Patents

Literature

78results about How to "Accurate temperature value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

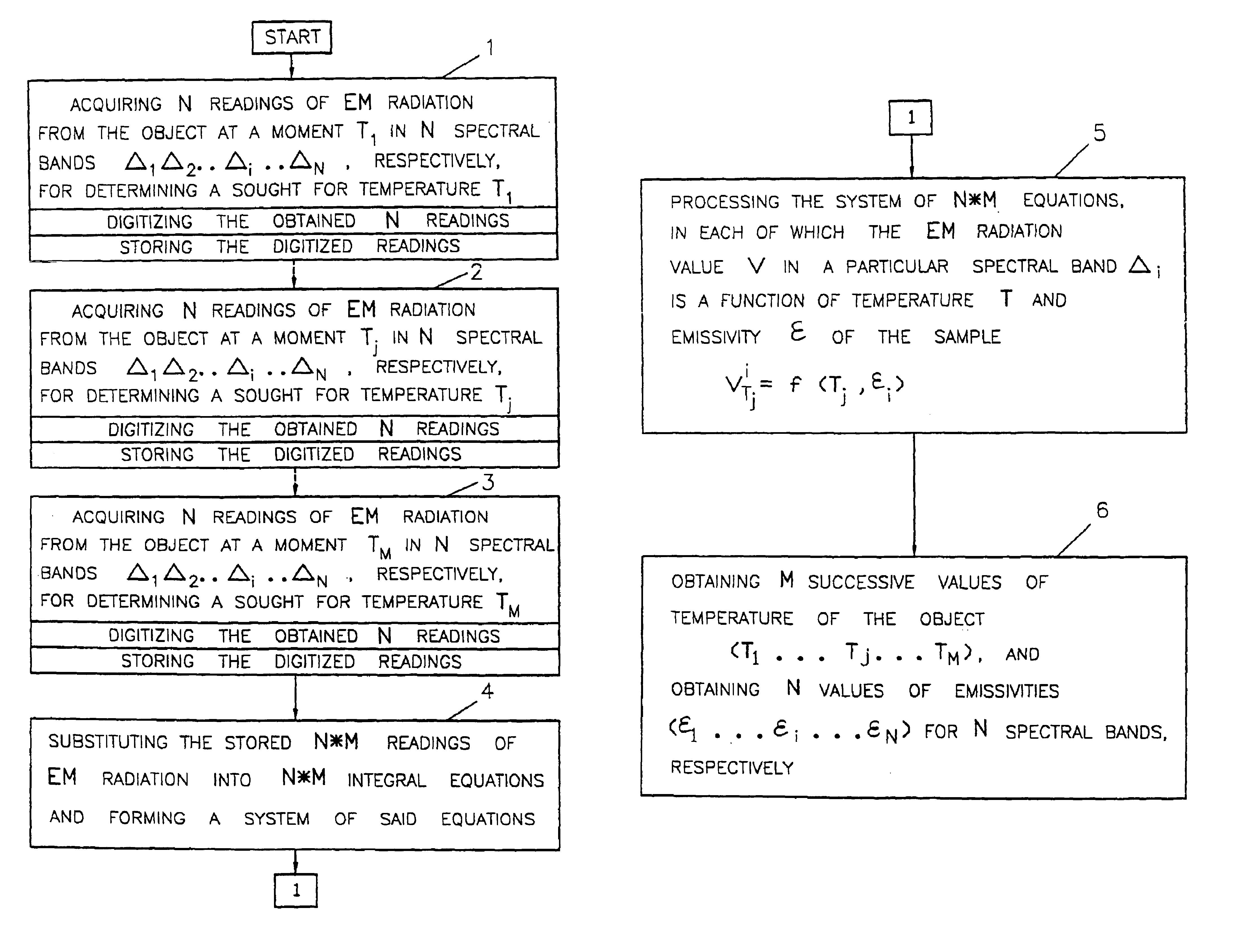

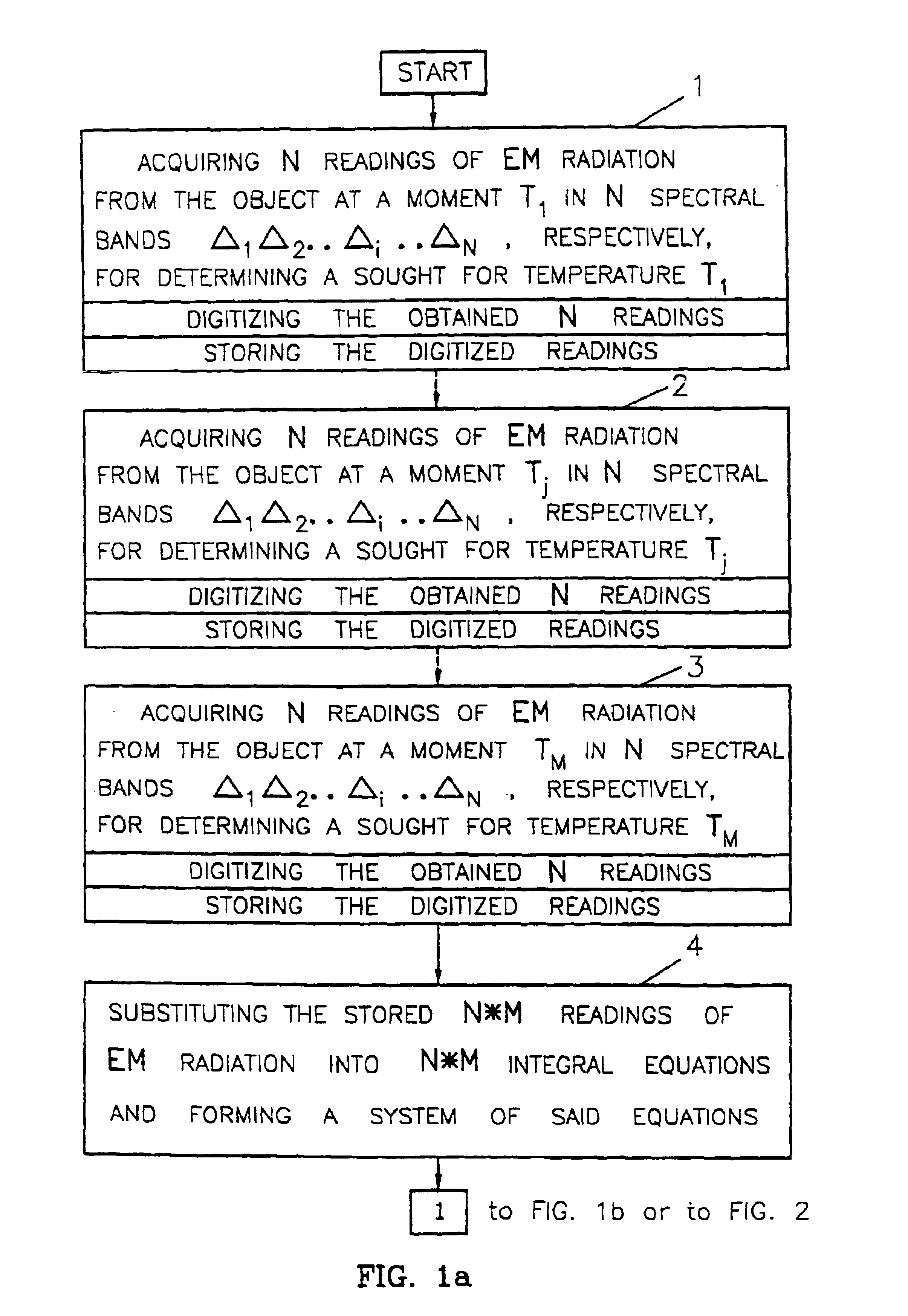

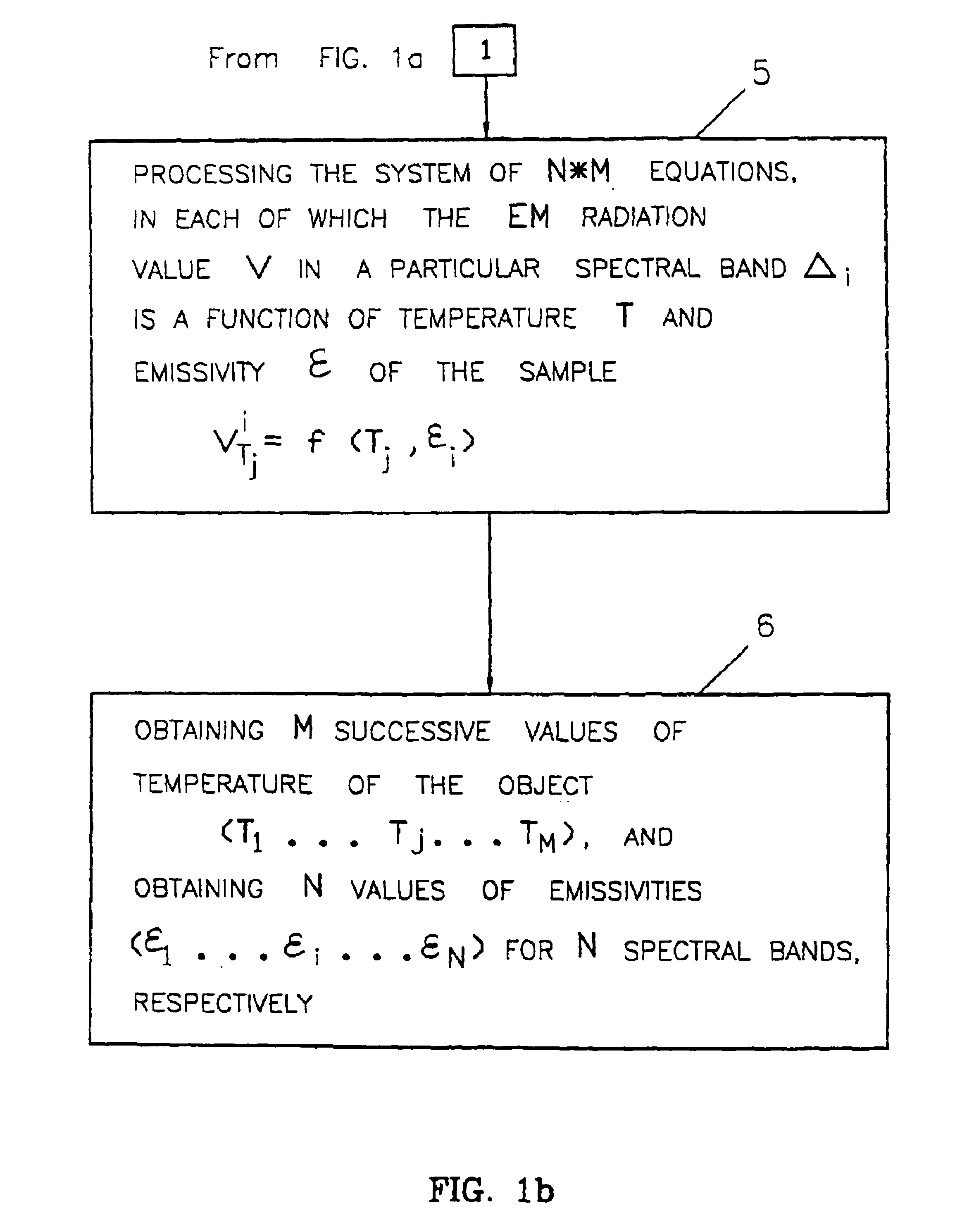

Detection and recognition of objects by multispectral sensing

InactiveUS6837617B1Accurate temperature valueIncrease temperature differenceRadiation pyrometryPhotometryEmissivitySpectral bands

A method and a system for determining temperature and / or emissivity of an object by remote sensing are described. Based on the concept of temperature and emissivity determination, there are also developed a method and a system for the detection and recognition of an object that includes a plurality of sub-objects. The method for the detection and recognition of an object comprises acquiring, inter alia, electromagnetic radiation data of electromagnetic radiation emitted from a selected region in at least two spectral bands, recording and storing the required electromagnetic radiation data, deriving descriptive maps constituted by pixels of the selected region from the stored data and classifying the pixels of said descriptive maps of said selected region by pattern recognition processor means.

Owner:ISRAEL AEROSPACE IND

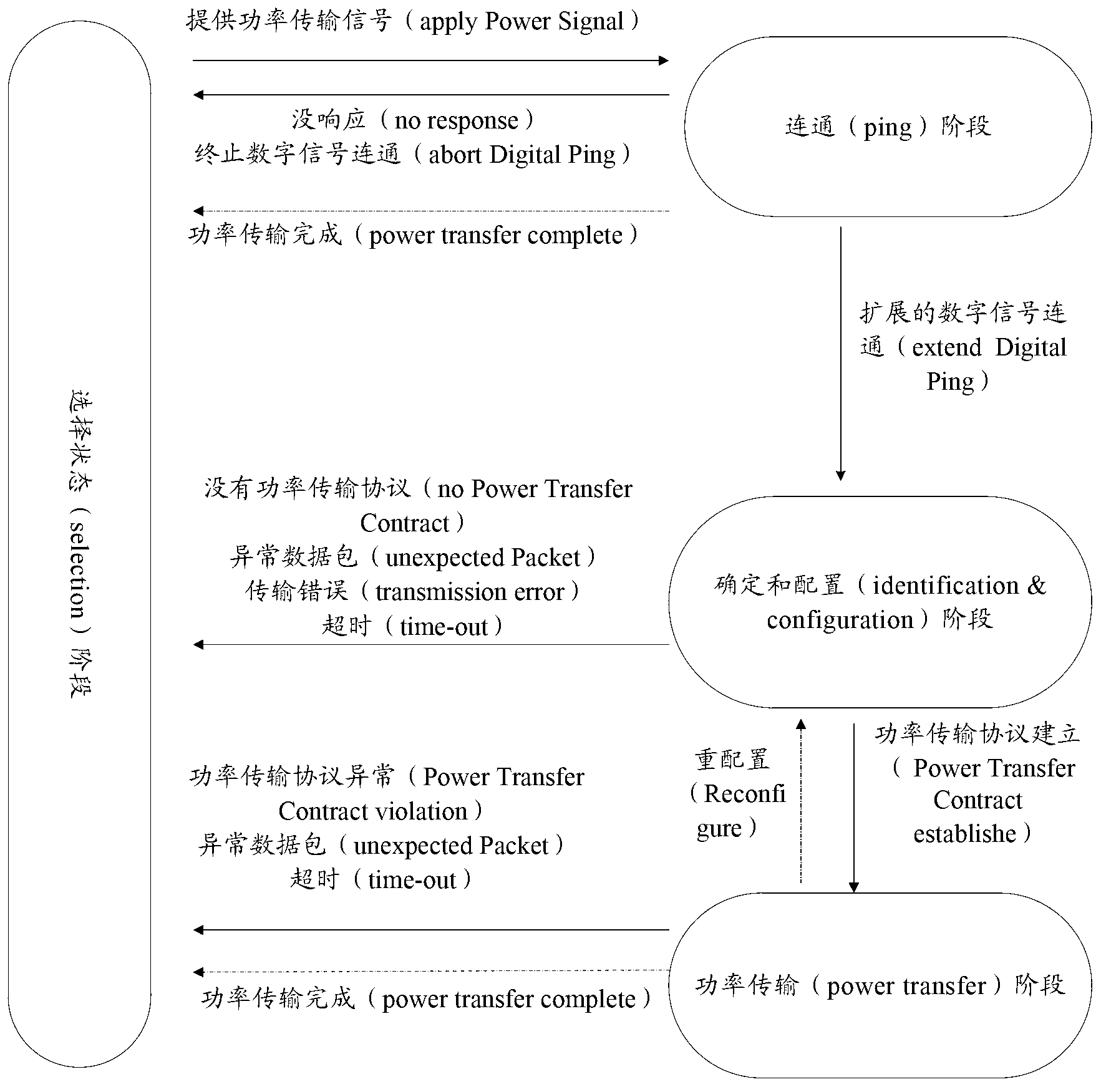

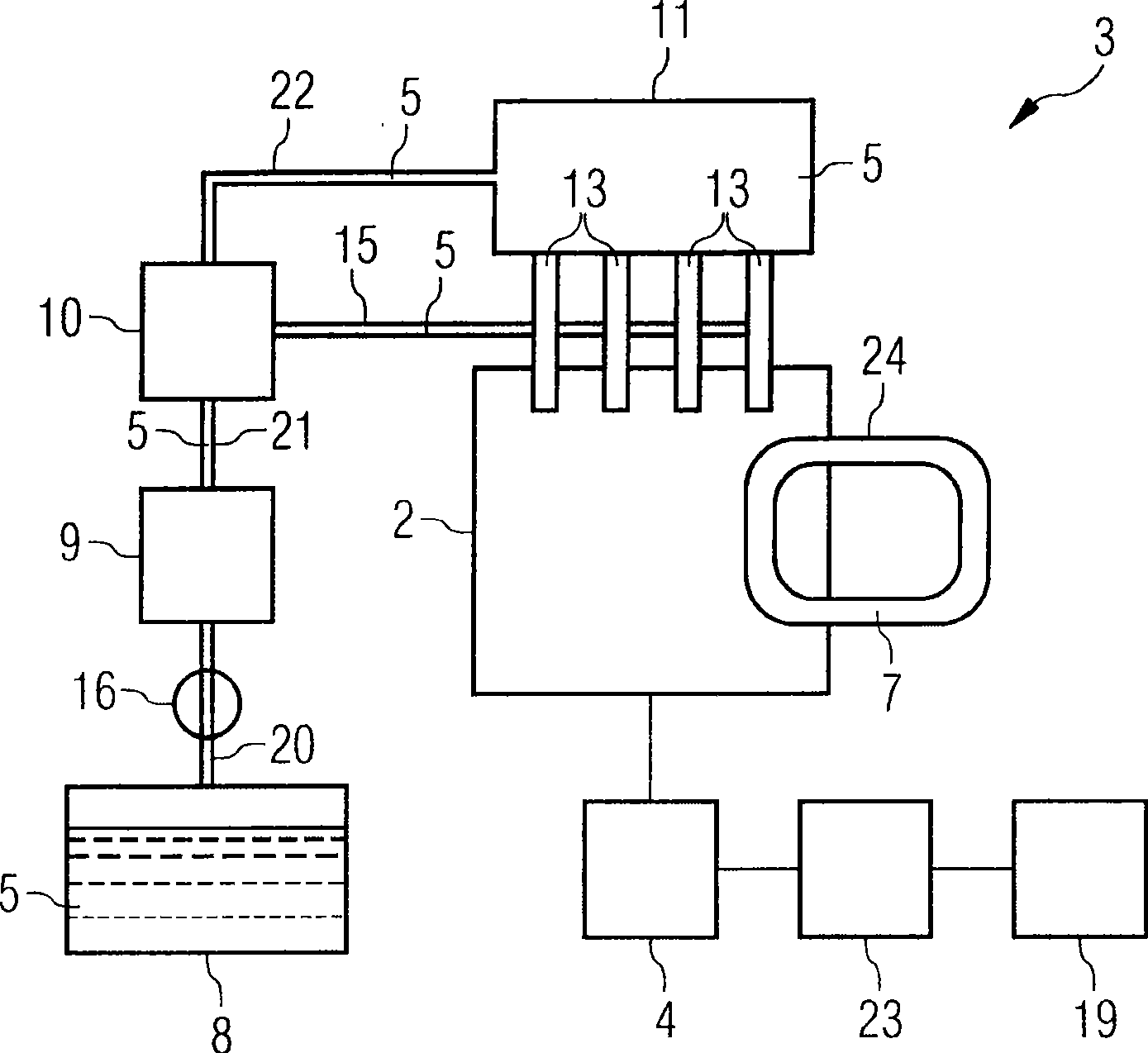

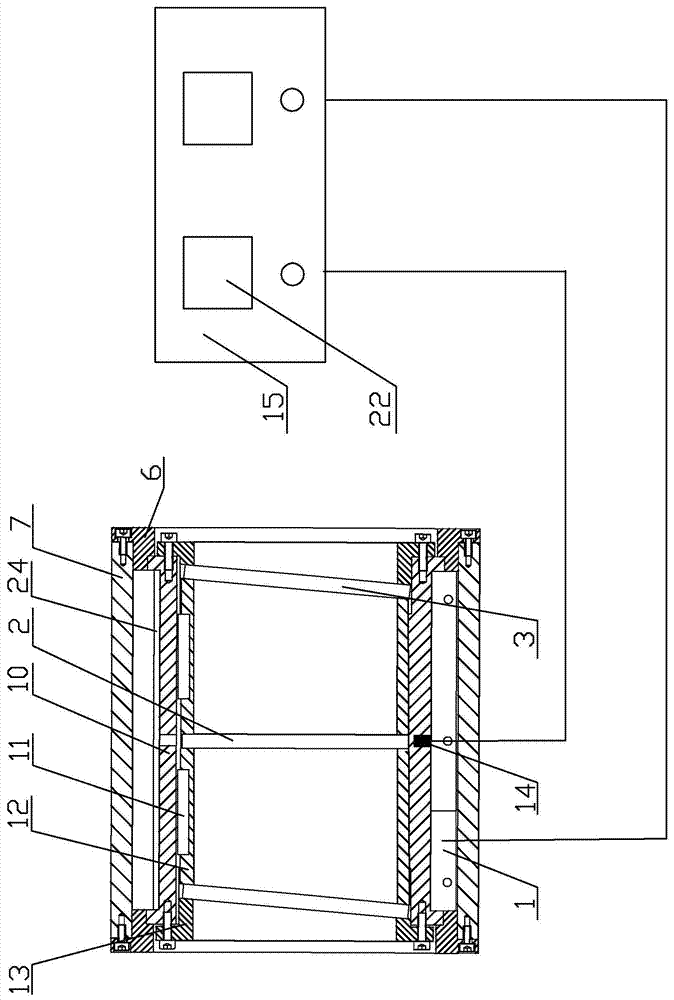

Method for charging by utilizing wireless charger and wireless charger

ActiveCN103269092AReliable chargingCharging safetyBatteries circuit arrangementsElectromagnetic wave systemEngineeringBattery charger

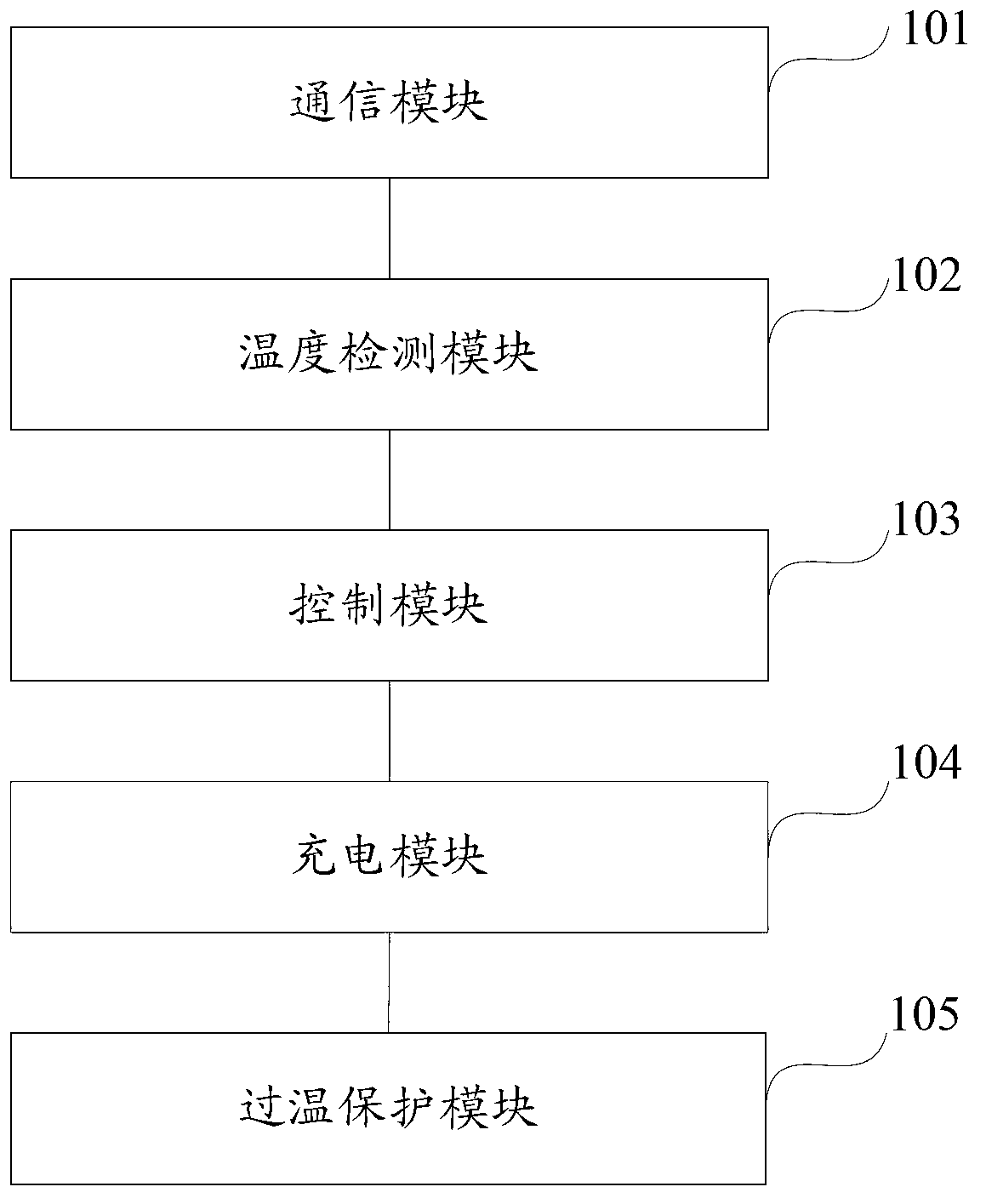

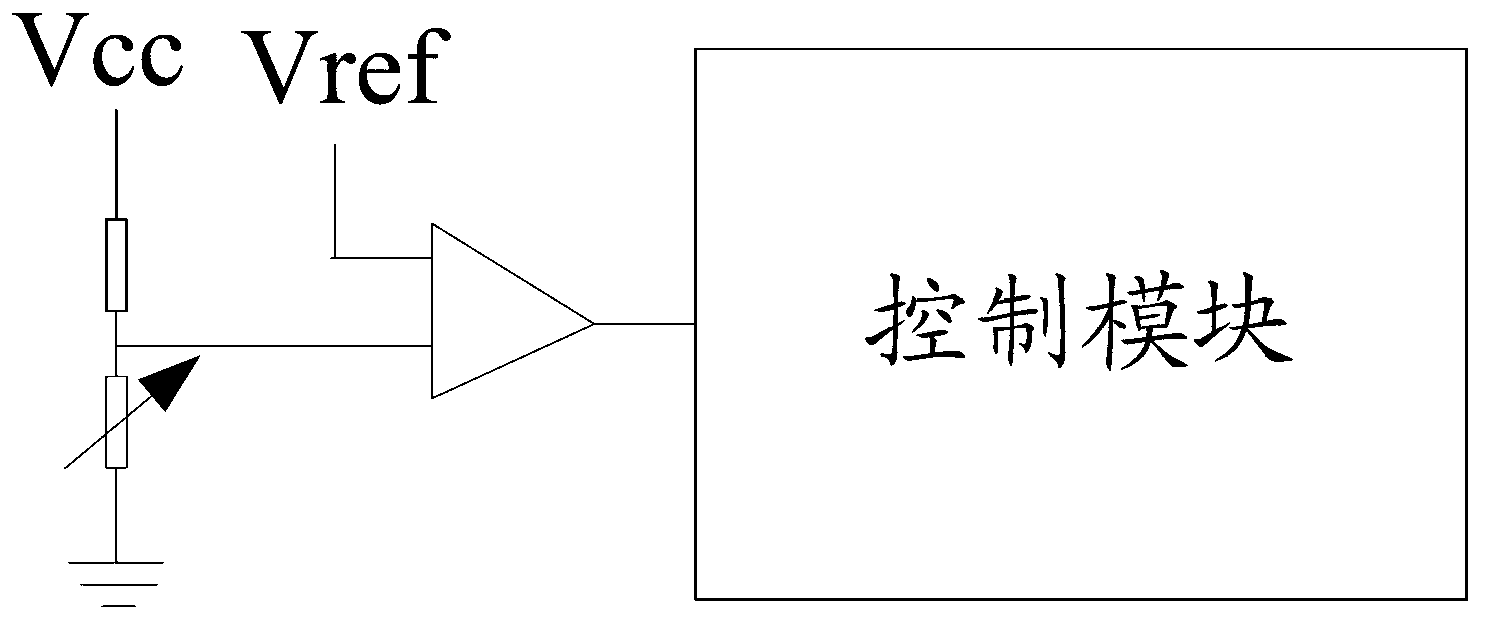

The embodiment of the invention provides a method for charging by utilizing a wireless charger and the wireless charger, wherein the wireless charger comprises a transmitting end and a receiving end; the transmitting end comprises a communication module, a temperature detection module, a control module, a charging module and over-temperature protection module; the communication module is used for judging whether the transmitting end communicates with the receiving end or not; the temperature detection module is used for detecting the temperature of the transmitting end after the transmitting end is communicated with the receiving end; the control module is used for judging whether the temperature of the transmitting end is higher than a preset threshold or not; the charging module is used for charging the receiving end when the temperature of the transmitting end is lower than or equal to the preset threshold; and the over-temperature protection module is used for stopping charging the receiving end when the temperature of the transmitting end is higher than the preset threshold. The embodiment of the method and the wireless charger can detect the surface temperature of the transmitting end, so that the wireless charging is enabled to be more reliable and safer.

