Cable intermediate joint temperature rise on-line monitoring device and method based on temperature difference method

A technology for cable intermediate joints and monitoring devices, which is applied to measuring devices, electrical devices, and thermometer parts, etc. It can solve problems such as poor real-time performance, difficulty in timely discovery of equipment safety hazards, waste of monitoring reliability, etc., to ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

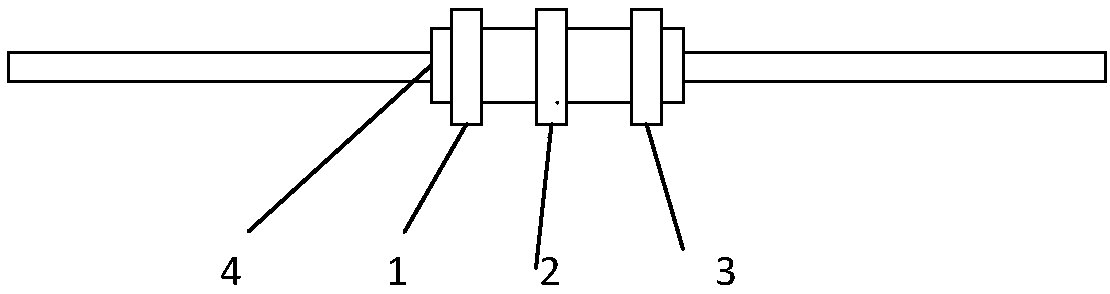

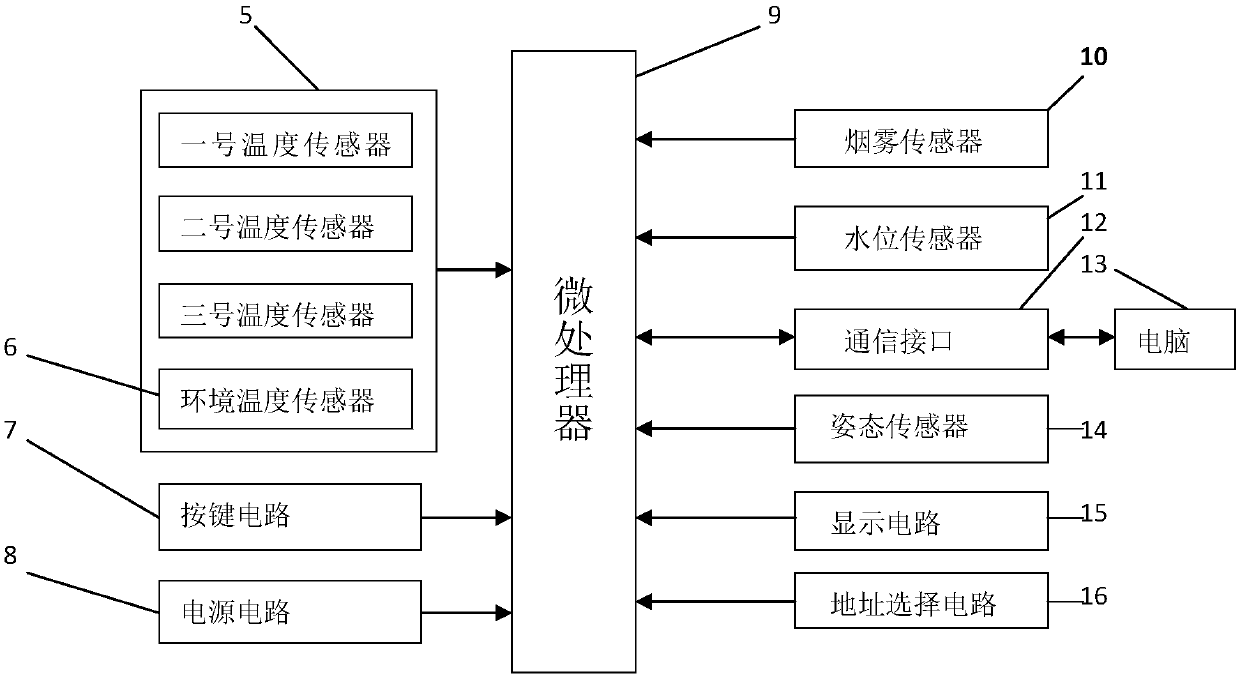

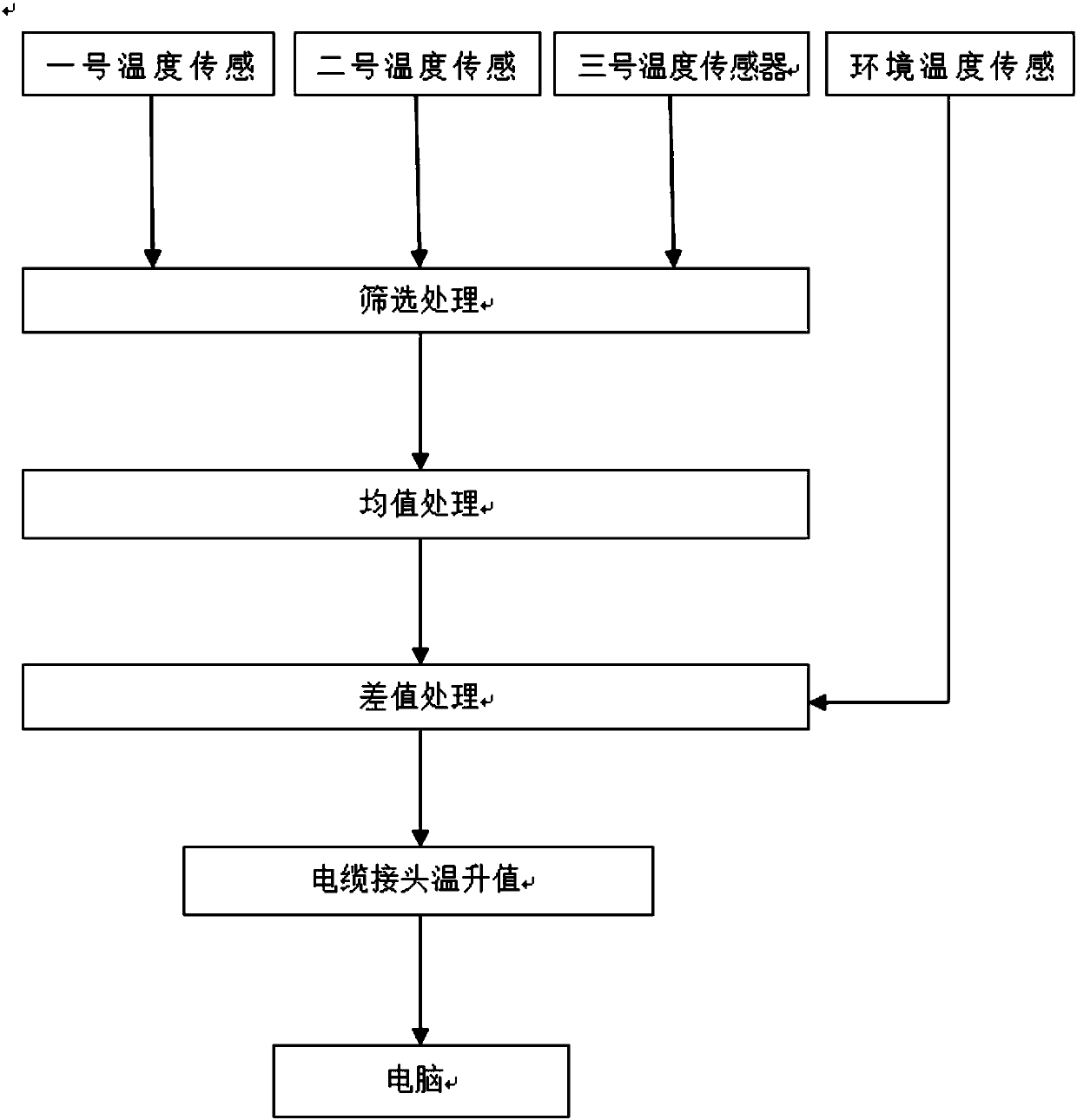

[0040] This embodiment is an online monitoring device for the temperature rise of the cable intermediate joint 4 based on the temperature difference method, such as figure 2As shown, the structure diagram of the centralized measurement module of the system device of the present invention includes a temperature sensing module, a button circuit 7, a microprocessor circuit 9, a power circuit 8, a smoke sensor 10, a water level sensor 11, an attitude sensor 14, a communication interface 12, a display Circuit 15, address selection circuit 16, computer 13; wherein the temperature sensing module includes temperature sensor 1 at point one, temperature sensor 2 at point two, temperature sensor 3 at point three, ambient temperature sensor 6, temperature sensor at point one, temperature sensor two The output ends of the No. 1 point temperature sensor, the No. 3 point temperature sensor, and the ambient temperature sensor are respectively connected with the I / O port of the microprocessor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com