A large aperture crystal defect detection method and device

A technology of crystal defect and detection device, which is applied in the direction of material excitation analysis, etc., to achieve the effects of high control accuracy, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

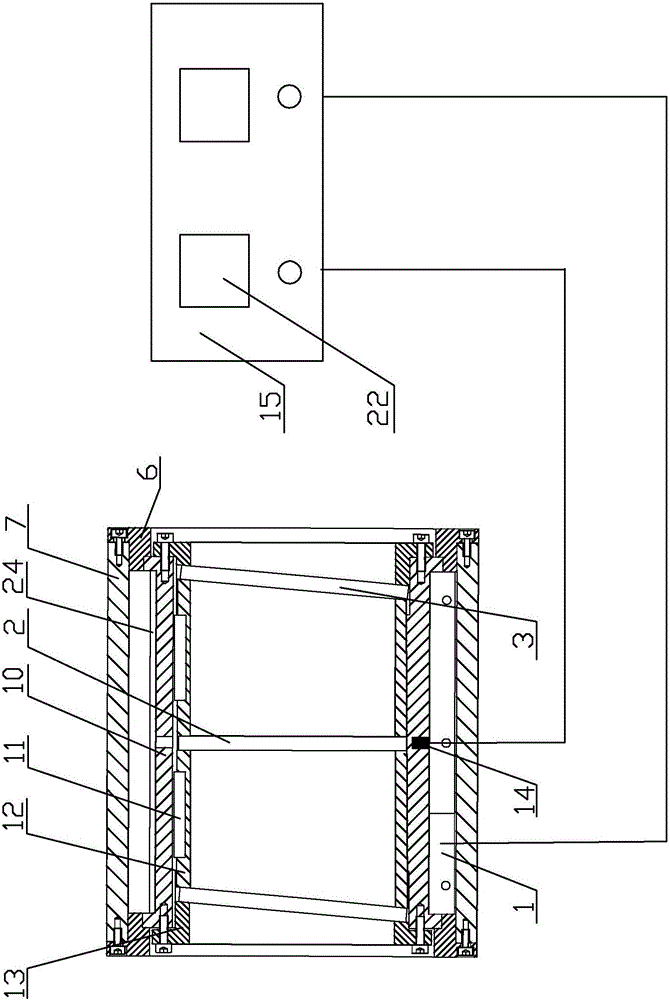

[0019] Specific implementation mode one: combine figure 1 and Figure 4 To illustrate, a large-aperture crystal defect detection method in this embodiment, the method includes the following steps:

[0020] Step 1. First, the crystal 2 is loaded into the large-diameter crystal defect detection device 26, and then the large-diameter crystal defect detection device 26 is set in the detection optical path, and the temperature of the temperature controller 15 in the large-diameter crystal defect detection device 26 is controlled. value, so that crystal 2 is heated or cooled with a temperature gradient of ±0.1°C, and the frequency doubling efficiency values of crystal 2 at different temperatures are obtained, and the temperature value of crystal 2 under the condition of the highest frequency doubling conversion efficiency is obtained by Gaussian fitting method , which is the best matching temperature, the temperature value of the temperature controller 15 is set as the best match...

