High-precision temperature control device for large-diameter crystal

A temperature control device and high-precision technology, applied in laser parts, electrical components, phonon exciters, etc., can solve the problem of inability to achieve accurate temperature control of large-diameter crystals, and achieve simple structure, low temperature gradient, and manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

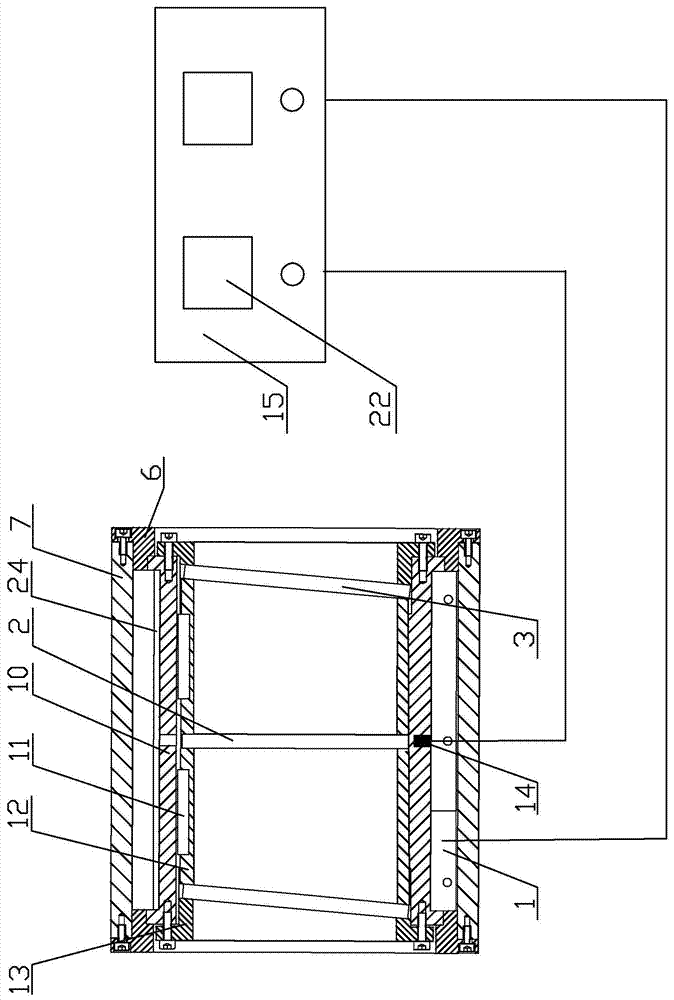

[0015] Specific implementation mode one: combine Figure 1-Figure 3 Explain that a high-precision temperature control device for a large-diameter crystal in this embodiment includes a heater 1; the high-precision temperature control device for a large-diameter crystal also includes a casing 7, a copper ring 10, a temperature control system, and two internal baffles. Ring 12, two window glass sheets 3, two internal fixed end caps 13 and two external fixed end caps 6, the temperature control system includes a temperature measuring thermocouple 14 and a temperature controller 15;

