Patents

Literature

38results about How to "Facilitate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method to provide and display enhanced feedback in an online transaction processing environment

The present invention is a system for and method to collect, calculate, and display user feedback ratings in an online transaction processing (OLTP) environment. The invention utilizes a client, a network, a Web site host system, and rule-based decision making, to 1) enable users and other systems to submit transaction performance information for a buyer or seller; 2) enable users to view transaction performance information; and 3) enable users to view detailed transaction performance measures for buyers or sellers within specific performance categories. Rating the transaction performance of users of an OLTP environment can serve to improve users' trust in the OLTP environment, improve the reputation of online trading venues, and increase the value of these venues.

Owner:EBAY INC

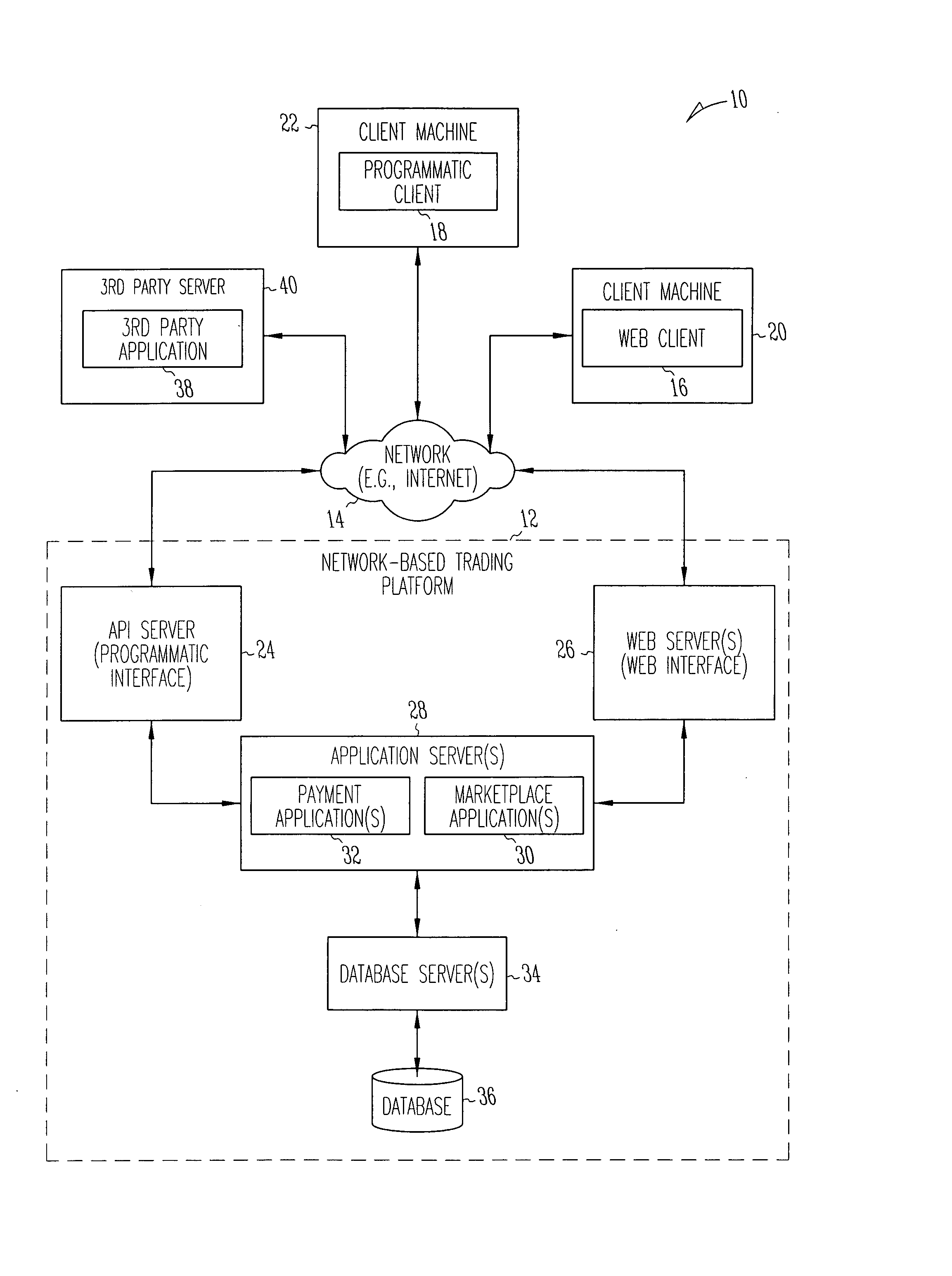

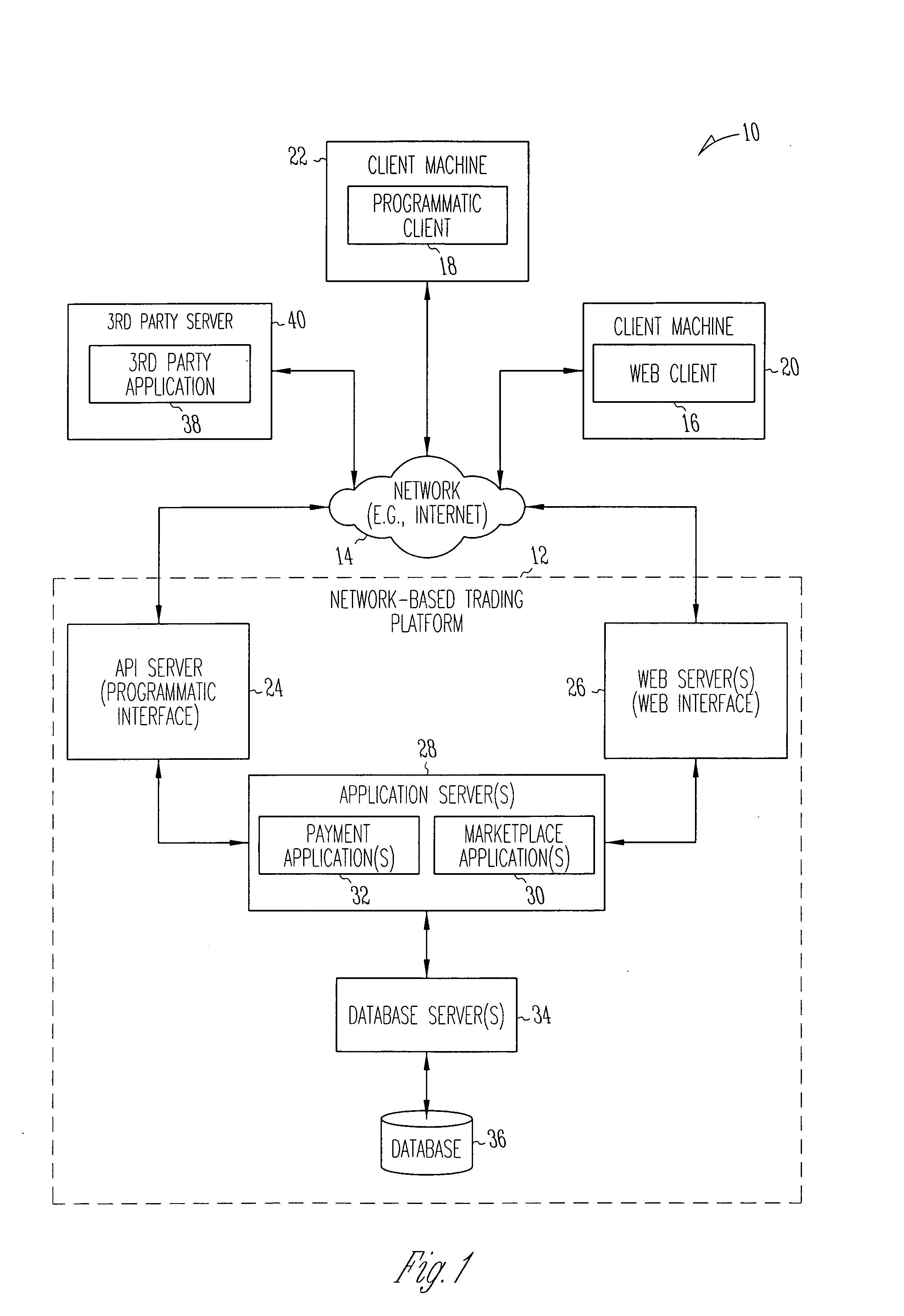

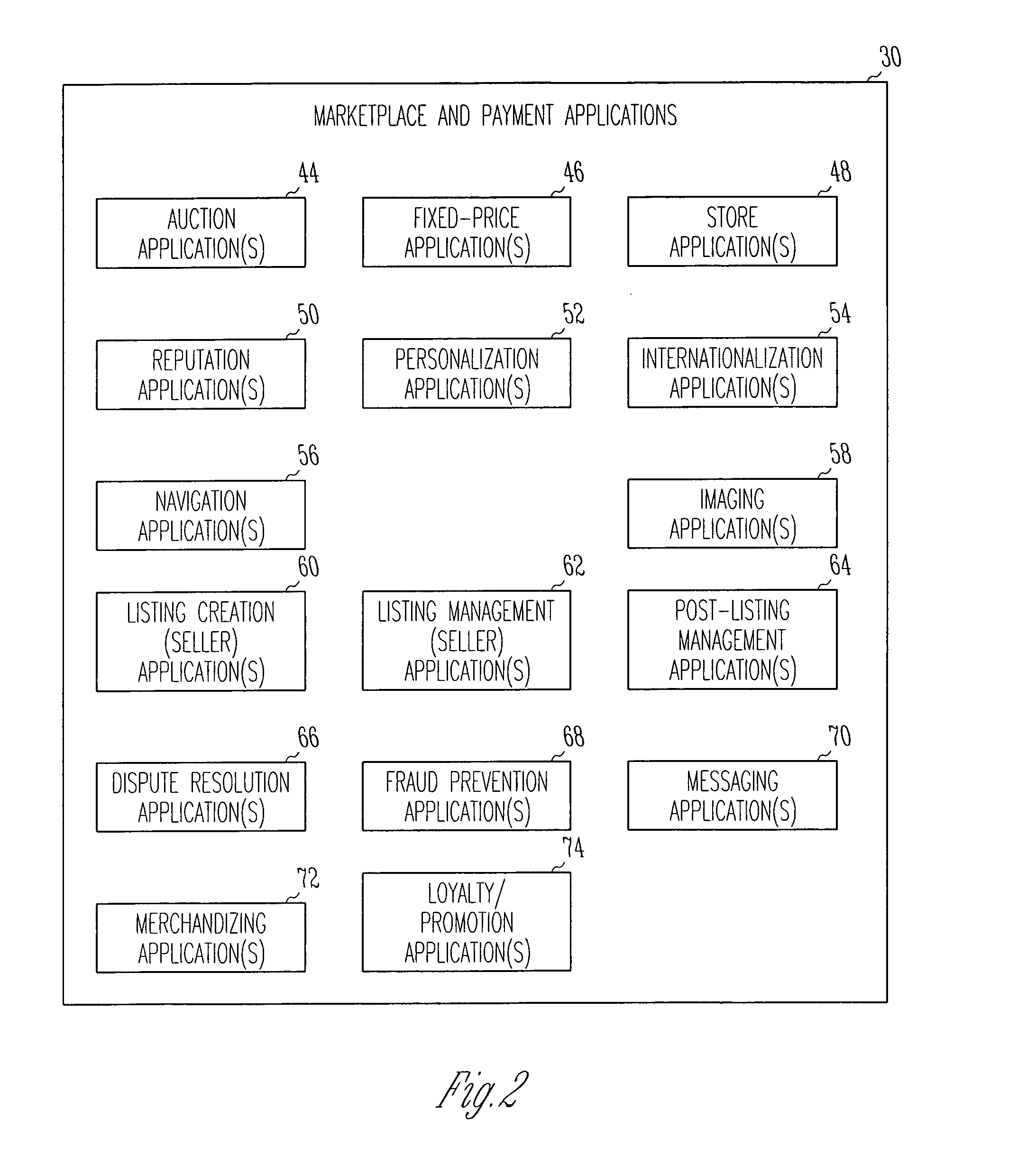

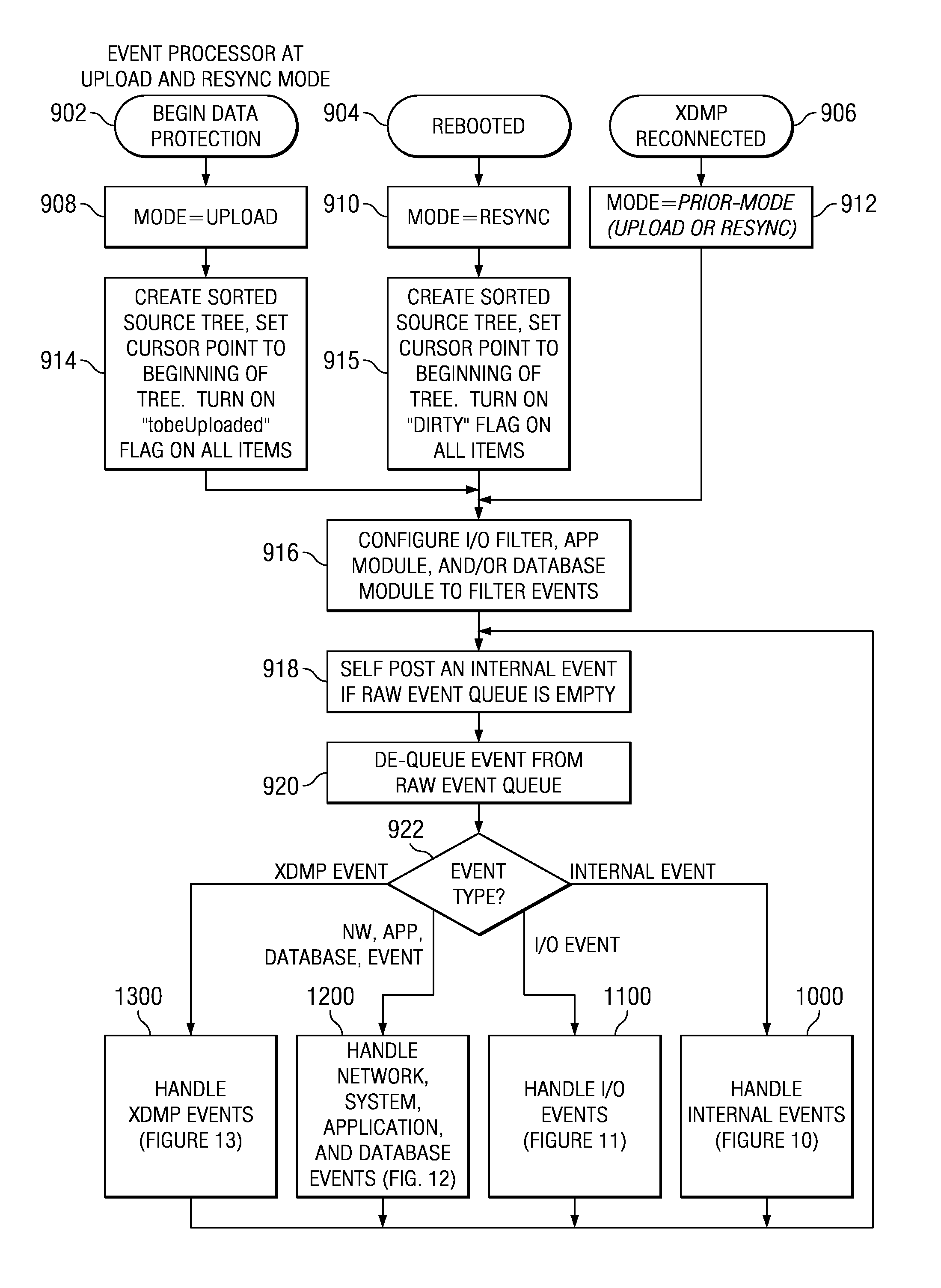

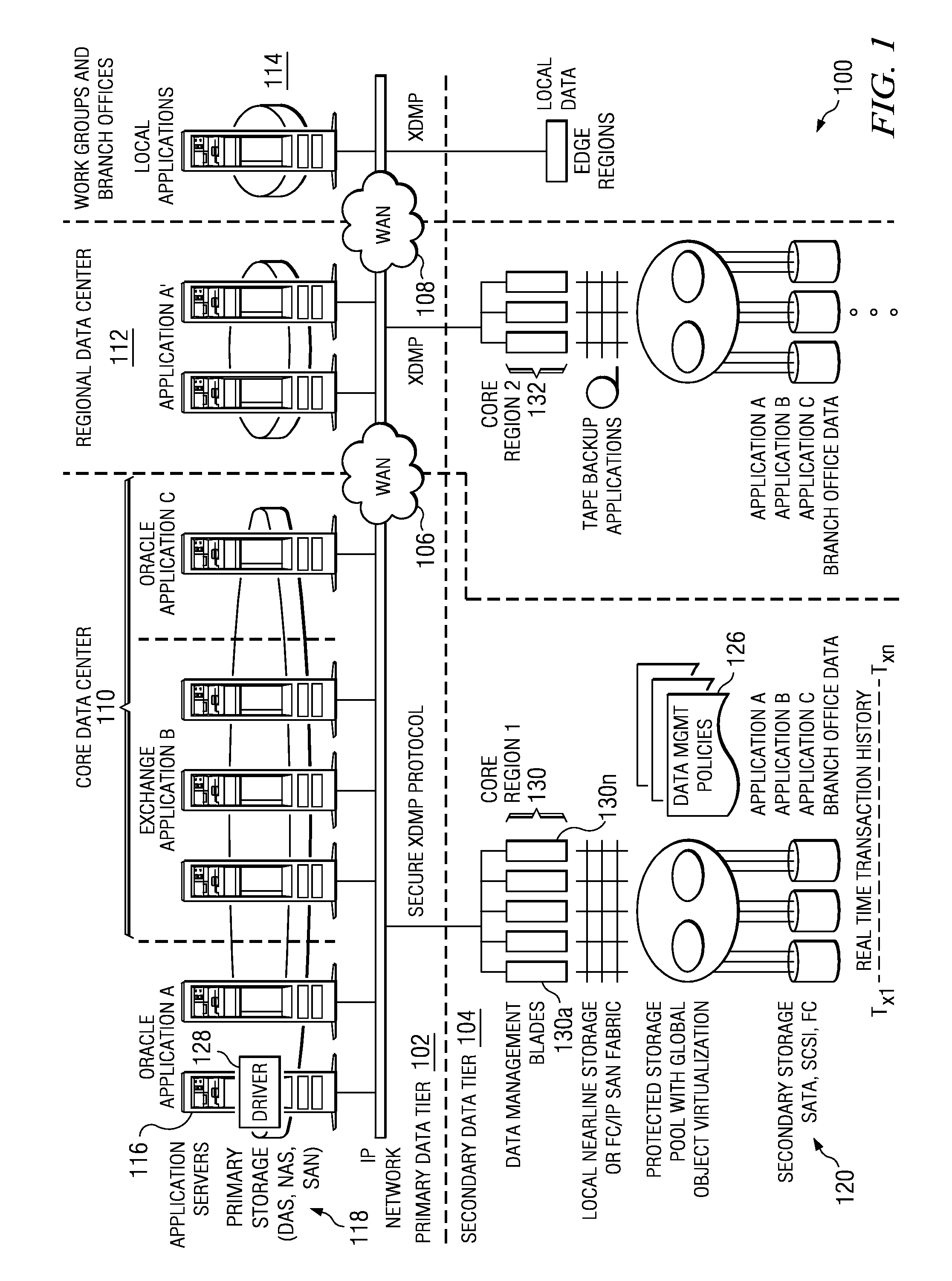

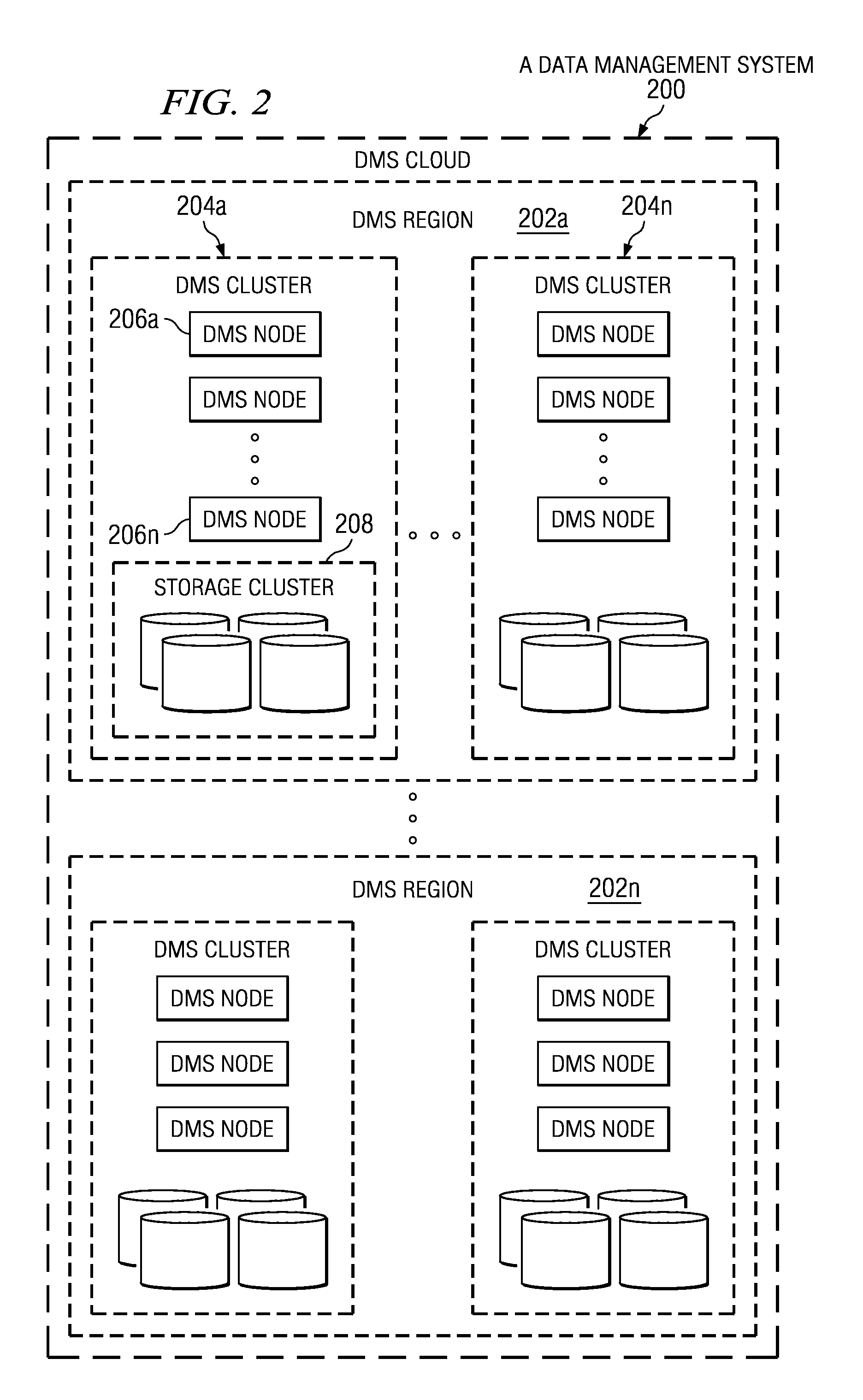

Method and system for no downtime, initial data upload for real-time, continuous data protection

A data management system or “DMS” provides an automated, continuous, real-time, substantially no downtime data protection service to one or more data sources associated with a set of application host servers. To facilitate the data protection service, a host driver embedded in an application server captures real-time data transactions, preferably in the form of an event journal that is provided to other DMS components. The driver functions to translate traditional file / database / block I / O and the like into a continuous, application-aware, output data stream. The host driver includes an event processor. When a data protection command for a given data source is forwarded to a host driver, the event processor enters into an initial upload state. During this state, the event processor gathers a list of data items of the data source to be protected and creates a data list. Then, the event processor moves the data (as an upload, preferably one data element at a time) to a DMS core to create initial baseline data. In an illustrative embodiment, the upload is a stream of granular application-aware data chunks that are attached to upload events. Simultaneously, while the baseline is uploading and as the application updates the data on the host, checkpoint granular data, metadata, and data events are continuously streamed into the DMS core. During this upload phase, the application does not have to be shutdown.

