Double-screen air suction type sapphire optical fiber high temperature sensor

A high temperature sensor, sapphire technology, applied in instruments, thermometers, scientific instruments, etc., can solve the problems of lack of accurate and effective temperature measurement methods, slow response speed, blank and other problems, to solve the problem of high temperature measurement, small comprehensive temperature measurement error, Accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and implementation example:

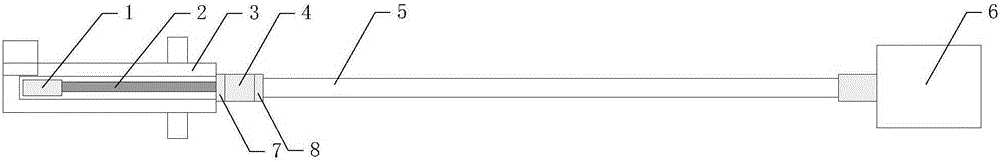

[0023] In this embodiment, the double-screen suction type sapphire fiber optic high temperature sensor has a structure such as figure 1 As shown, it includes: black body cavity 1, sapphire fiber 2, shielding cover 3, spectroscopic detection system 4, transmission fiber 5, photoelectric conversion and data processing system 6, coupler I7 and coupler II8.

[0024] Its connection relationship is:

[0025] The blackbody cavity 1 is sleeved outside one end of the sapphire fiber 2; the other end of the sapphire fiber 2 is connected to the input end of the coupler I7; the blackbody cavity 1 and the sapphire fiber 2 are fixed inside the shielding cover 3. The output end of the coupler I7 is fixedly connected to the input end of the spectroscopic detection system 4; the output end of the spectroscopic detection system 4 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com