A machine vision-based cloth inspection device and method

A machine vision and camera technology, applied in the field of cloth inspection, can solve problems such as loss of real-time production guidance, complex inspection links, and product quality restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The technical solution of the present invention is further described in detail below, but the protection scope of the present invention is not limited to the following description.

[0080] The object of the present invention is achieved through the following technical solutions: a method for inspecting cloth based on machine vision, the steps are as follows:

[0081] S1. Get the fabric image:

[0082] Use an industrial camera to shoot the finished fabric to be inspected after heat setting to obtain a real-time image. The actual range of the camera imaging is a×b mm and a>b;

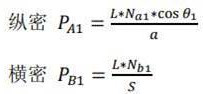

[0083] S2. Use methods 1 and 2 to calculate the longitudinal and transverse densities of fabrics:

[0084] method one:

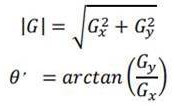

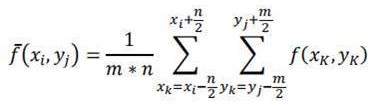

[0085] 1. carry out Fourier transform to described real-time image, obtain Fourier spectrum figure;

[0086] II. the gray value corresponding to each coordinate point in the spectrogram is set to the Z coordinate to obtain a three-dimensional view of the Fourier spectrogram; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com