Online temperature detection method for three-phase box-sharing GIS (Gas Insulated Switchgear) bus joint

A technology of busbar joints and busbars, applied in the field of online temperature detection of three-phase common-box GIS busbar joints, can solve the problems of not being able to determine the number of faulty joints and the location of faulty joints, difficult to capture fault characteristics, and lack of feasibility, etc., to achieve Realize the effect of detection automation, convenient detection automation, high safety and feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] In order to further illustrate the technical means adopted by the present invention and the achieved effects, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and preferred embodiments.

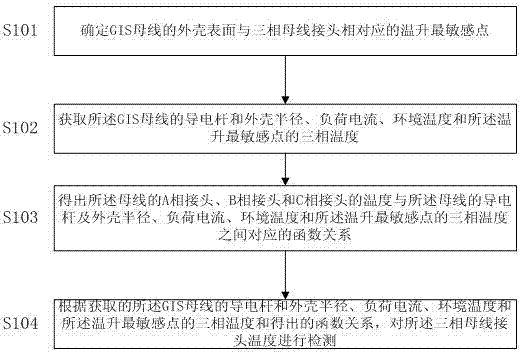

[0023] see figure 1 , is a schematic flow chart of the temperature detection method for the GIS bus joint of the present invention. The temperature detecting method of GIS bus joint of the present invention comprises the following steps:

[0024] S101 Determine the most sensitive point of temperature rise corresponding to the shell surface of the GIS busbar and the three-phase busbar joint;

[0025] As one of the embodiments, the finite element numerical calculation method is used to determine the most sensitive point of temperature rise corresponding to the shell surface of the GIS busbar and the three-phase busbar joint.

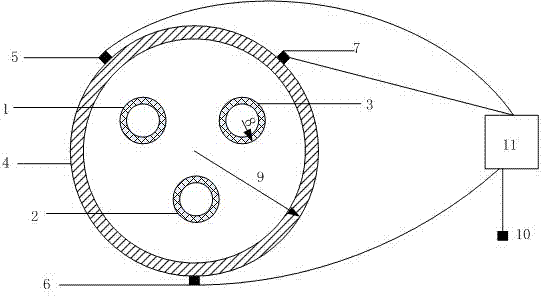

[0026] Since the hottest points reflected on the shell surface by jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com