Owner:XIAOMI INC

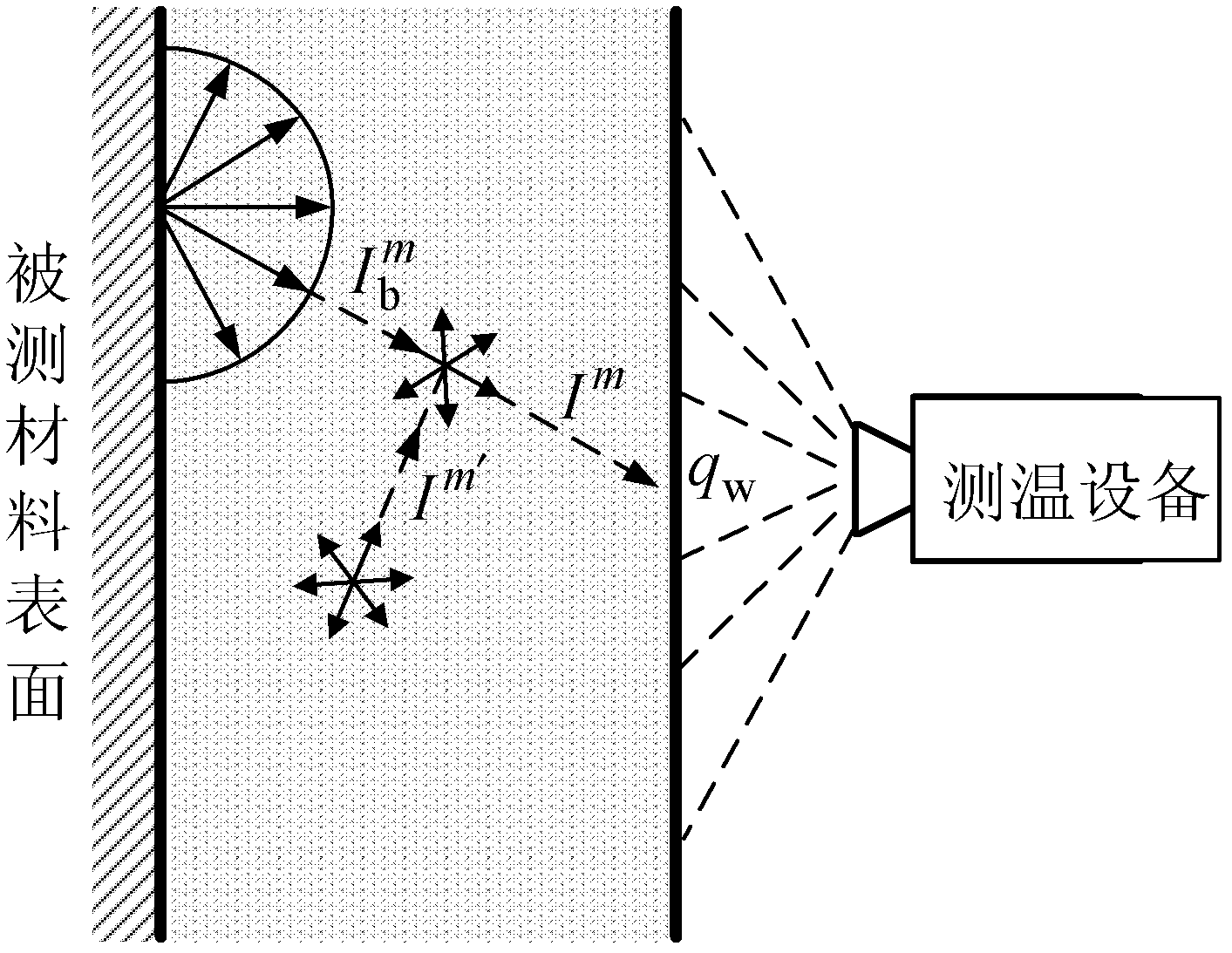

Method of correction for non-contact thermometry in translucent medium environment

ActiveCN102353478AAchieve correctionAccurate temperature valueThermometer testing/calibrationEmissivityExchange model

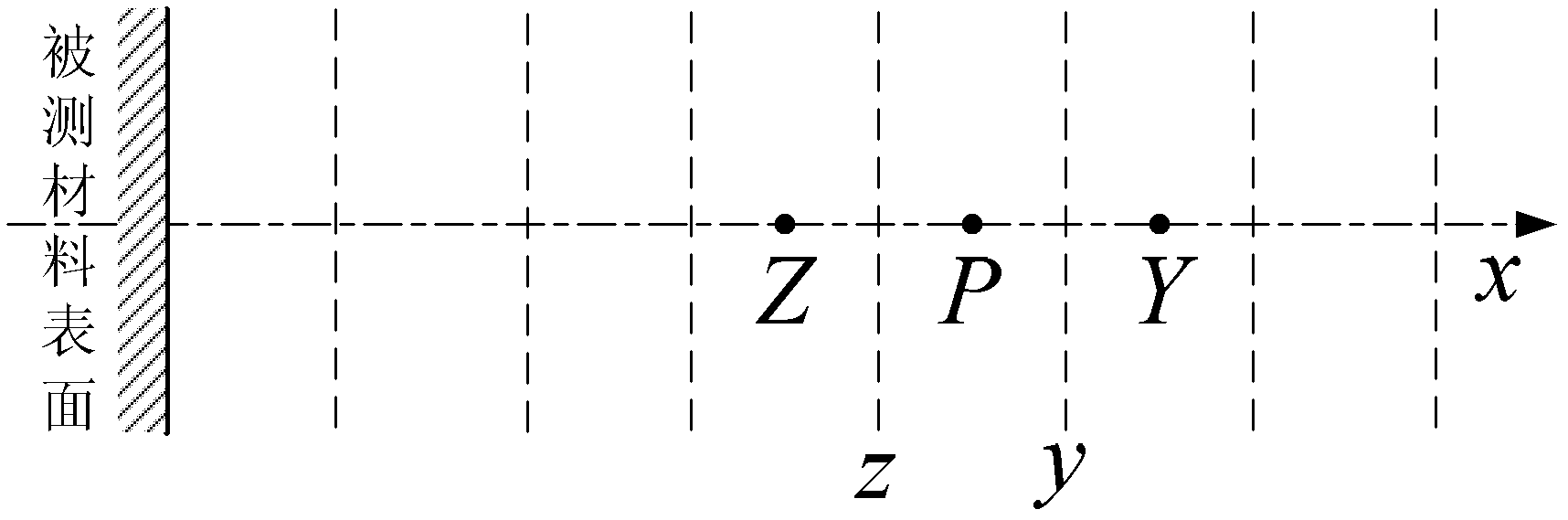

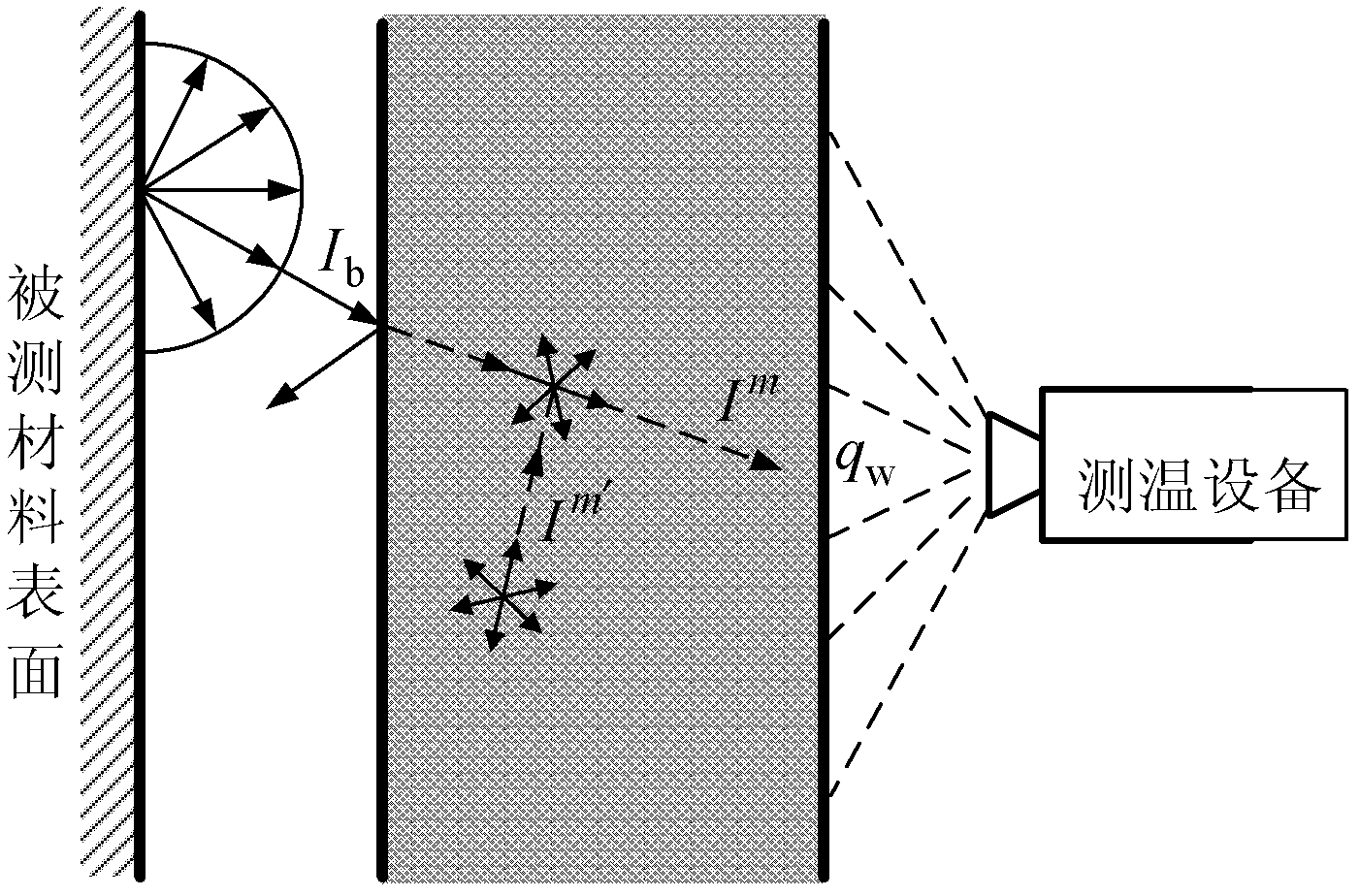

The invention relates to a method of correction for non-contact thermometry in a translucent medium environment, which belongs to the technical field of pyrometry. The problem that when the surface of an object to be measured is in a translucent medium coverage environment, radiation energy detected through a traditional method can not be corrected through a traditional material surface emissivity correction method, so that the actual temperature can not be obtained is solved. The method comprises the following steps of: firstly, judging whether a translucent medium is contacted with the surface of the object to be measured, if so, selecting a one-dimensional coupling heat exchange model, adopting a finite volume method to calculate a forward model, and obtaining a theoretical radiation energy value capable of being obtained by temperature measuring equipment; if not, selecting a one-dimensional pure radiation heat exchange model, adopting the finite volume method to calculate the forward model, and obtaining the theoretical radiation energy value capable of being obtained by the temperature measuring equipment; then measuring an actual radiation energy value of the surface of theobject to be measured; and adopting an intelligent particle swarm optimization algorithm to inverse an actual temperature value of the surface of the object to be measured. The method provided by theinvention is applied to temperature measurement of the surface of the object to be measured in the translucent medium environment.

Owner:HARBIN INST OF TECH

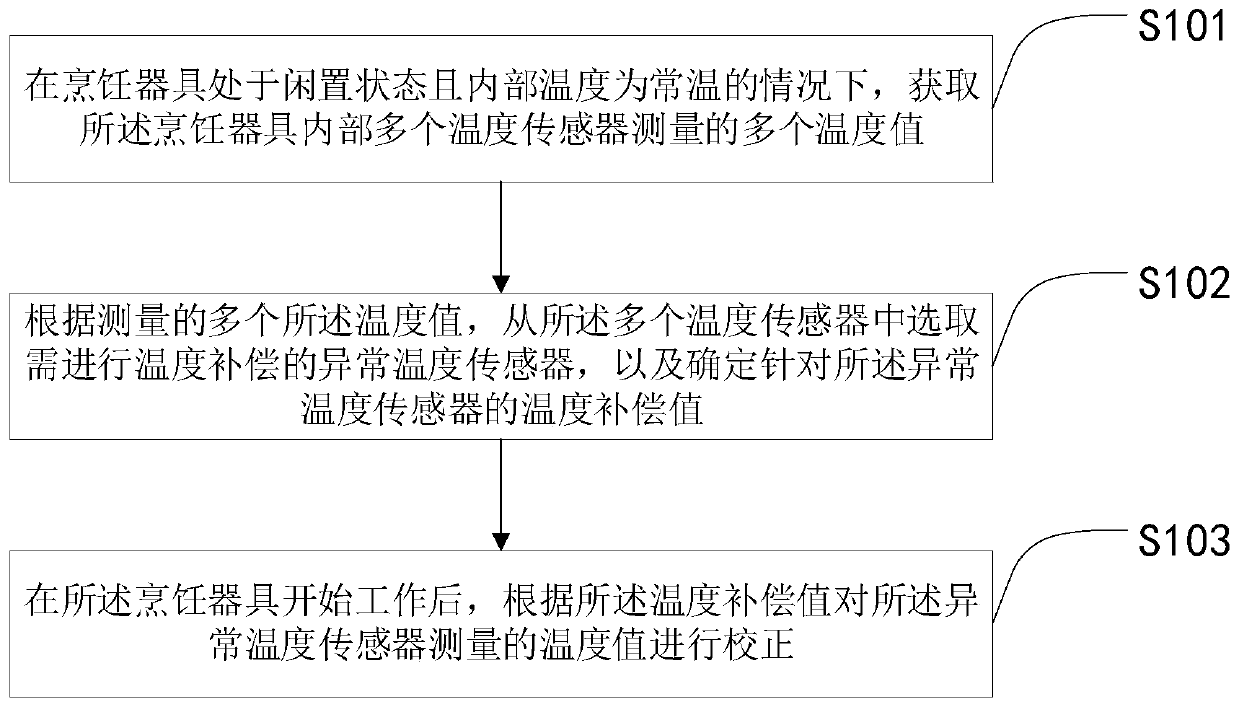

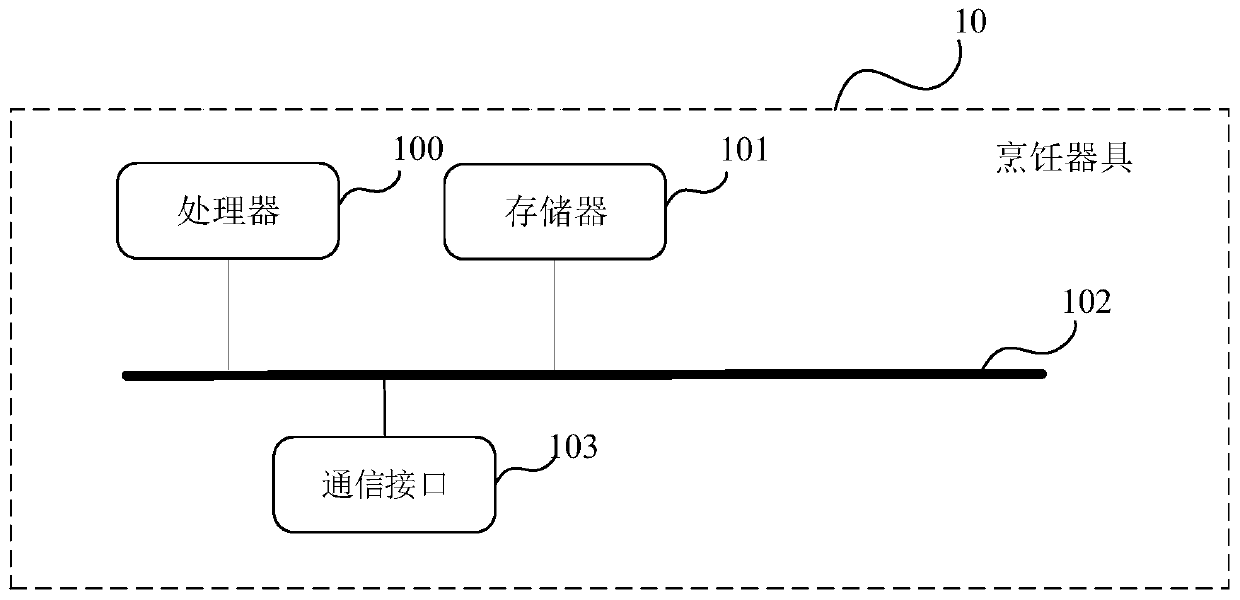

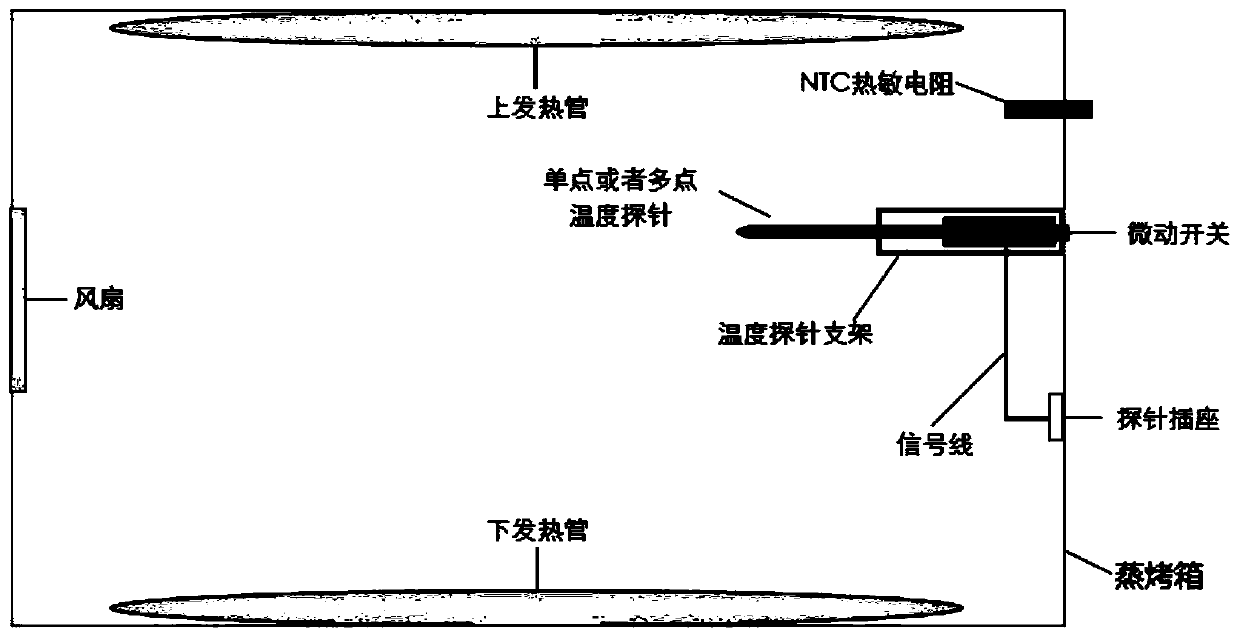

Temperature correction method, cooking utensil and medium

PendingCN110579294AAccurate temperature valueAccurate temperature controlThermometer testing/calibrationTemperature controlRoom temperature

The invention provides a temperature correction method, a cooking utensil and a computer readable medium. The method comprises the following steps: when a cooking utensil is in an idle state and the internal temperature is normal temperature, acquiring a plurality of temperature values measured by a plurality of temperature sensors in the cooking utensil; according to the plurality of measured temperature values, selecting an abnormal temperature sensor needing temperature compensation from the plurality of temperature sensors, and determining a temperature compensation value for the abnormaltemperature sensor; and after the cooking utensil starts to work, correcting the temperature value measured by the abnormal temperature sensor according to the temperature compensation value. An accurate temperature value can be obtained through correction, and accurate temperature control can be achieved. The quality of cooking on the basis can be ensured, fire disasters caused by too high temperature in the cavity of the cooking utensil can be avoided, and potential safety hazards can be eliminated.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

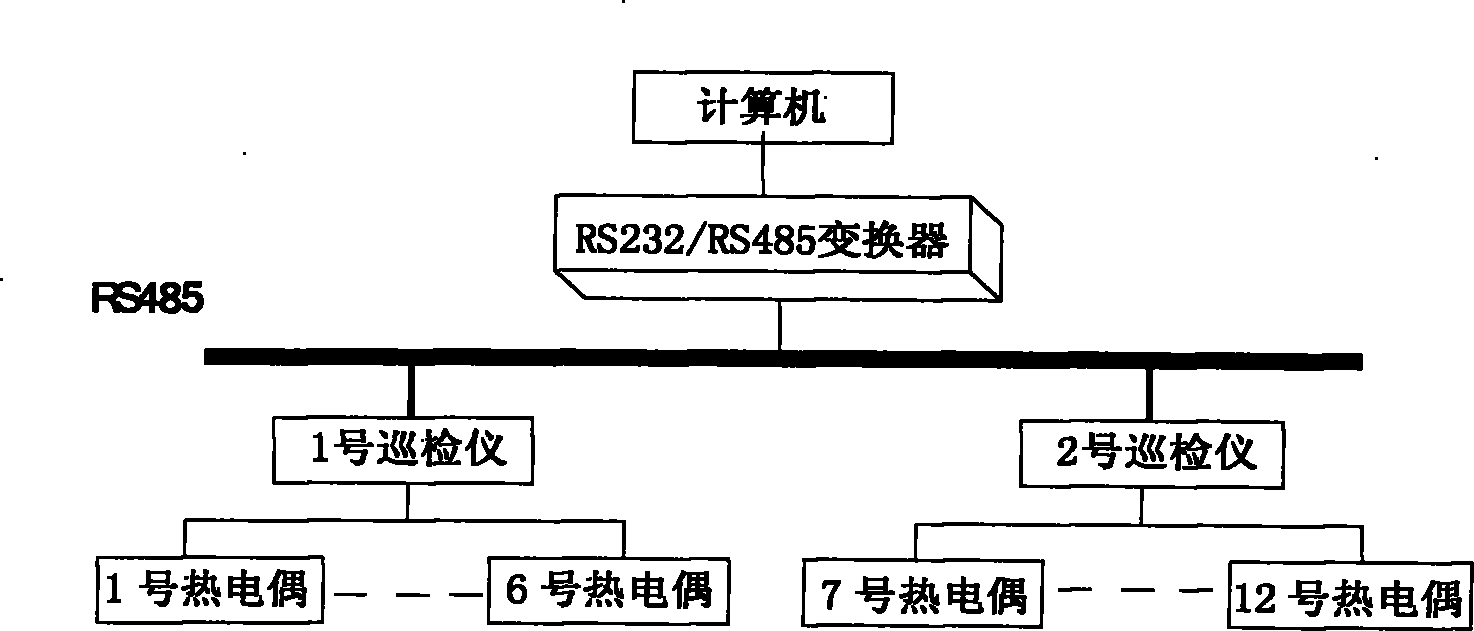

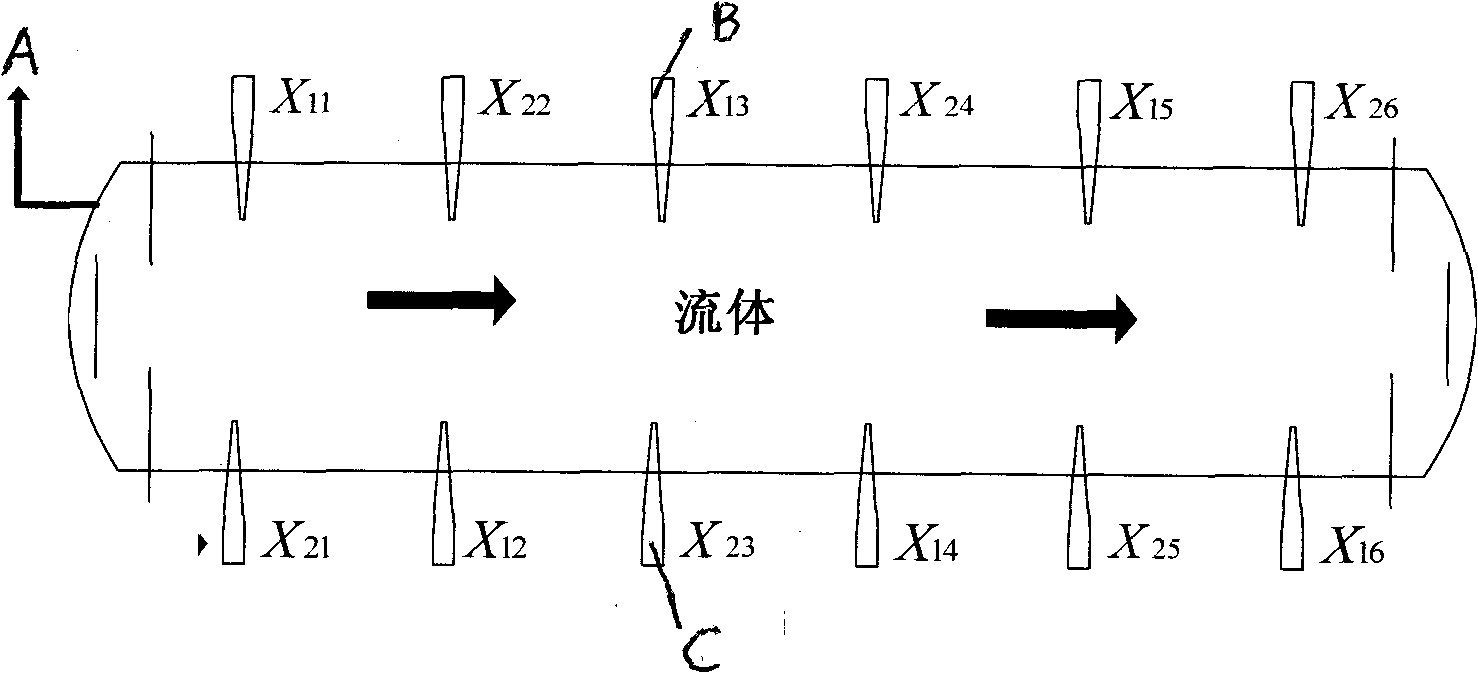

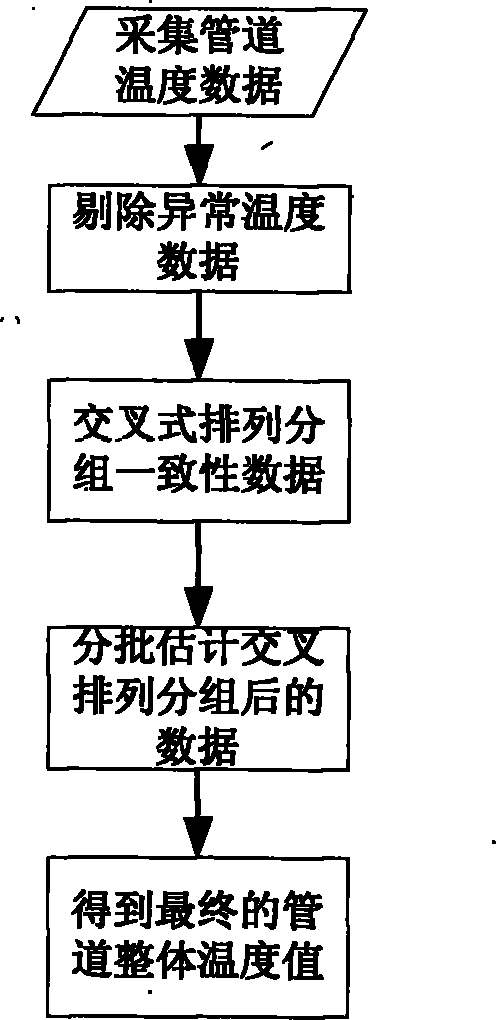

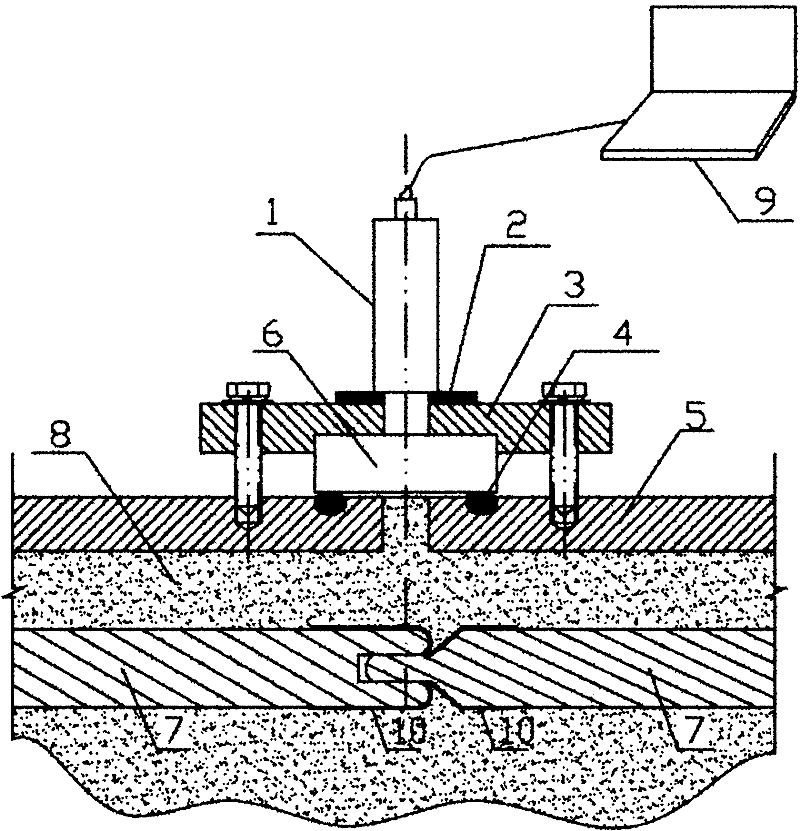

Pipeline temperature detection and abnormal temperature data reject method and system

InactiveCN101776212AAccurate temperature valueSensitive detectionPipeline systemsEstimation methodsData transmission

The invention relates to a pipeline temperature detection and abnormal temperature data reject method and a system. The method comprises the following steps: (1) a thermoelectric couple is used for collecting the internal temperature of a pipeline, the temperature data is transmitted to a computer, Grubbs program programmed inside the computer is used for processing the temperature data so as to judge whether the temperature data has abnormal data, and the abnormal data is rejected; (2) a staggered-form arranging grouping and batching estimation program inside the computer is used for processing the consistent temperature data which is obtained after the error is rejected, the consistent temperature data is divided into two groups according to the installation position of sensors (staggered-form arranging and grouping), the batching estimation method is adopted for the average value of the two groups of data so as to estimate a fusion value which is close to the real value of the integral temperature of the pipeline. The detection method and the system are simple and easy, can flexibly, rapidly, reliably and instantly detect the situation of the integral temperature inside the pipeline, and provide a reliable and practical detection solution to the pipelines of different types. The detection method and the system are mainly used for the real-time monitoring and process and safety control technology of the interior of the pipeline.

Owner:KUNMING UNIV OF SCI & TECH

Anti-interference infrared temperature measurement method and apparatus thereof

InactiveCN102207406AEasy to install and debugImprove interferenceRadiation pyrometryElectrical testingElectromagnetic interferenceChalcogenide glass

The invention, which can be used for various voltage grade GIS equipment to on-line monitor internal buses and joints so as to provide a monitoring means for safe operation of the GIS equipment, relates to an anti-interference infrared temperature measurement method and an apparatus thereof. The apparatus comprises an infrared temperature sensor and GIS equipment which is full of SF6 seal gas under a pressure of about 0.4MPa. The invention is characterized in that: a seal tank shell of the GIS equipment has a window which is provided with chalcogenide glass; positions of the measured buses and joints are coated with paints which can increase infrared emissing ability; the infrared temperature sensor, which is installed out of the seal tank, on-line collects temperature signals of the measured buses and joints through the chalcogenide glass window of the seal tank; accurate temperature values of the measured buses and joints can be acquired through corrections made by software. An anti-electromagnetic interference effect is good.

