Temperature correction method, cooking utensil and medium

A technology for cooking utensils and temperature correction, used in thermometer testing/calibration, thermometers, instruments, etc., can solve problems such as inaccurate temperature measurement, cooking temperature control deviation, temperature sensor aging, etc., to ensure cooking quality and avoid excessive temperature. High, the effect of eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

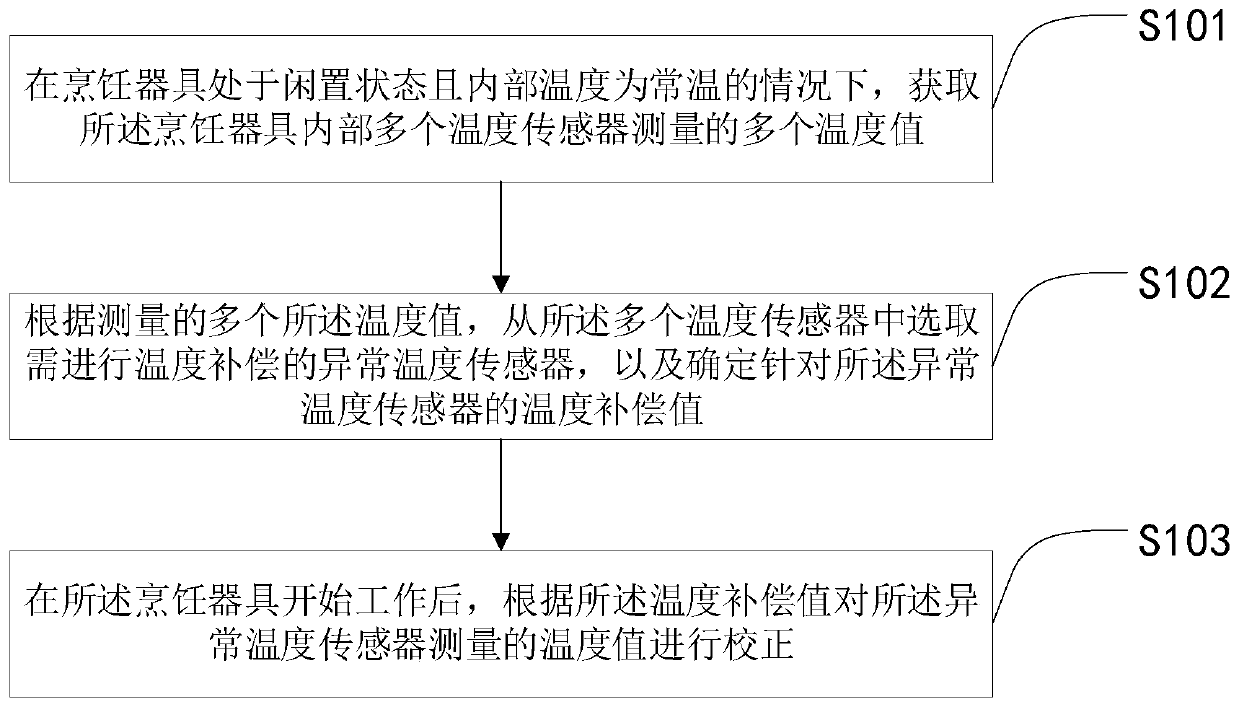

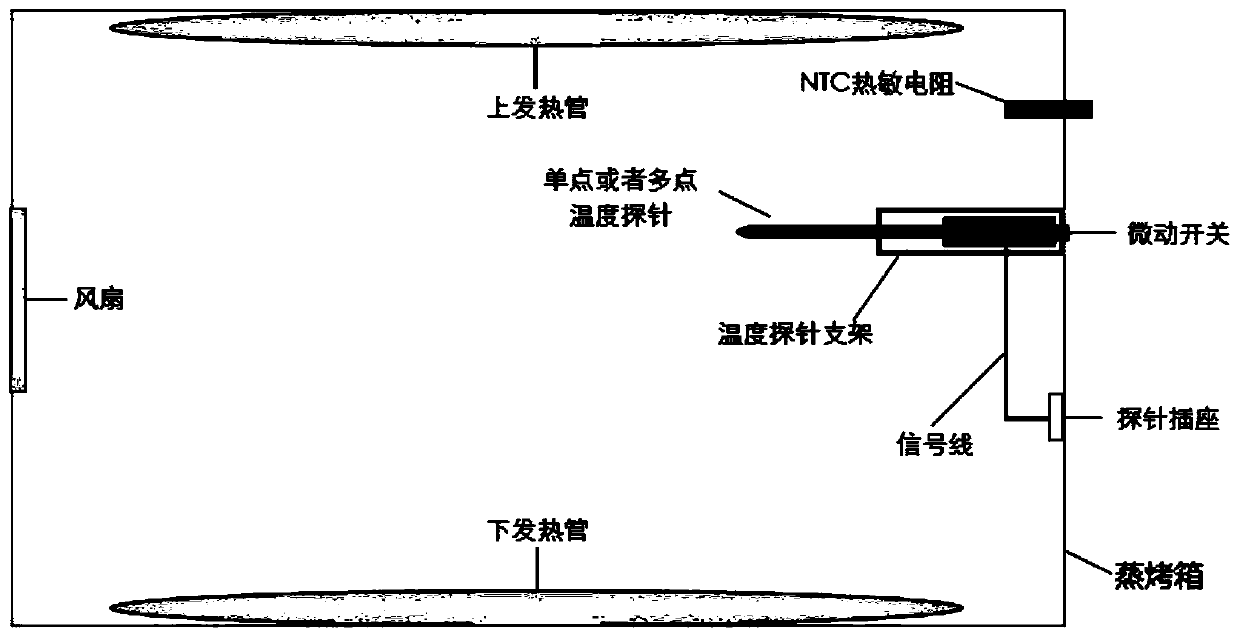

[0108] The plurality of temperature sensors mentioned in step S101 include a cavity temperature sensor disposed on the cavity of the steam oven and a temperature probe temperature sensor disposed on the temperature probe, refer to image 3 And its description, assuming that the steam oven has been able to detect that the temperature probe is placed on the temperature probe bracket, and the temperature probe has been inserted into the temperature probe socket, the steam oven can read the temperature of the temperature probe. The temperature probe is a single-point temperature probe, then the temperature calibration method may include the following steps:

[0109] a. It is detected that the steam oven is currently in a non-working state (ie idle state).

[0110] b. When it is detected that the temperature probe is not inserted into the temperature probe bracket, exit the calibration process without entering the next step. Otherwise, if it is detected that the temperature probe ...

specific Embodiment 2