Owner:QUEST SOFTWARE INC

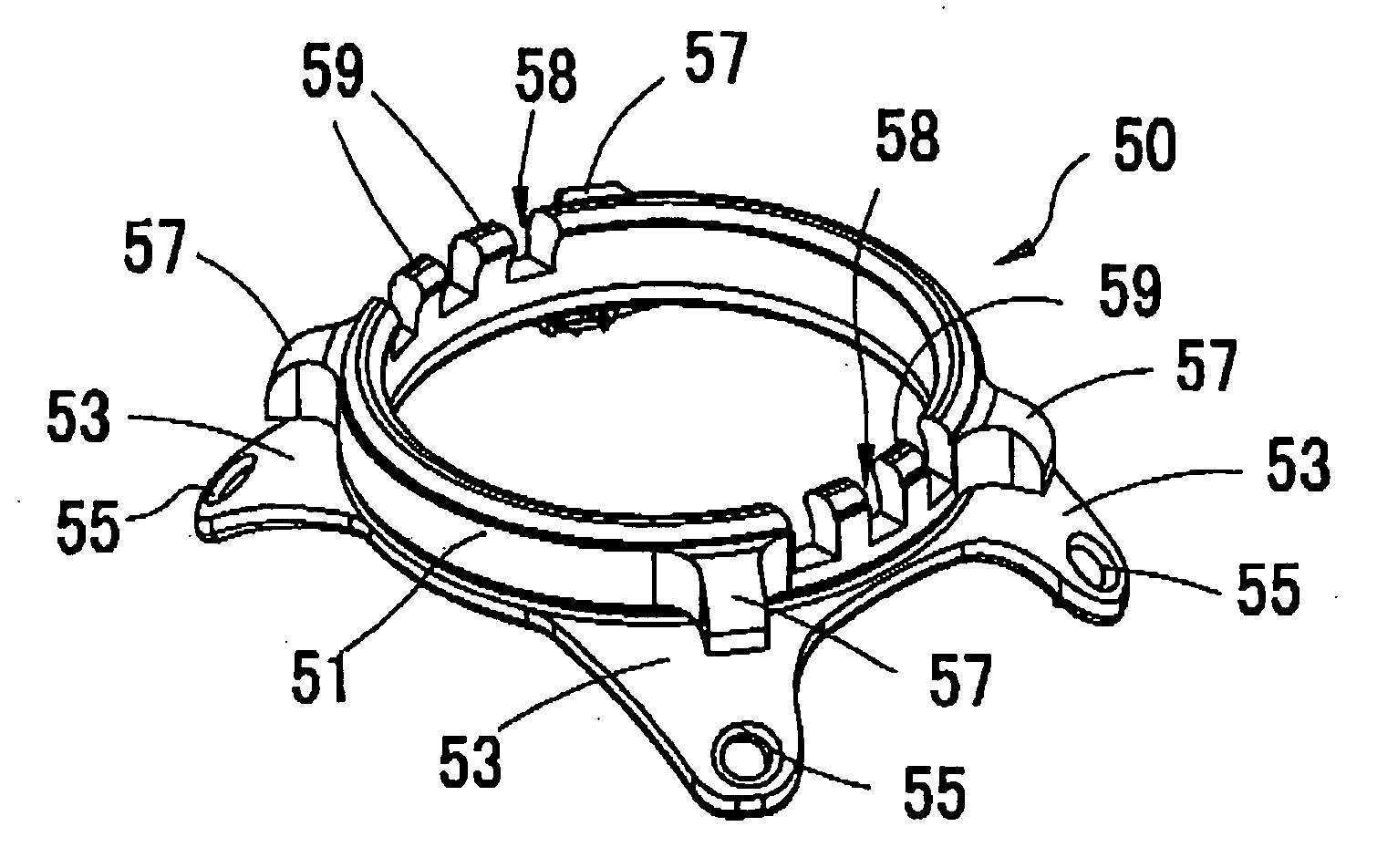

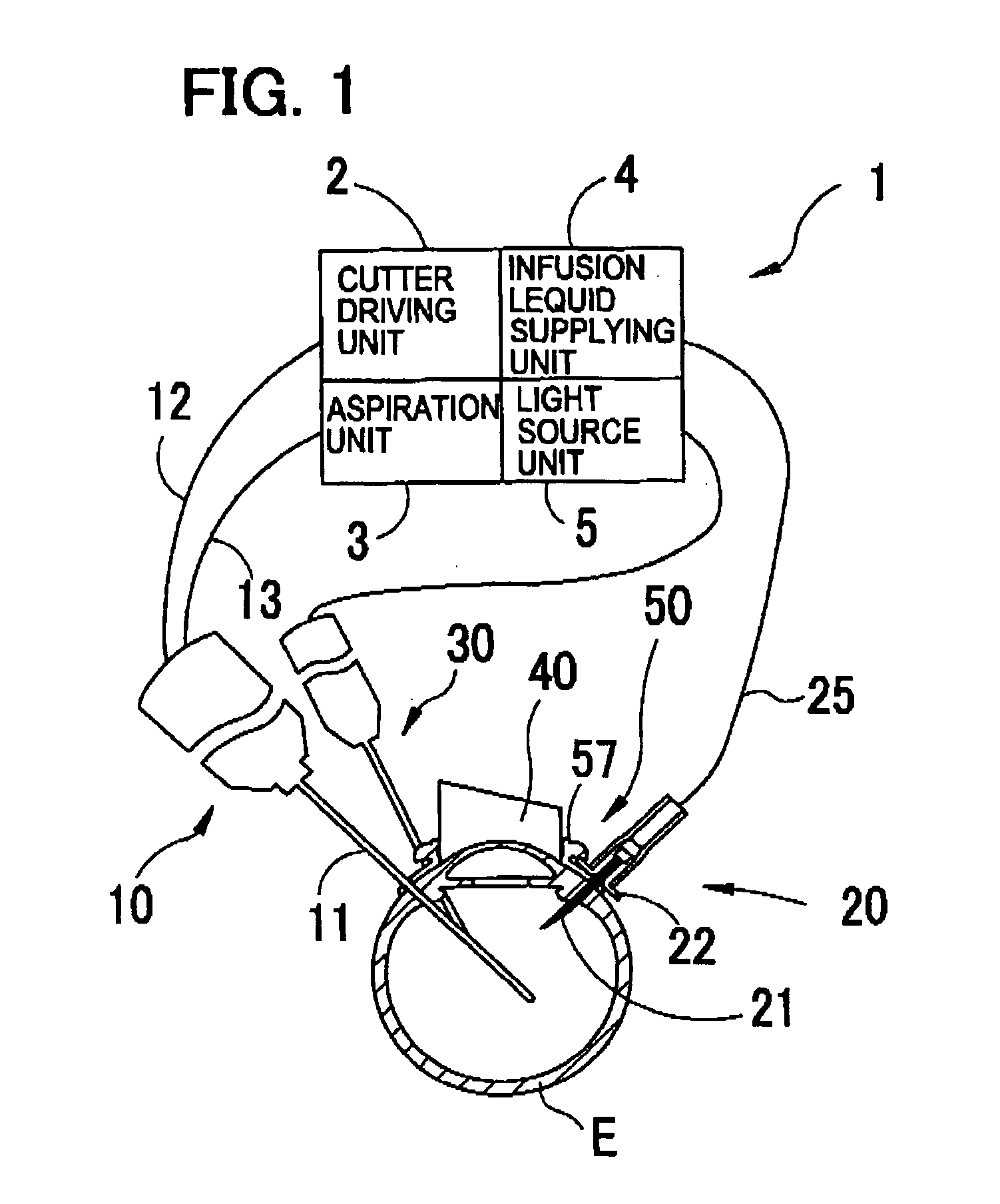

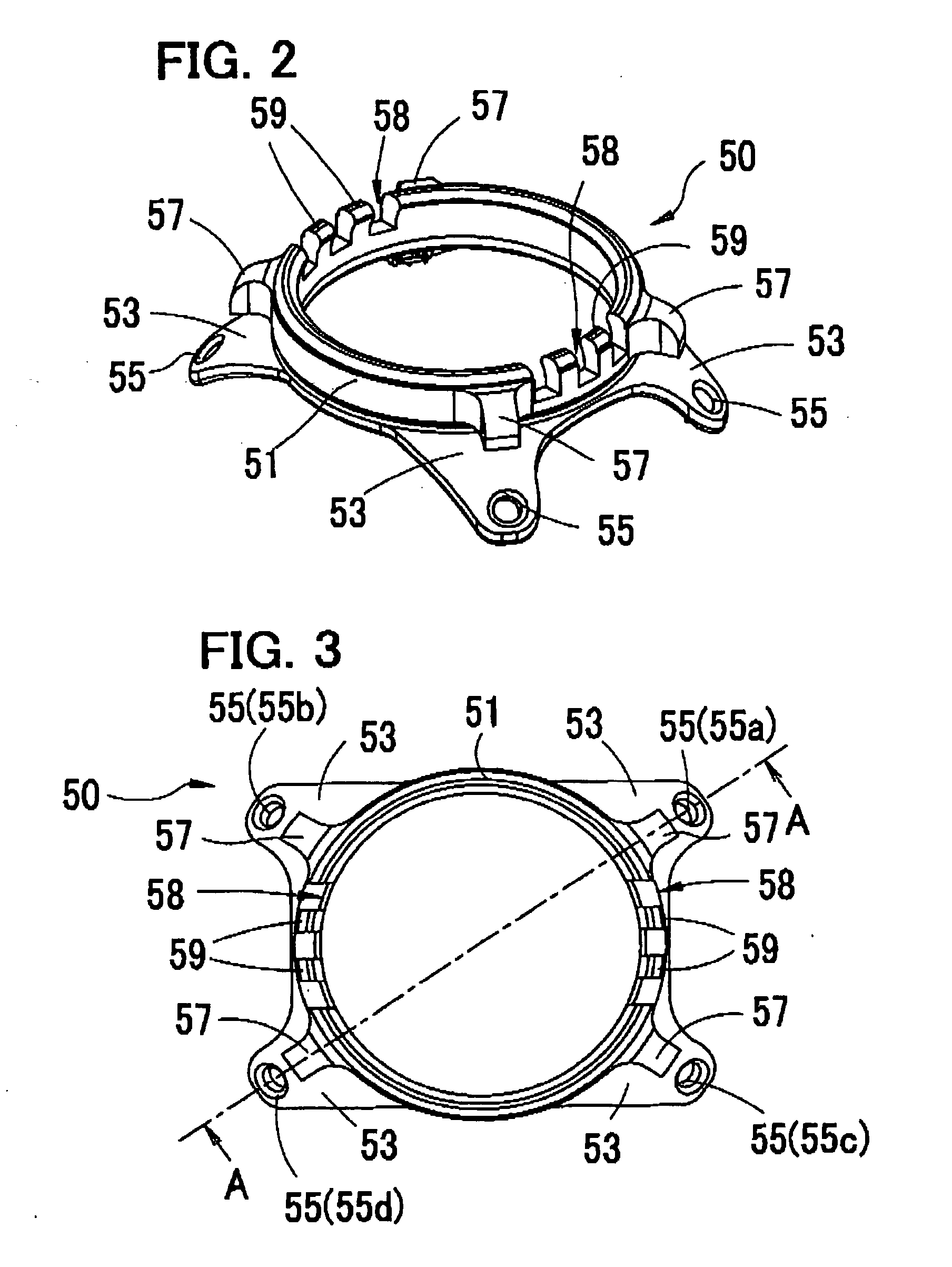

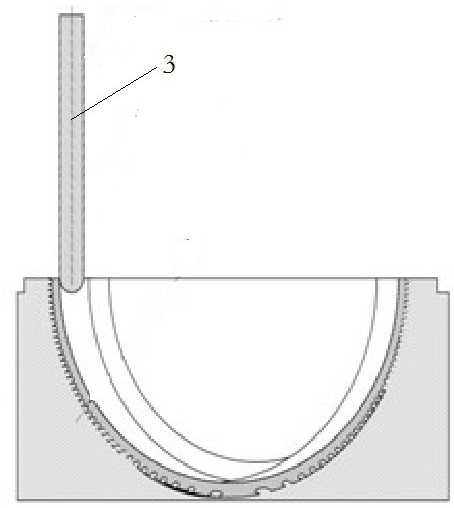

Ring for vitreous surgery for supporting contact lens for the vitreous surgery, cannula used in combination with the ring, and plug used in combination with the ring

InactiveUS20050288697A1Easily recognizeFacilitateCannulasSurgical needlesConjunctivaSurgical instrument

A ring for vitreous surgery, adapted to support a contact lens for the vitreous surgery on a patient's eye, the ring comprises: a ring body; a flange having a contact surface of a curved shape to be fitted with a curved shape of a sclera of the eye, the flange being provided on an outer edge of the ring body; a hole provided in the flange, in which an intraocular insertion surgical instrument is insertable; and a projection provided in the vicinity of the hole on the contact surface of the flange, the projection being able to bite into a conjunctiva of the eye.