Owner:STATE GRID ELECTRIC POWER RES INST

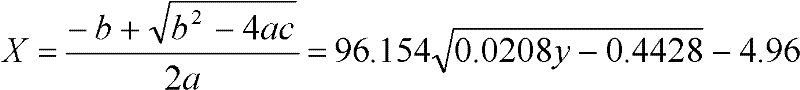

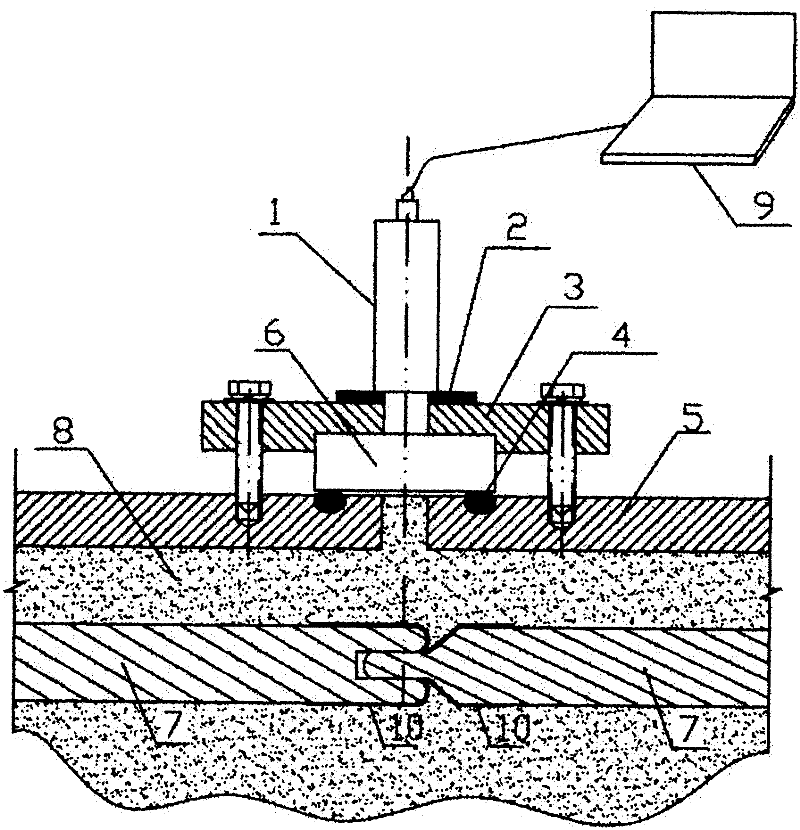

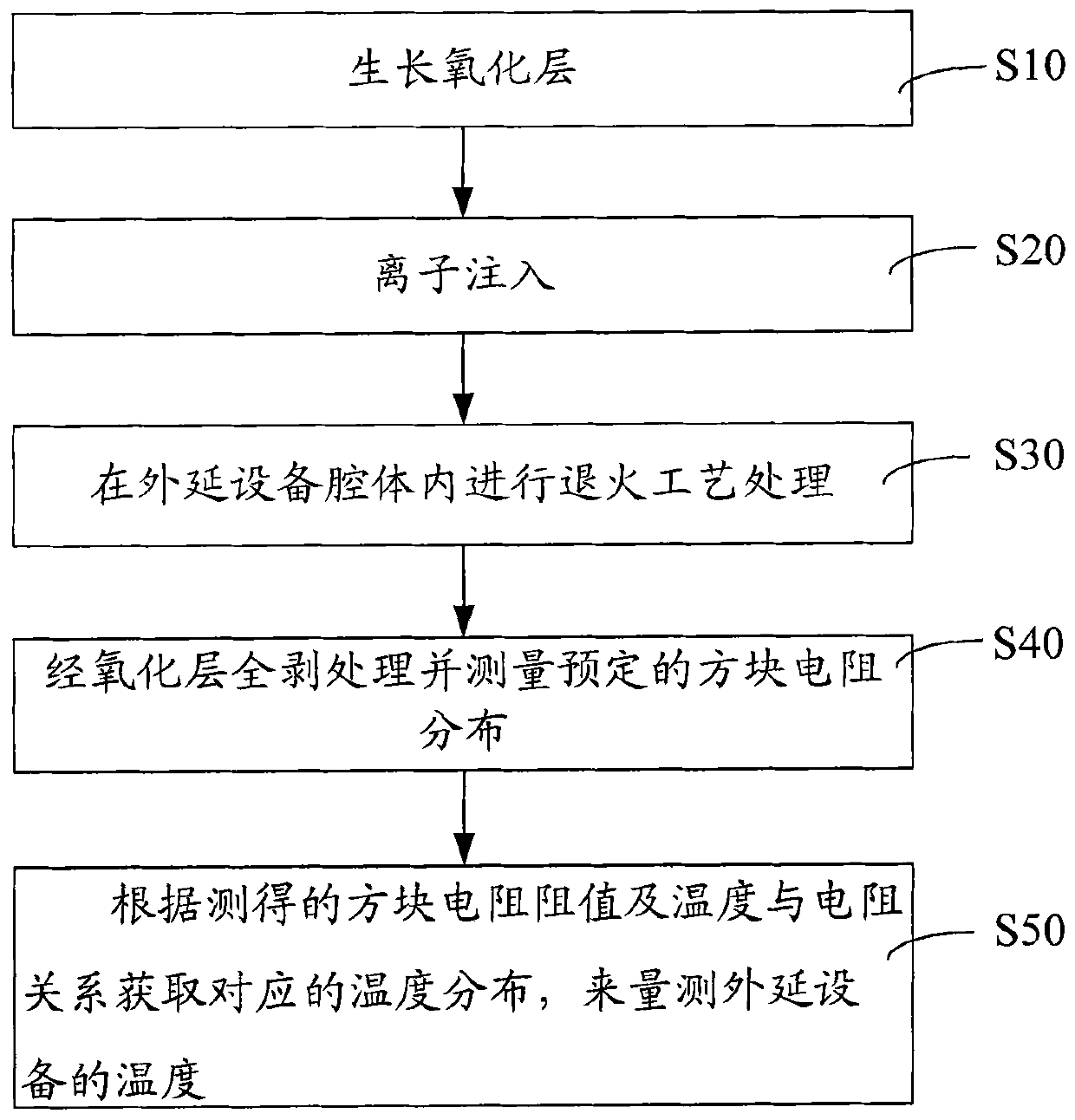

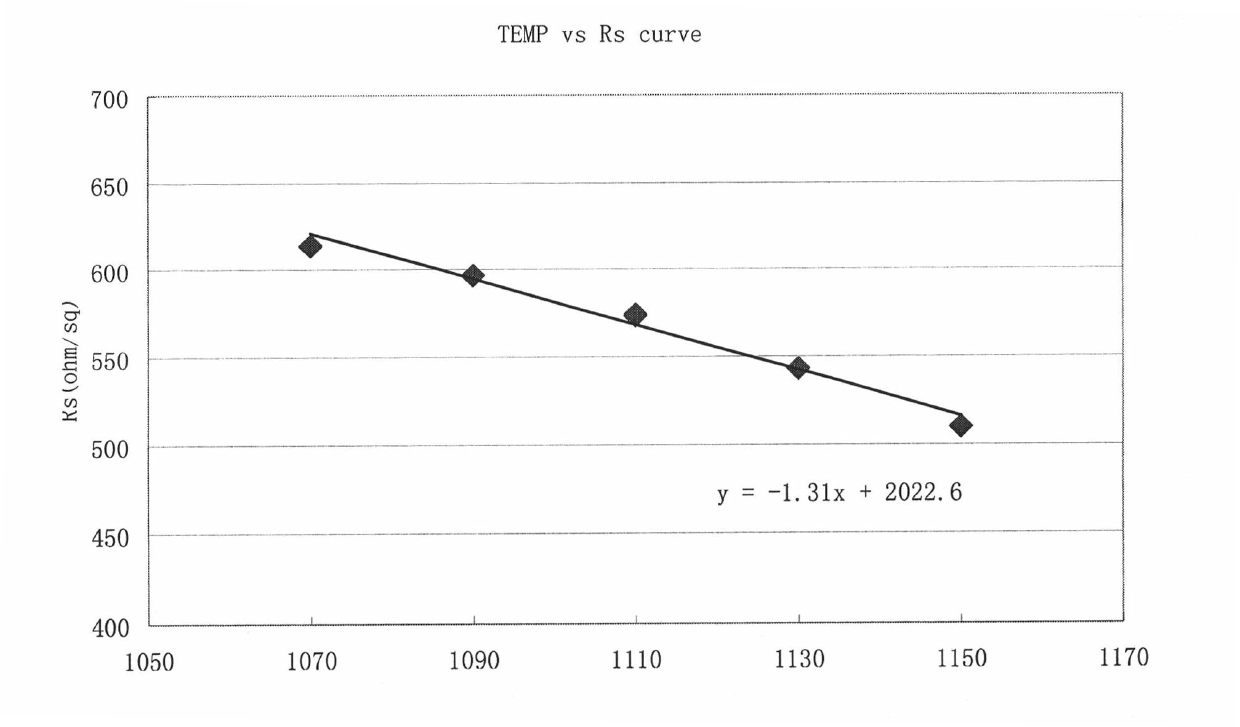

Method for measuring temperature of cavity of epitaxial equipment

InactiveCN102087953AAccurate resistanceAccurate temperature valueSemiconductor/solid-state device testing/measurementThermometers using electric/magnetic elementsPhysicsEngineering

The invention relates to a method for measuring temperature of a cavity of epitaxial equipment. The method comprises the following steps of: growing an oxide layer; performing ion implantation; performing an annealing process in the cavity of the epitaxial equipment; completely stripping off the oxide layer and measuring predetermined square resistance distribution; and acquiring corresponding temperature distribution according to a measured square resistance value and temperature-resistance relationship so as to measure the temperature of the epitaxial equipment. In the method for measuring the temperature of the cavity of the epitaxial equipment, the ion implantation is adopted and the annealing is performed in the cavity of the epitaxial equipment, so that the predetermined square resistance distribution is measured, then the corresponding temperature distribution is acquired, and overall temperature distribution of each region in the cavity of the epitaxial equipment is acquired to completely monitor the temperature of the cavity of the epitaxial equipment.

Owner:CSMC TECH FAB1 +1

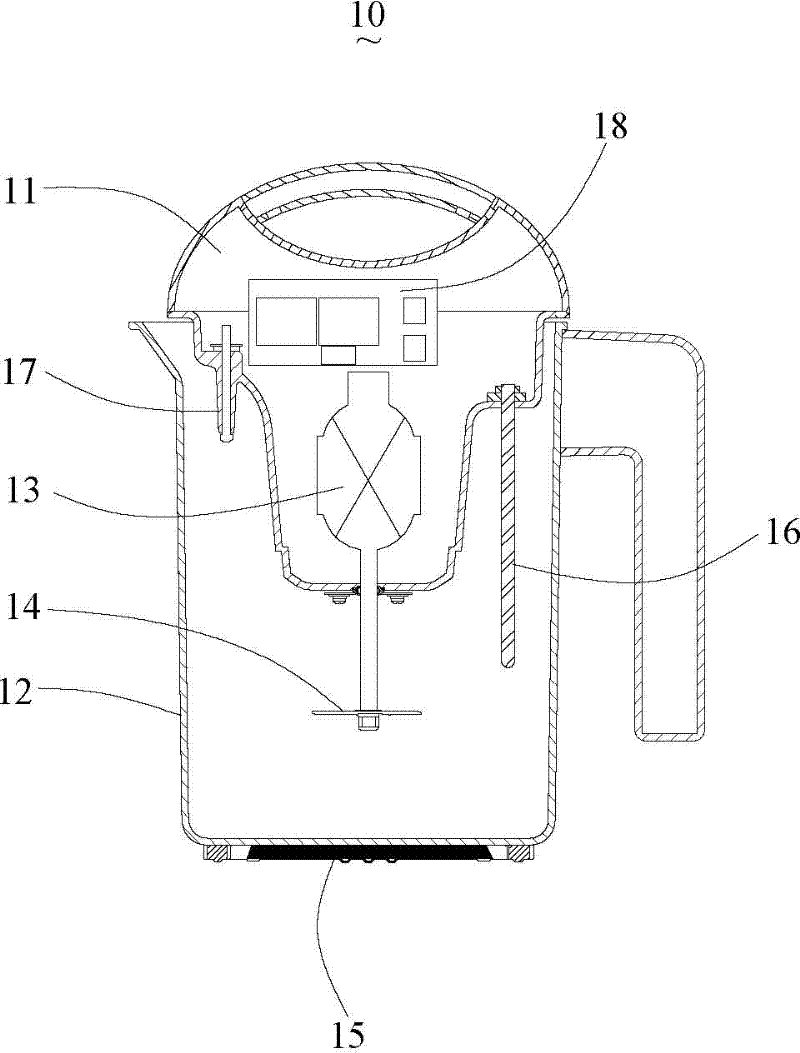

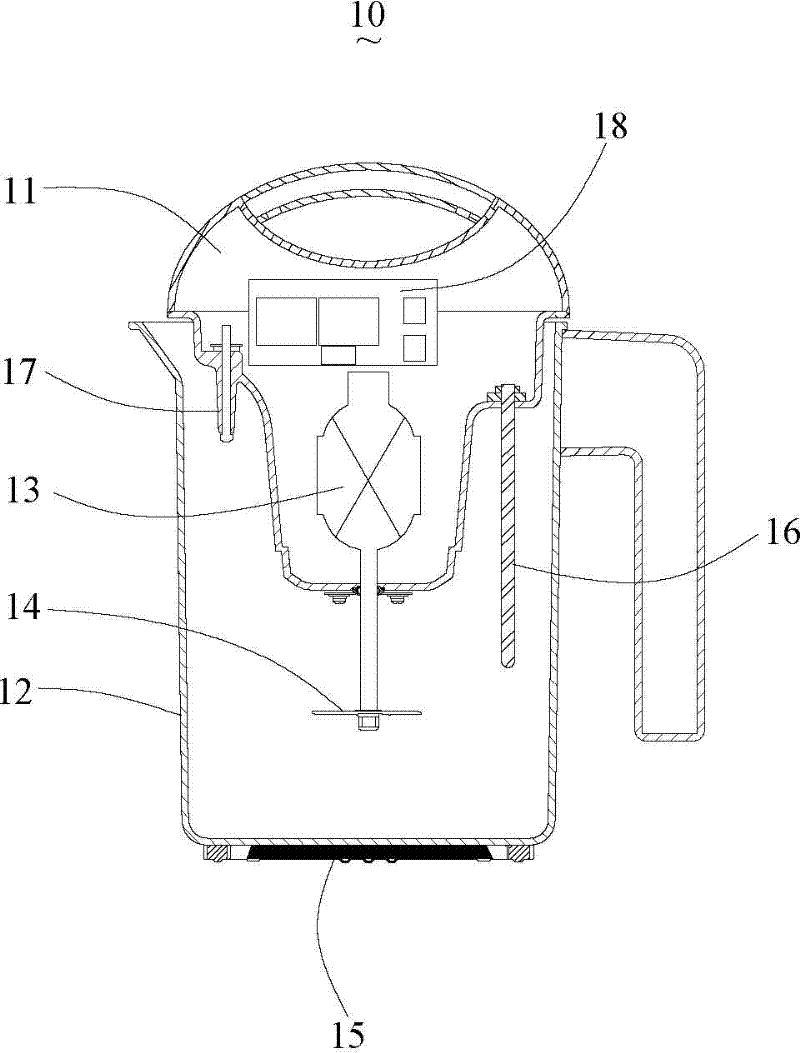

Altitude adaptive soya-bean milk manufacture method and soya-bean milk machine thereof

The invention relates to an altitude adaptive soya-bean milk manufacture method and a soya-bean milk machine thereof. In a heating stage, the altitude adaptive soya-bean milk manufacture method comprises an altitude judgment step of providing an overflow-proof electrode, a temperature sensor and a control device with at least two soya-bean milk manufacturing procedures, wherein the overflow-proofelectrode and the temperature sensor are electrically connected with the control device; the temperature sensor detects the practical temperature value of preheated water and soya-bean contained materials till foams touch the overflow-proof electrode; the control device is preset with a temperature set value; and according to a comparison result between the practical temperature value and the preset temperature value, the soya-bean milk manufacturing procedure is selected. Compared with the prior art, the boundedness for people to use the soya-bean milk machine in the highland is solved, and people in the highland can drink the soya-bean milk with higher quality.

Owner:JOYOUNG CO LTD

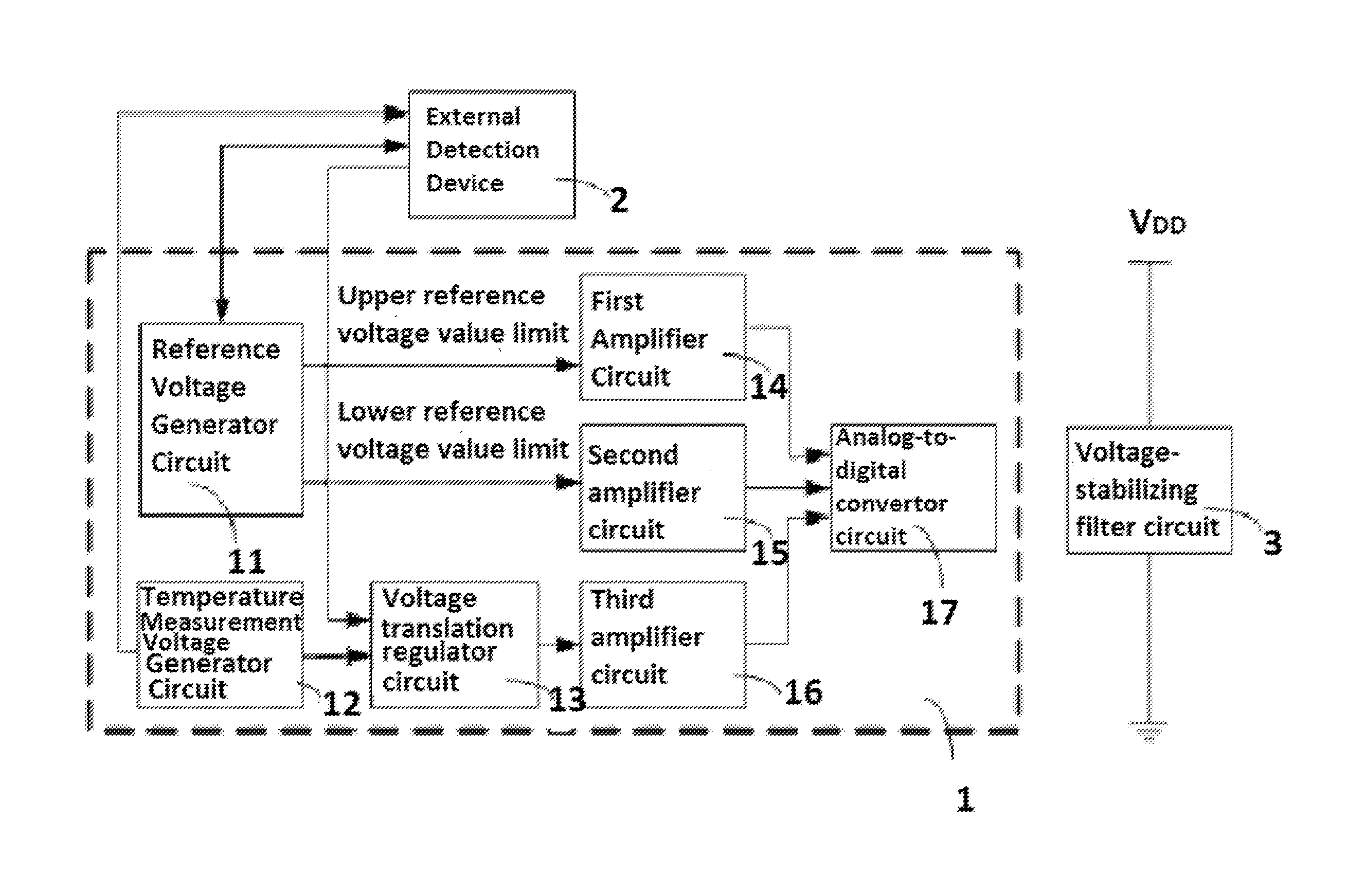

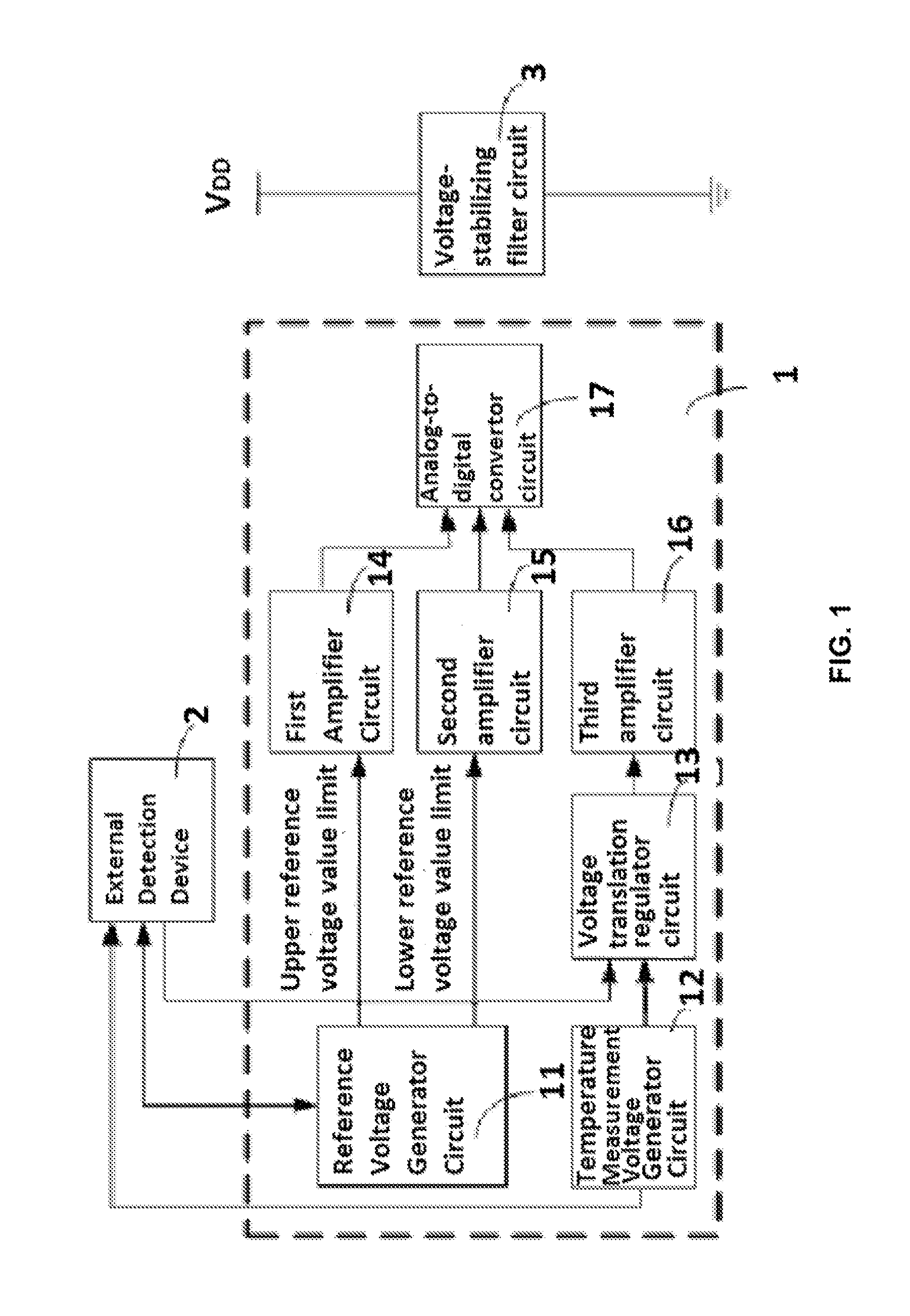

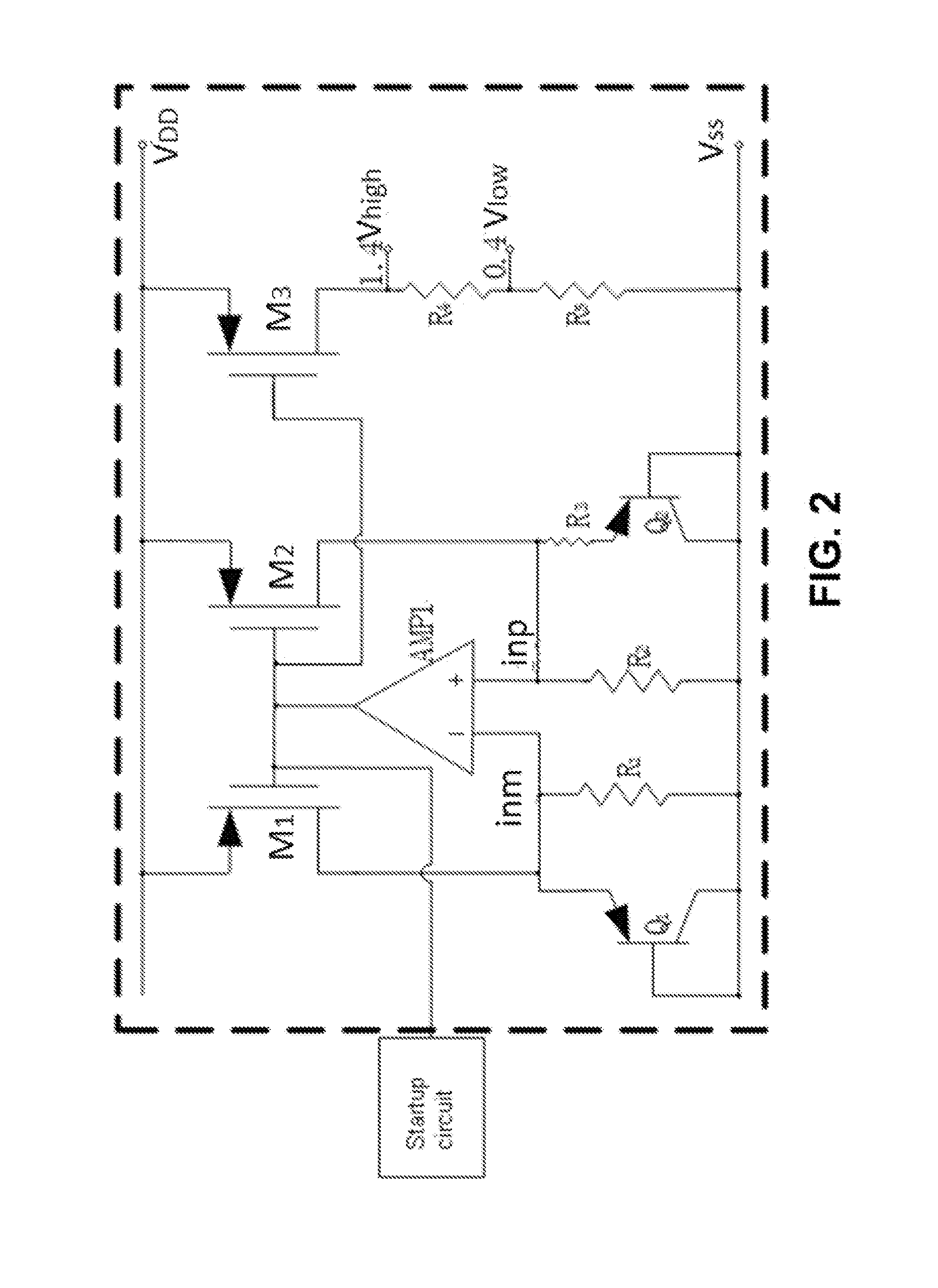

Temperature measurement and calibration circuit, passive radio frequency identification tag and method for measuring temperature

ActiveUS20150268103A1Eliminate the problemHigh measurement accuracyThermometer detailsThermometer testing/calibrationProcess deviationsVoltage generator

The present invention relates to the field of radio frequency identification, in particular to a temperature measurement and calibration circuit and a passive radio frequency identification tag. Meanwhile, the present invention further relates to a method for performing temperature measurement by using the tag. The temperature measurement and calibration circuit of the tag generates an upper reference voltage value limit and a lower reference voltage value limit, which do not change with temperature, then calibrates the upper reference voltage value limit and the lower reference voltage value limit to a uniform upper voltage value limit and a uniform lower voltage value limit, and eliminates the problem of different reference voltages of tags due to the power supply voltage fluctuation and process deviation. Meanwhile, a temperature measurement voltage generator circuit of the tag generates a calibration voltage value under a uniform calibration temperature. After the calibration voltage value is subjected to translational calibration, the calibration voltage values of the tags to be measured are equal, so that the consistency of temperature values of different tags is ensured. The circuit and tag provided by the present invention may be widely applied to ambient temperature detection, animal temperature detection, cold chain temperature detection or other fields, and have high accuracy of measurement.

Owner:EXCELIO TECH SHENZHEN +1

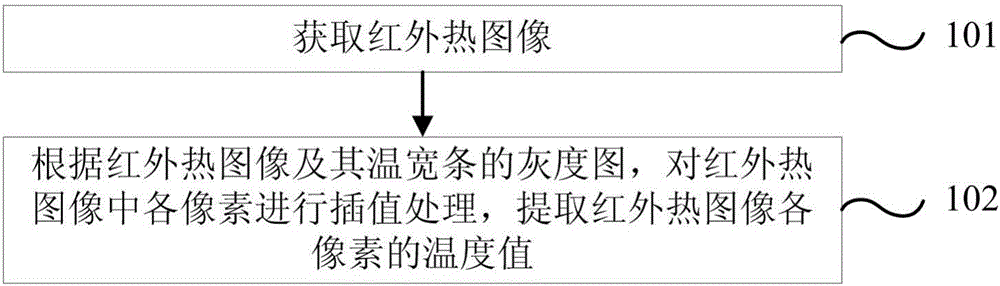

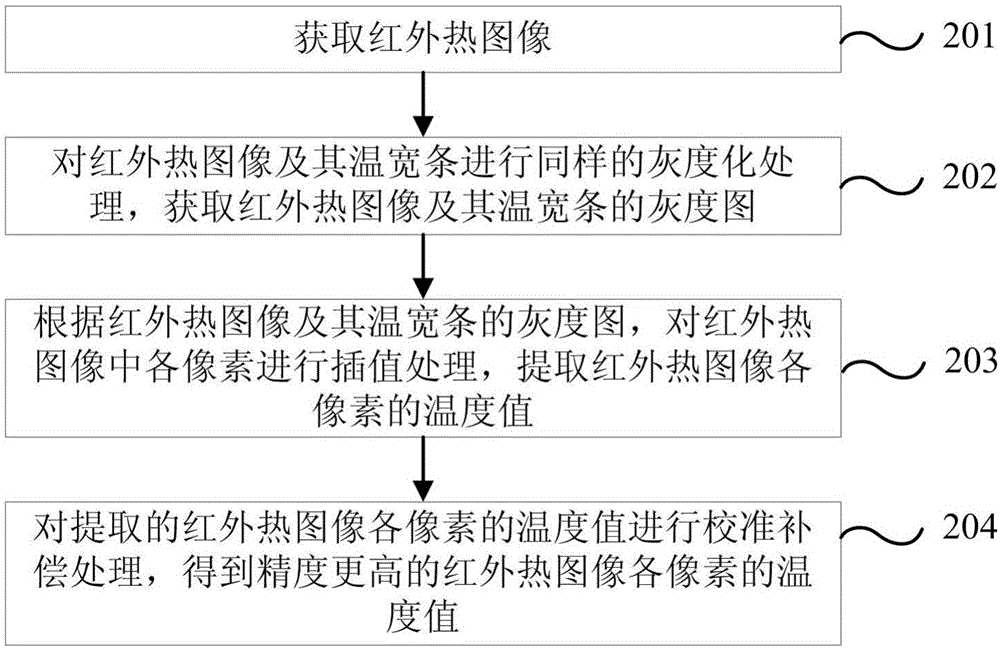

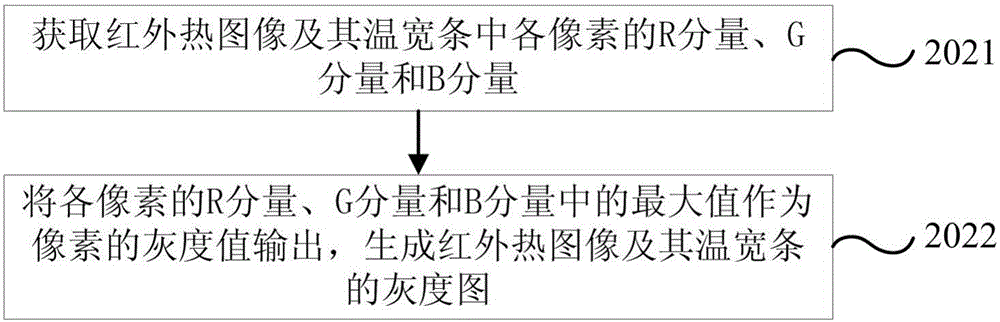

Temperature extraction method and apparatus for infrared thermal image

InactiveCN106289532AEasy for secondary analysisIncrease profitRadiation pyrometryPower equipmentSecondary analysis

The invention provides a temperature extraction method and apparatus for an infrared thermal image. The method comprises the following steps: acquiring an infrared thermal image; performing interpolation processing on each pixel in the infrared thermal image according to the grey-scale maps of the infrared thermal image and a temperature wide bar thereof, and extracting the temperature value of each pixel of the infrared thermal image. The apparatus comprises an image acquisition unit for acquiring the infrared thermal image; a processing unit for performing interpolation processing on each pixel in the infrared thermal image according to the grey-scale maps of the infrared thermal image and the temperature wide bar thereof, and extracting the temperature value of each pixel of the infrared thermal image. The method and apparatus can obtain the temperature value of each pixel in the infrared thermal image so that the temperature data contained in the captured infrared thermal image can be acquired so as to facilitate the secondary analysis of the photographed infrared thermal image to find the failure of power equipment. Thus, the utilization rate of the infrared thermal image is improved.

