Built-in cable joint temperature fiber on-line monitoring sensor

A technology for monitoring sensors and cable joints, applied to thermometers, thermometers with physical/chemical changes, instruments, etc., can solve problems such as large errors and large environmental impacts, and achieve improved accuracy and precision, low cost, and easy installation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

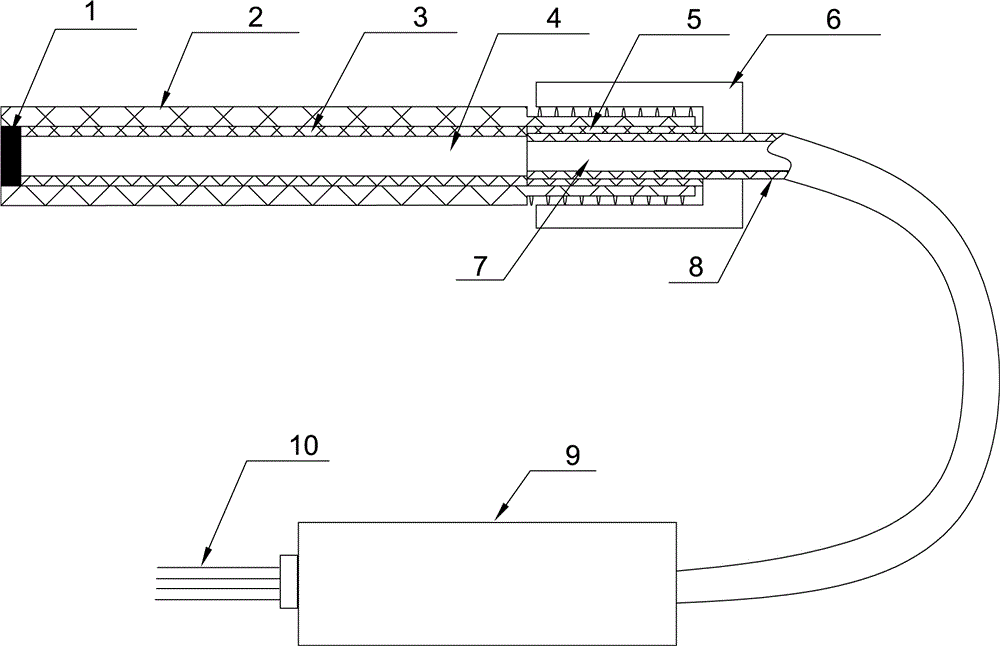

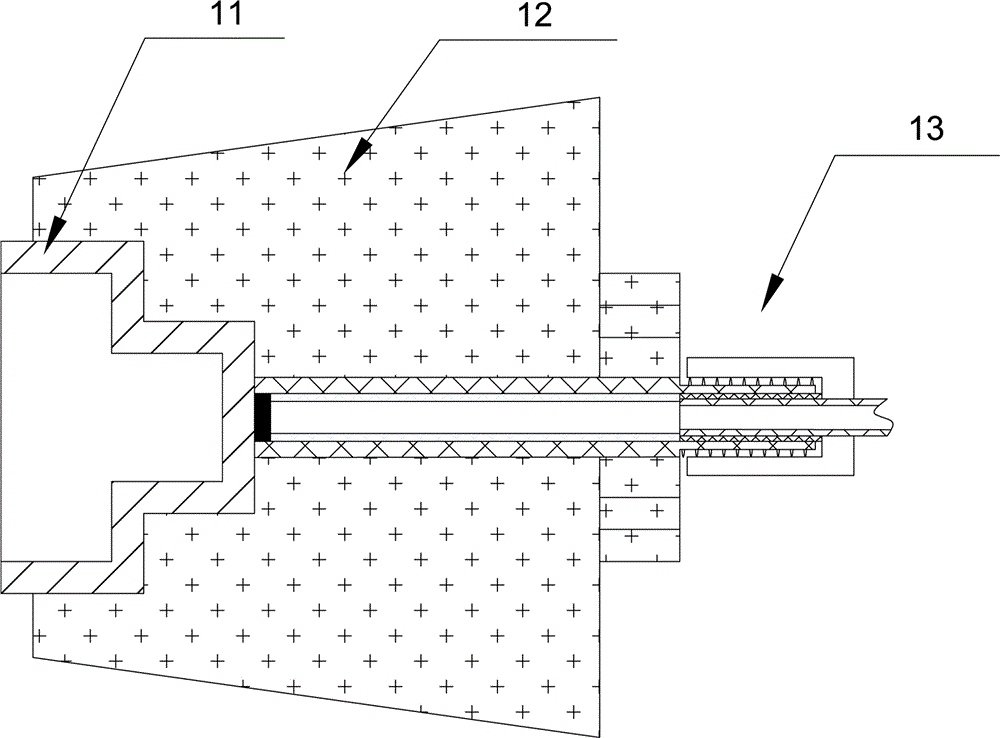

[0017] Such as figure 1 As shown, this embodiment includes: fluorescent materials, insulating ceramic tubes with threaded fasteners, fully transparent Teflon sleeves, quartz rods or quartz optical fibers, plastic ferrules, nuts, plastic optical fiber cores, plastic optical fibers, photoelectric processing modules, 485 output, metal nut for cable gland, cast epoxy and built-in temperature sensing head.

[0018] The fluorescent material 1 is pasted on the front end of the quartz rod or the quartz optical fiber 4, which is close to the metal nut of the cable joint of the measured object; the outer part of the quartz rod or the quartz optical fiber 4 is a fully transparent Teflon sleeve 3 and an insulating ceramic with a threaded buckle. Tube 2. The quartz rod or quartz optical fiber 4 and the fully transparent Teflon sleeve 3 are ironed; the ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com