Wireless and passive power cable joint temperature monitoring system

A wireless passive and cable joint technology, which is applied to thermometers, signal transmission systems, and parts of thermometers, etc., can solve problems such as non-real-time and active power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

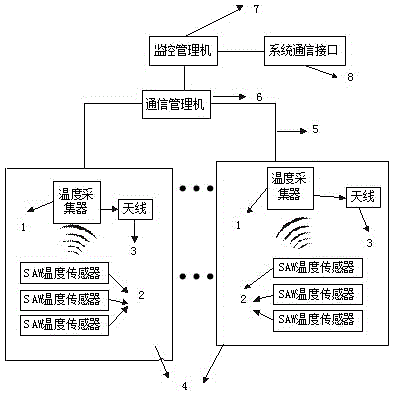

[0015] Embodiment: A wireless passive power cable joint temperature monitoring system based on surface acoustic wave technology, combined with figure 1 The method provided by the present invention is described in detail.

[0016] Specifically, there is a power conversion chip in the temperature collector 1, and its function is to convert the alternating current in the power grid into the 12V direct current required by the temperature collector 1. The SAW temperature sensor 2 obtains energy through the electromagnetic wave signal sent by the temperature collector 1, so the SAW temperature sensor 2 is passive.

[0017] The monitoring and management machine 7 first sets the temperature collection period T according to the specific environment and sends it to the temperature collector 1. The collection period T here can reach 100ms at the fastest, so the scanning frequency of the temperature collector 1 is particularly fast. The temperature collector 1 sends the received temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com