Owner:XIAN SI TOP ELECTRIC CO LTD

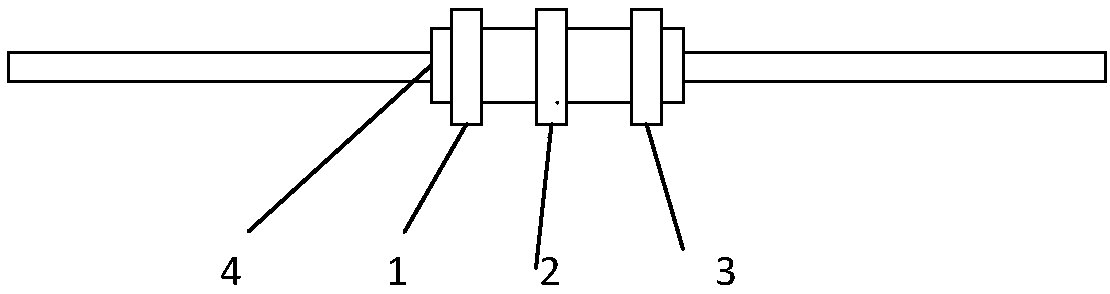

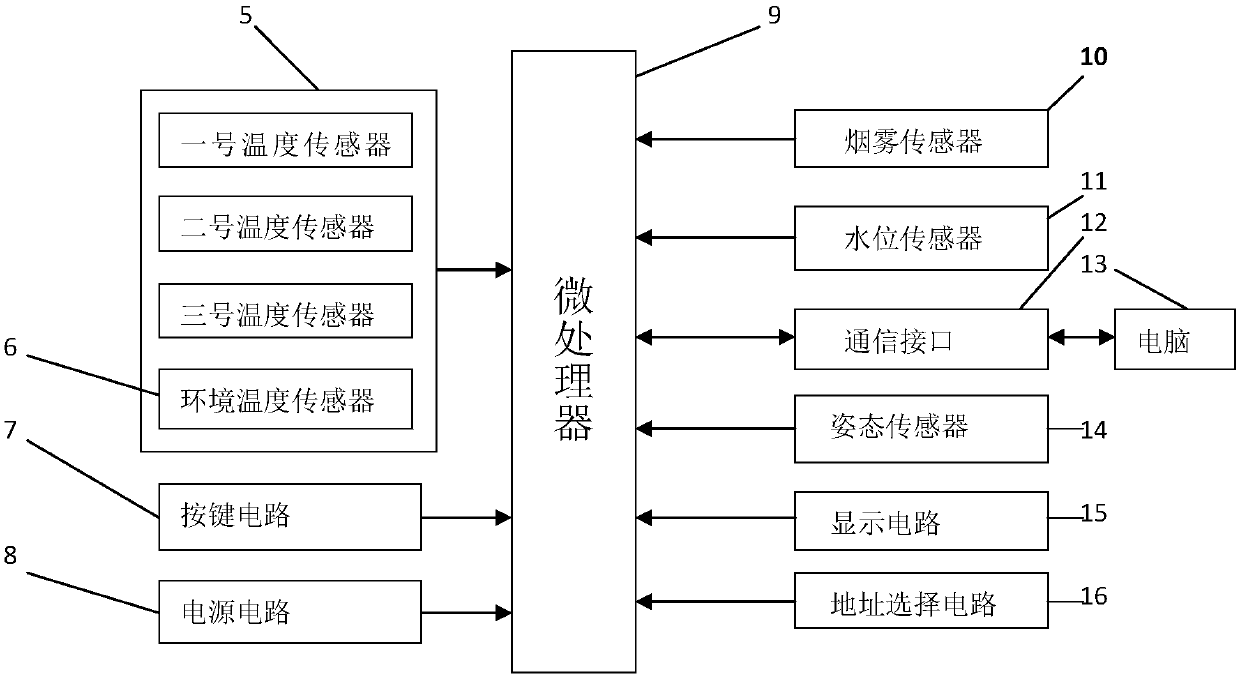

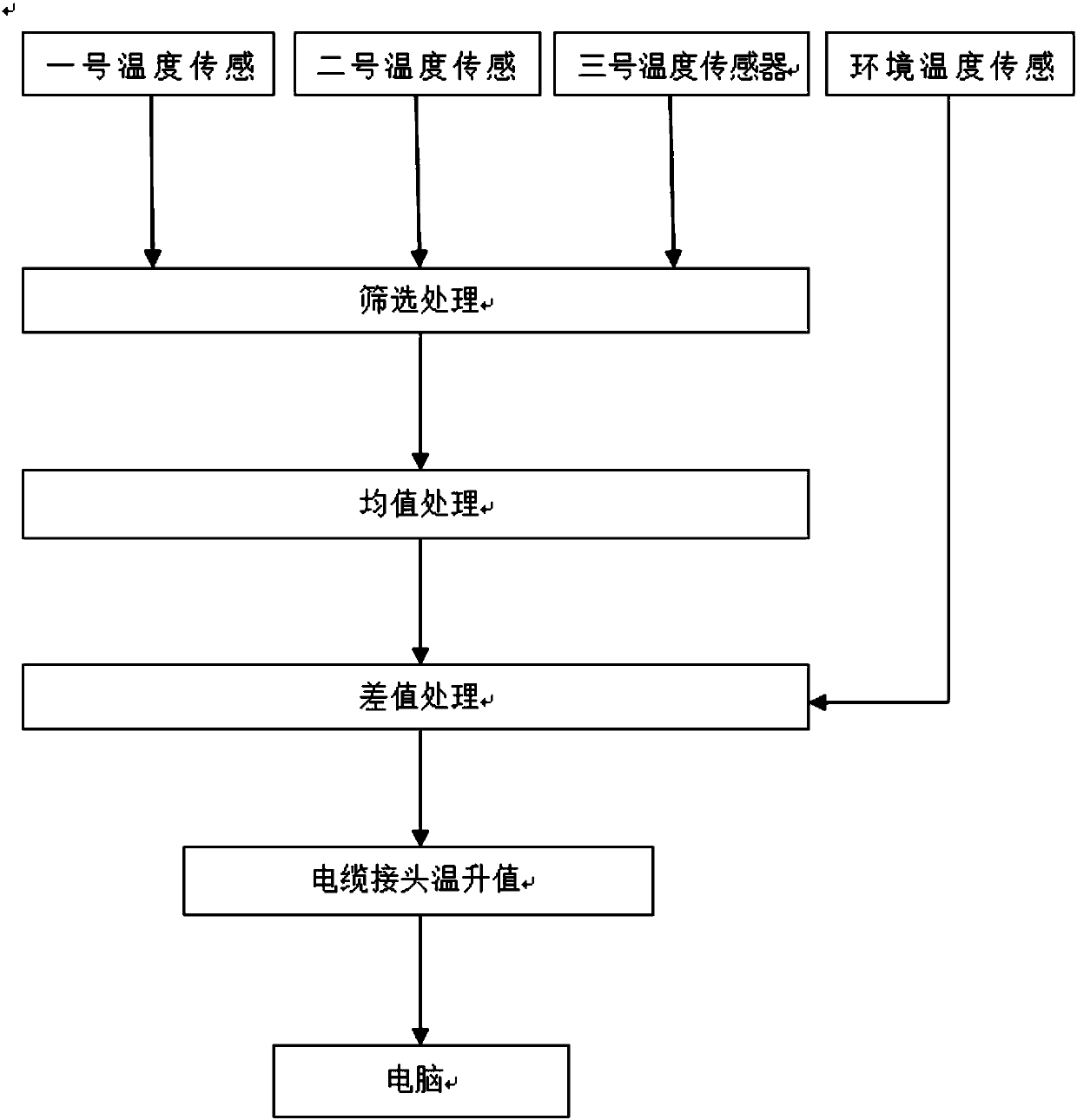

Cable intermediate joint temperature rise on-line monitoring device and method based on temperature difference method

InactiveCN107764424APrecise positioningTimely repairThermometer detailsThermometers using electric/magnetic elementsTemperature differenceMaterial resources

The invention relates to a cable intermediate joint temperature rise on-line monitoring device and method, and mainly solves the problems of waste of manpower, material resources and financial resources, low monitoring reliability, poor real-time performance, and being difficult to find equipment safety hazards of a conventional cable joint manual inspection method in the prior art. The device comprises a temperature sensing module, a microprocessor and a power supply circuit. The method is characterized by carrying out screening on the detected temperature and calculating the difference valuebetween the temperature value and environmental temperature value to judge whether the temperature rise is normal. The method and device can accurately obtain the cable joint temperature and can carry out real-time monitoring on the cable joint temperature, thereby ensuring health and safe operation of a cable.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +3

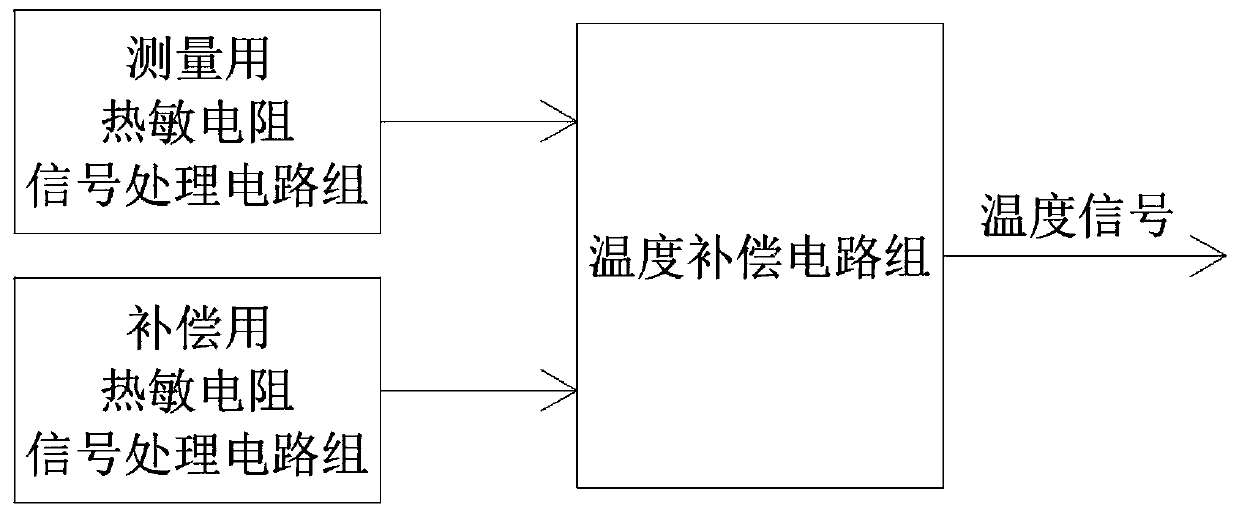

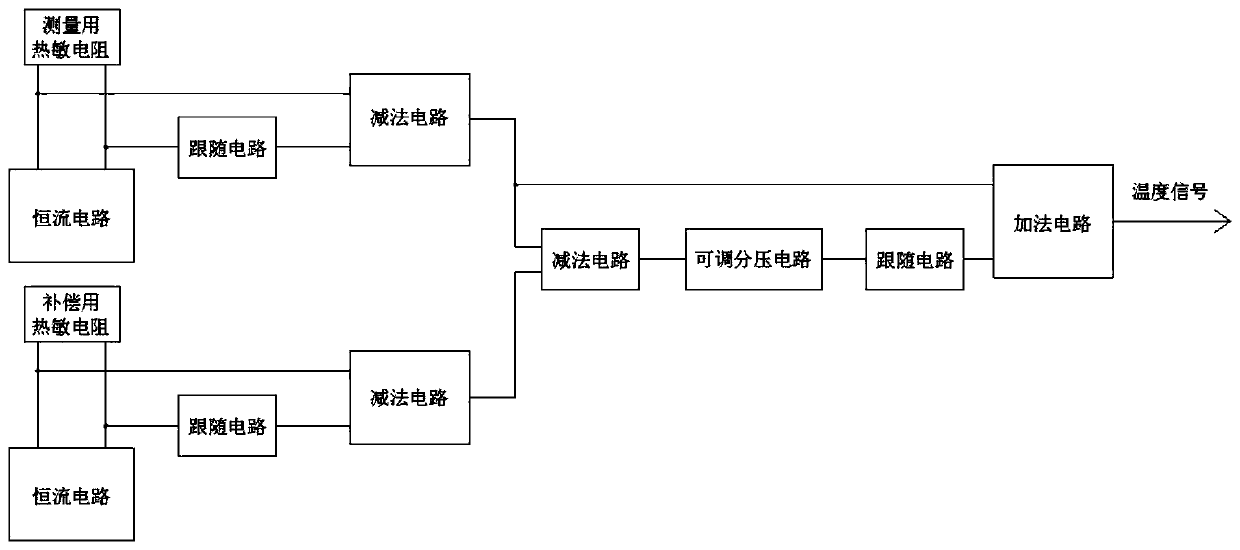

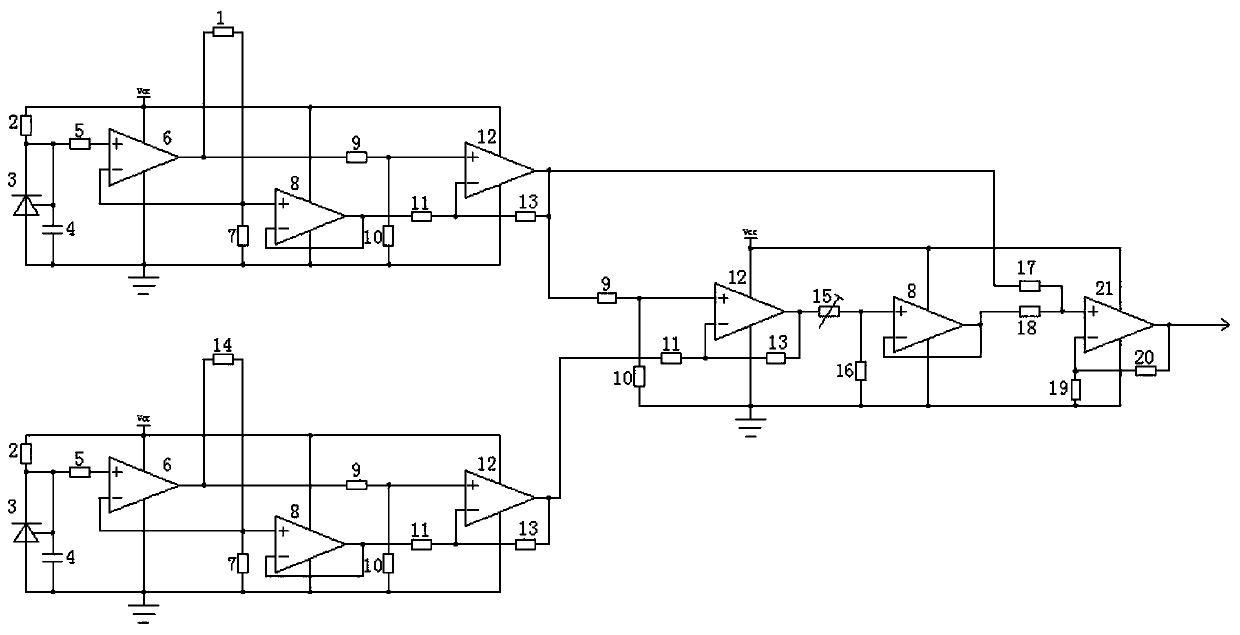

High-precision temperature measurement circuit with compensation function

ActiveCN111486983AGuaranteed processing accuracyReduce installation costsThermometer detailsThermometers using electric/magnetic elementsSignal processing circuitsDividing circuits

The invention discloses a high-precision temperature measurement circuit with a compensation function and belongs to the technical field of power electronics. The high-precision temperature measurement circuit comprises a thermistor signal processing circuit group for measurement, a thermistor signal processing circuit group for compensation and a temperature compensation circuit group. The thermistor signal processing circuit group for measurement comprises a thermistor for measurement, a constant current circuit, a follower circuit and a subtraction circuit; the thermistor signal processingcircuit group for compensation comprises a thermistor for compensation, a constant current circuit, a follower circuit and a subtraction circuit. Therefore, the influence of thermal resistance from atemperature measurement point to the thermistor body for measurement on processing errors can be weakened and the temperature value of the temperature measuring point can be obtained more accurately;meanwhile, an adjustable voltage division circuit is adopted, and adjustment can be conducted according to the actual application working condition, so that the application range is widened; the constant-current circuit is applied to provide power for the thermistor, and subsequent linear electric signal processing is facilitated.

Owner:TIANSHENGQIAO BUREAU CSG EHV POWER TRANSMISSION CO

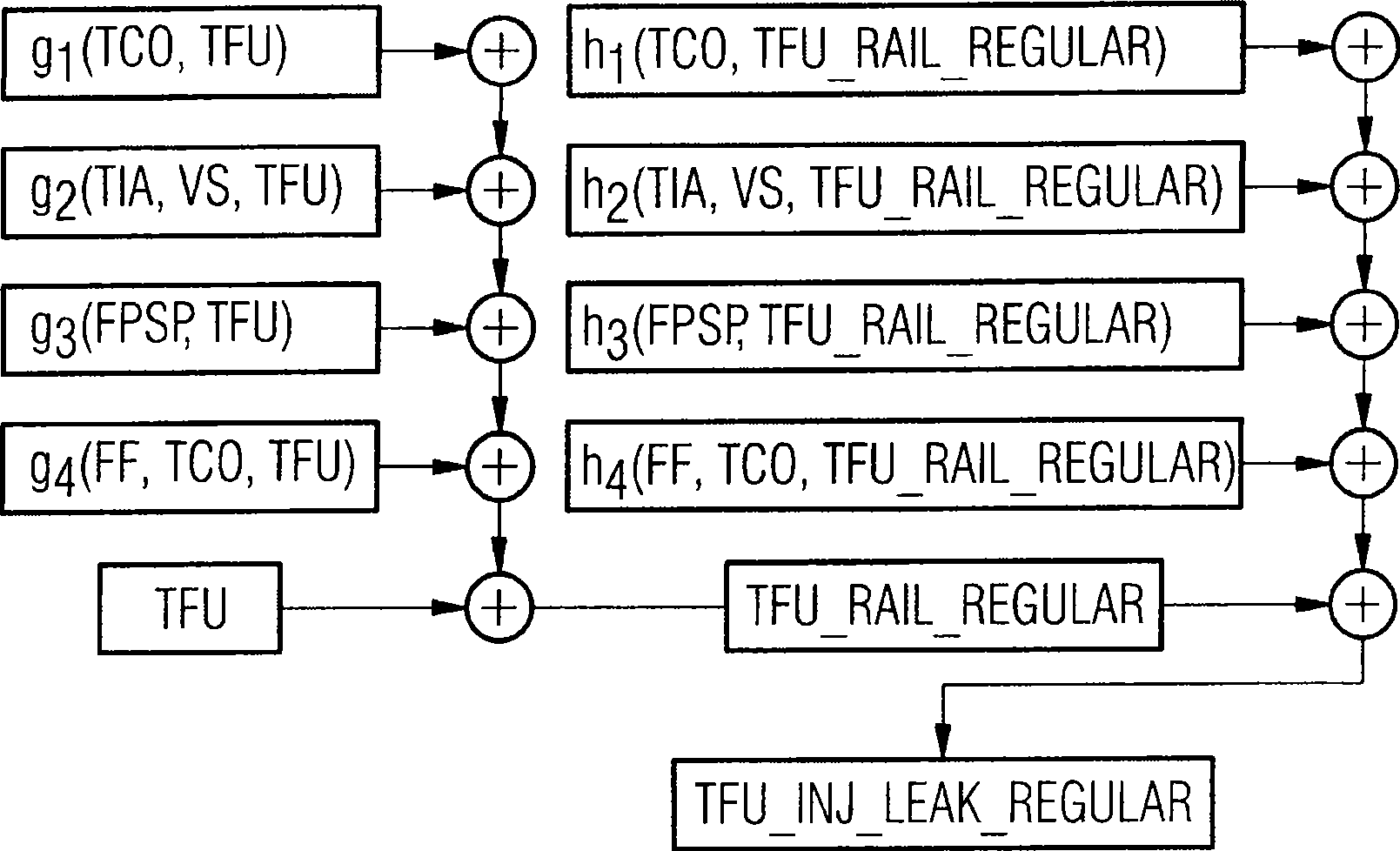

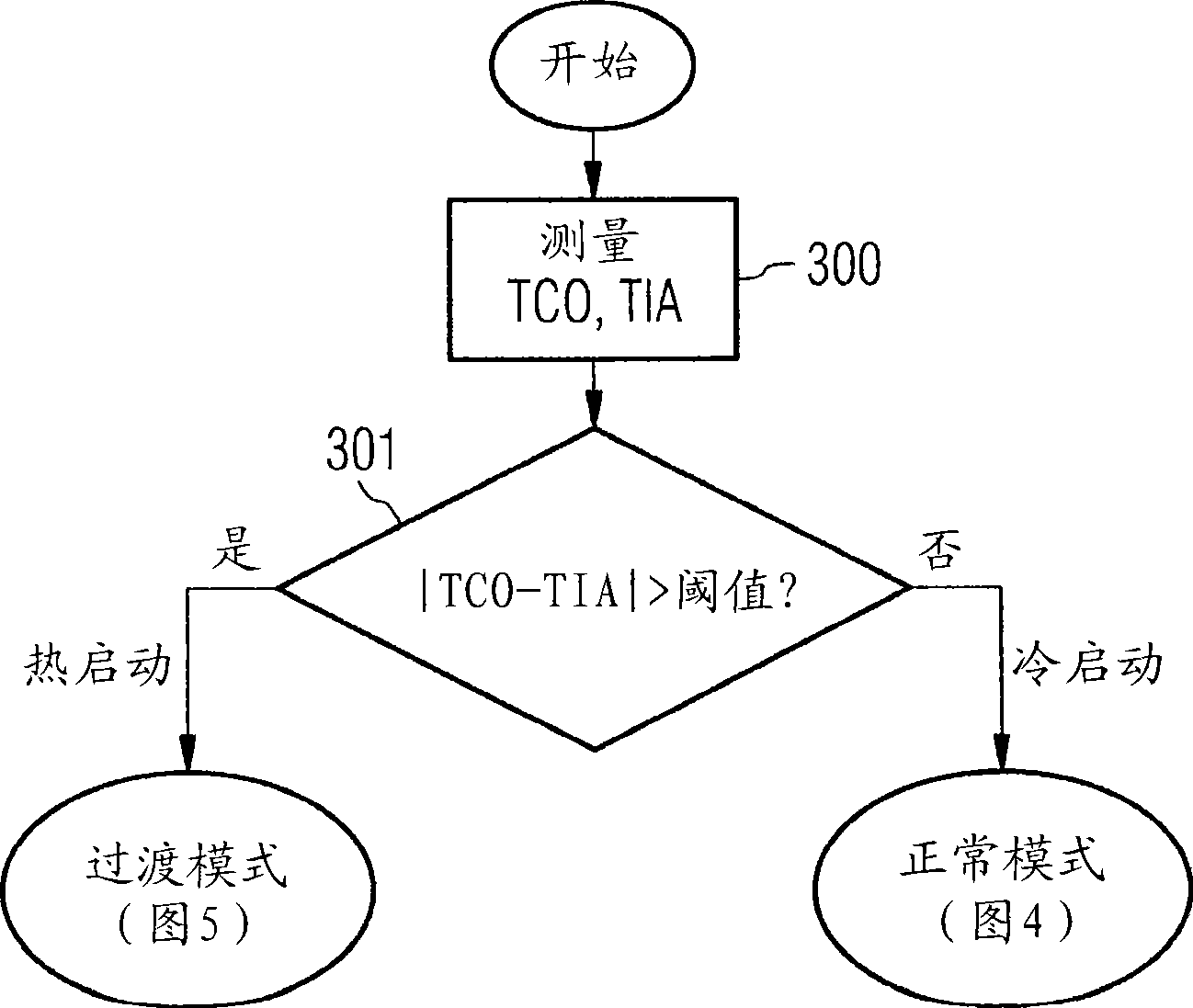

Method to determine the fuel temperature in a common rail injection system

InactiveCN101429896AEasy to measureNo feeTemperature measurement in motorsElectrical controlCommon railAutomotive engineering

In a method to determine the temperature of a fuel in a common rail injection system of an engine, the fuel temperature at one place of the common rail injection system is calculated from a fuel temperature at another place of the common rail injection system.

Owner:CONTINENTAL AUTOMOTIVE GMBH

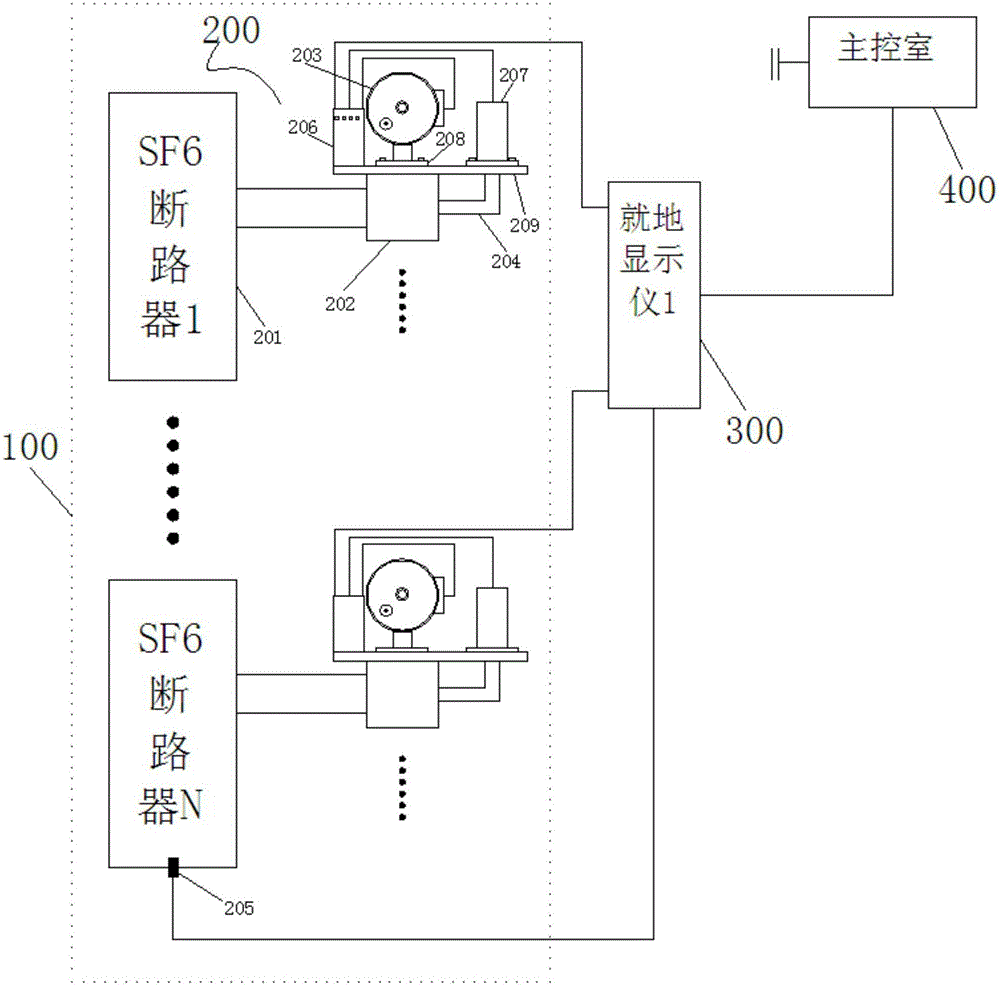

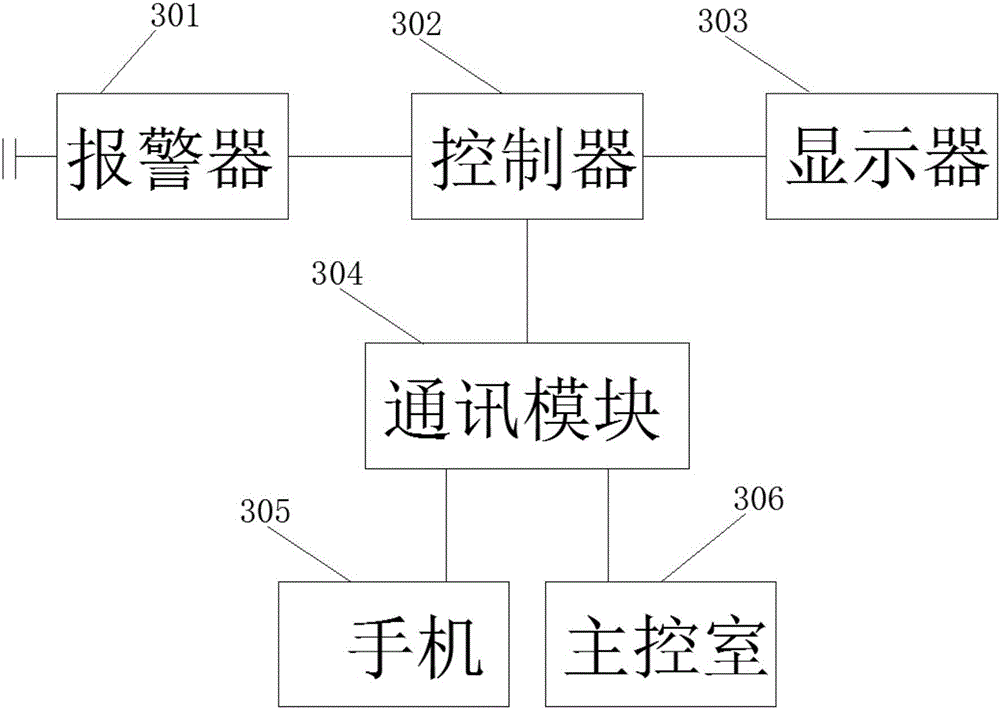

Onsite display instrument-based GIS sulfur hexafluoride density online monitoring system

InactiveCN106596329AWill not cause fragile phenomenaNeat wiringThermometers using electric/magnetic elementsUsing electrical meansElectricitySulfur hexafluoride

The invention discloses an onsite display instrument-based GIS sulfur hexafluoride density online monitoring system. A monitoring pipeline is provided with a gas exporting tee joint; one outlet of the gas exporting tee joint communicates with the gas collecting opening of a sulfur hexafluoride density meter; another outlet of the gas exporting tee joint communicates with the collecting opening of a pressure collecting sensor; the system also includes a horizontally mounted mounting platform, and the sulfur hexafluoride density meter and the pressure collecting sensor are respectively mounted on the mounting platform through mounting flanges, and are vertical to the mounting platform; the mounting platform positioned on the side surface of the sulfur hexafluoride density meter is provided with a wiring terminal strip, and the wiring terminal strip is electrically connected to the signal input channel of an onsite display instrument; and the quantity of SF6 breakers is more than one, and a gas chamber shell of one of the SF6 breakers in the same indoor environment is provided with a temperature sensor used for measuring the gas temperature in the SF6 breaker gas chamber.

