Heat-resisting ceramic-armored high-temperature thermocouple and manufacturing method thereof

A thermocouple and ceramic technology, applied in thermometers, thermometers, measuring devices, etc., which are directly sensitive to heat, electric/magnetic components, can solve the problems of reduced service life and performance, easy oxidation failure, use, etc. Increased sensitivity, overcomes poor thermal conductivity, and reduces manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

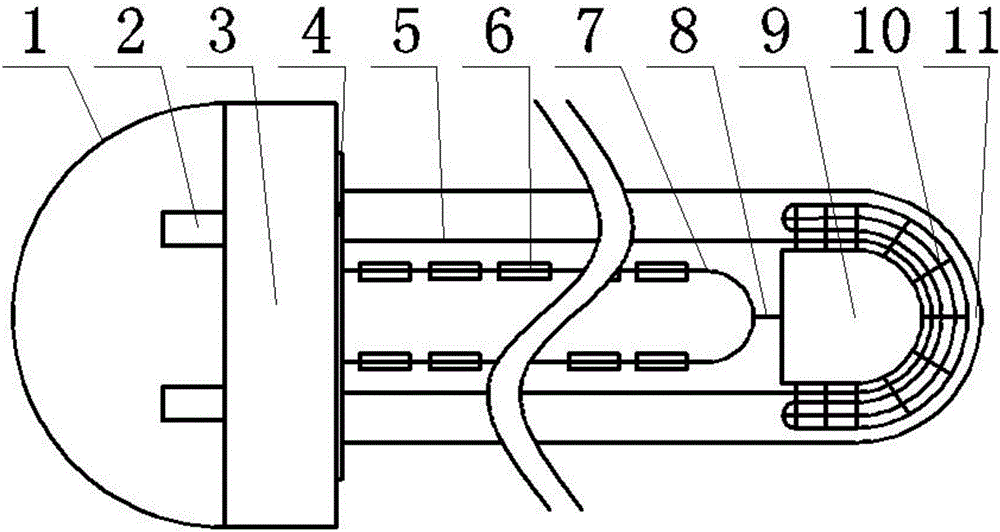

[0024] A heat-resistant ceramic armored high-temperature thermocouple, consisting of a junction box 3, a case 1 fixed on the edge of the junction box 3, a terminal post 2 fixed on the junction box 3, a protective sleeve 11, and a protective sleeve 11 The sealing tape 4 between the junction box 3, the insulating layer 5 fixed on the inner surface of the protective sleeve 11, the lead wire 8, the thermocouple wire 7 connected to the lead wire 8 and the terminal 2 respectively, and the thermocouple wire 7 inserted on the Insulator 6, wherein: the protective sleeve 11 is made of alumina-based high-temperature ceramics, and a carbon fiber basket 10 is integrated in the ceramic body, and the side of the carbon fiber basket 10 facing the inside of the protective sleeve 11 exceeds the inner surface of the protective sleeve 11 The insulating layer 5; the inner end of the protective sleeve 11 is also provided with a heat conduction block 9, the heat conduction block 9 is made of pure tit...

Embodiment 2

[0041] The present embodiment structure and most of method steps are all identical with embodiment 1, difference is as follows:

[0042] The airtight space formed by the high-temperature glue and the junction box 3 is a protective atmosphere environment, and the pressure of the package is 2×10 4 Argon in Pa;

[0043] 1) Preparation of raw materials, equipment and tooling

[0044] ①Raw materials: prepare a sufficient amount of alumina-based ceramic powder with a mass fraction of 10% aluminate binder, a sufficient amount of carbon fiber, intersperse and fix the insulator 6 according to conventional technology, and connect the positive and negative pole wires through the intermediate connection point Ni-CrSi-NiSi thermocouple wire 7, sufficient amount of pure titanium powder, lead wire 8 braided by silicon carbide ceramic fiber, junction box 3 with cover 1 and terminal 2 installed, high temperature glue HN-767A;

[0045] ②Equipment and tooling: prepare vacuum ceramic sintering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com