specific Embodiment approach 2

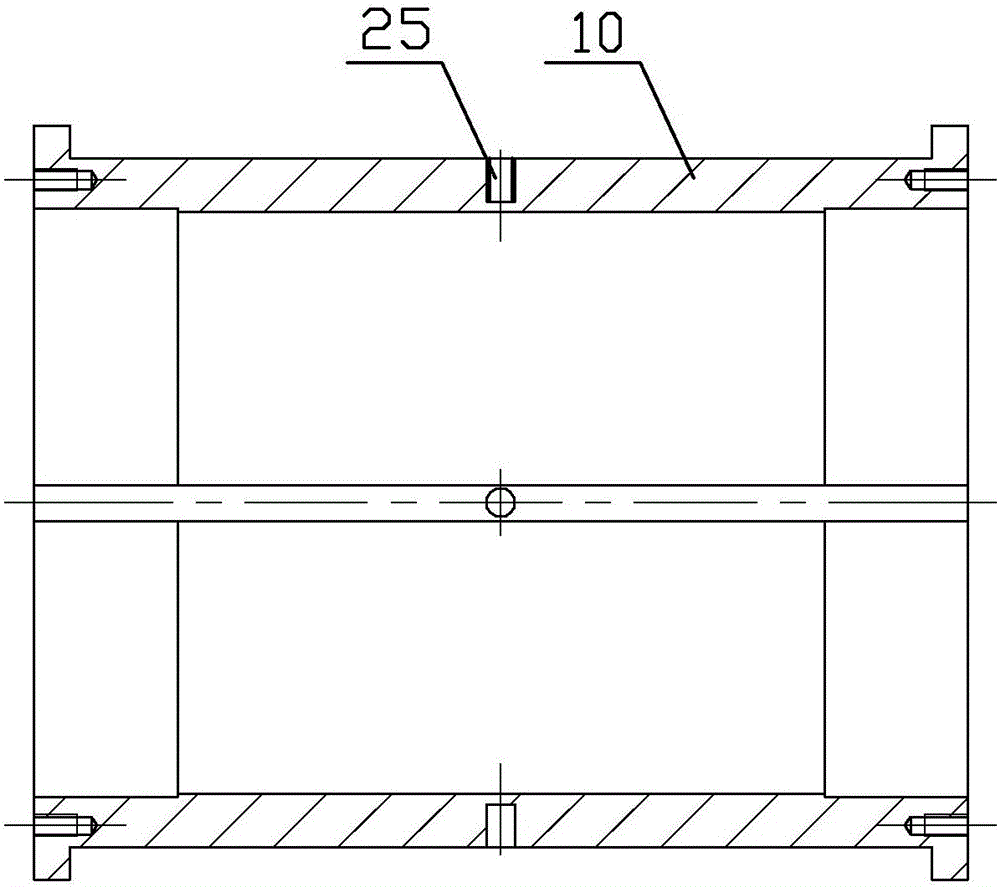

[0024] Specific implementation mode two: combination Figure 1-Figure 3 Explanation, the implementation of this embodiment is a large-diameter crystal defect detection device adopted in the method of the first embodiment, and the large-diameter crystal defect detection device 26 includes a heater 1, a casing 7, a copper ring 10, a temperature control system, two An inner retaining ring 12, two window glass sheets 3, two inner fixed end caps 13 and two outer fixed end caps 6, the temperature control system includes a temperature measuring thermocouple 14 and a temperature controller 15;

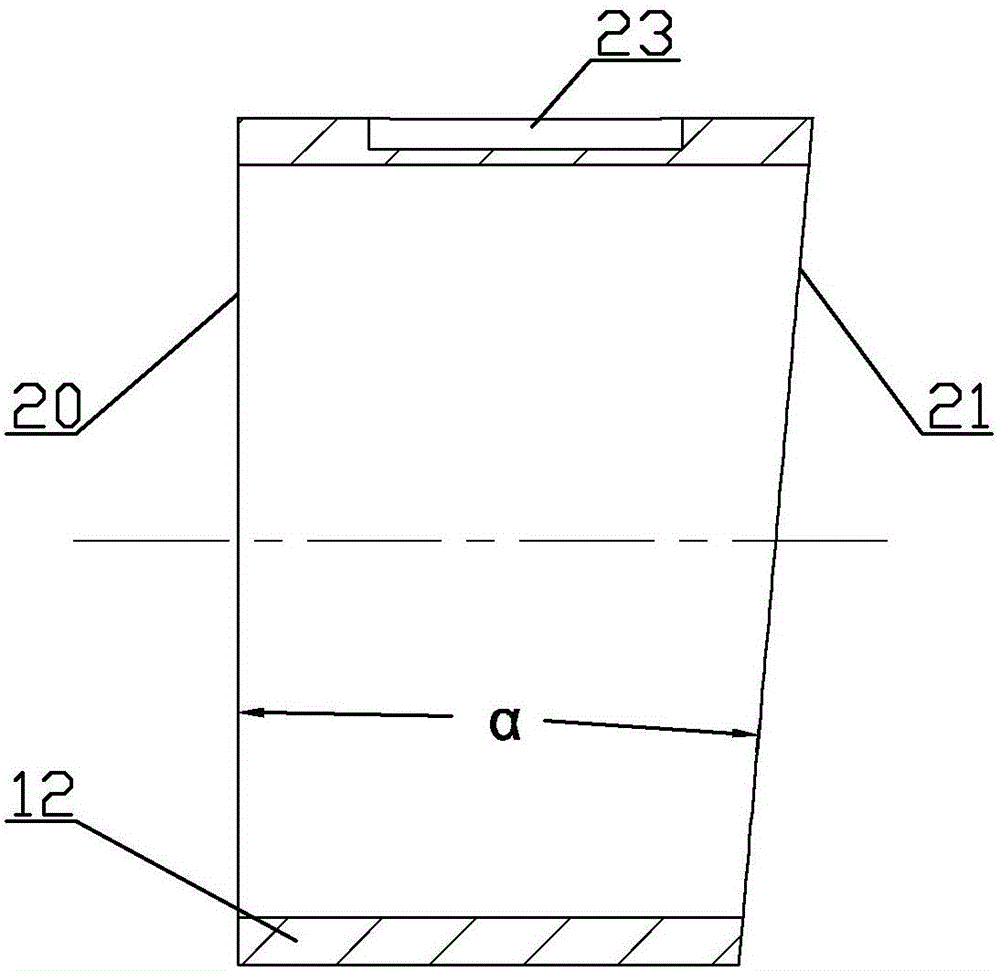

[0025] One of the two opposite end faces of each inner retaining ring 12 is a straight end face 20, and the other end face is an oblique end face 21. The outer circumferential surface of the copper ring 10 is fixed with a heater 1, and the two inner retaining rings 12 The straight end faces 20 are oppositely arranged and fitted inside the copper ring 10, the two inner retaining rings 12 are ra...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 1 and figure 2 Explain that the outer walls of the two inner retaining rings 12 in this embodiment are respectively provided with a keyway 23, and the two keyways 23 are arranged on the same straight line (to ensure that the window glass sheet 3 is placed in parallel), and the inner wall of the copper ring 10 is along the length There is a through groove 24 in the direction, the through groove 24 corresponds to the two key grooves 23, each corresponding key groove 23 and the through groove 24 are equipped with a key 11, and the two inner retaining rings 12 each pass through a key 11 and the copper ring 10 The connection is detachable in the radial direction, and the outer sidewalls of the two inner retaining rings 12 are in close contact with the inner sidewalls of the copper ring 10 . The connection is stable and convenient, and at the same time it is easy to install. The undisclosed technical features in this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com