Owner:HUANENG INT POWER CO LTD YUHUAN POWER PLANT +1

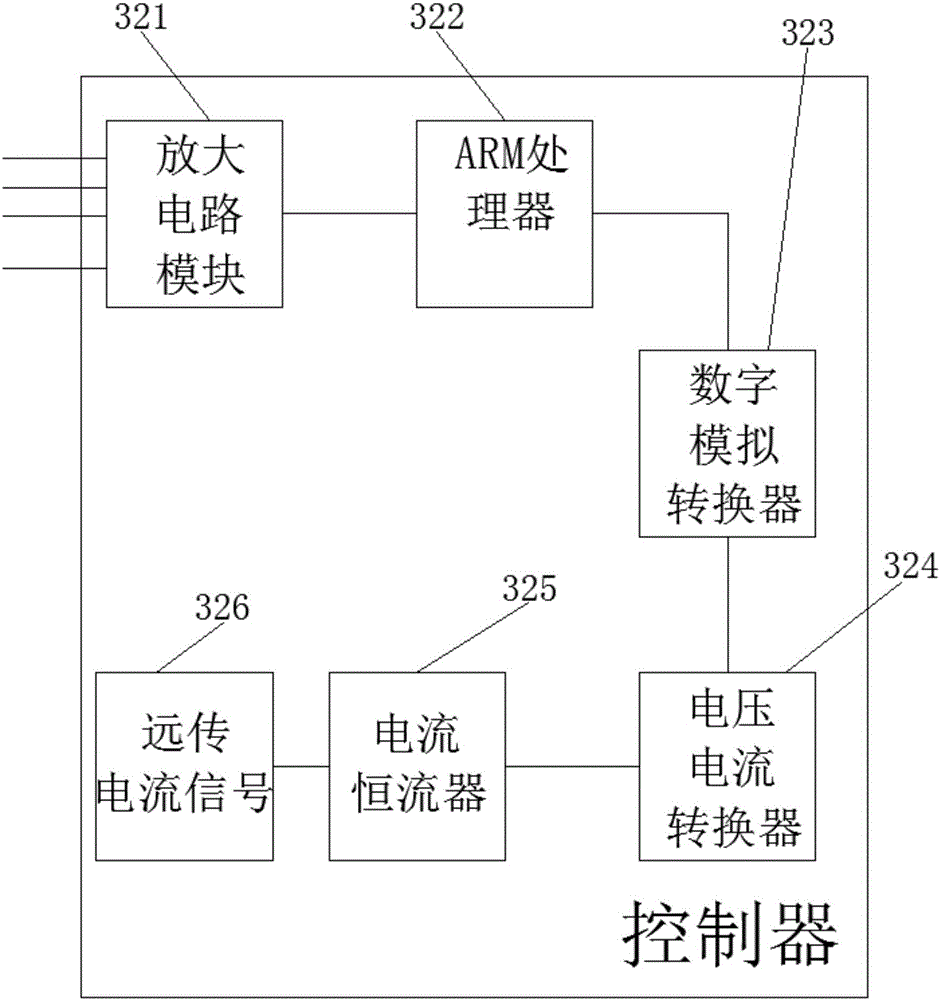

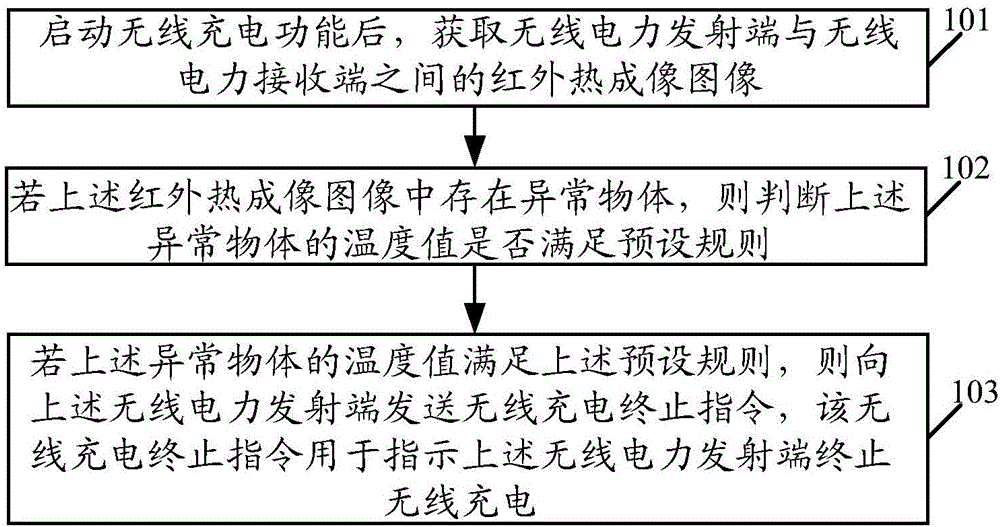

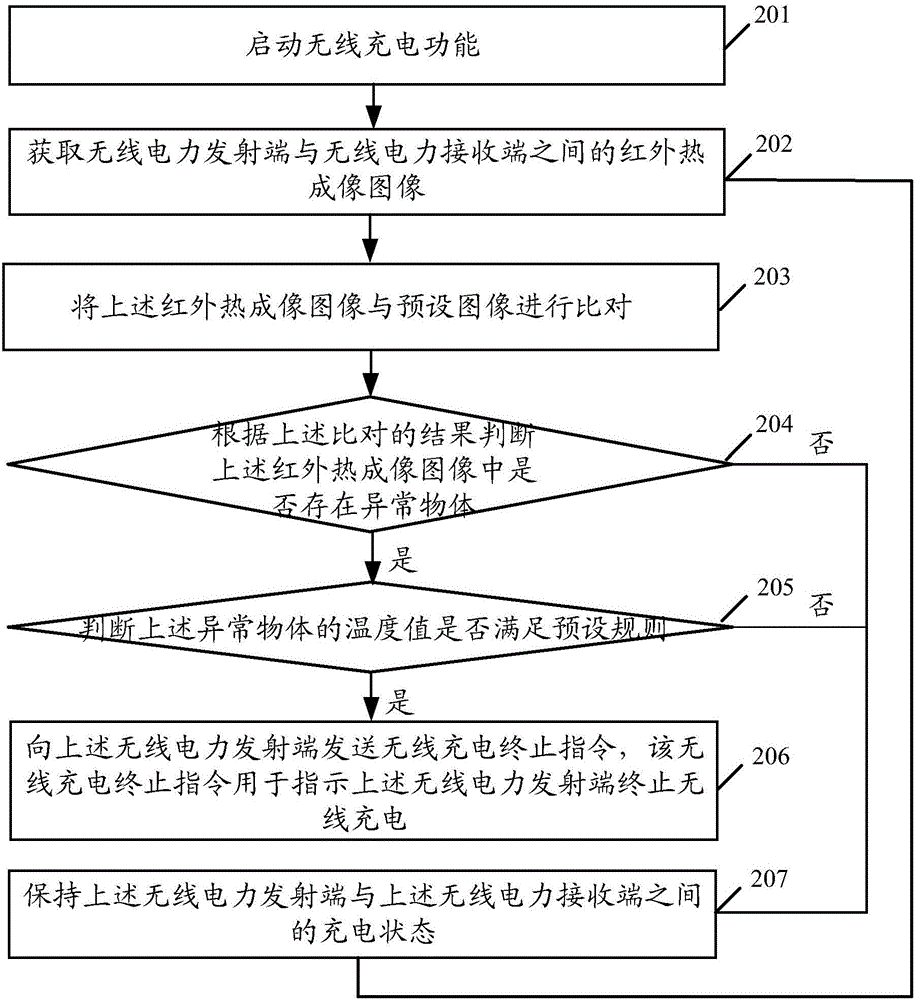

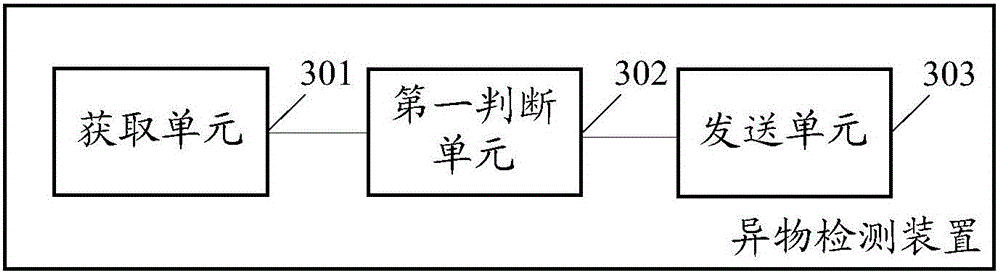

Foreign matter detection method and apparatus, and terminal device

ActiveCN106412293AImprove accuracyImprove securityRadiation pyrometrySubstation equipmentInductive chargingForeign matter

The embodiment of the invention discloses a foreign matter detection method and apparatus, and a terminal device, applied to the field of electronic technology. The method disclosed by the embodiment of the invention comprises the following steps: after a wireless charging function is started, acquiring an infrared thermal imaging image between a wireless power transmitting terminal and a wireless power receiving terminal; if an abnormal object exists in the infrared thermal imaging image, judging whether a temperature value of the abnormal object meets a preset rule; and if the temperature value of the abnormal object meets the preset rule, sending a wireless charging termination instruction to the wireless power transmitting terminal, wherein the wireless charging termination instruction is used for indicating the wireless power transmitting terminal to terminate the wireless charging. By implementation of the embodiment of the invention, the foreign matter detection accuracy in a wireless charging process can be improved, and thus the security in the wireless charging process is improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

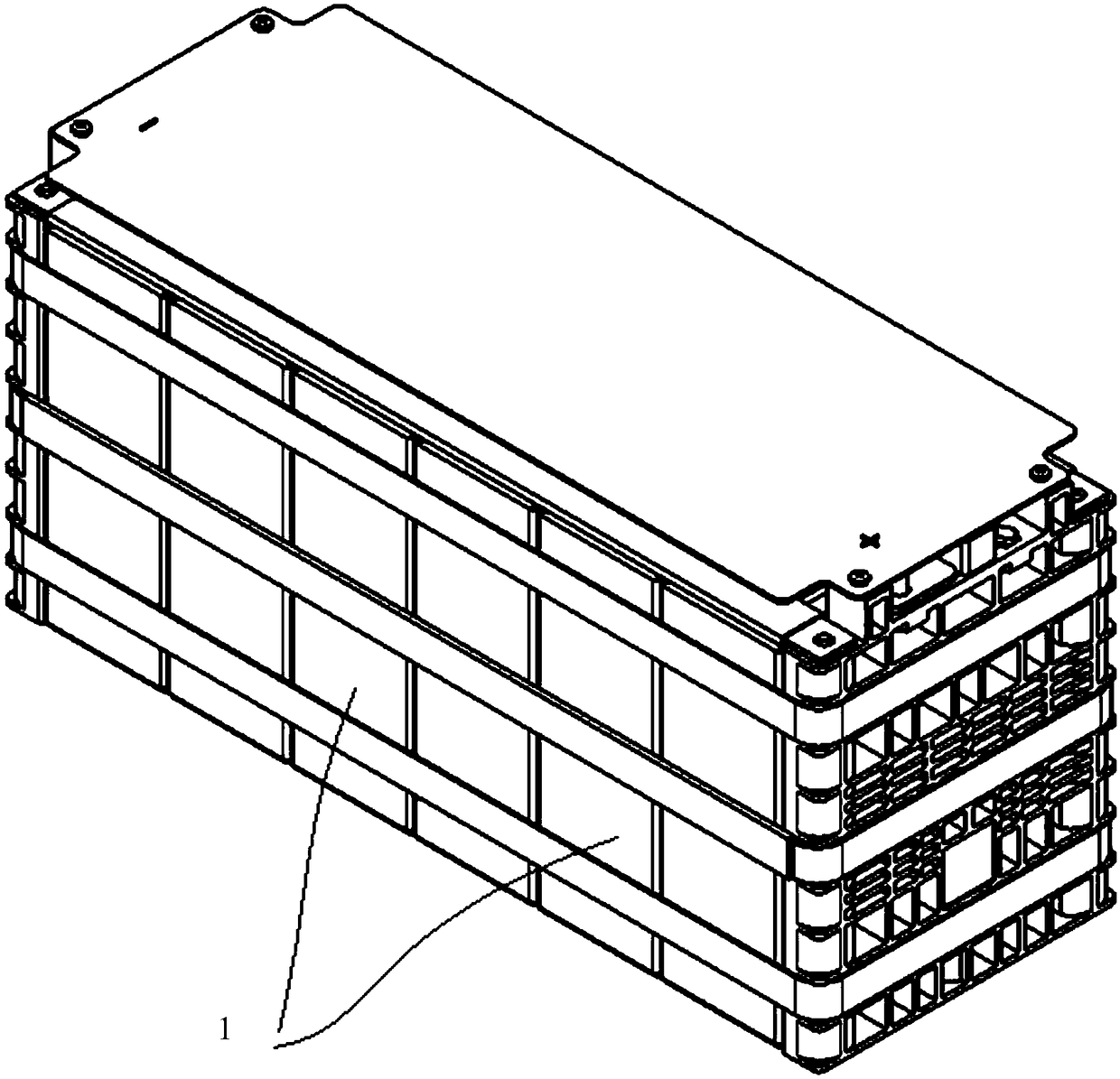

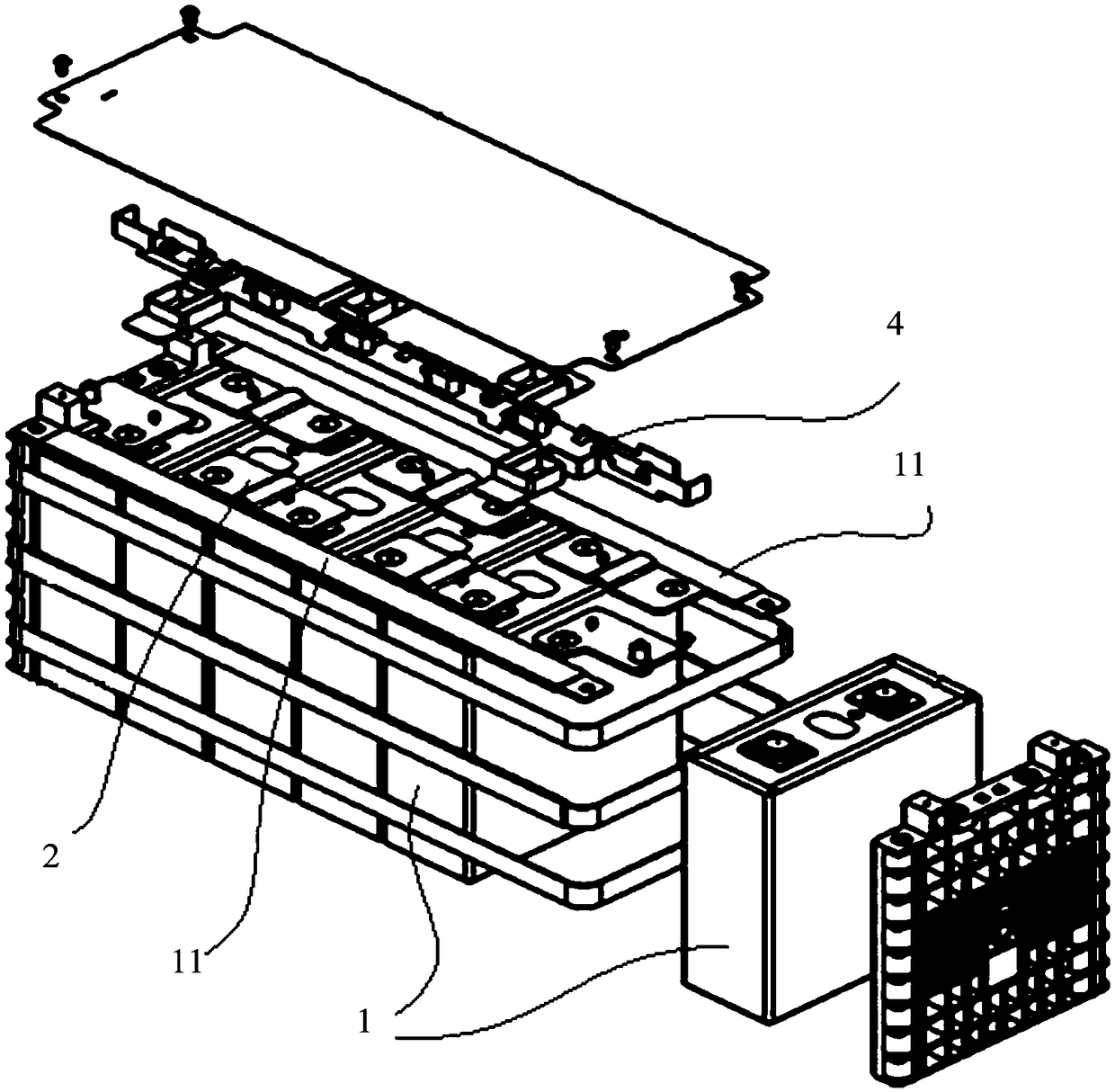

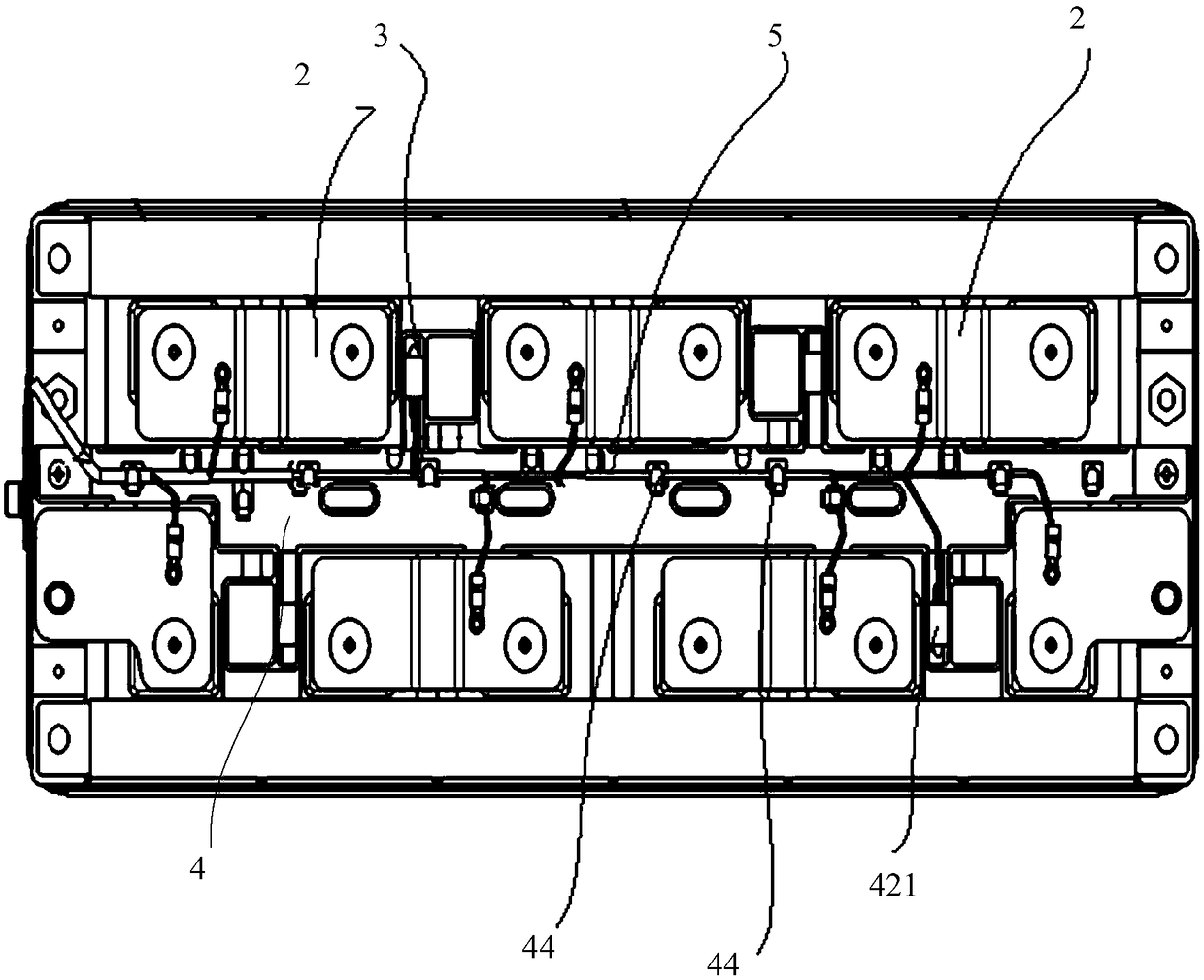

Battery device and new energy vehicle

PendingCN109148993AImprove securityAccurate temperature valueBattery isolationSecondary cellsElectricityNew energy

The invention provides a battery device and a new energy vehicle. Wherein the battery device comprises a temperature sensor, a connection assembly and a plurality of cells; the plurality of cells areelectrically connected through the connection assembly; the temperature sensor is in direct contact with the outer surfaces of the cells and is used to detect the temperature of the cells. The invention also provides a new energy vehicle, comprising a vehicle body and a battery device, wherein the battery device is fixedly connected with the vehicle body. The battery device and the new energy vehicle provided by the invention are in direct contact with the outer surface of the battery cell, and the temperature sensor can directly detect the temperature of the battery cell, and the measured temperature value is more accurate, which is favorable for improving the safety of the new energy vehicle.

Owner:BEIJING HYPERSTRONG TECH

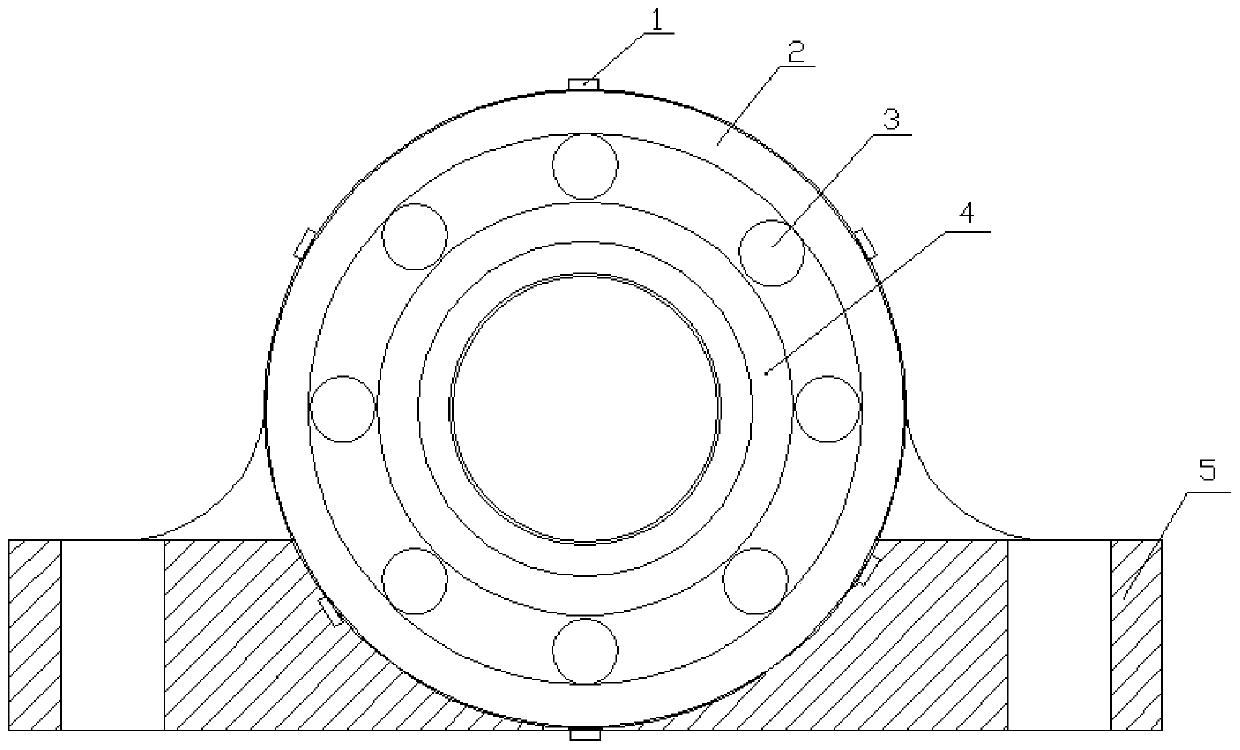

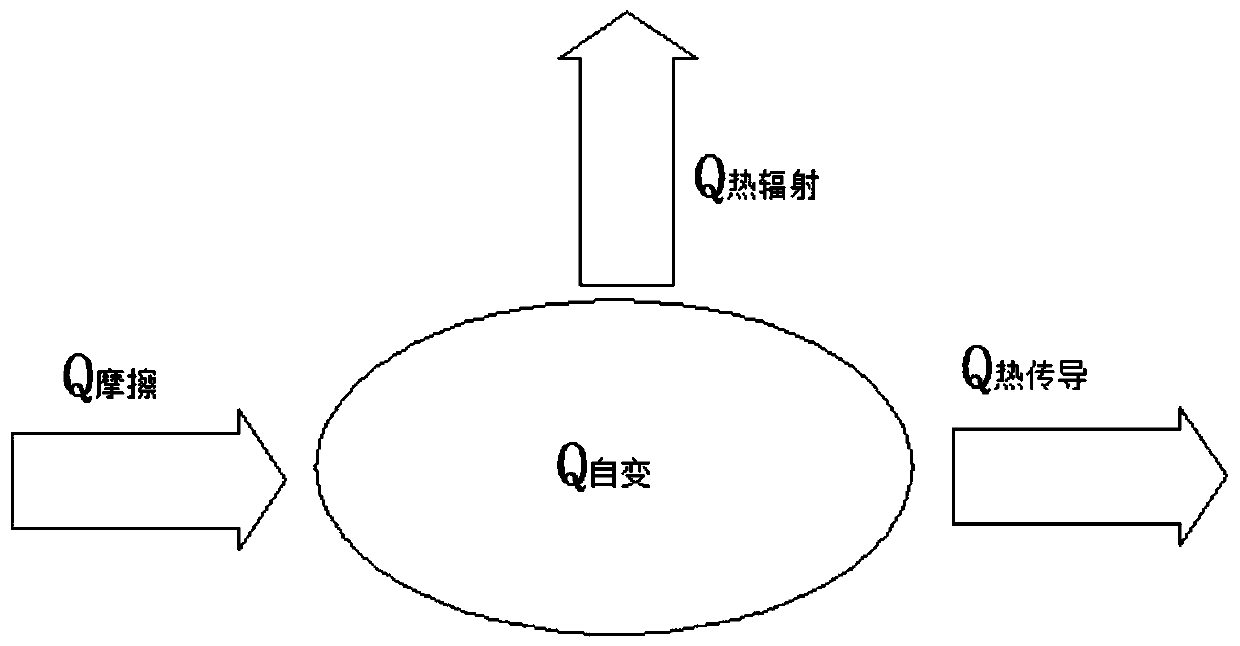

Indirect measuring method for wind turbine generator main bearing inner temperature

ActiveCN110307125AAccurate temperature valueRealize detectionMachines/enginesWind motor monitoringElectricityThird party

The invention discloses an indirect measuring method for wind turbine generator main bearing inner temperature, and belongs to the technical field of wind power. A plurality of temperature sensors arearranged along the circumference of a main bearing, the main bearing outer layer temperature is measured in a multi-point mode, and the temperature average value of the multi-point measurement is calculated as the main bearing outer layer temperature T outer; the influences of the cabin environment temperature T environment and the wind speed n on the cabin main bearing temperature are combined,a mathematical model for main bearing temperature measuring is constructed, and function relationships between the main bearing inner temperature T inner and the cabin inner environment temperature Tenvironment, the main bearing outer layer temperature T outer and the fan rotating speed n are obtained through function fitting; and the main bearing inner temperature T inner is calculated through afunction expression after fitting. According to the method, the main bearing inner temperature can be detected, a relatively accurate main bearing temperature value can be obtained, the value has important reference significance in the operation of a fan and the maintainance, and the problems that a third party cannot directly measure the main bearing inner temperature or obtain data and interfaces of the main bearing direct measuring temperature are solved.

Owner:SHENYANG JIAYUE ELECTRIC POWER TECH CO LTD

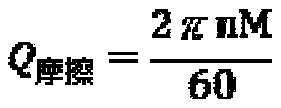

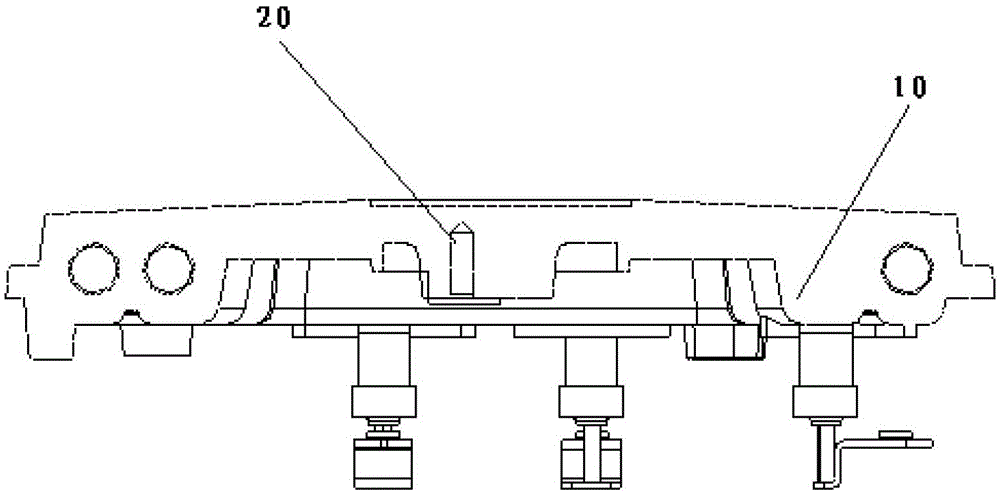

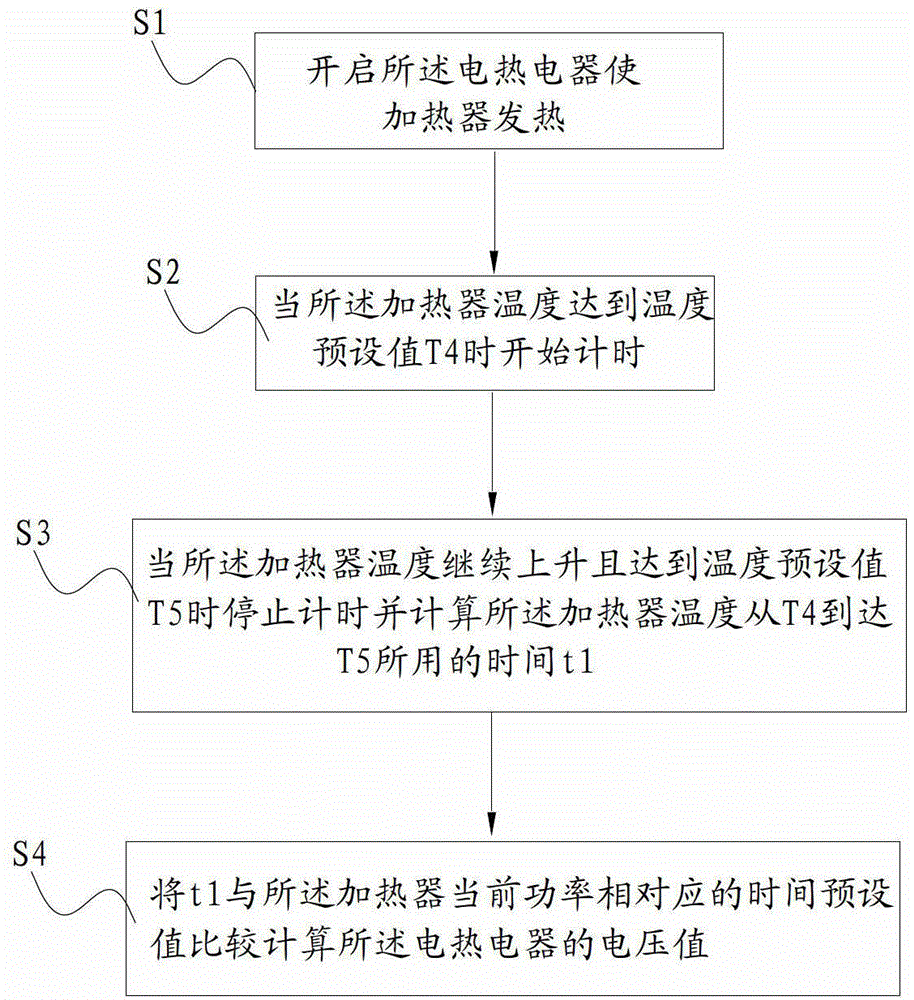

Electrothermal equipment and voltage detection method

InactiveCN104007775ASimple structureEasy to manufactureAuxillary controllers with auxillary heating devicesWarming devicesElectricityHeating time

The invention brings forward electrothermal equipment and its voltage detection method. The voltage detection method comprises the following steps: Step 1, turning on the electrothermal equipment to make a heater to give out heat and beginning reckoning by time; Step 2, detecting temperature T0 of the heater when heating time reaches t0; and Step 3, comparing T0 with a temperature preset value corresponding to current power of the heater to calculate a voltage value of the electrothermal equipment. Thus, by the voltage detection method of the electrothermal equipment provided by the embodiment of the invention, the voltage value of the electrothermal equipment is accurately calculated by directly detecting temperature changes of the heater in unit time. Thus, it is ensured that the electrothermal equipment can automatically adjust the mode of heating under the working condition of unsteady voltage.

