A temperature detection method for bus joints of gas insulated switchgear

A technology for gas-insulated switches and busbar joints, which is applied in the direction of thermometers, thermometers, thermometer parts, etc. with physical/chemical changes. It is difficult to capture fault characteristics and other problems to achieve the effect of easy detection automation, high safety and feasibility, and automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

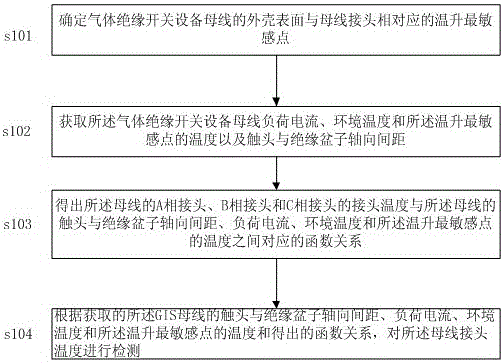

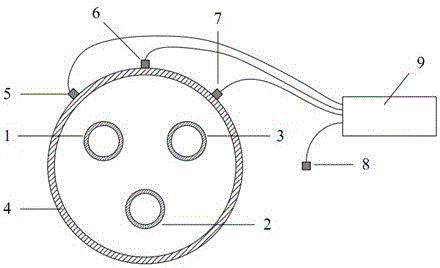

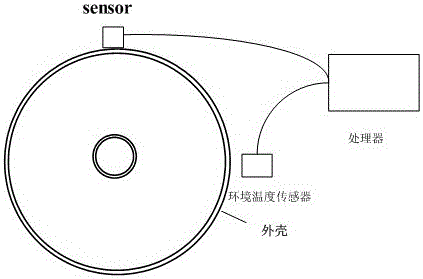

[0023] see figure 1 , is a schematic flow chart of the method for detecting the temperature of the gas-insulated switchgear bus joint of the present invention. The temperature detection method of the gas insulated switchgear bus joint of the present invention comprises the following steps:

[0024] S101 Determine the most sensitive point of temperature rise corresponding to the surface of the busbar of the gas insulated switchgear busbar and the busbar joint;

[0025] As one of the embodiments, the finite element numerical calculation method is used to determine the most sensitive point of temperature rise corresponding to the shell surface of the gas insulated switchgear busbar and the busbar joint.

[0026] Since the hottest points reflected on the surface of the shell by joints at different positions are different, the temperature field distribution of the busbar is calculated by the finite element numerical calculation method, and the most sensitive point of the GIS secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com