Owner:NIDEK CO LTD

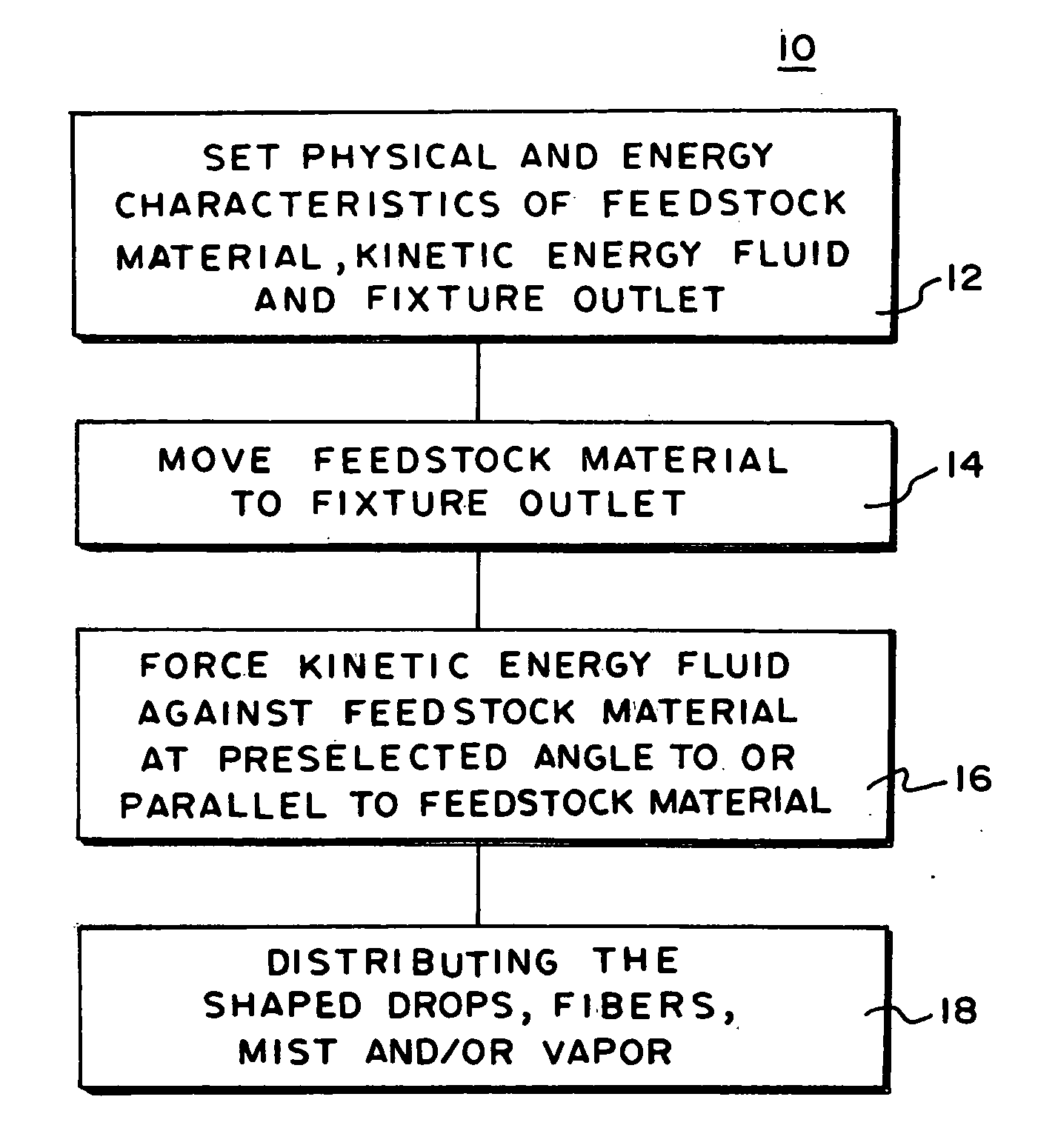

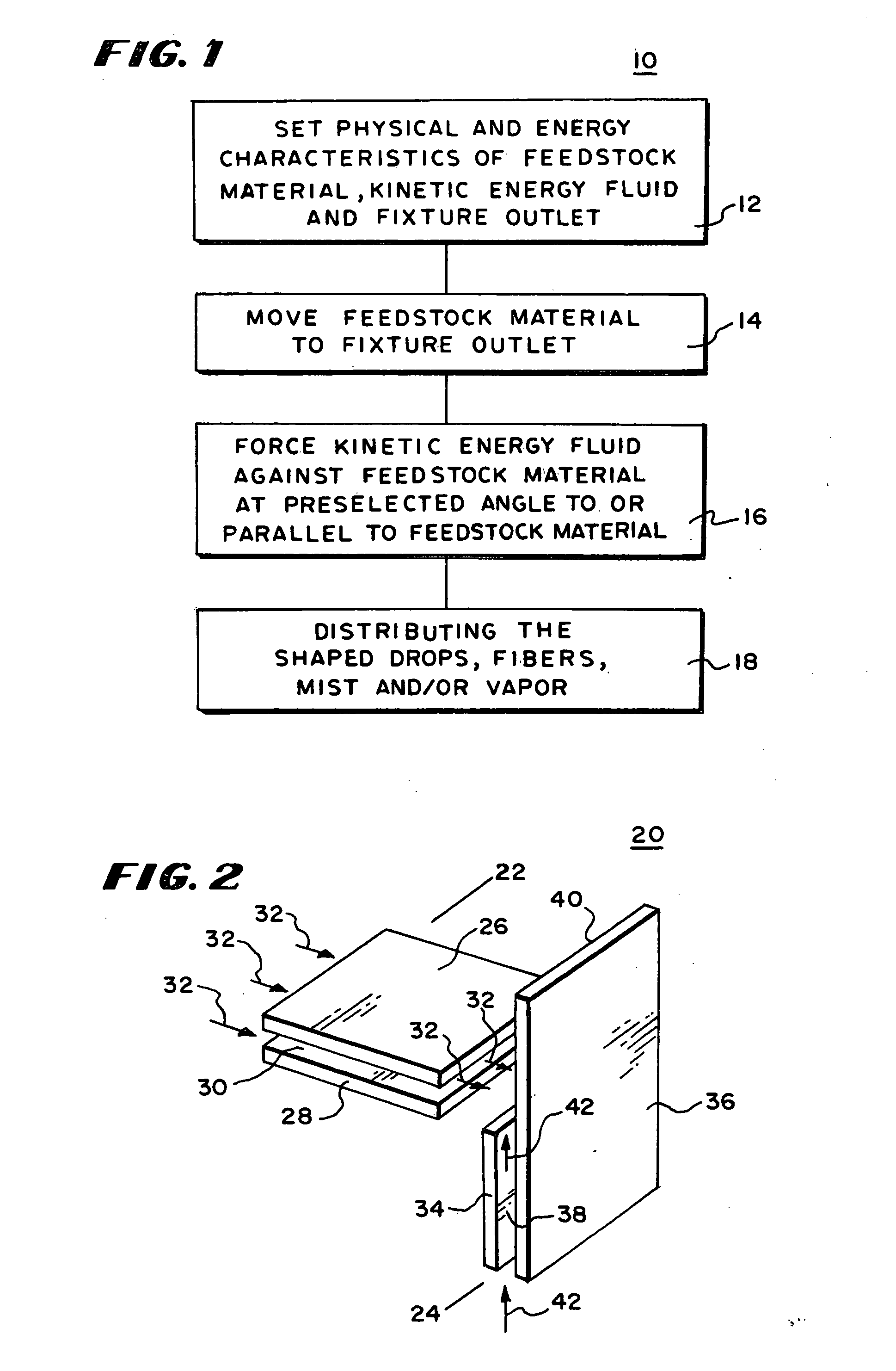

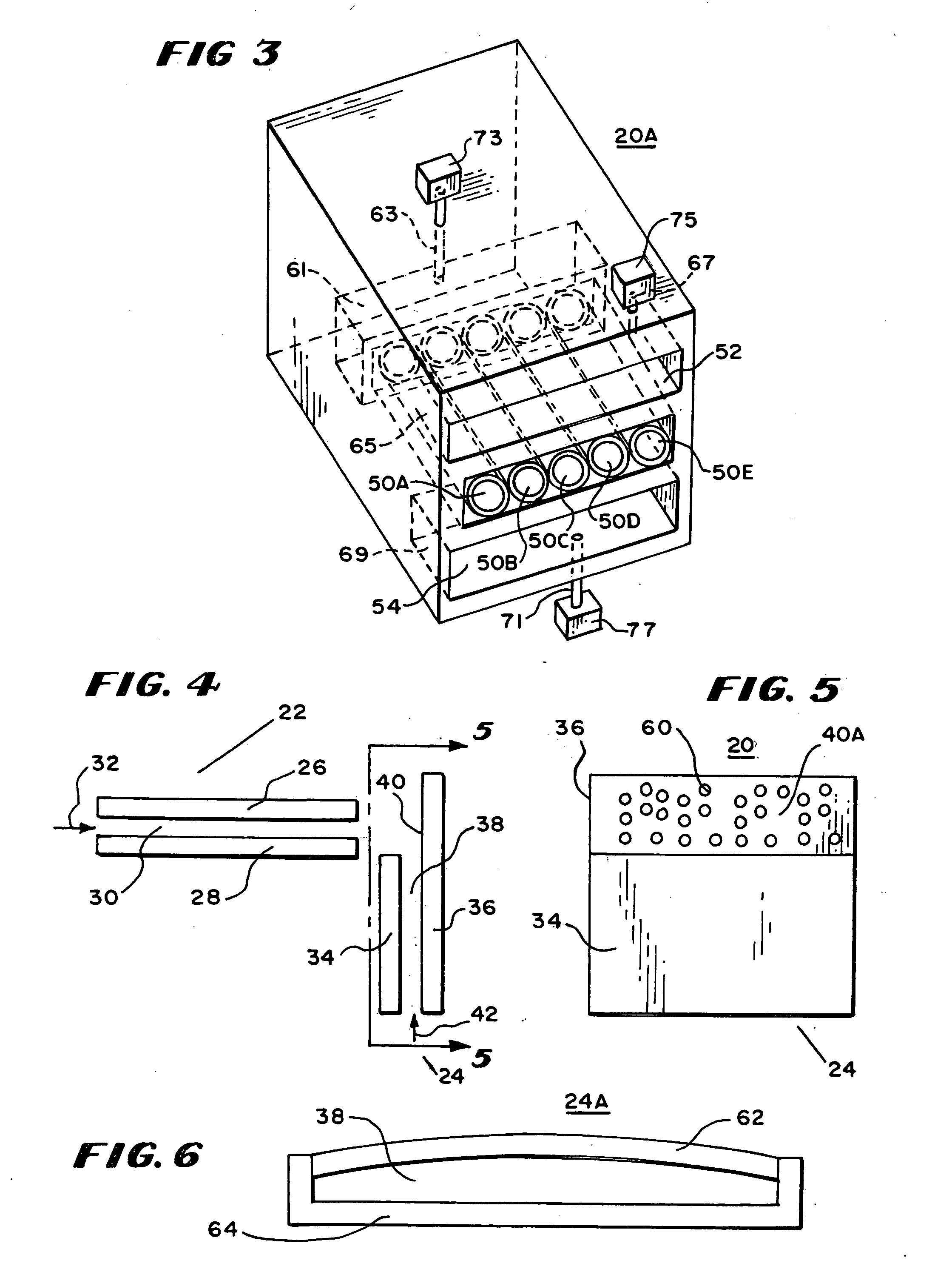

Systems for the control and use of fluids and particles

ActiveUS20060231000A1FacilitateHigh viscosityLiquid seeding techniquesLiquid fertiliser distributionEngineeringFiber

The configuration of a feedstock material is controlled by bringing it into contact with at least a first gas moving against it at a location with an area and thickness of the feedstock liquid that forms drops or fibers of a selected size. In one embodiment, drops of agricultural input materials are formed for spraying on agricultural fields. In another embodiment, nanofibers of materials such as chitosan or metals are formed. In another embodiment seeds are planted with gel.