Owner:MIDEA GRP CO LTD

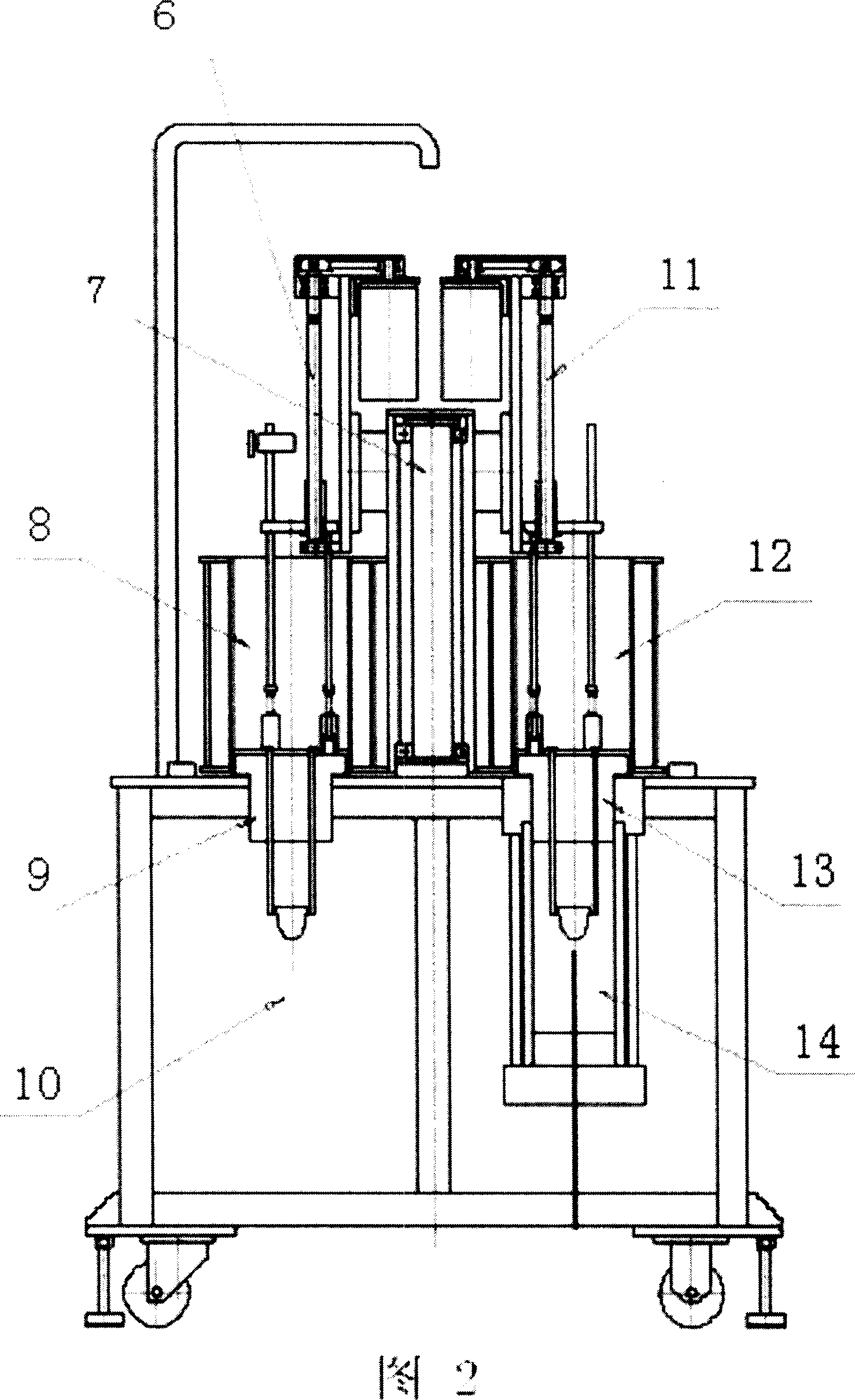

Liquidus temperature detection oven systematic device for aluminum electrolysis

ActiveCN101055145AAccurate temperature valueReduce power consumptionFurnace typesInvestigating phase/state changeThermal insulationManipulator

The invention discloses an aluminum electrolysis primary crystal temperature detecting furnace system. Its power is electrically connected to primary crystal temperature detecting furnace 2, furnace temperature control cabinet 3, data collection system 4, industrial computer 5. The primary crystal temperature detecting furnace 2 is mainly comprised by manipulator for picking sample, rotating transposition mechanism, temperature detecting room, furnace cover, cooling cabin, heating cabin, wherein the cooling cabin and the heating cabin are both split structure, and the furnace cover is arranged at the bottom of the rotating transposition mechanism and above table-board of the furnace body, lower portion of the furnace cover is equipped with thermal insulation material, and the heating cabin is at the right side bottom of the furnace body, and the cooling cabin is at the left side bottom of the furnace body, and the cooling cabin and heating cabin forms an included angle of 180 DEG, and the rotating transposition mechanism is at the center of the furnace body, which main shaft coincides with central axis of the furnace body. The invention can detects and calculates the temperature of the aluminum electrolysis primary crystal, and is helpful to further stable control for the aluminum electrolysis condition.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

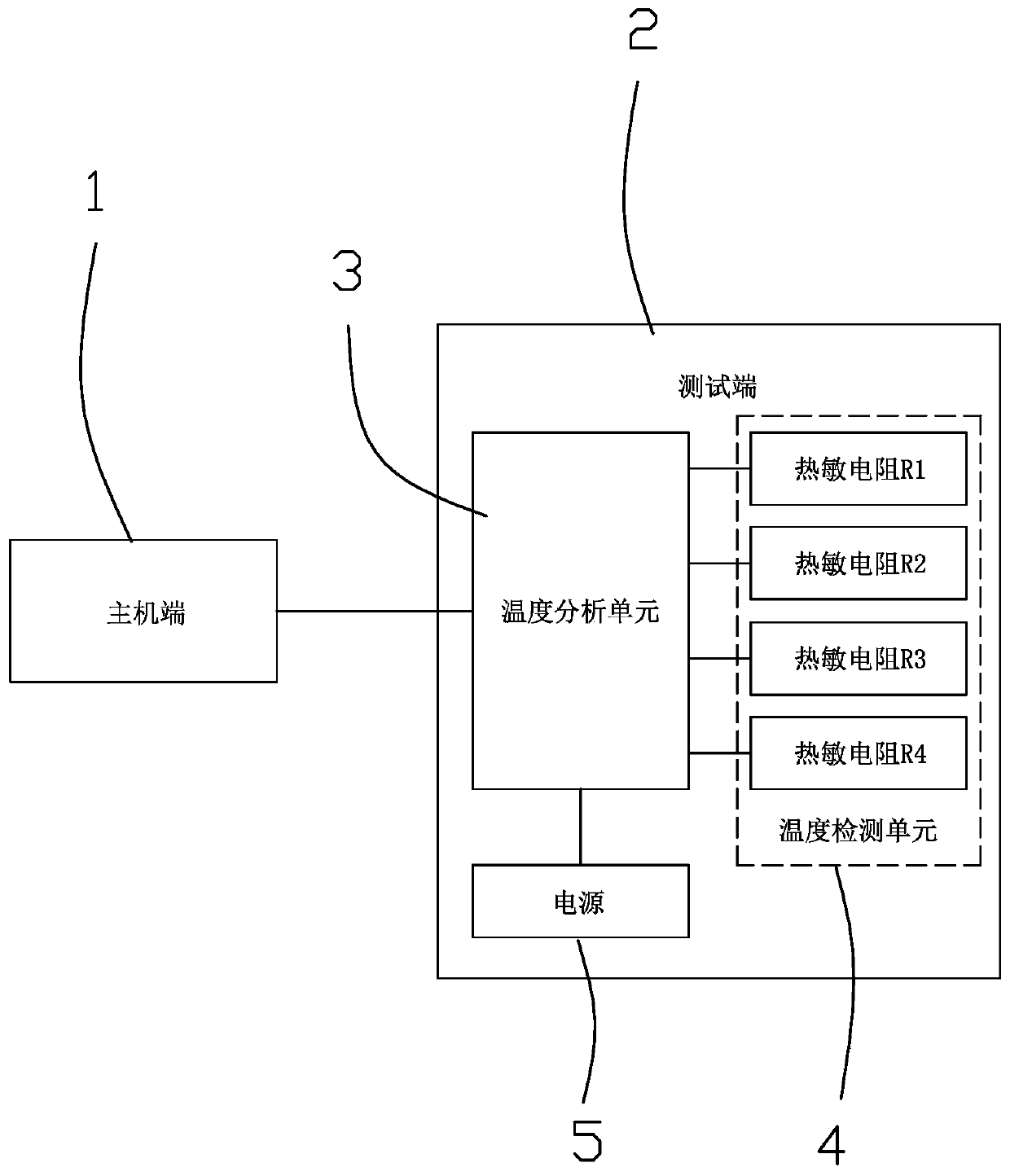

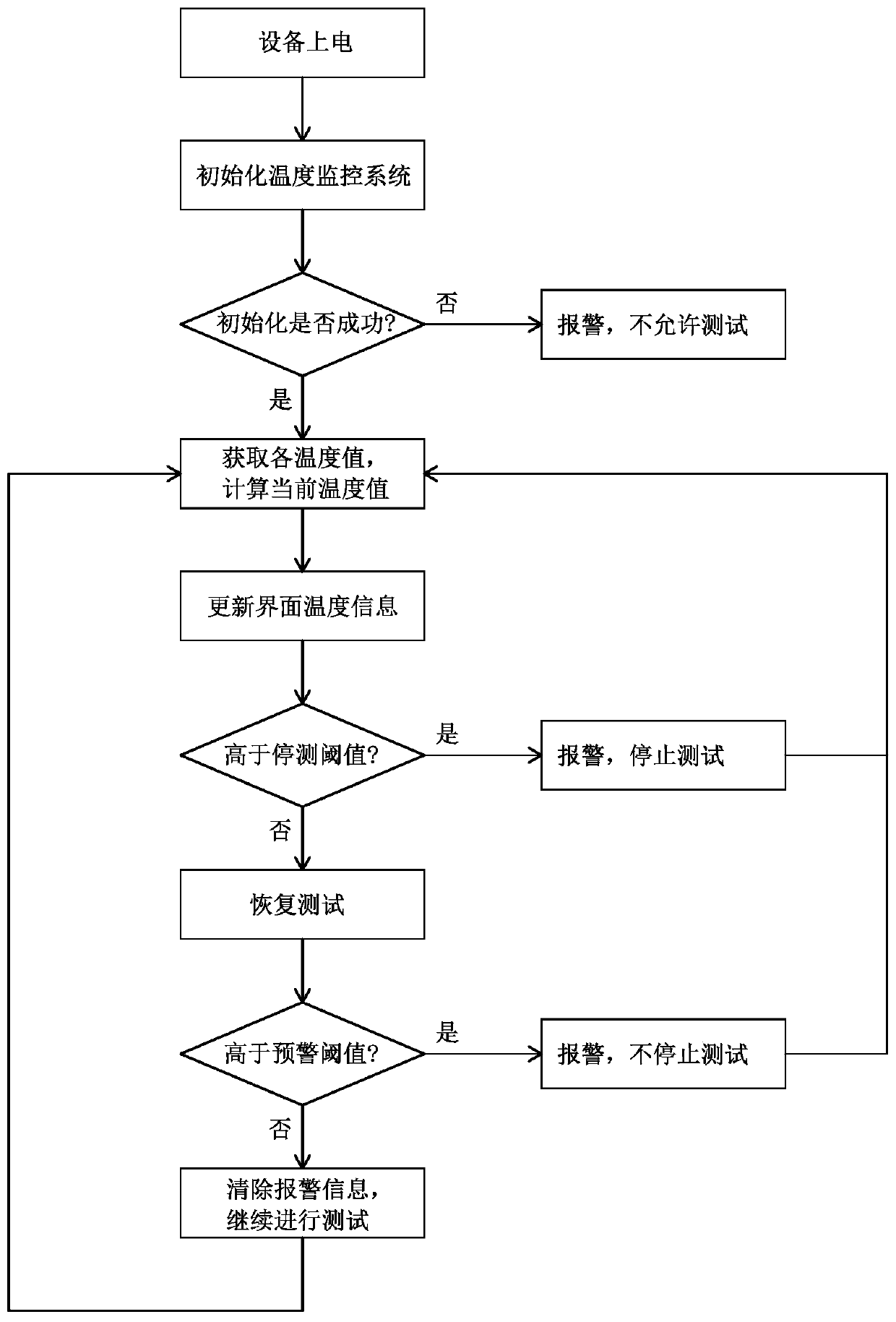

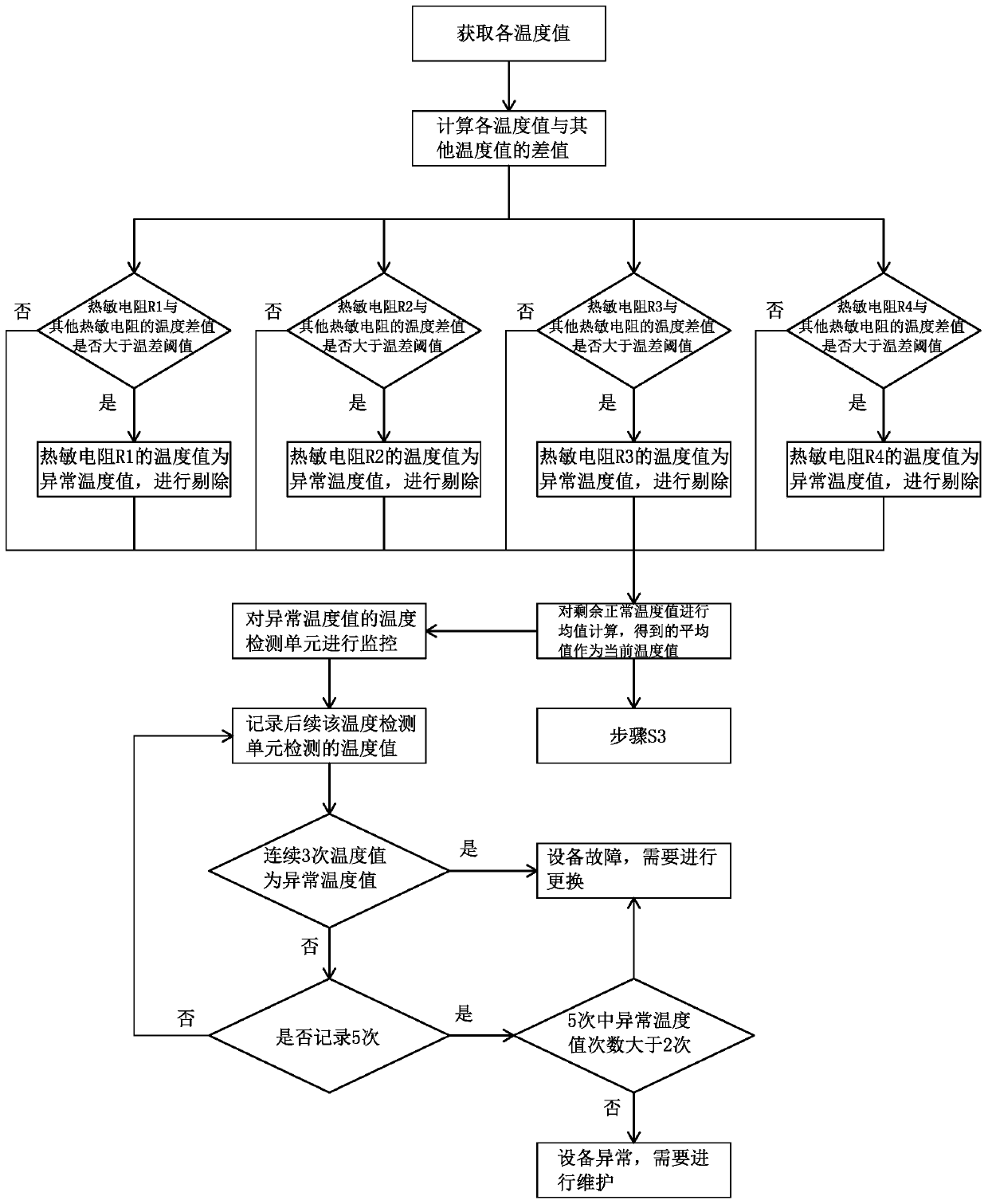

Real-time temperature monitoring system and method for integrated circuit testing device

InactiveCN109959862AThe current temperature value is accurateAvoid detection errors and biasElectronic circuit testingIntegrated circuitInternal temperature

The invention relates to a real-time temperature monitoring system and method for an integrated circuit testing device, thereby solving problems that the stability and precision of the testing deviceare affected by the too high temperature to cause the test offset and thus the serious quality is caused. The system comprises a host terminal and a testing terminal. The testing terminal includes a plurality of temperature detecting units and a temperature analyzing unit; the temperature detecting units are connected to the temperature analyzing unit respectively; and the temperature analyzing unit is connected to the host terminal. The host terminal reads temperature data in real time; when the temperature value is higher than an early warning threshold, alarming is performed; and when the temperature value is higher than a detection stop threshold, alarming is performed and current testing is stopped. According to the invention, the internal temperature of the integrated circuit test equipment can be monitored; alarming is performed when the temperature is too high and testing can be stopped in a forced manner, so that problems that the test stability of the testing device is reduced and the testing precision offset is caused because the heat in the testing device is not dissipated timely and the internal temperature of the testing device is too high are solved.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

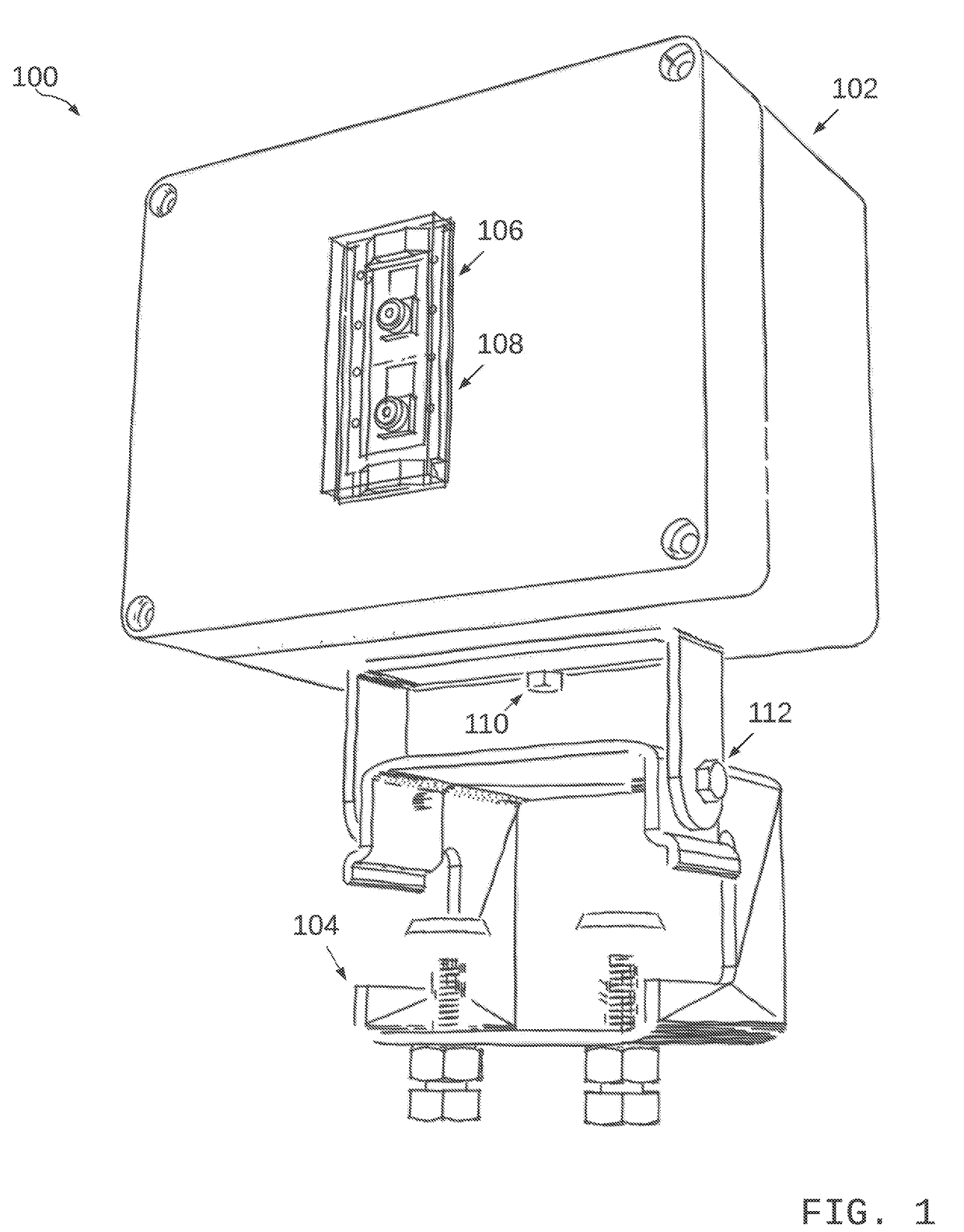

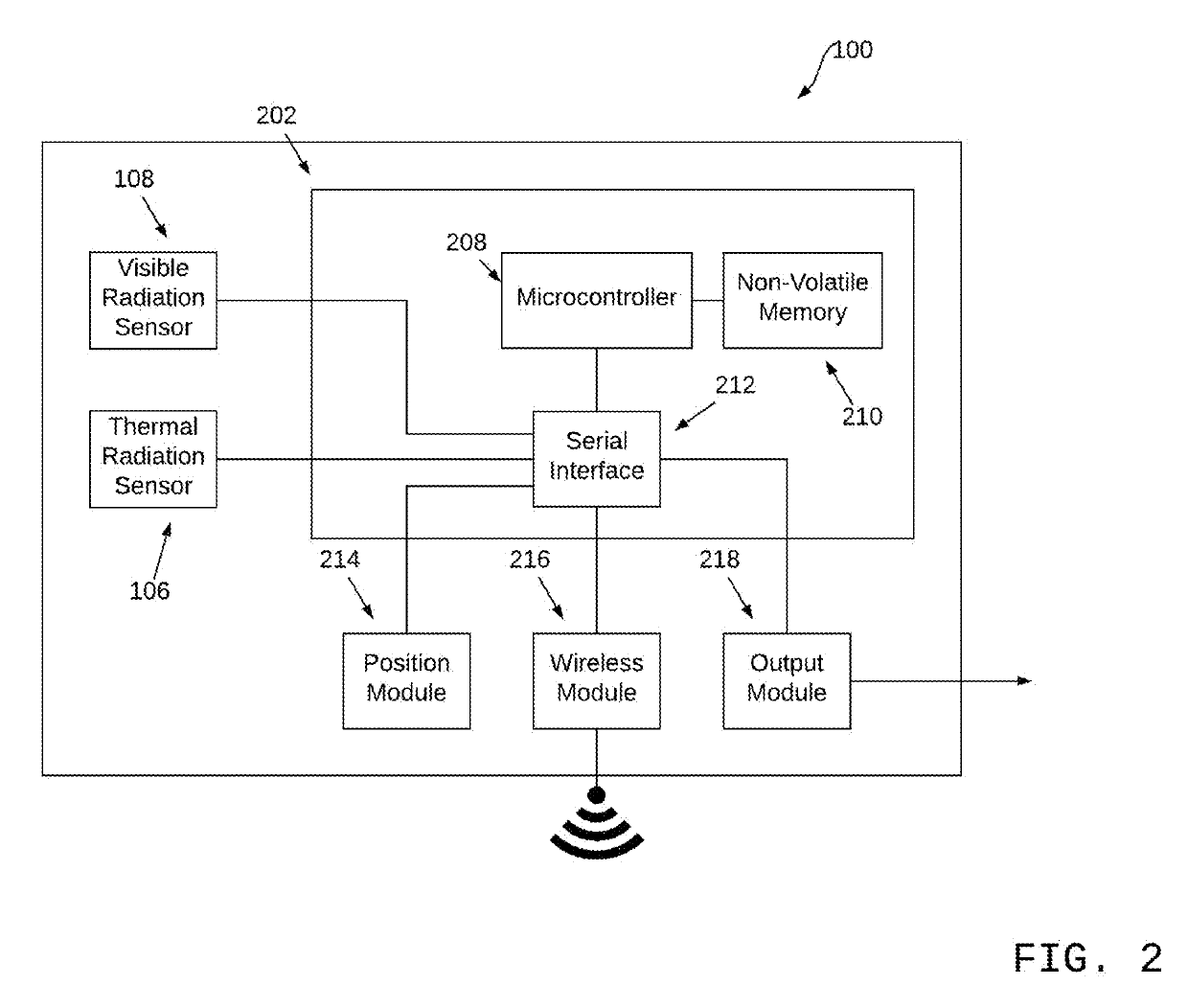

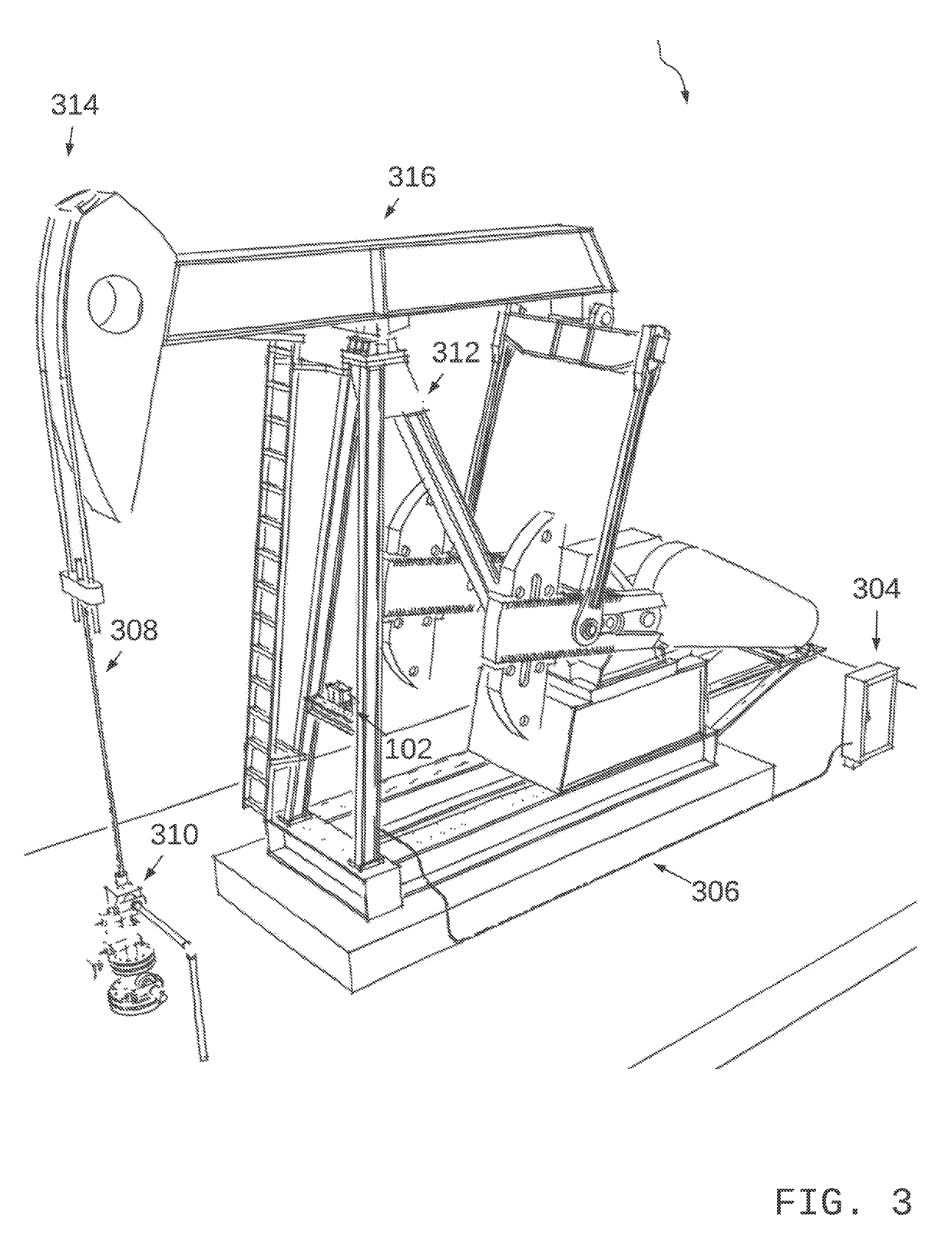

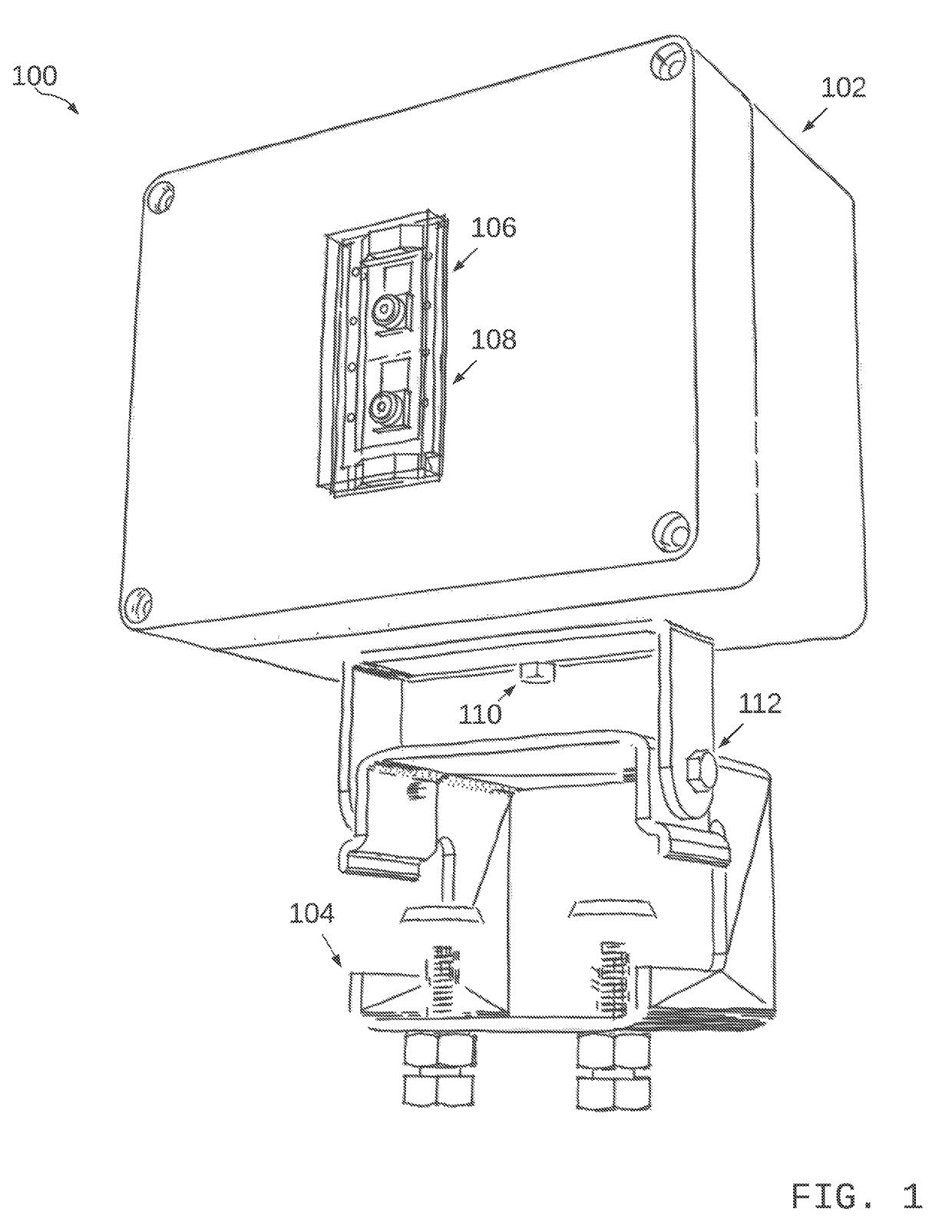

Polished-rod thermal imaging system for preventing failures in the operation of a sucker rod pump

