Ring main unit cable joint temperature sensing system

A cable joint and sensing system technology, applied in thermometers, thermometer applications, thermometer components and other directions, can solve the problems of labor-intensive, temperature location is not the core area of heating, temperature deviation, etc., to achieve a compact, reasonable and easy-to-use overall structure. Installation and maintenance, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

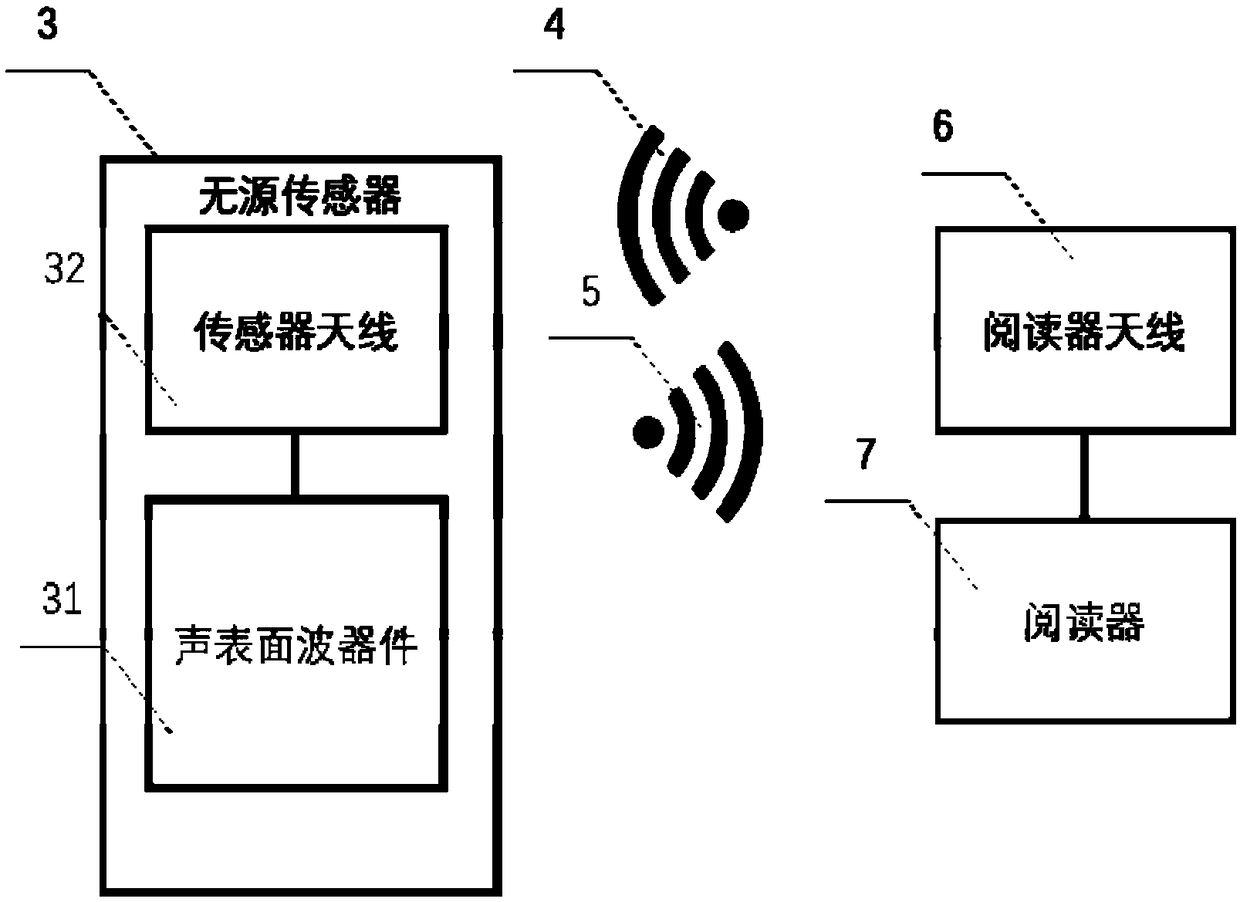

[0075] Such as Figure 4 As shown, the temperature sensing system of the cable joint of the ring network cabinet provided by the present invention includes: a plug 28, a connecting part 27, a double-way bushing seat 25, a silicone rubber sleeve 26, a temperature sensor 20, an antenna PCB 21, and an antenna PCB circuit 22 , Antenna metal radiator 23, central copper column 24, double-pass casing seat 25 and copper cap 29. The temperature sensor 20 and the antenna metal radiation piece 23 are welded on the corresponding position of the antenna PCB 21, and then poured on the outside of the inner center copper column 24 of the epoxy resin in the double-way casing seat 25, and the double-way casing 25 and the silicone rubber sleeve 26 sets After being connected and assembled, it is connected with the plug 28 through the connecting part 27.

[0076] In the above-mentioned embodiment, the central copper column 24, the connection part 27 and the copper cap 29 are connected to each oth...

Embodiment 2

[0078] Such as Figure 5 As shown, the temperature sensing system of the cable joint of the ring network cabinet provided by the present invention includes: a plug 28, a connecting part 27, a double-way bushing seat 25, a silicone rubber sleeve 26, a temperature sensor 20, an antenna PCB 21, and an antenna PCB circuit 22 , Antenna metal radiator 23, central copper column 24, double-pass casing seat 25 and copper cap 29. The temperature sensor 20 and the antenna metal radiation piece 23 are welded on the corresponding position of the antenna PCB 21, and then poured on the outside of the epoxy resin inner copper cap 29 in the plug 28, and the double-way sleeve 25 and the silicone rubber sleeve 26 are socketed and assembled and passed through The connecting portion 27 is connected to a plug 28 .

[0079] In the above-mentioned embodiment, the central copper column 24, the connection part 27 and the copper cap 29 are connected to each other, and here is the heating core area, and...

Embodiment 3

[0081] Such as Figure 6 The wireless temperature sensor shown in the cable joint of the ring network cabinet includes: a plug 28, a connecting part 27, a double-pass bushing seat 25, a silicone rubber sleeve 26, a temperature sensor 20, an antenna PCB 21, an antenna PCB line 22, and an antenna metal radiator 23 , central copper column 24, double-pass casing seat 25 and copper cap 29. The temperature sensor 20 and the antenna metal radiator 23 are welded to the corresponding positions of the antenna PCB 21, and then assembled outside the connection part 27. The double-way sleeve 25 is socketed and assembled with the silicone rubber sleeve 26 and connected to the plug 28 through the connection part 27.

[0082] In the above-mentioned embodiment, the central copper column 24, the connection part 27 and the copper cap 29 are connected to each other, and here is the heating core area, and the heat conduction temperature sensor 20 senses the real-time temperature data. After the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com