Owner:KAMTERTER PROD LLC

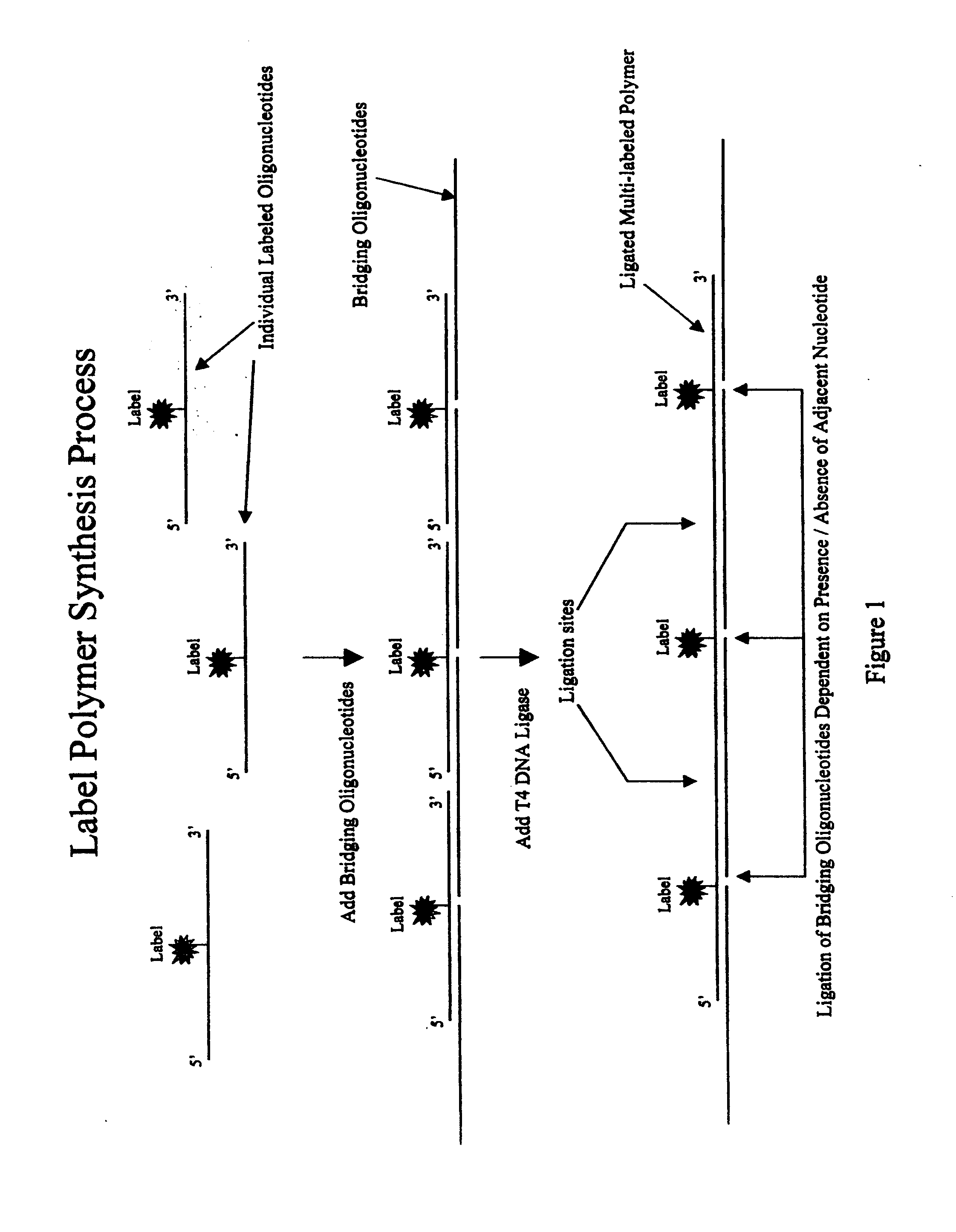

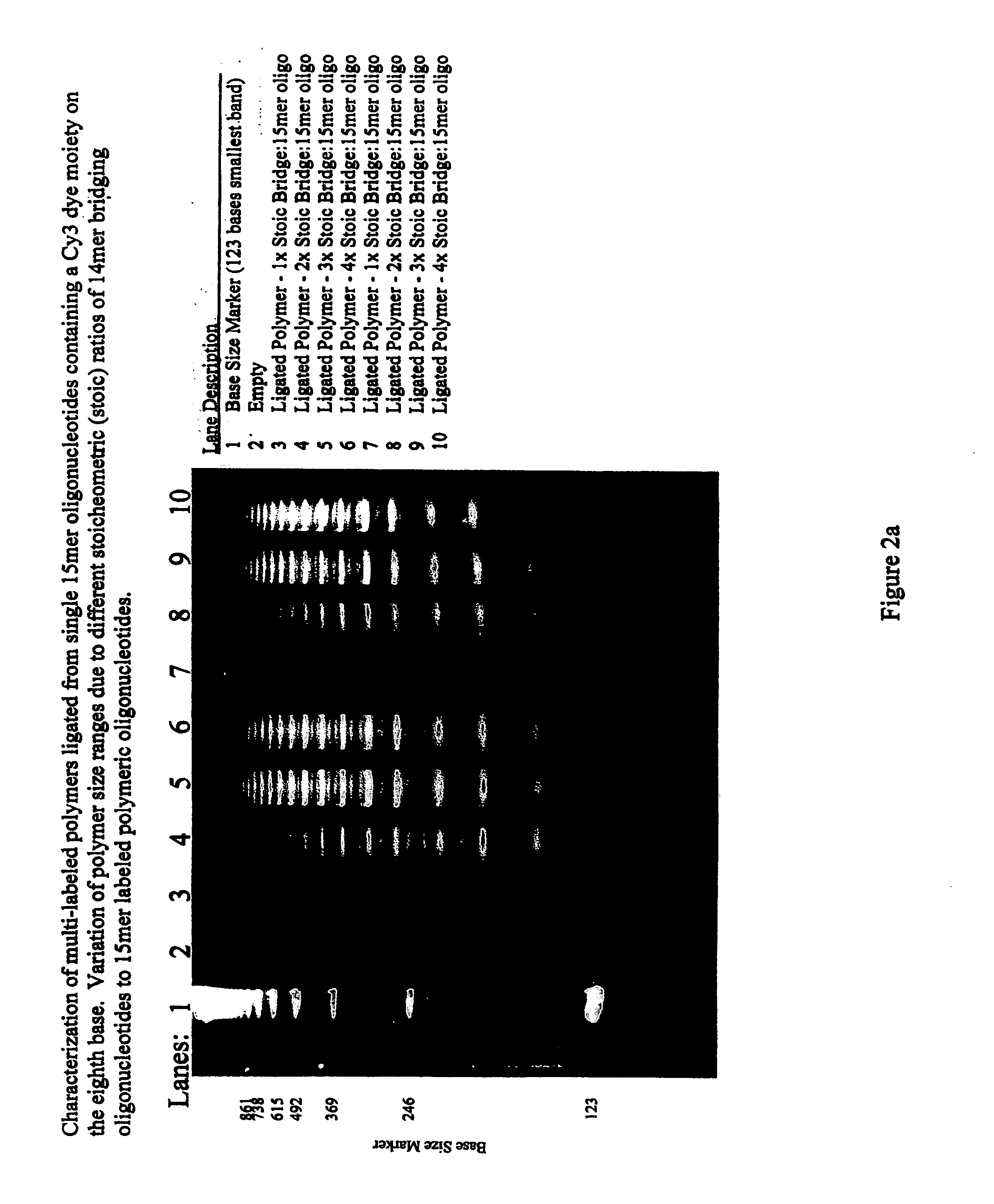

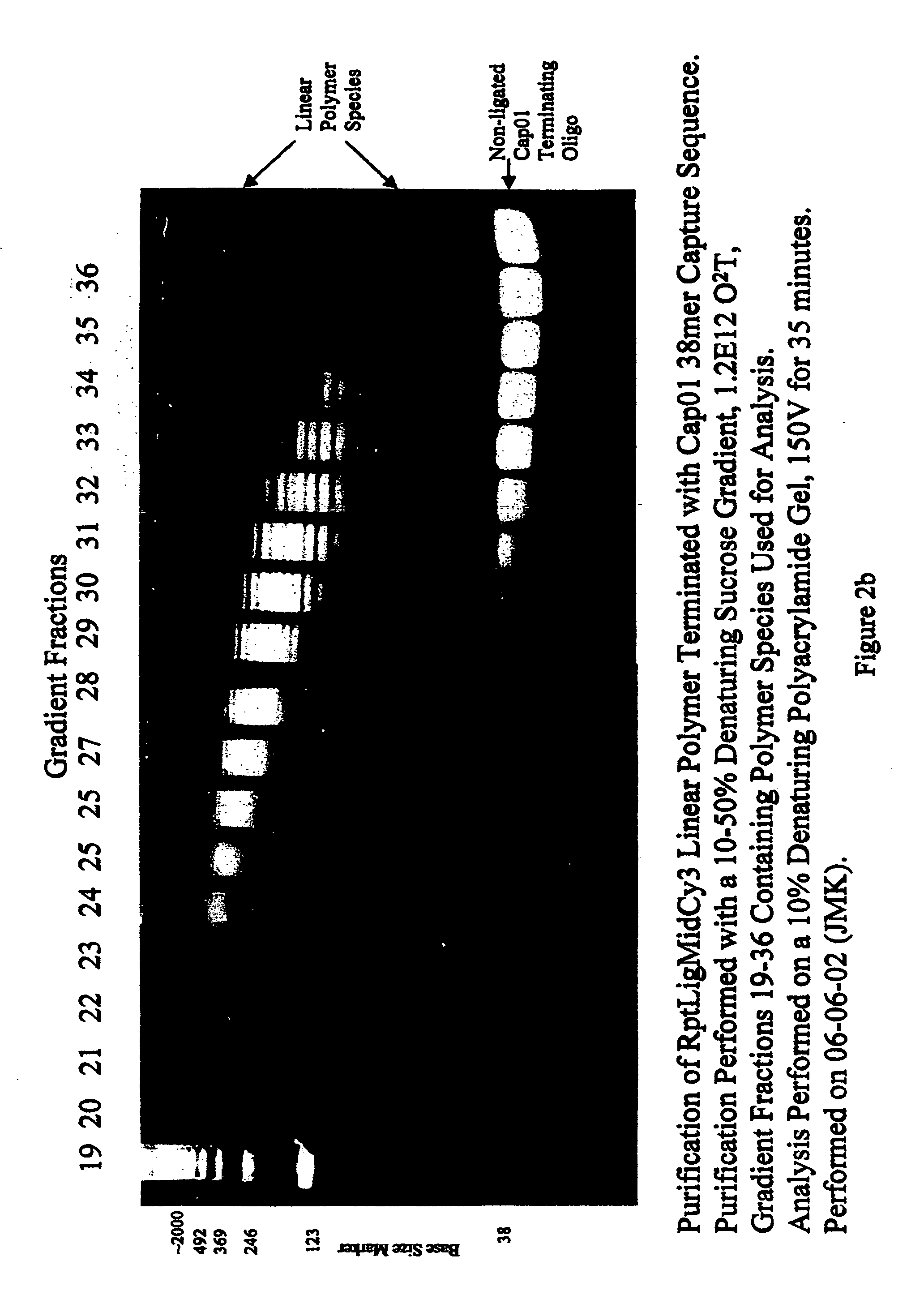

Polymeric label molecules

InactiveUS20060160098A1FacilitateImprove efficiencyMicrobiological testing/measurementOther foreign material introduction processesOligonucleotideMonomer

A method of constructing a highly labeled linear polymeric molecule for use in any desired application, and linear polymeric molecules of such structure. The polymeric molecule is a nucleic acid constructed from a large number of one or more types of monomeric oligonucleotide units that are attached together to form an extended strand. Within each polymer, at least one type of monomeric unit is provided which is bound to or designed to bind to a label moiety, providing a polymer with a large number of repeat sequences designed for labeling purposes, resulting in extremely effective signal carrying molecule of considerable versatility.