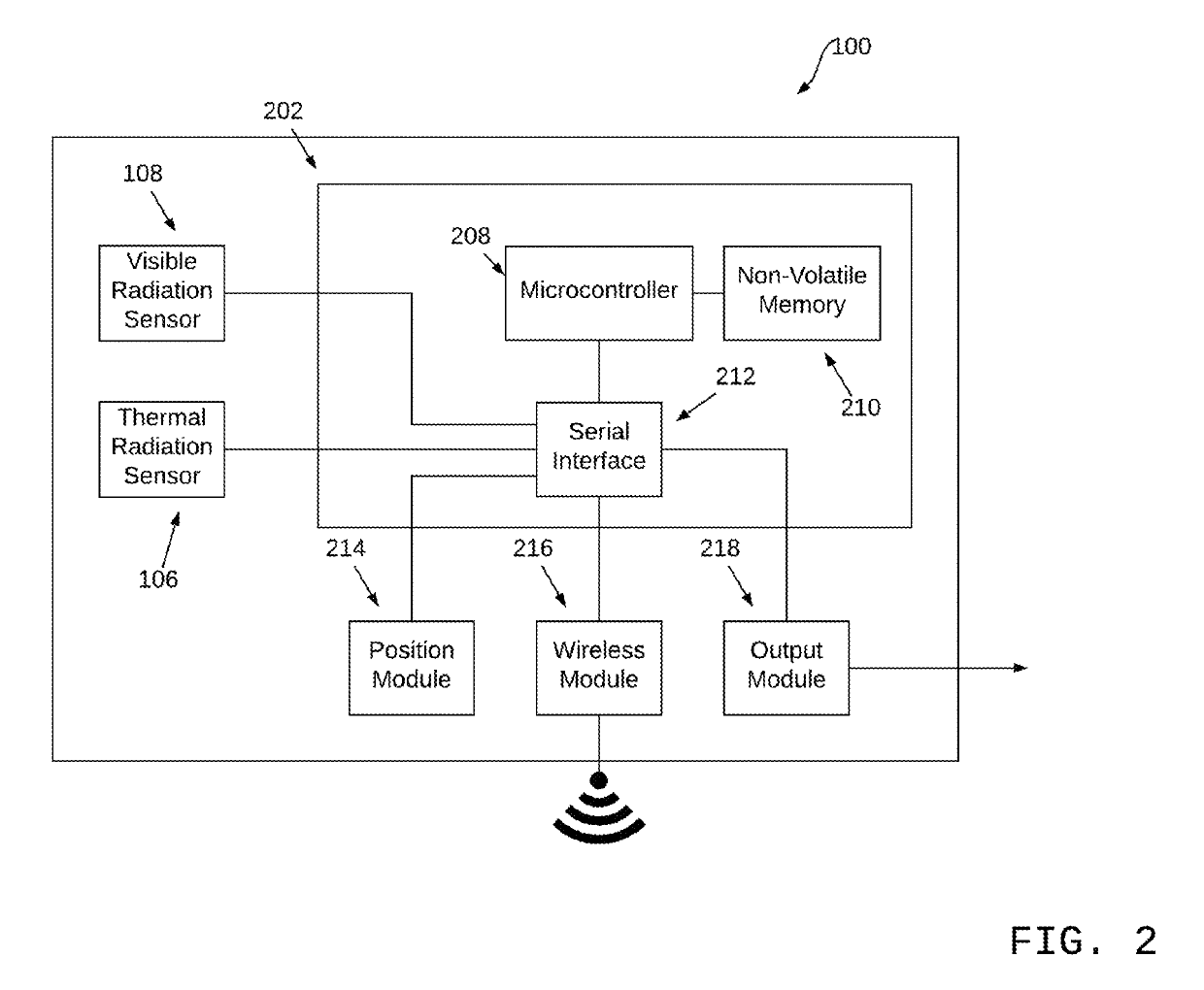

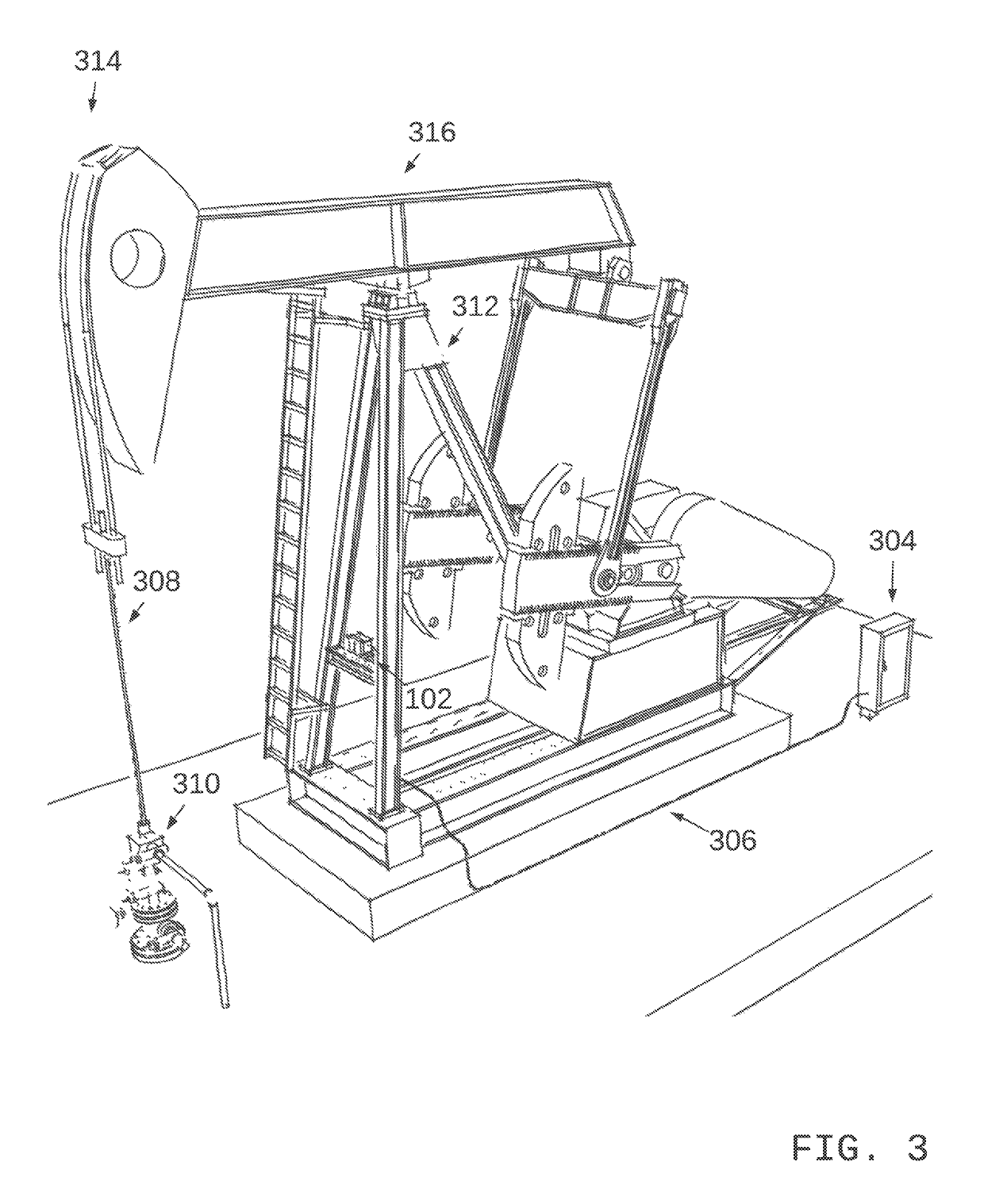

ActiveUS20190100990A1Sensing temperature is accurateAccurate temperature valueImage enhancementTelevision system detailsMicrocontrollerElectronic communication

A device for detecting temperatures of a rod on a well having a housing ; a clamp to secure the housing to a post of the well; a thermal radiation sensor secured to the front end of the housing; a visual radiation sensor secured to the front end of the housing, the visual radiation sensor is vertically aligned with the thermal radiation sensor; a microcontroller system placed inside housing, the microcontroller system includes a microcontroller, a non-volatile memory, and a serial interface in electronic communication; a position device placed inside the housing; a wireless device placed inside the housing; output device placed in the interior cavity of the housing; the microcontroller is in electronic communication with the serial interface for communicating with the visible radiation sensor, the thermal radiation sensor, the output module, the wireless module, and the position module.

Owner:GASOLINEOG AUTOMATION

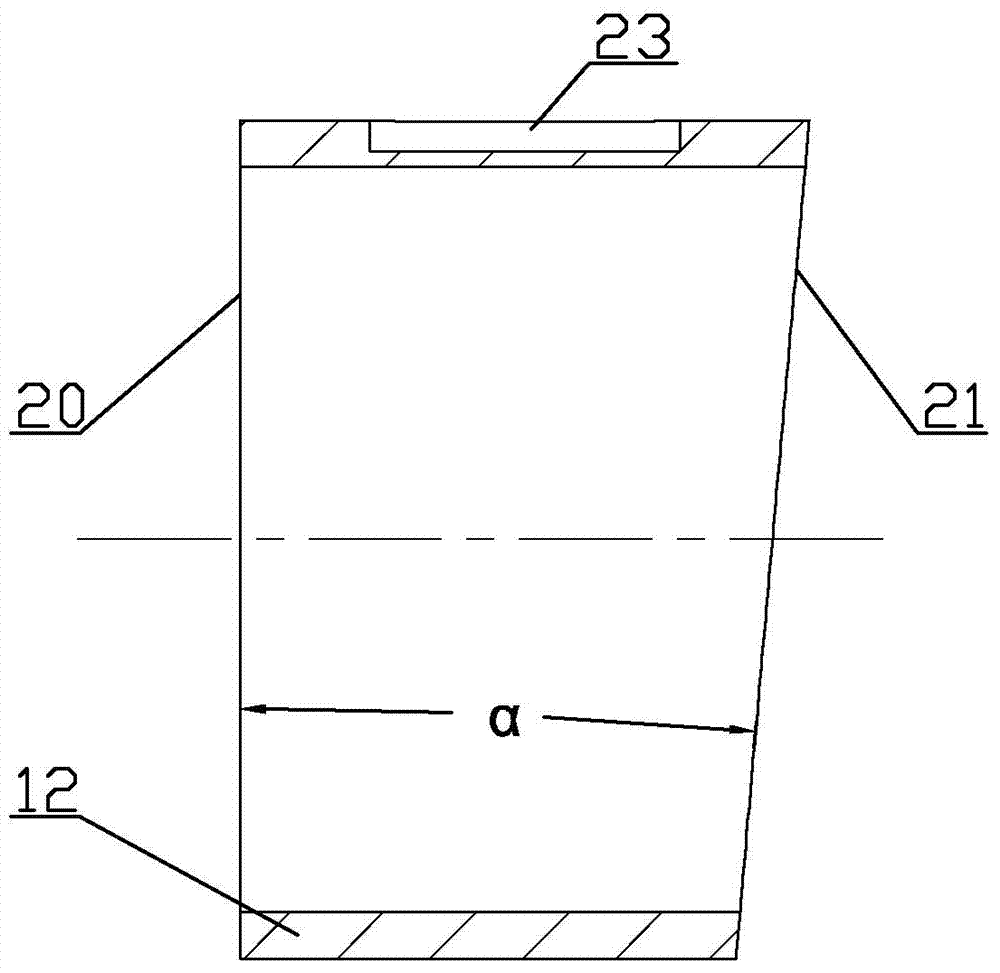

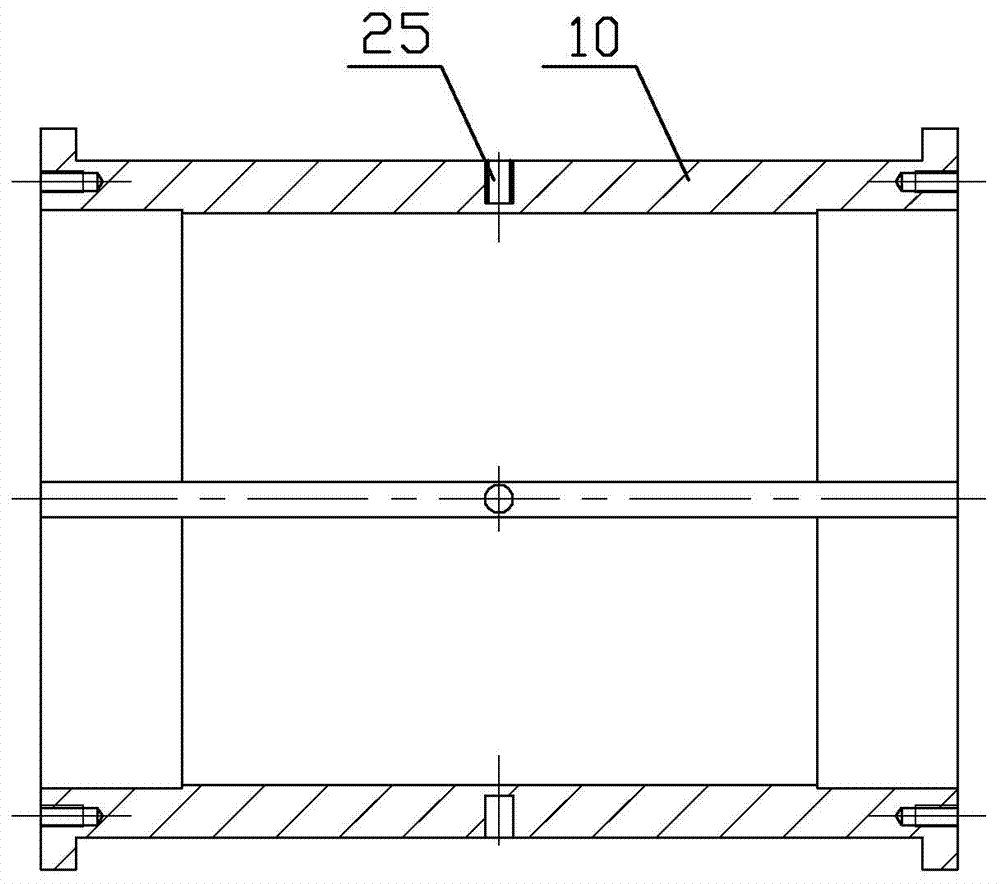

High-precision temperature control device for large-diameter crystal

The invention discloses a high-precision temperature control device for a large-diameter crystal, relates to a crystal temperature control device and aims at solving the problems that an existing heating device cannot realize precise temperature control of the large-diameter crystal and cannot maintain the temperature gradient of the crystal within 0.2 DEG C. A heater is fixed on the circumferential face of the excircle of a copper ring. The straight end faces of two inner check rings are arranged in an opposite mode, are arranged in the copper ring in a sleeved mode and are in detachable connection with the copper ring in the radial direction. A vertically-arranged crystal is fixed between the straight end faces of the two inner check rings. An inner fixed end cover is fixedly connected with the copper ring. A window glass sheet is fixed on the inclined end faces of the inner check rings in a sealing mode through the inner fixed end cover. The outer side of the heater is sleeved with an outer shell. The two ends of the outer shell are fixed with an outer fixed end cover. A temperature measuring thermal couple is fixed on the copper ring. A display instrument of the temperature measuring thermal couple is arranged on a temperature controller. The temperature measuring thermal couple is connected with the display instrument of the temperature measuring thermal couple through a wire. The display instrument transmits temperature to the temperature controller. The temperature controller is connected with the heater through a wire. The high-precision temperature control device for the large-diameter crystal is used for high-precision temperature control of the large-diameter crystal.

Owner:HARBIN INST OF TECH

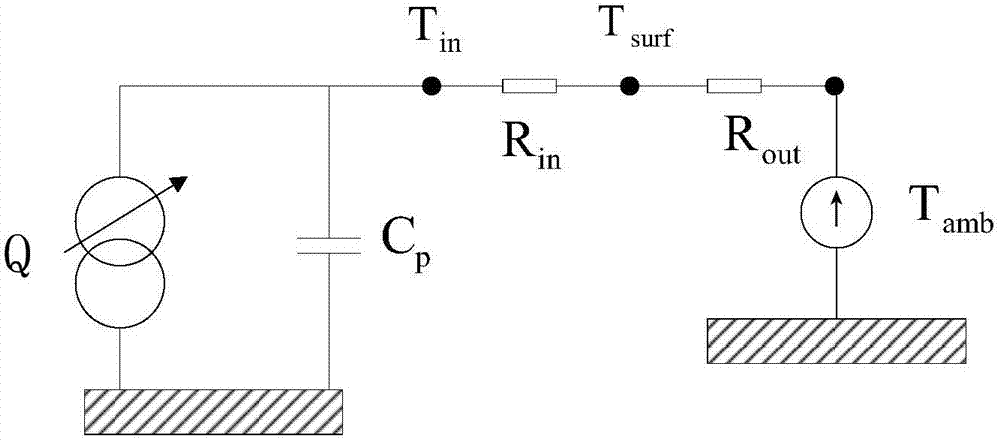

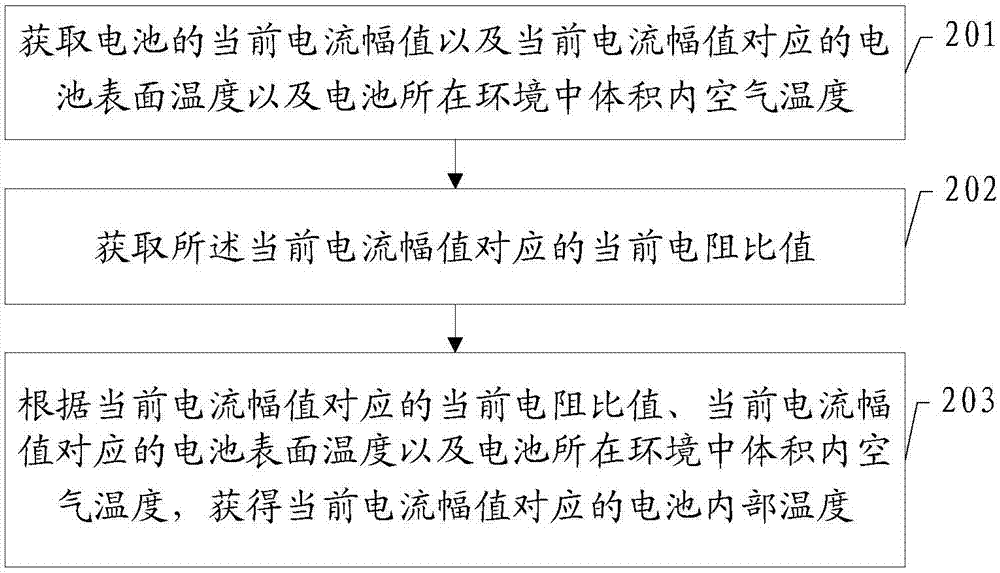

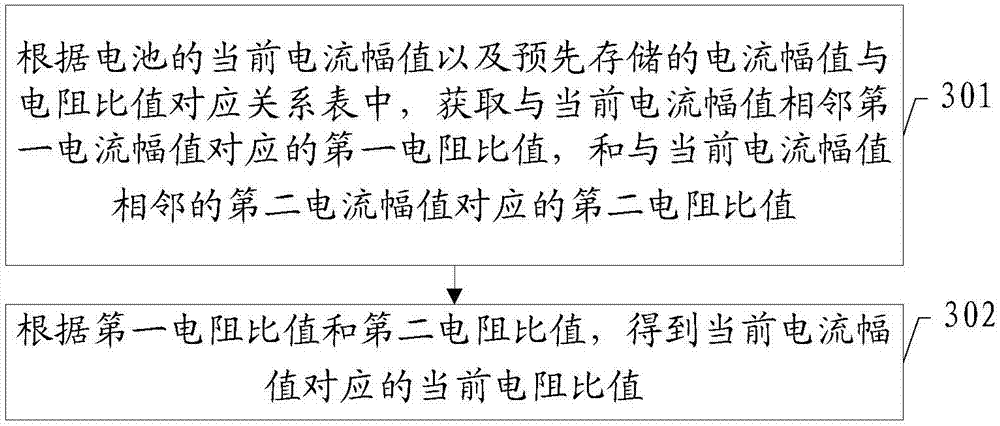

Method and device for obtaining internal temperature of cylindrical battery

ActiveCN107579300ALow efficiencyReduced service lifeSecondary cells servicing/maintenanceElectrical resistance and conductanceCurrent electric

The invention provides a method and a device for obtaining the internal temperature of a cylindrical battery. The method for obtaining the internal temperature of the cylindrical battery comprises thefollowing steps: obtaining a current current amplitude of the battery, a battery surface temperature corresponding to the current current amplitude, and the air temperature in a volume in an environment where the battery is located; obtaining the current resistance ratio Rin / Rout corresponding to the current current amplitude; obtaining the battery internal temperature corresponding to the current current amplitude according to the current resistance ratio Rin / Rout corresponding to the current current amplitude, the battery surface temperature corresponding to the current current amplitude and the air temperature of the volume in the environment where the battery is located. The invention enables a battery management system controller and a driver to obtain the accurate battery internal temperature, so that appropriate measures can be taken to avoid the risks of the lowering of the battery using efficiency, the reduction of the service life of the battery and the exploding of the battery due to the high temperature.

Owner:成都前锋电子股份有限公司

Polished-rod thermal imaging system for preventing failures in the operation of a sucker rod pump

ActiveUS10465495B2Sensing temperature is accurateAccurate temperature valueImage enhancementTelevision system detailsMicrocontrollerElectronic communication

A device for detecting temperatures of a rod on a well having a housing; a clamp to secure the housing to a post of the well; a thermal radiation sensor secured to the front end of the housing; a visual radiation sensor secured to the front end of the housing, the visual radiation sensor is vertically aligned with the thermal radiation sensor; a microcontroller system placed inside housing, the microcontroller system includes a microcontroller, a non-volatile memory, and a serial interface in electronic communication; a position device placed inside the housing; a wireless device placed inside the housing; output device placed in the interior cavity of the housing; the microcontroller is in electronic communication with the serial interface for communicating with the visible radiation sensor, the thermal radiation sensor, the output module, the wireless module, and the position module.

Owner:GASOLINEOG AUTOMATION

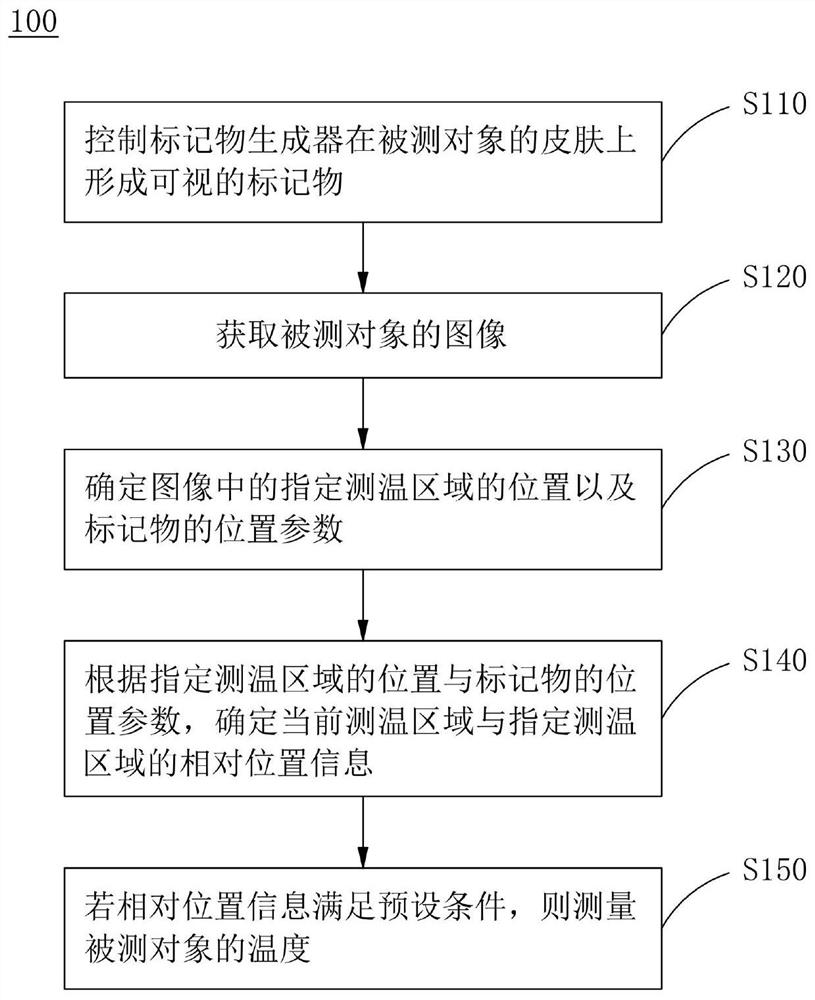

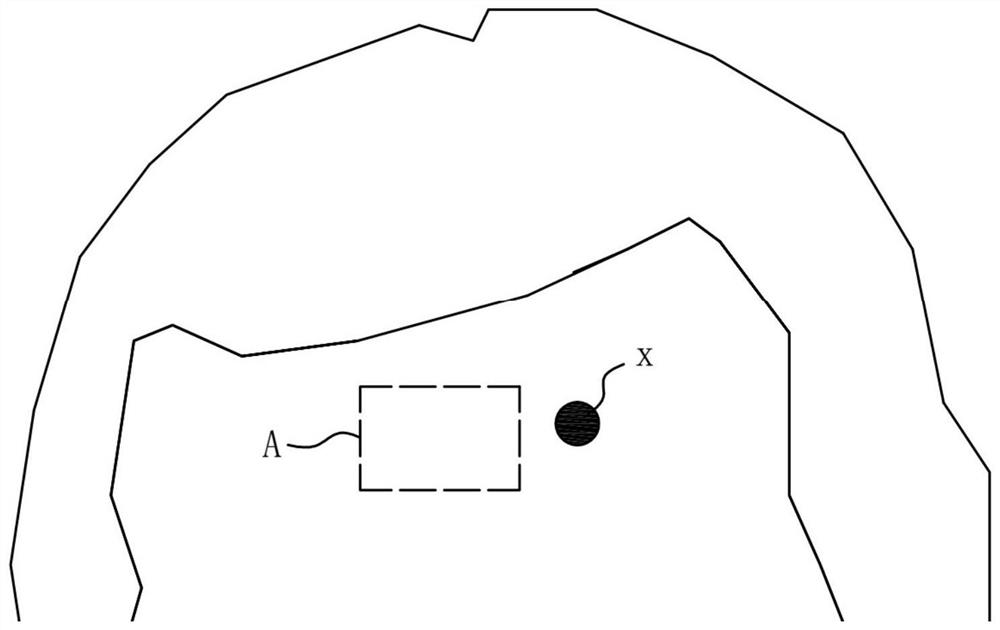

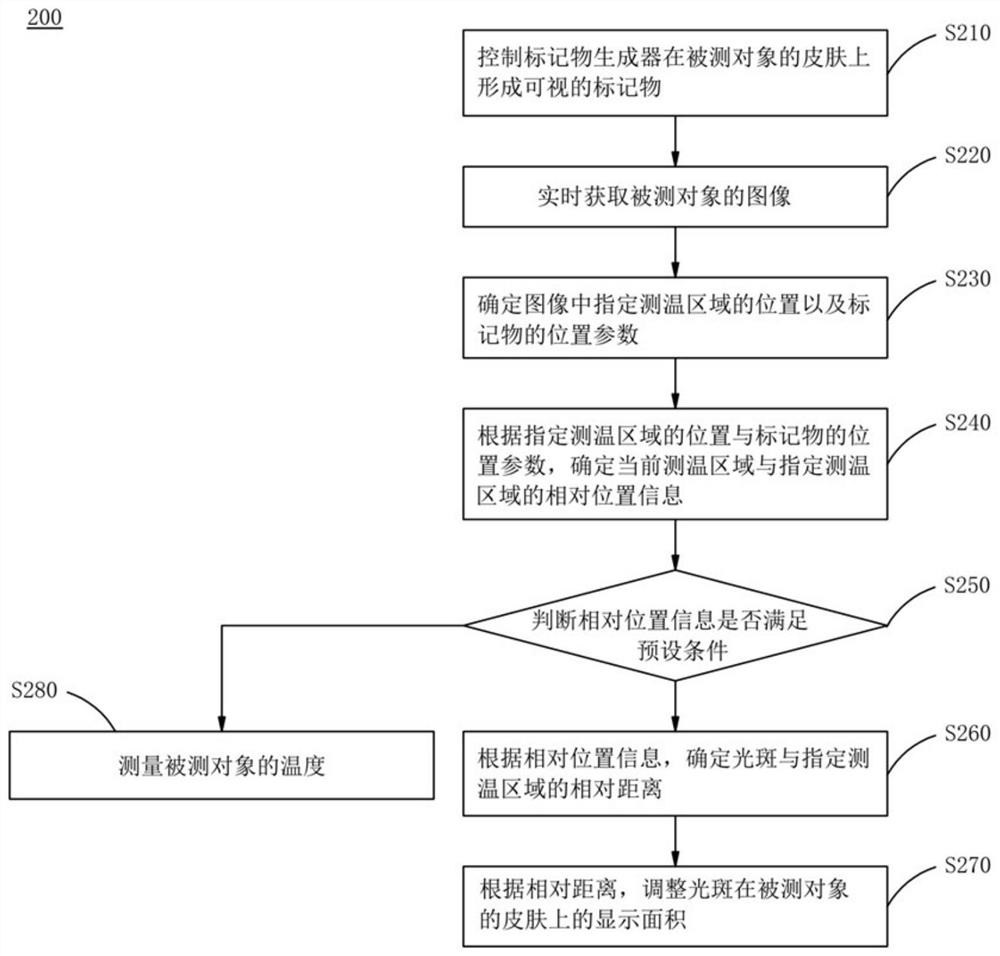

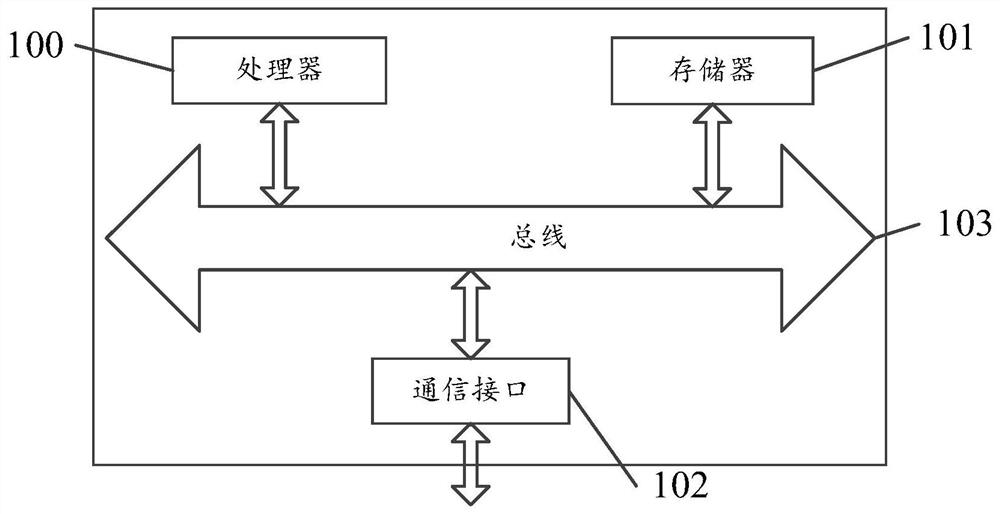

Temperature measurement method, temperature measurement control device, temperature measurement equipment and storage medium

ActiveCN111795748AAccurate temperature measurementAccurate temperature valueSensing radiation from moving bodiesUsing optical meansEngineeringMechanical engineering

The invention provides a temperature measurement method, a temperature measurement control device, temperature measurement equipment and a storage medium, the temperature measurement method comprisesthe steps: controlling a marker generator to form a visual marker on the skin of a measured object, wherein the marker is used for indicating a current temperature measurement area; acquiring an imageof the measured object; determining the position of a specified temperature measurement area in the image and the position parameter of the marker; determining relative position information of the current temperature measurement area and the specified temperature measurement area according to the position of the specified temperature measurement area and the position parameter of the marker; andif the relative position information meets the preset condition, measuring the temperature of the measured object. According to the temperature measurement method provided by the embodiment of the invention, the temperature of the temperature measurement part can be accurately measured, so that an accurate temperature value is obtained.

