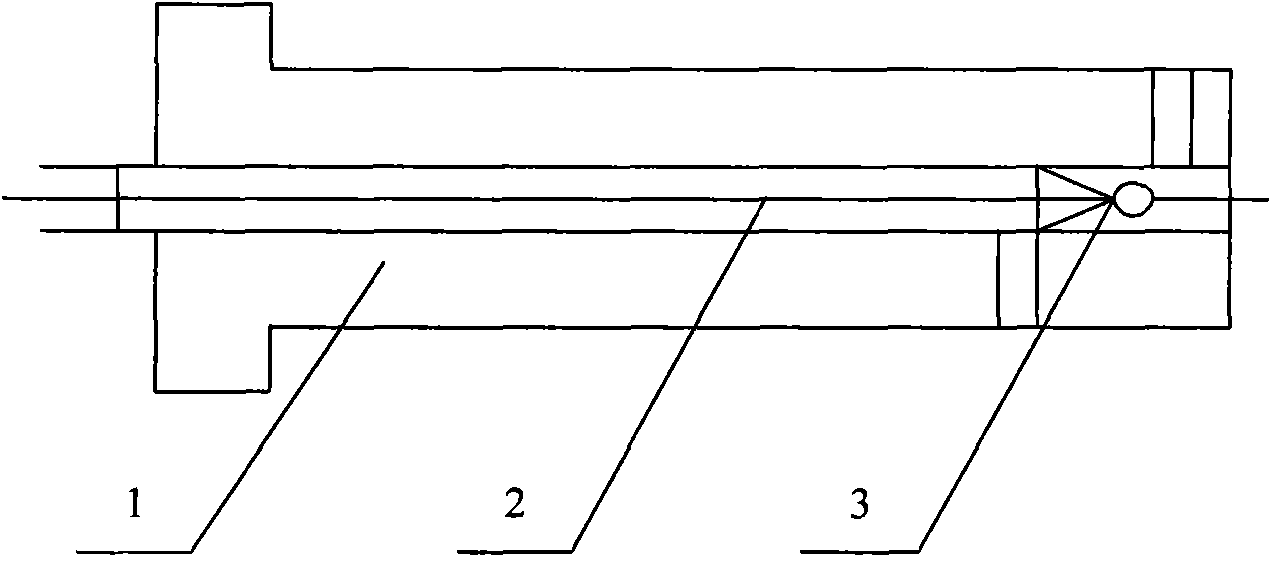

[0014] The high-temperature temperature sensor of the present invention includes a protective sleeve 1, an insulating porcelain tube 2 and a tungsten-rhenium thermocouple 3, and the surface of the tungsten-rhenium thermocouple 3 is coated with a high-temperature-resistant ceramic material; the insulating porcelain tube 2 is made of magnesium oxide material ; The protection sleeve 1 adopts metal tungsten, metal molybdenum, tungsten-lanthanum alloy or high-temperature alloy heating barrier coating, and the structure of the protection sleeve 1 adopts a single-shielding stagnation type or a single-shielding direct blowing type.

[0015] Described tungsten-rhenium thermocouple 3, the substrate material of surface coating is metal Zr, and the main component of coating material is ZrO 2 , mixed with an appropriate amount of Y 2 o 3 , as a phase stabilizer, the thickness of the film layer does not exceed 10μm, and the color of the even wire after coating is gray or blue. The length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com