Owner:ZAK S +3

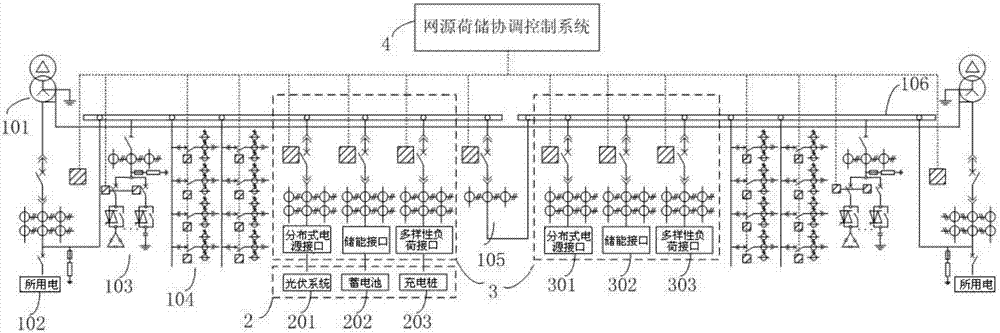

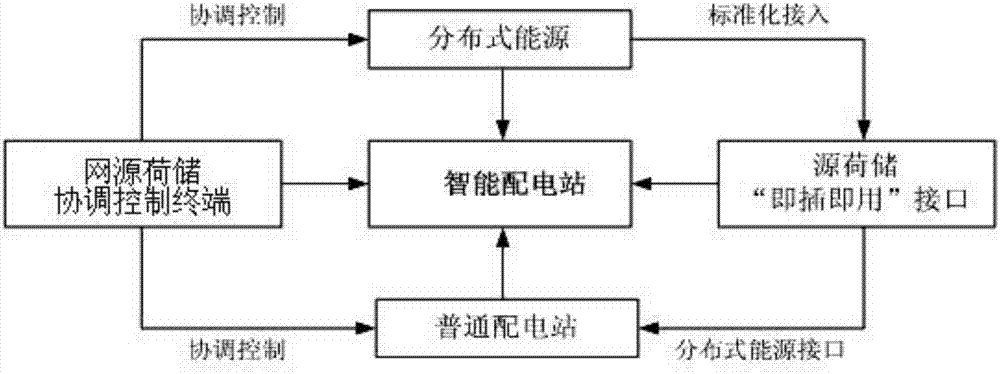

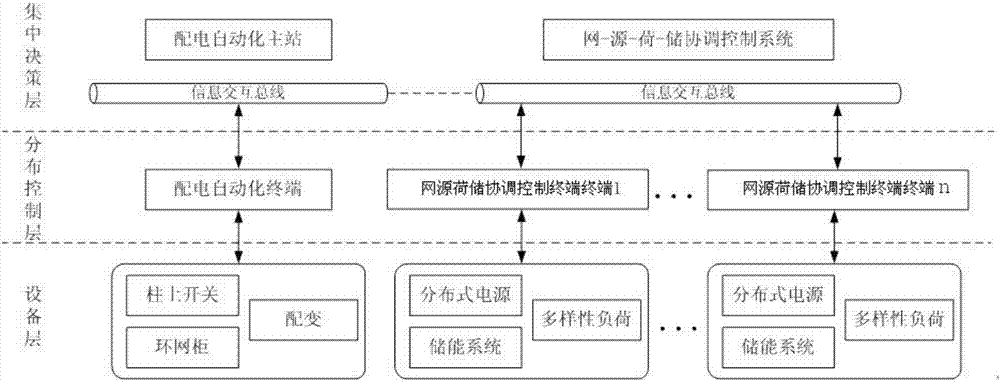

Intelligent power distribution station based on grid source load storage coordinated control and grid source load storage coordinated control system thereof

InactiveCN107171361ANetworkingFacilitateSingle network parallel feeding arrangementsEnergy storageDistribution controlLow voltage

The invention discloses a power distribution station based on grid source load storage coordinated control and a grid source load storage coordinated control system thereof. The system comprises a centralized decision layer, a distribution control layer and an equipment layer which are connected through the network. The equipment layer comprises power distribution equipment of multiple power distribution stations and distributed energy sources. The distributed energy sources comprise a photovoltaic system, an energy storage system and charging piles which are constructed in a way of being combined with the power distribution equipment and accessed to a low voltage side bus through distributed energy source interfaces. The distribution control layer comprises power distribution automatic terminals and grid source load storage coordinated control terminals which are corresponding to all the power distribution stations. The centralized decision layer comprises a power distribution automatic scheduling master station which is connected with all the power distribution automatic terminals and a grid source load storage coordinated control master station which is connected with all the grid source load storage coordinated control terminals. The grid source load storage coordinated control master station controls working of the distributed energy sources in the corresponding power distribution stations through the grid source load storage coordinated control terminals of all the power distribution stations. Coordinated control of the distributed energy sources can be realized by using the grid source load storage coordinated control system so as to achieve the objective of scheduling optimization.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +3