Owner:CHIPSEA TECH SHENZHEN CO LTD

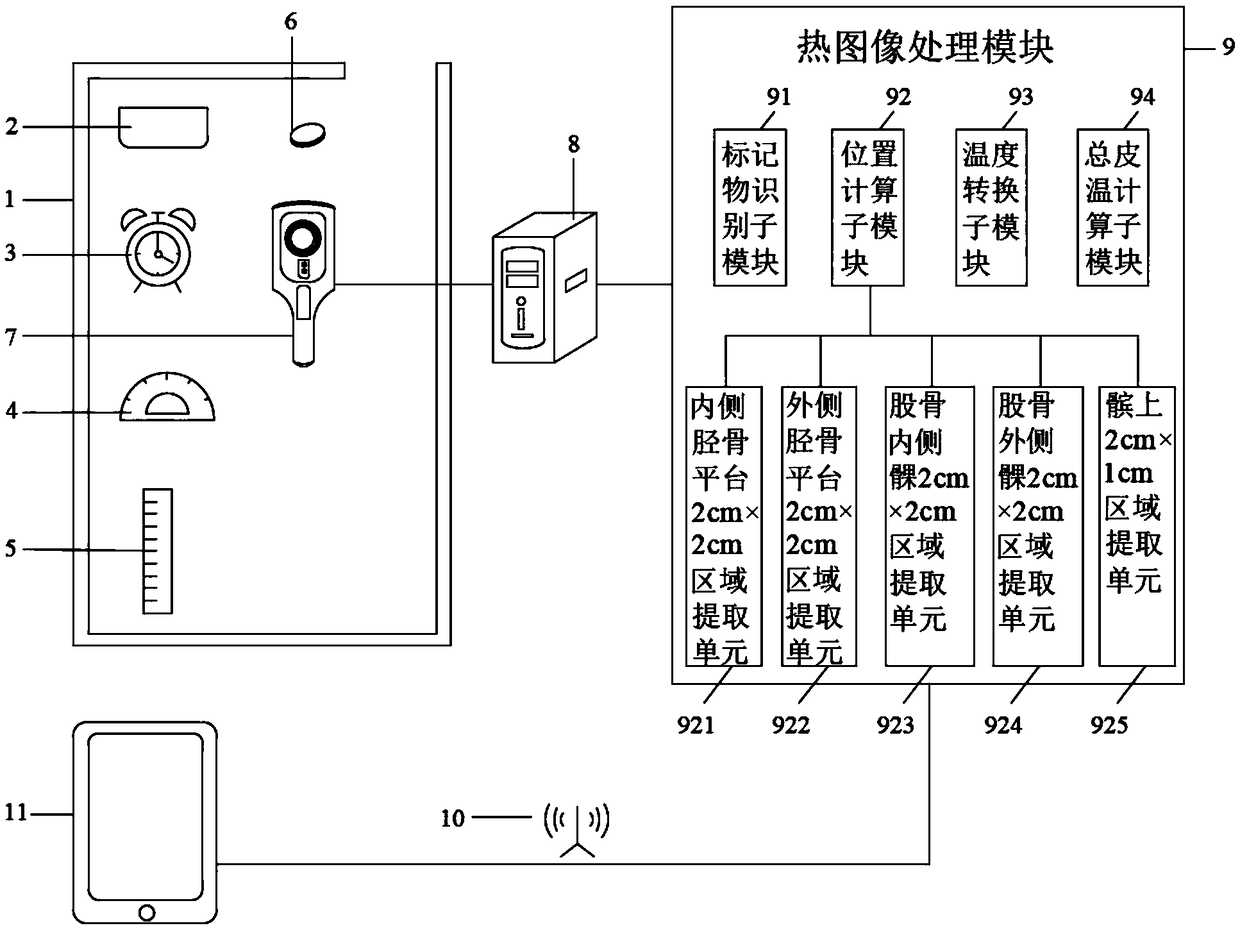

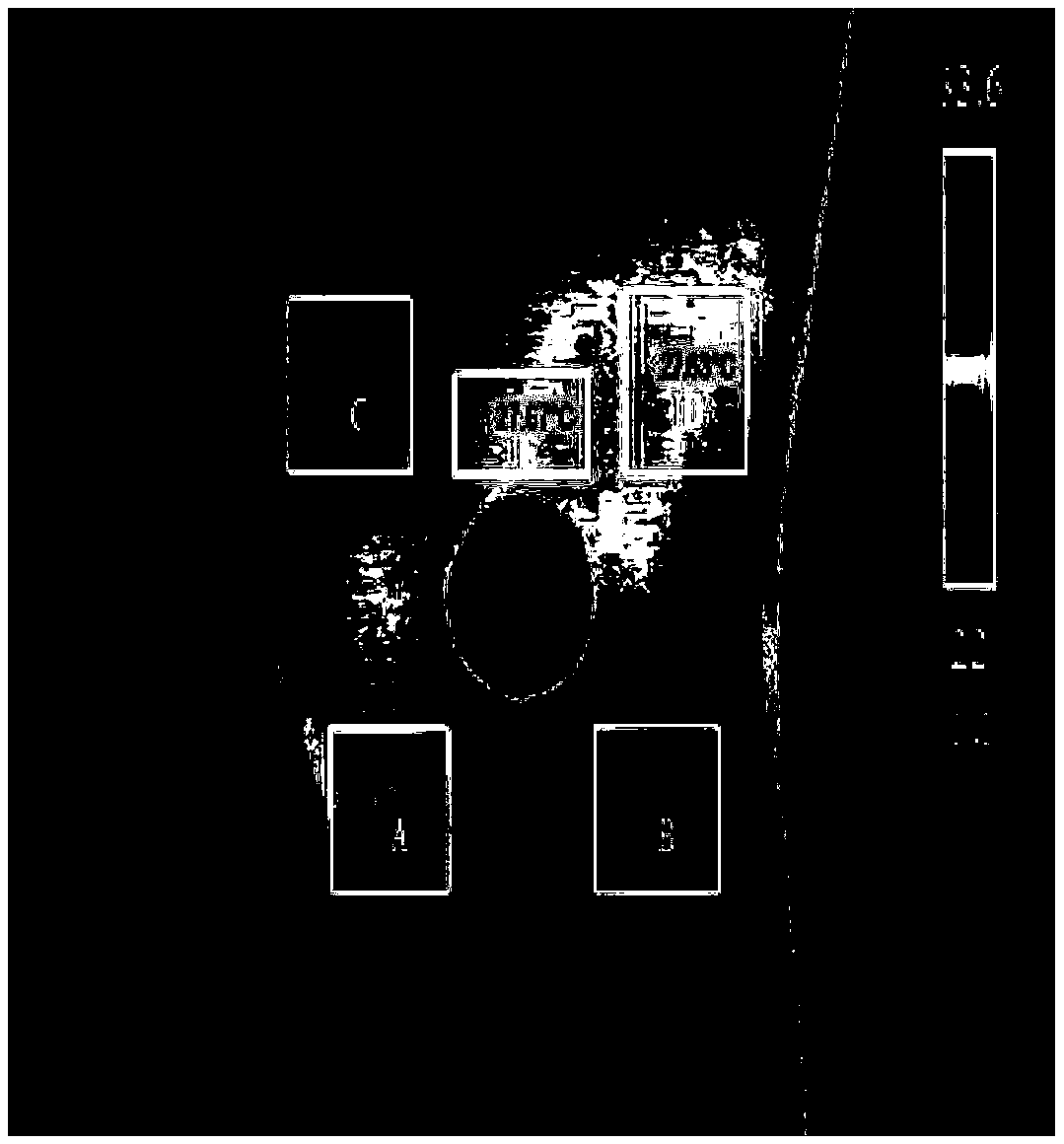

Knee osteoarthritis remote diagnosis and treatment system based on infrared imaging

ActiveCN109394180ASave time and moneyAvoid the possibility of subjective judgment errorDiagnostics using spectroscopySensorsNuclear medicineFemur

The invention relates to a knee osteoarthritis remote diagnosis and treatment system based on infrared imaging. The system comprises a detection room which is provided with a temperature control device, a timer, an angle calibrating component, a distance calibrating component, a marker and an infrared thermal imaging system, a computer, a thermal image processing module, a network and a diagnosisand treatment terminal, wherein the thermal image processing module is used for extracting position of the marker and taking the position as a reference, and the thermal image processing module is used for computing and extracting temperatures of the following five regions: medial tibial plateau 2cm*2cm region, lateral tibial plateau 2cm*2cm region, condylus medialis femoris 2cm*2cm region, condylus lateralis 2cm*2cm region and suprapatellar 2cm*1cm region; and by virtue of the network, results, which are extracted by the thermal image processing module, are transmitted to the diagnosis and treatment terminal, so that doctors can make out diagnosis furthermore. With the application of the remote diagnosis and treatment system provided by the invention, accurate knee joint skin temperaturevalues of patients with knee osteoarthritis can be remotely provided for doctor experts, so as to help the doctor experts to make diagnosis and treatment scheme early and to benefit patients.

Owner:SHUGUANG HOSPITAL AFFILIATED WITH SHANGHAI UNIV OF T C M

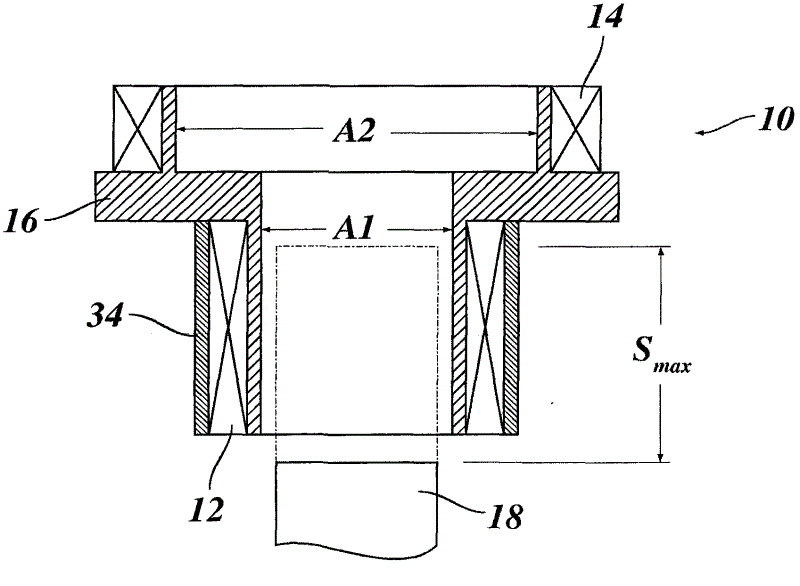

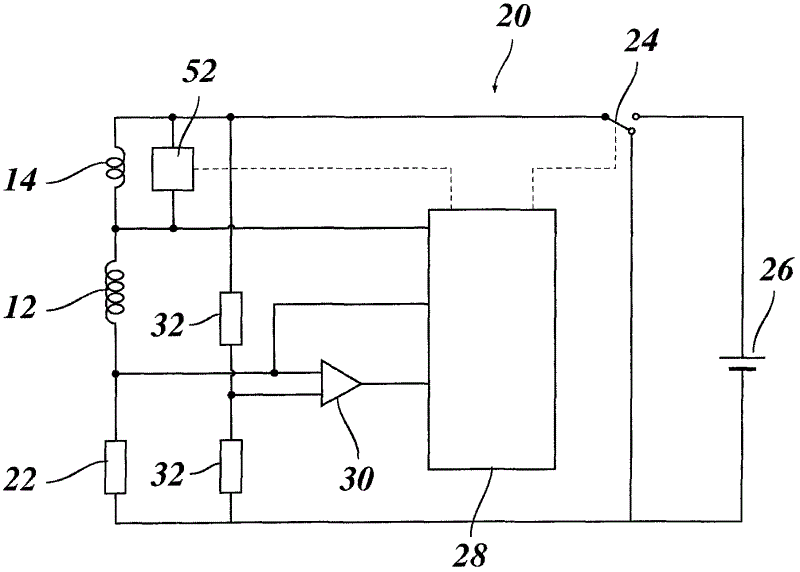

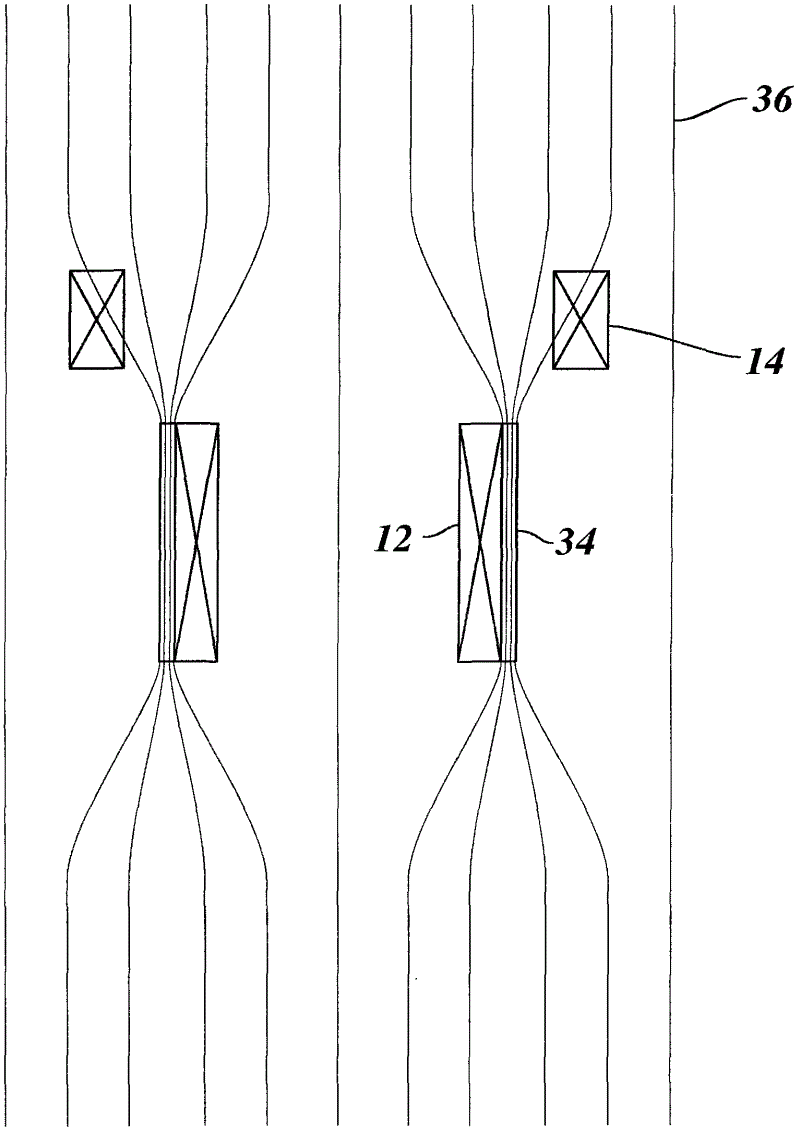

Inductive position sensor

InactiveCN102620752AHigh precisionAccurate temperature valueThermometers using electric/magnetic elementsUsing electrical meansPosition sensorInductance

The measuring device has a measuring plunger (18) that is relatively movable with respect to a measuring coil (12). A measuring circuit measures path of the plunger based on inductance of the coil, and an electronic evaluation and control unit calculates distance traveled by the plunger as a function of the measured inductance. A temperature sensor measures temperature of the plunger and the control unit adjusts temperature of the plunger based on the measured inductance.

Owner:ROLLAX GMBH & CO KG

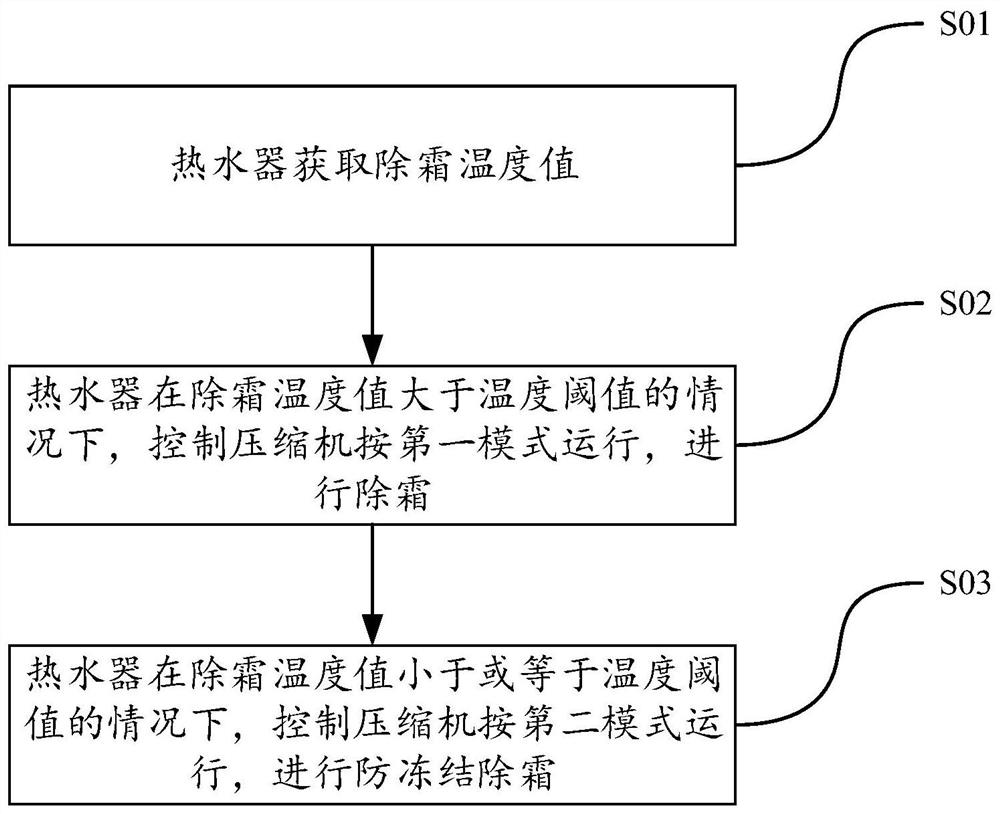

Defrosting method and device for water heater, water heater and storage medium

ActiveCN113847741AAdjust operating frequencyAvoid frequent start and stopFluid heatersCorrosion preventionProcess engineeringControl theory

The invention relates to the technical field of intelligent household appliances, and discloses a defrosting method for a water heater. The defrosting method comprises the following steps of acquiring a defrosting temperature value; under the condition that the defrosting temperature value is greater than a temperature threshold value, the compressor is controlled to operate in a first mode, and defrosting is conducted; and under the condition that the defrosting temperature value is less than or equal to the temperature threshold value, the compressor is controlled to operate in a second mode, and anti-freezing defrosting is conducted. and whether the operation mode of the compressor needs the defrosting mode of anti-freezing protection or not is judged by comparing the defrosting temperature value with the temperature threshold value, therefore, the running frequency of the compressor can be adjusted by setting a higher temperature threshold value under the condition that the heat exchanger is not frozen, so that the compressor can be always in a running state in the whole defrosting process without shutdown, and the stability of the system is improved. The invention further discloses a defrosting device for the water heater, the water heater and a storage medium.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +2

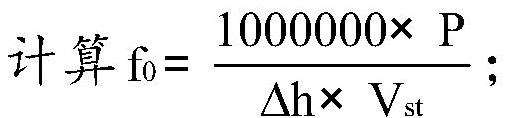

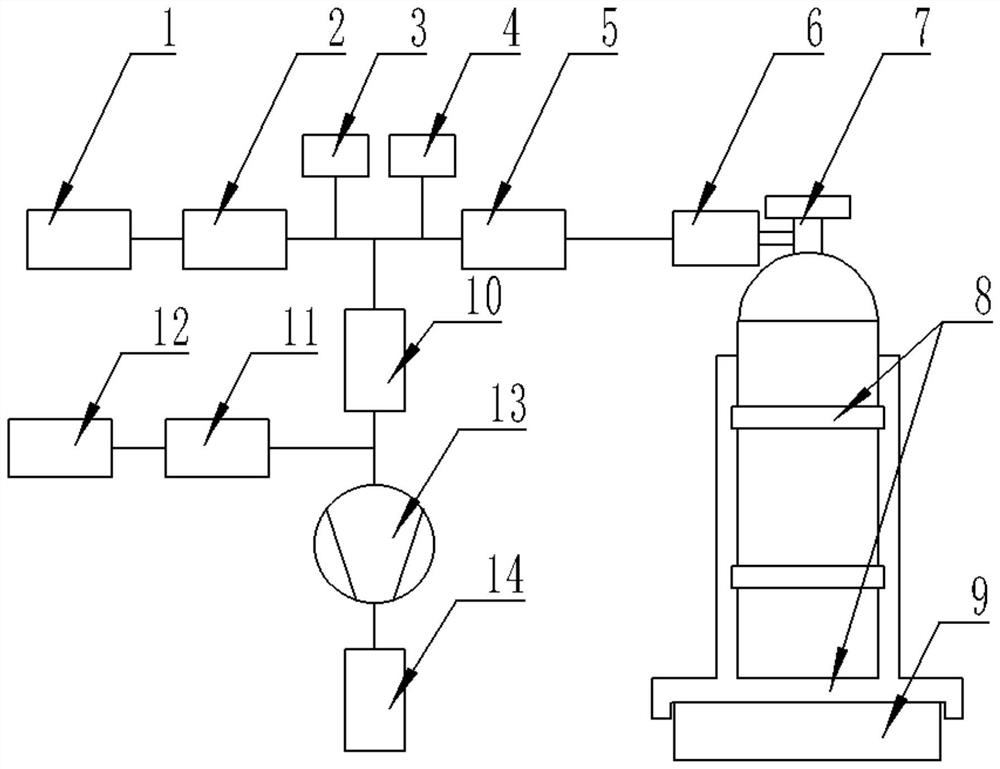

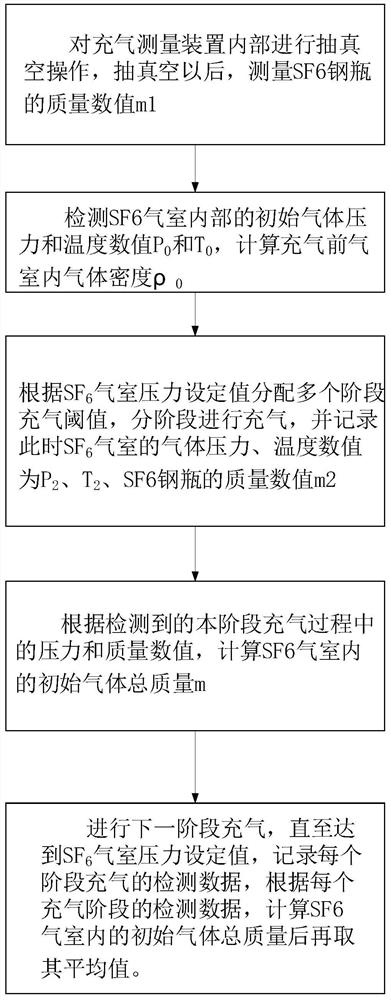

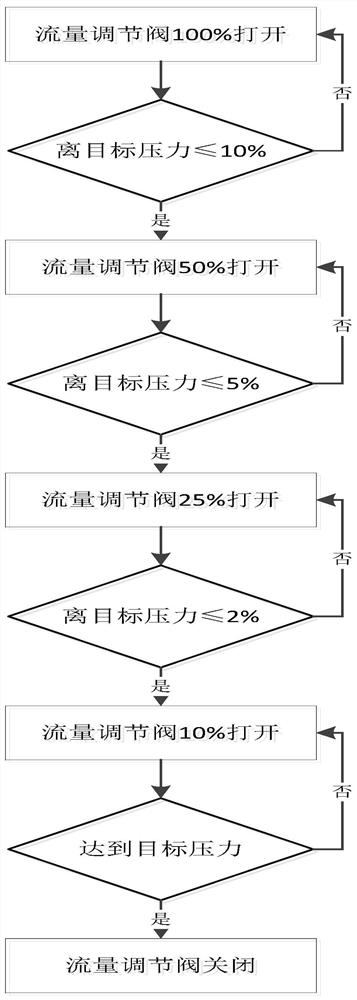

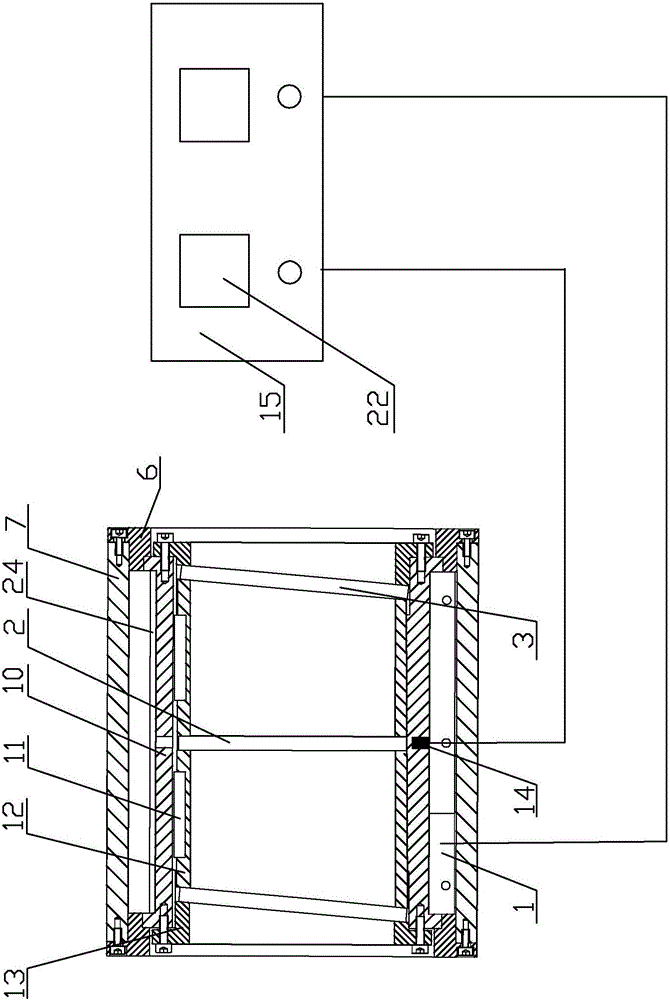

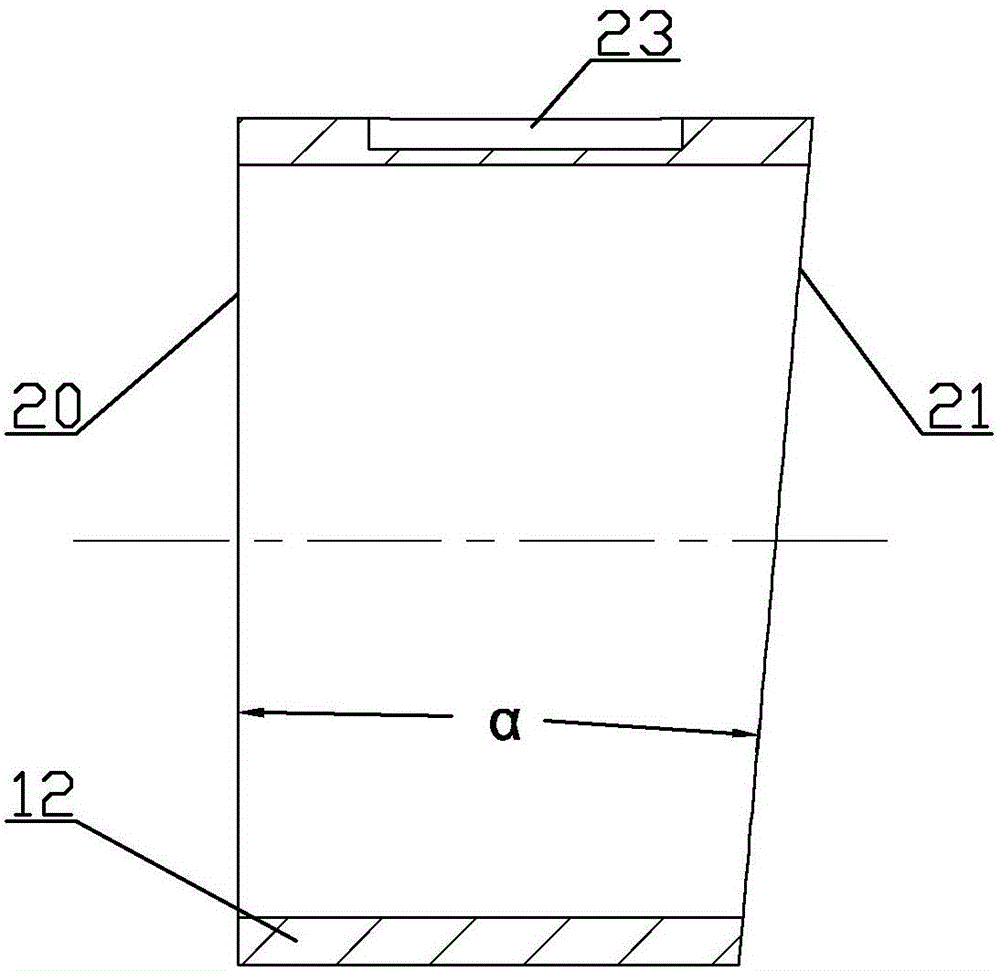

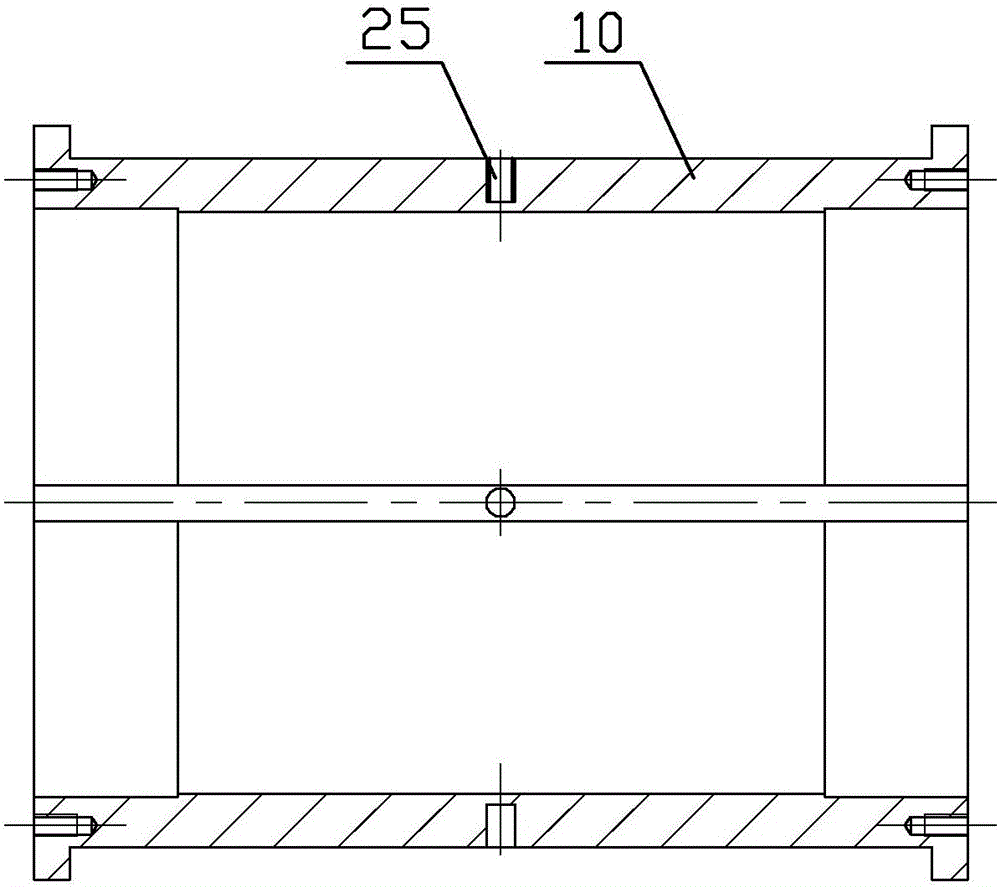

Gradient inflatable SF6 gas chamber volume measurement method based on weighing method

ActiveCN112556774AEliminate Measurement Accuracy LimitationsHigh precisionVolume measurement apparatus/methodsContainer filling methodsEngineeringElectric equipment

The invention discloses a gradient inflatable SF6 gas chamber volume measurement method based on a weighing method, belongs to the technical field of SF6 measurement equipment, and solves the problemof how to accurately and precisely measure and calculate the gas amount in an SF6 gas chamber of electrical equipment. A plurality of stages of inflation thresholds are distributed according to a pressure set value of the gas chamber, the gas chamber is inflated in stages, data are measured, the volume of the gas chamber and the internal original gas mass are calculated in each stage, and then theaverage value of the data measured in each stage is taken, so that the problem that when the gas chamber is inflated due to measurement accuracy limitation of a pressure sensor, large accidental errors are caused by one-time measurement from an initial value to a set value is solved, and the accuracy of a calculation result is improved; and the gas real-time pressure can be accurately measured, the inflation flow can be controlled when the gas real-time pressure is close to the set pressure value, the pressure sensor can conduct detection when the gas is stable, detection data are more accurate, and potential safety hazards caused by too high gas pressure due to the fact that the gas chamber is filled with too much gas are avoided.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

A large aperture crystal defect detection method and device

ActiveCN103808694BHigh temperature sensitivityReduced multiplication efficiencyAnalysis by material excitationGlass chipEngineering

The invention discloses a large-diameter crystal defect detection method and a large-diameter crystal defect detection device, solving the problem that at present, no method and device for detecting the growth defects of a crystal by using a frequency multiplication efficiency measurement method in a constant temperature state are available for the crystal. The large-diameter crystal defect detection device with the crystal is arranged inside a defect detection light path of the detection device; according to the device, a heater is fixed outside a copper ring; two inner baffle rings are arranged inside the copper ring in a sleeving mannerand are in detachable connection with the copper ring; a vertically arranged large-diameter crystal is fixed between the two baffle rings; inner fixing end covers are fixedly connected with the copper ring; window glass sheets are fixed on inclined end surfaces of the inner baffle rings through the inner fixing end covers; the outer side of the heater is sleeved with a shell; two ends of the shell are fixed with the outer fixing end covers; a temperature thermocouple is fixed on the copper ring; the temperature thermocouple is connected with a display meter of the temperature thermocouple through a lead; the display meter is used for outputting temperature to a temperature controller; the temperature controller is connected with the heater through a lead. The method and the device are applied to large-diameter crystal defect detection.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com