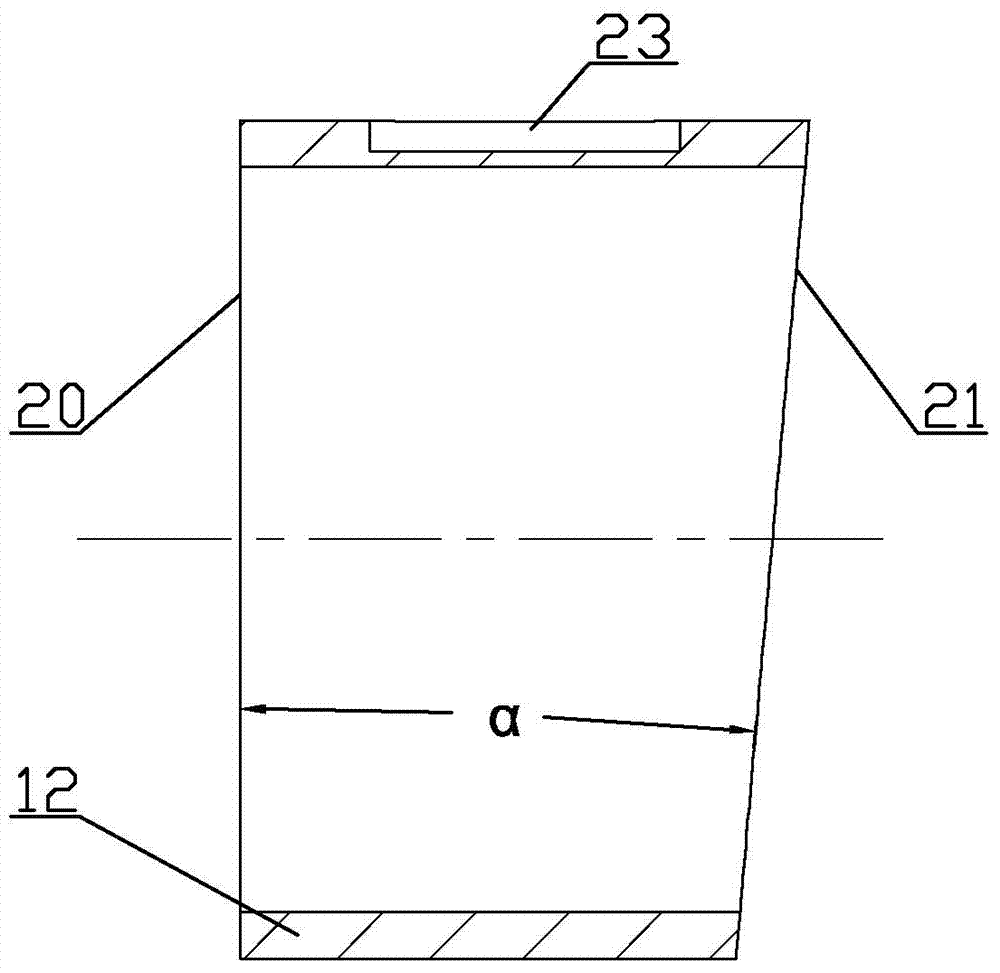

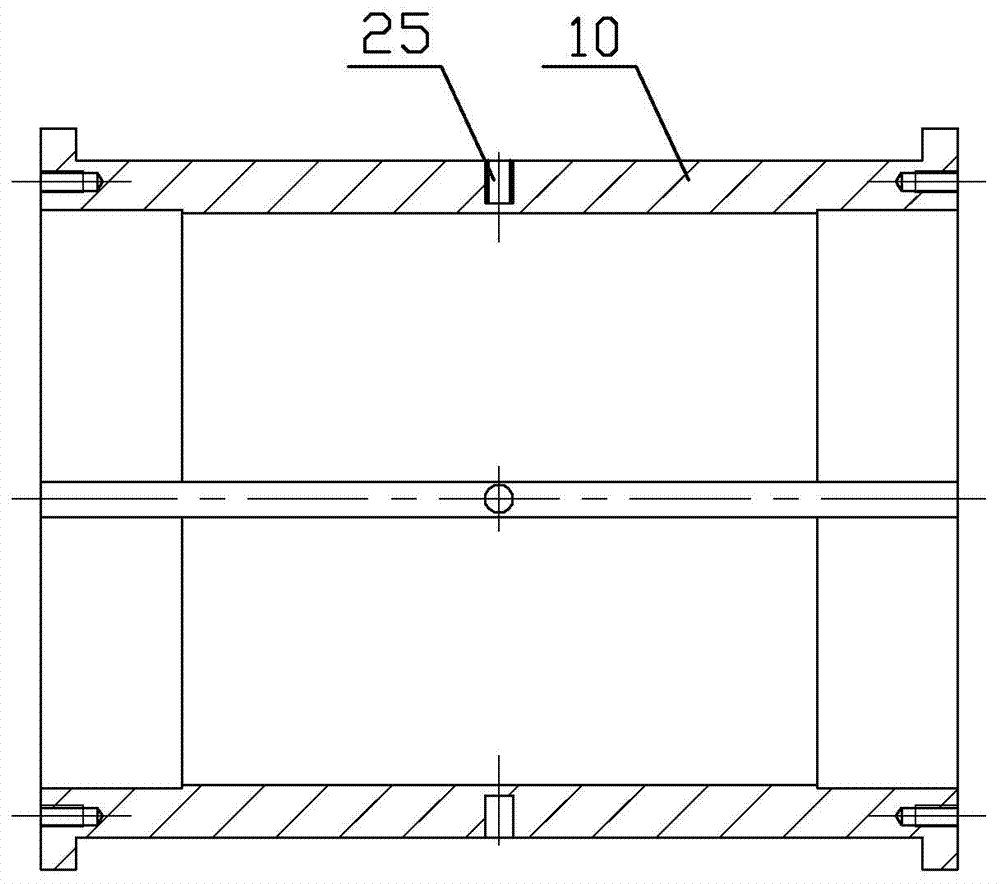

[0016] One of the two opposite end faces of each inner retaining ring 12 is a straight end face 20, and the other end face is an oblique end face 21. The outer circumferential surface of the copper ring 10 is fixed with a heater 1, and the two inner retaining rings 12 The straight end faces 20 are oppositely arranged and set in the copper ring 10, and the two inner retaining rings 12 are radially detac...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 and figure 2 Note that the outer walls of the two inner retaining rings 12 in this embodiment are each provided with a keyway 23, and the two keyways 23 are arranged on the same straight line (to ensure that the window glass sheet 3 is placed in parallel), and the length of the upper edge of the inner wall of the copper ring 10 is There is a through groove 24 in the direction, the through groove 24 corresponds to the two key grooves 23, each corresponding key groove 23 and the through groove 24 are equipped with a key 11, and the two inner retaining rings 12 each pass through a key 11 and the copper ring 10 The connection is detachable in the radial direction, and the outer sidewalls of the two inner retaining rings 12 are in close contact with the inner sidewalls of the copper ring 10 . The connection is stable and convenient, and at the same time it is easy to install. The undisclosed technical features in this ...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 2 Note that the included angle between the oblique end surface 21 and the straight end surface 20 of each inner retaining ring 12 in this embodiment is α, where α=5°, so as to eliminate the influence of stray light. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com