Real-time temperature monitoring system and method for integrated circuit testing device

A technology for testing equipment and integrated circuits, which is applied in the field of real-time temperature monitoring systems for integrated circuit testing equipment, can solve problems such as test accuracy offset, test deviation, and test equipment stability degradation, achieve accurate current temperature values, and avoid detection errors. and bias, improving stability and fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

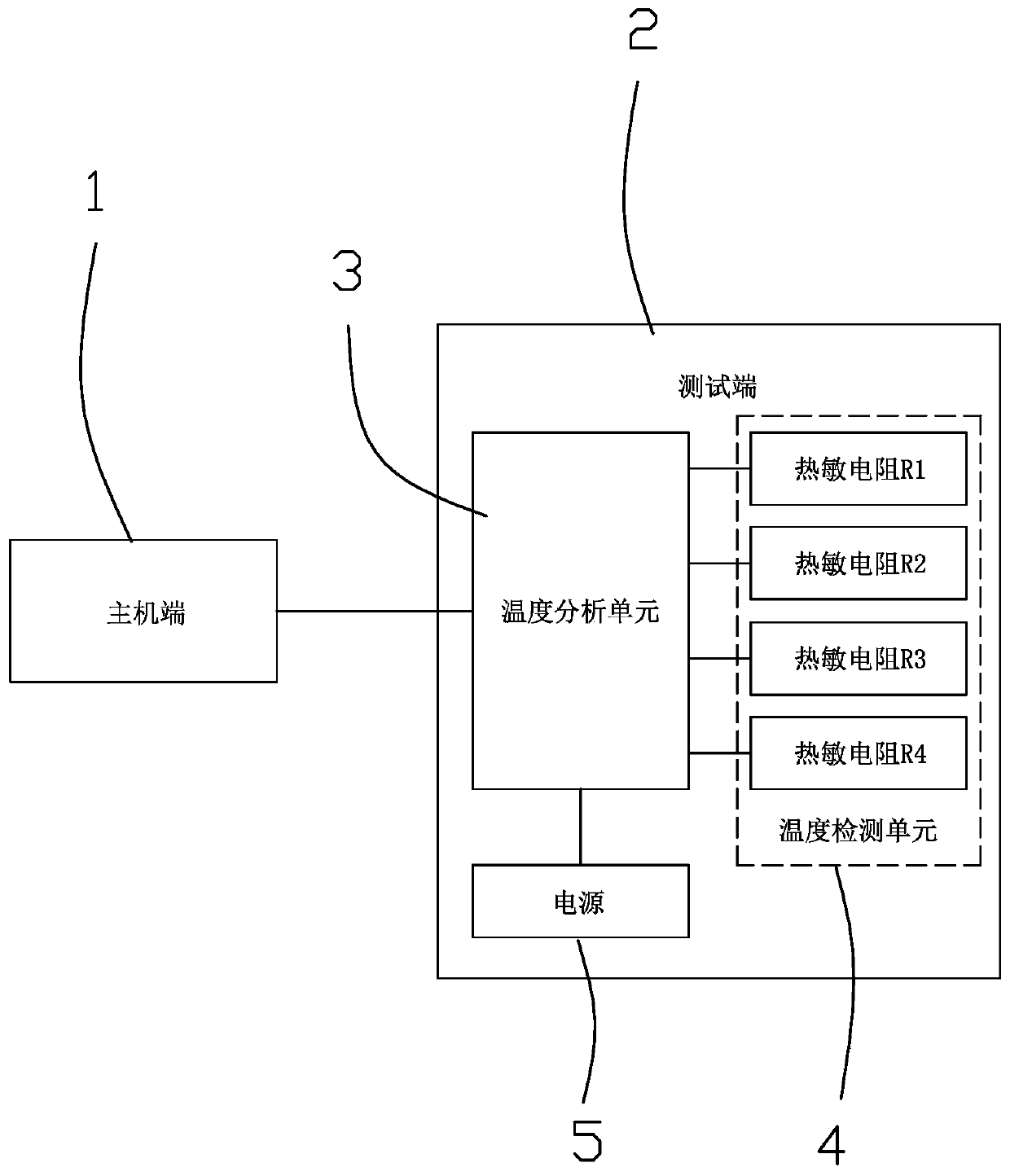

[0041] In this embodiment, a real-time temperature monitoring system for integrated circuit testing equipment, such as figure 1 As shown, it includes a host terminal 1 and a test terminal 2. The test terminal includes several temperature detection units 4 and temperature analysis units 3. The temperature detection units are respectively connected to the temperature analysis units, and the temperature analysis units are connected to the host terminal.

[0042]The temperature detection unit is used to detect the internal temperature of the integrated circuit testing equipment. There are multiple temperature detection units. Resistor R2, thermistor R3 and thermistor R4, thermistor R1, thermistor R2, thermistor R3, and thermistor R4 are respectively connected to the temperature analysis unit. The thermistor adopts three-wire PT100, which has more accurate and sensitive detection, fast thermal response and longer service life.

[0043] The temperature analysis unit is used to read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com