Onsite display instrument-based GIS sulfur hexafluoride density online monitoring system

A sulfur hexafluoride and monitoring system technology, applied to thermometers, instruments, thermometers, etc. that use electric/magnetic components that are directly sensitive to heat, can solve adverse faults that are immediately and accurately detected and prevented, inconsistent gas chambers, and large temperature differences and other problems, to achieve the effect of easy maintenance, easy wiring structure, stable and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

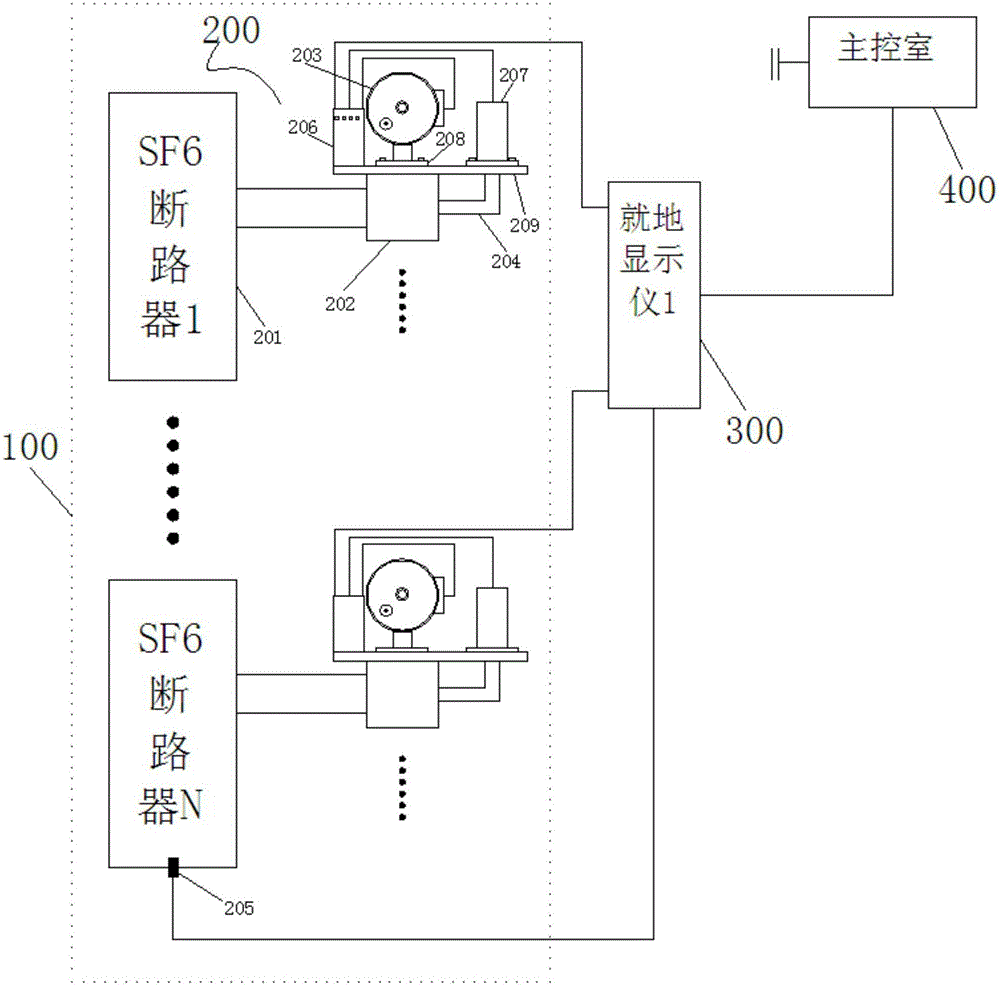

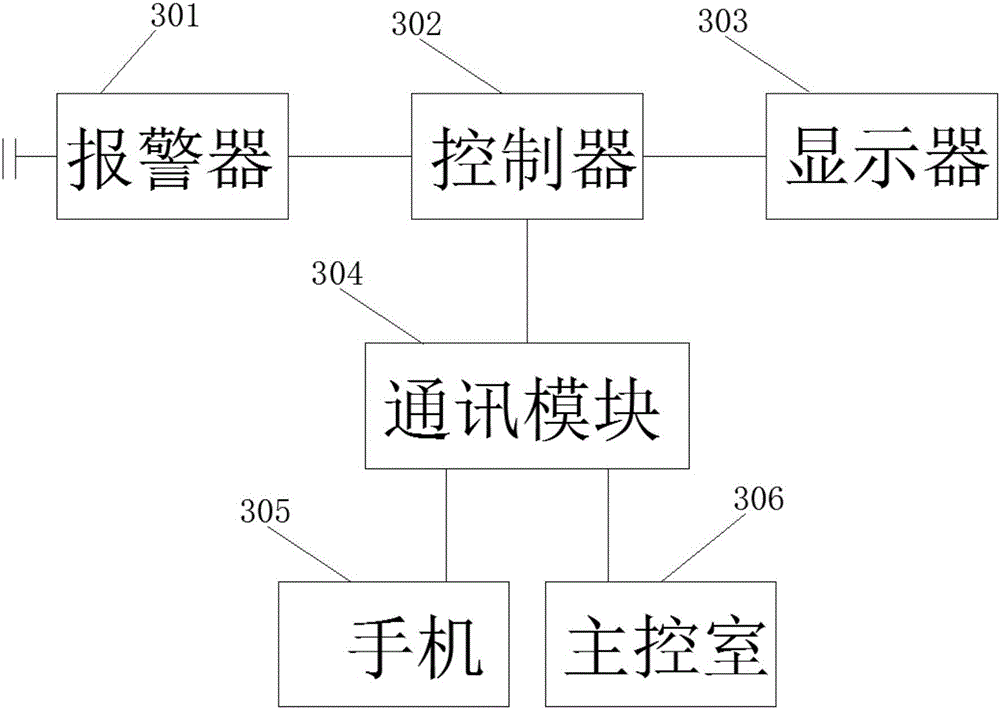

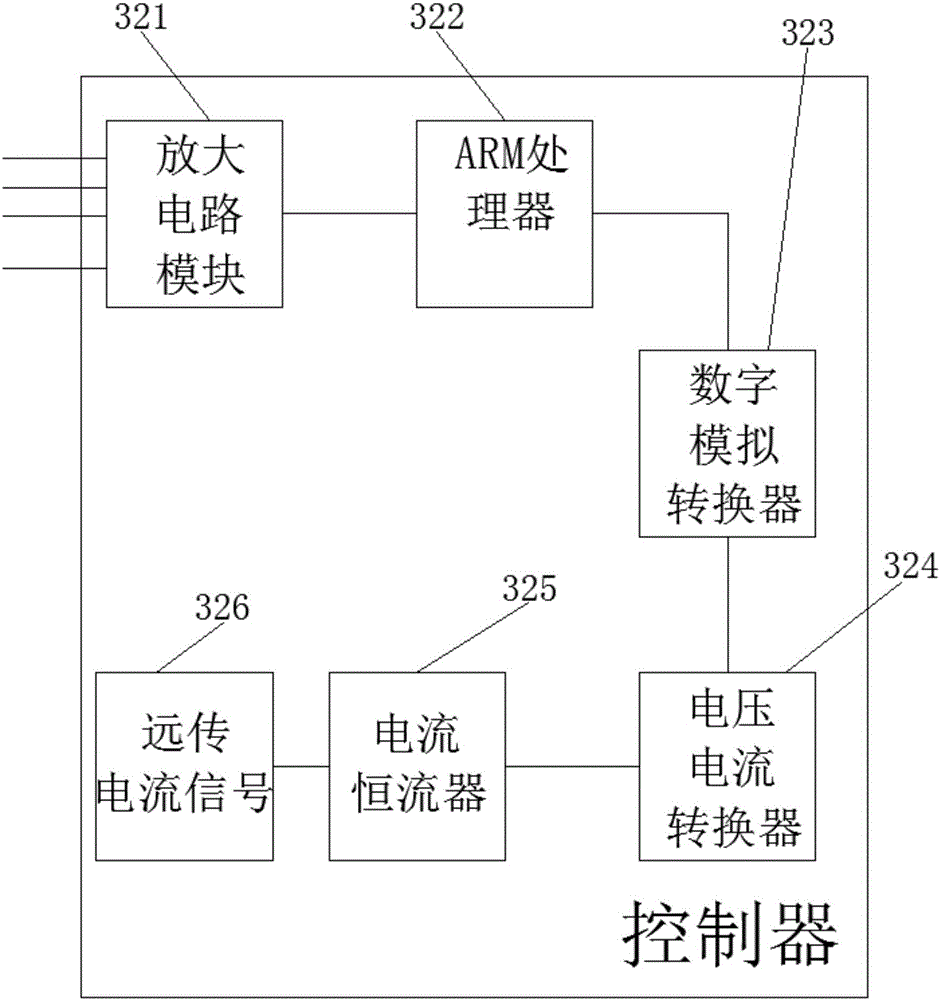

[0041] Such as Figure 1~5 As shown, it shows the specific implementation of the present invention, as shown in the figure, the GIS sulfur hexafluoride density on-line monitoring system based on the local display instrument disclosed by the present invention, the gas chamber of the SF6 circuit breaker leads a plurality of monitoring pipes A sulfur hexafluoride density meter 203 for SF6 gas pressure is installed on the monitoring pipeline; a gas deriving tee 202 is installed on the monitoring pipeline; an outlet of the gas deriving tee is connected with the sulfur hexafluoride density meter The gas path collection port is connected; the other outlet of the gas export tee is connected with the collection port of the pressure collection sensor 207;

[0042] It also includes a horizontally installed installation platform 209, the sulfur hexafluoride density meter and the pressure acquisition sensor are fixedly installed on the installation platform through the installation flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com