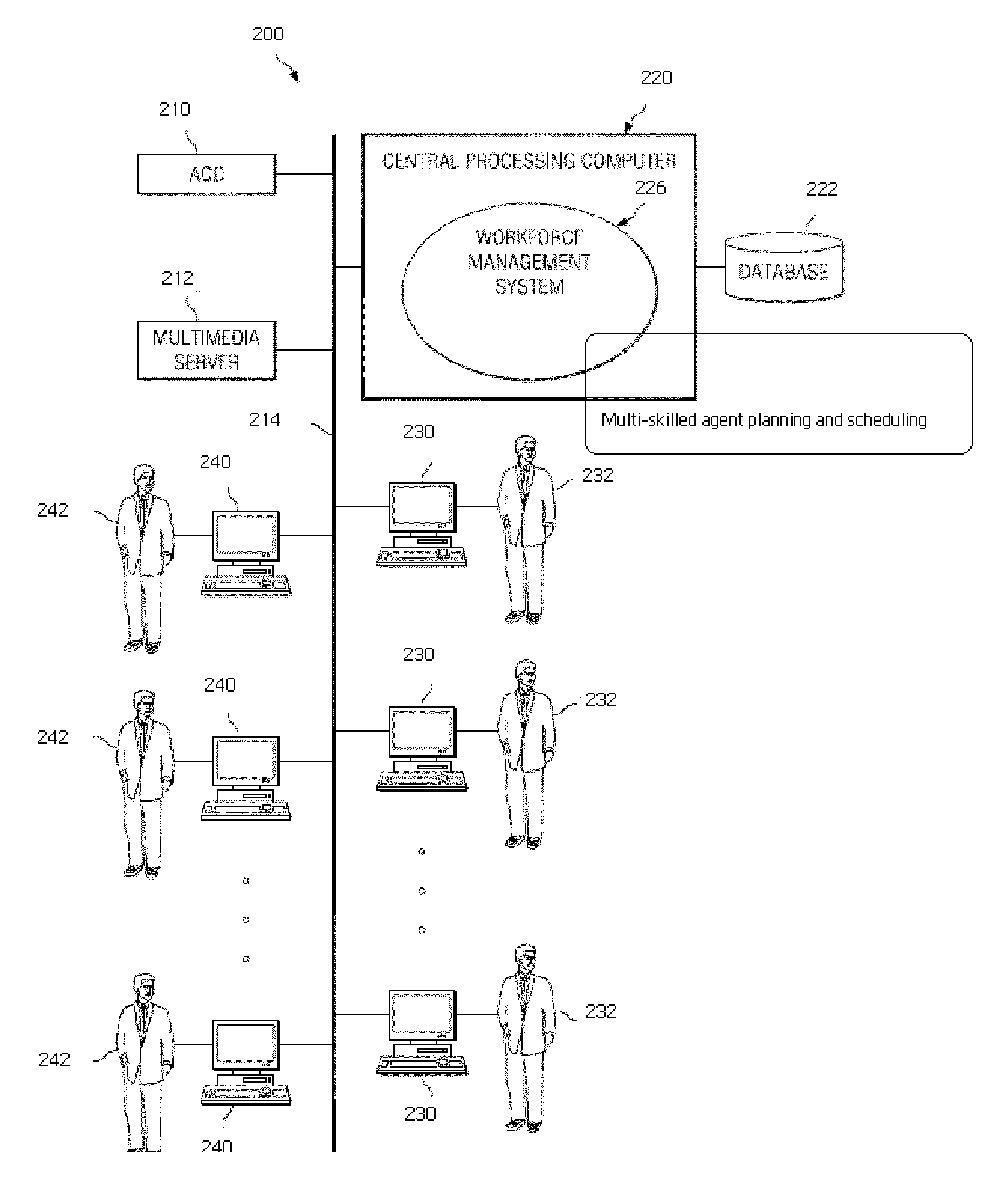

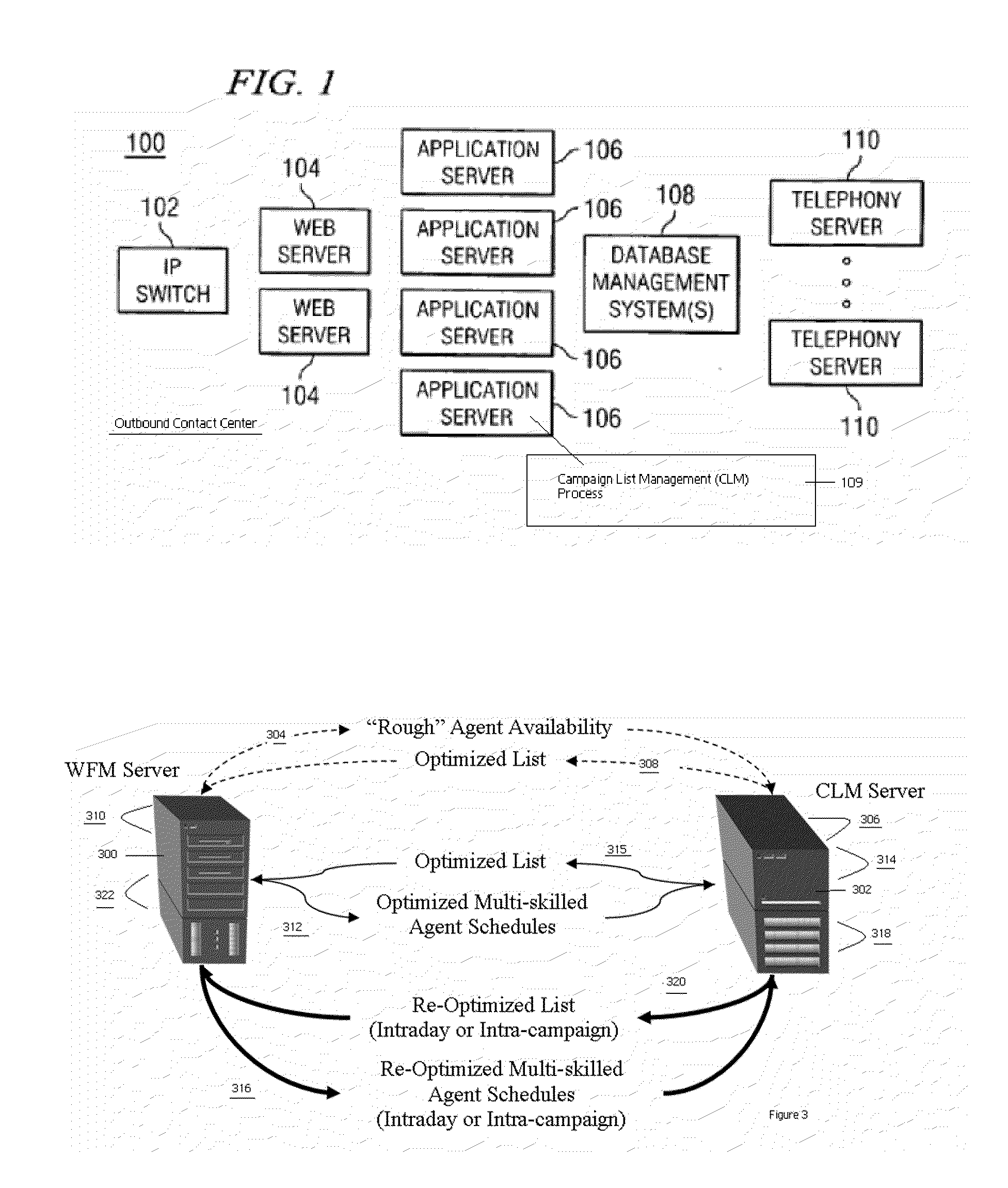

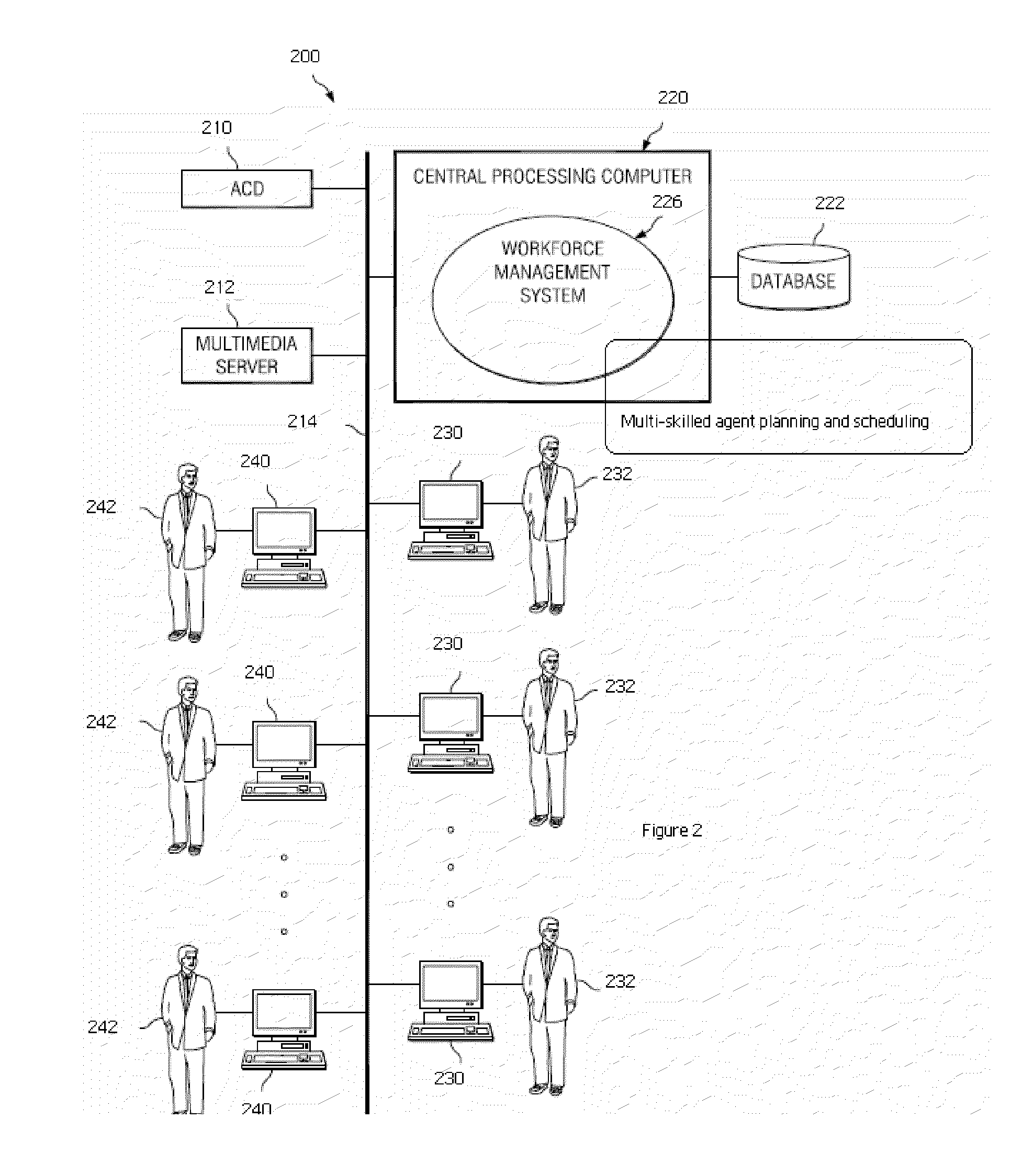

Iterative scheduling and campaign management

ActiveUS20110150208A1FacilitateManual exchangesAutomatic exchangesCampaign managementProgram planning

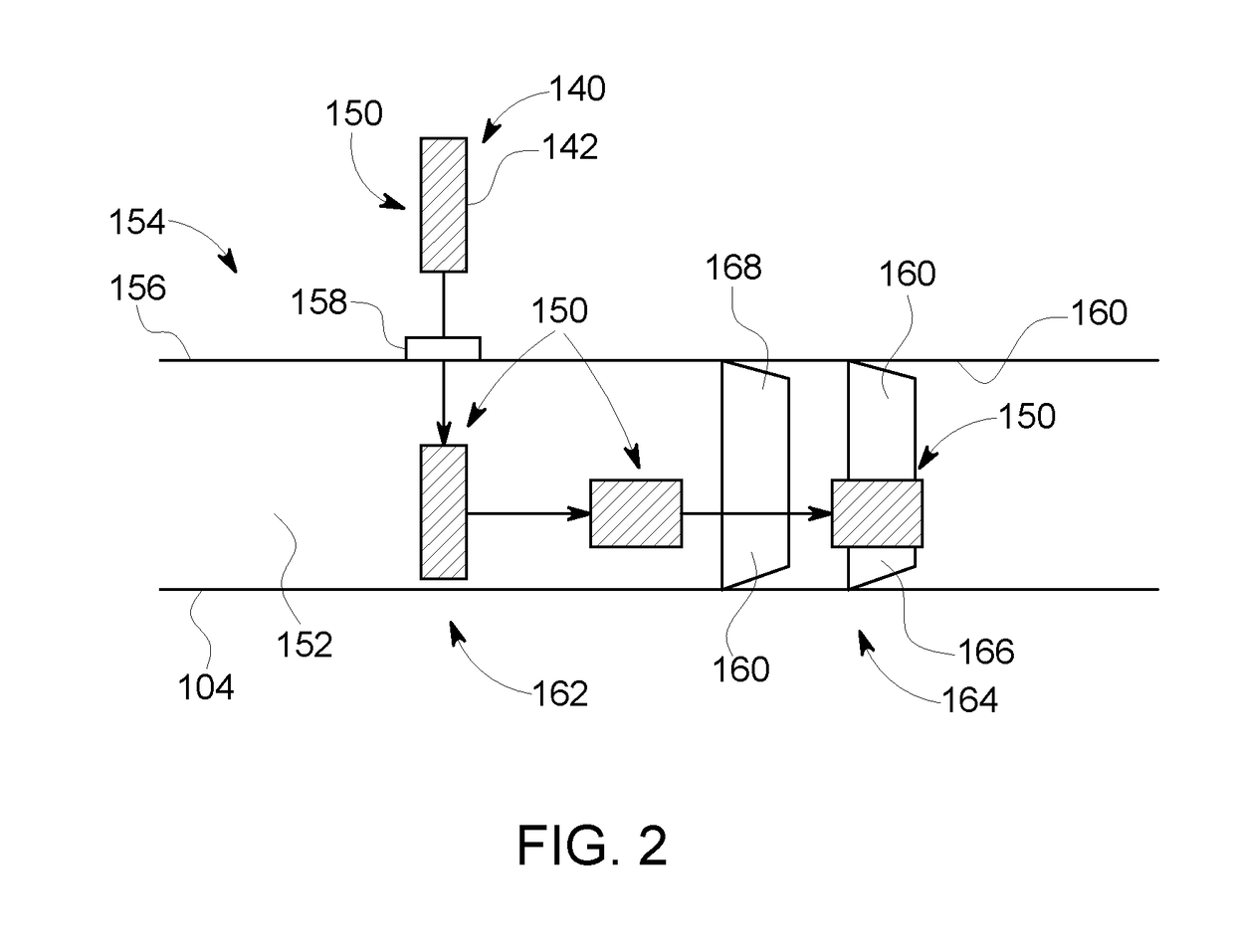

An iterative scheduling and campaign management process uses a WFM system and a CLM system. These systems may be independent or consolidated. In a first step of the process, the WFM system provides the CLM system coarse agent availability data. The coarse agent availability data is used by the CLM system to generate a first list order for a given outbound contact list, which contact list is then provided back to the WFM system. In a second step of the process, the WFM uses the first list order to facilitate a multi-skilled agent scheduling routine. The resulting set of multi-skilled agent schedules (or staffing level data derived from those schedules) is then provided by the WFM system to the CLM system. The CLM system then uses the multi-skilled agent schedules (or staffing level data) to create a second list order for the given outbound contact list. This list may be considered an optimized list given the agent schedule data provided by the WFM system. The outbound campaign is then initiated. Thereafter, and periodically during the outbound campaign, the WFM system provides the CLM system intraday (or intra-campaign) updates to the multi-skilled agent schedules and, in response, the CLM creates at least one re-optimized list order for the contact list based on the intraday data update received from the WFM system. The process can then be repeated iteratively throughout the campaign.