[0116] The multiple temperature sensors mentioned in step S101 include a cavity temperature sensor set on the cavity of the steam oven and a temperature probe temperature sensor set on the temperature probe, refer to image 3 And its description, assuming that the steam oven has been able to detect that the temperature probe is placed on the temperature probe bracket, and the temperature probe has been inserted into the temperature probe socket, the steam oven can read the temperature of the temperature probe. The temperature probe is a three-point temperature probe, then the temperature correction method may include the following steps:

[0117] a. It is detected that the steam oven is currently in a non-working state (ie idle state).

[0118] b. When it is detected that the temperature probe is not inserted into the temperature probe bracket, exit the calibration process without entering the next step. Otherwise, if it is detected that the temperature probe has been inserte...

specific Embodiment 3

[0124] The multiple temperature sensors mentioned in step S101 include a cavity temperature sensor set on the cavity of the steam oven and a temperature probe temperature sensor set on the temperature probe, refer to image 3 And its description, assuming that the steam oven has been able to detect that the temperature probe is placed on the temperature probe bracket, and the temperature probe has been inserted into the temperature probe socket, the steam oven can read the temperature of the temperature probe. The temperature probe is a five-point temperature probe, and the temperature correction method may include the following steps:

[0125] a. It is detected that the steam oven is currently in a non-working state (ie idle state).

[0126] b. When it is detected that the temperature probe is not inserted into the temperature probe bracket, exit the calibration process without entering the next step. Otherwise, if it is detected that the temperature probe has been inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com