Owner:IEX CORP

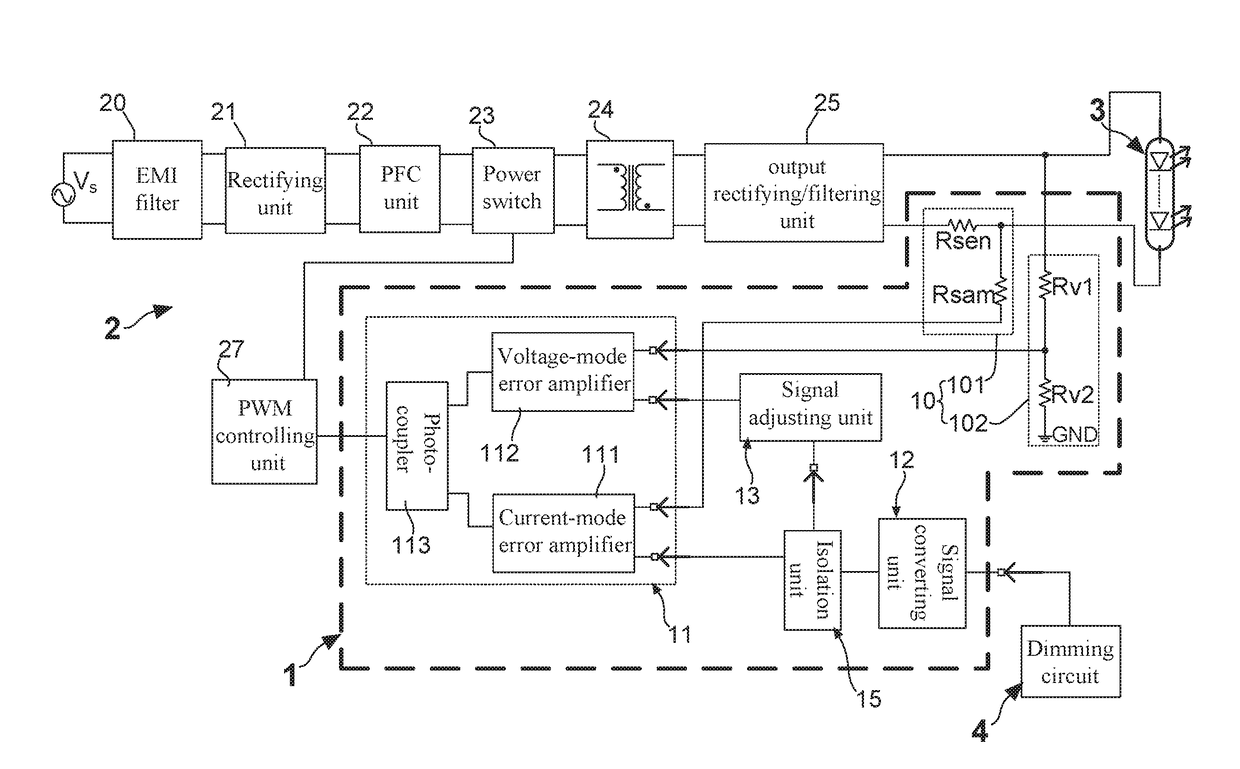

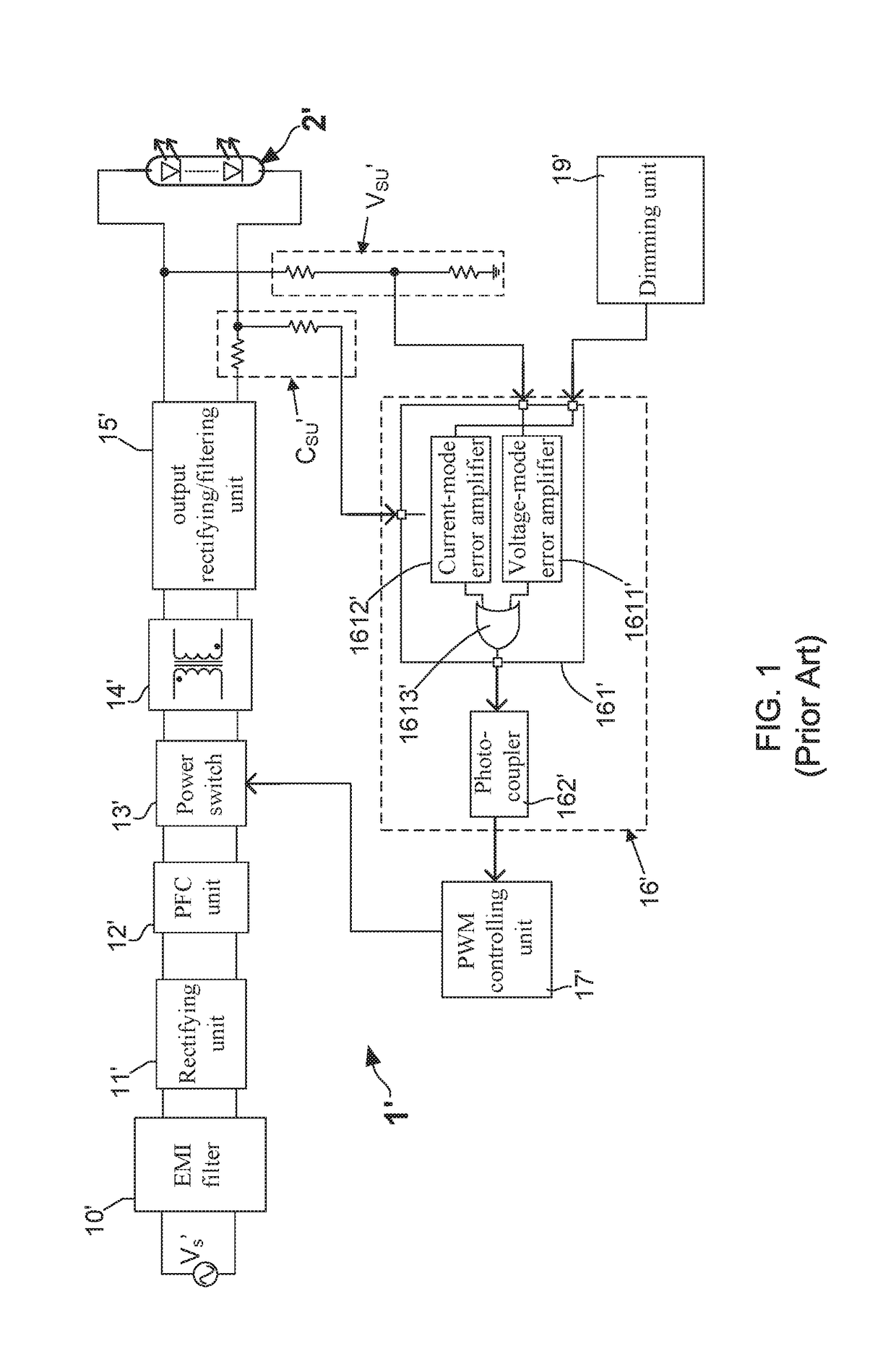

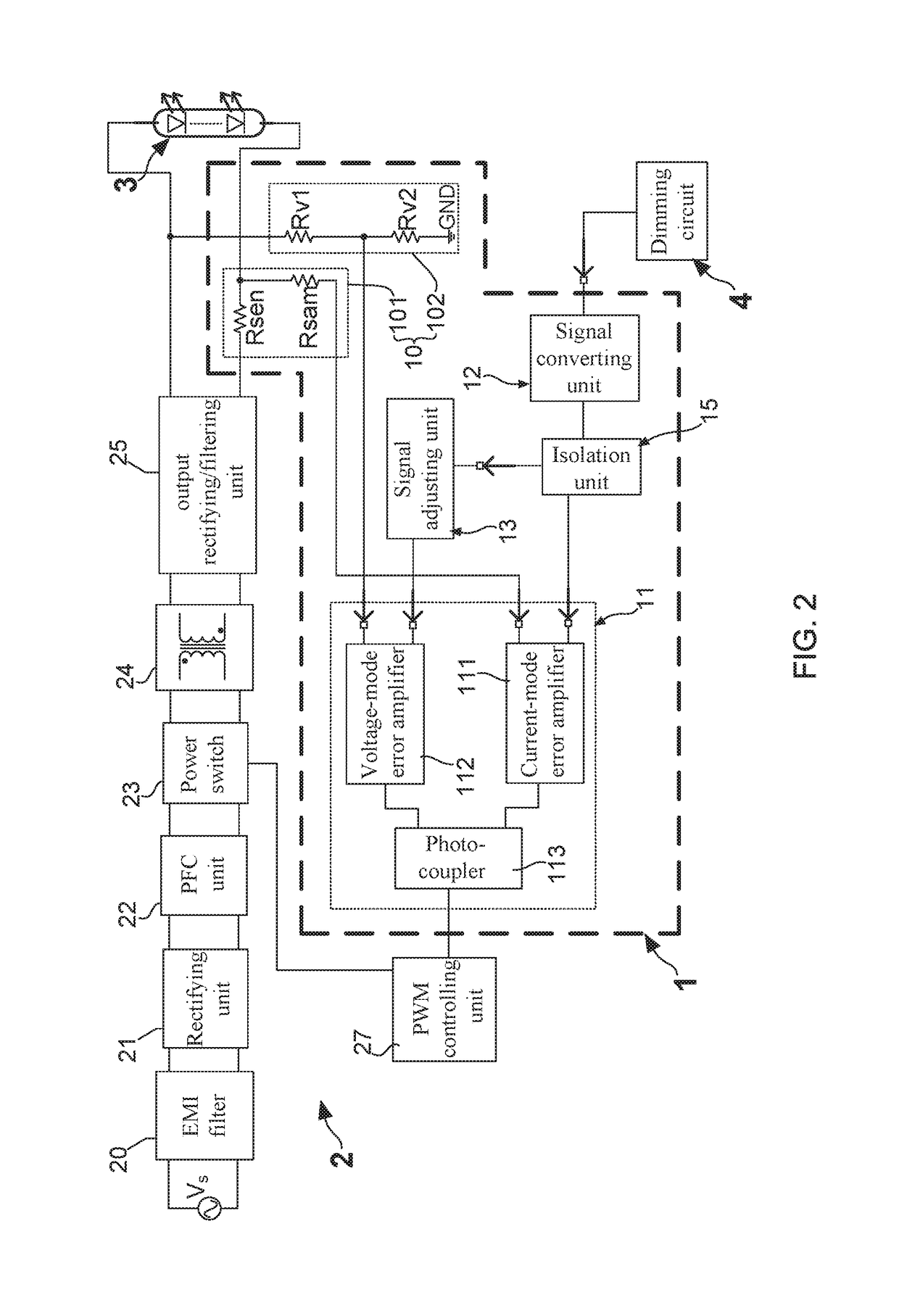

Feedback circuit

ActiveUS10039171B1FacilitateConstant output powerElectrical apparatusElectroluminescent light sourcesLed driverEngineering

The present invention particularly discloses a novel feedback circuit, mainly comprising: a signal sampling unit, a feedback unit, a signal concerting unit, and a signal adjusting unit. During the operation of the feedback circuit, a current-mode error amplifier unit is configured to output a current error signal based on a current sampling signal and a dimming signal outputted by the signal converting unit, so as to activate a PWM controlling unit to stabilize an output current of a LED driver circuit. In the meantime, a voltage-mode error amplifier unit cooperates with the PWM controlling unit to adaptively regulate an output voltage of the LED driver circuit based on a voltage sampling signal and an adjustment signal outputted by the signal adjusting unit, in order to facilitate the LED driver circuit provides a constant output power.

Owner:MEANWELL GUANGZHOU ELECTRONICS

Method for preparing absorbable suture

ActiveCN104491920APromote wound healingLow antigenicitySuture equipmentsTissue CompatibilitySide effect

The invention relates to sutures and in particular relates to a method for preparing an absorbable suture. The method for preparing the absorbable suture disclosed by the invention comprises the following steps: (1) separating protein chorion; (2) purifying collagen fibers; (3) deoiling and degreasing; (4) inactivating viruses; (5) performing chrome tanning; (6) performing crosslinking dehydration; (7) polishing; (8) performing chitosan atomization; and (9) packaging. The absorbable suture prepared by the method disclosed by the invention has the characteristics of high tensile strength, knotting firmness, high biocompatibility and small toxic and side effects, and the suture can be absorbed by the body. The suture is completely absorbed, an absorption reaction is avoided, the suture does not need to be taken out, the tissue compatibility is high, and an adverse reaction in the human body is avoided regardless of the time; and moreover, the surface is smooth, the suture is difficultly infected by germs, and infection can be avoided.

Owner:SHANDONG BODA MEDICAL PROD CO LTD +1

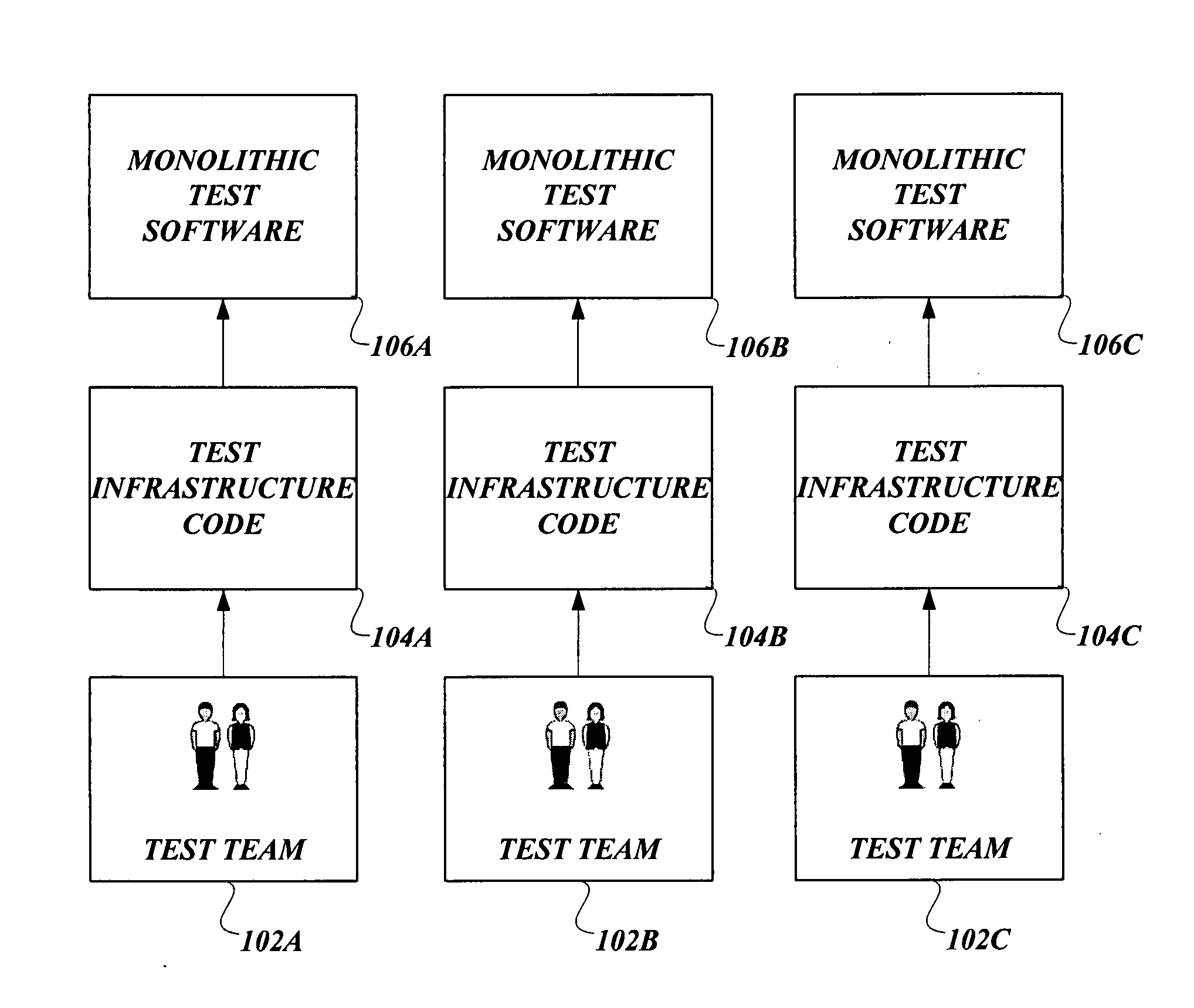

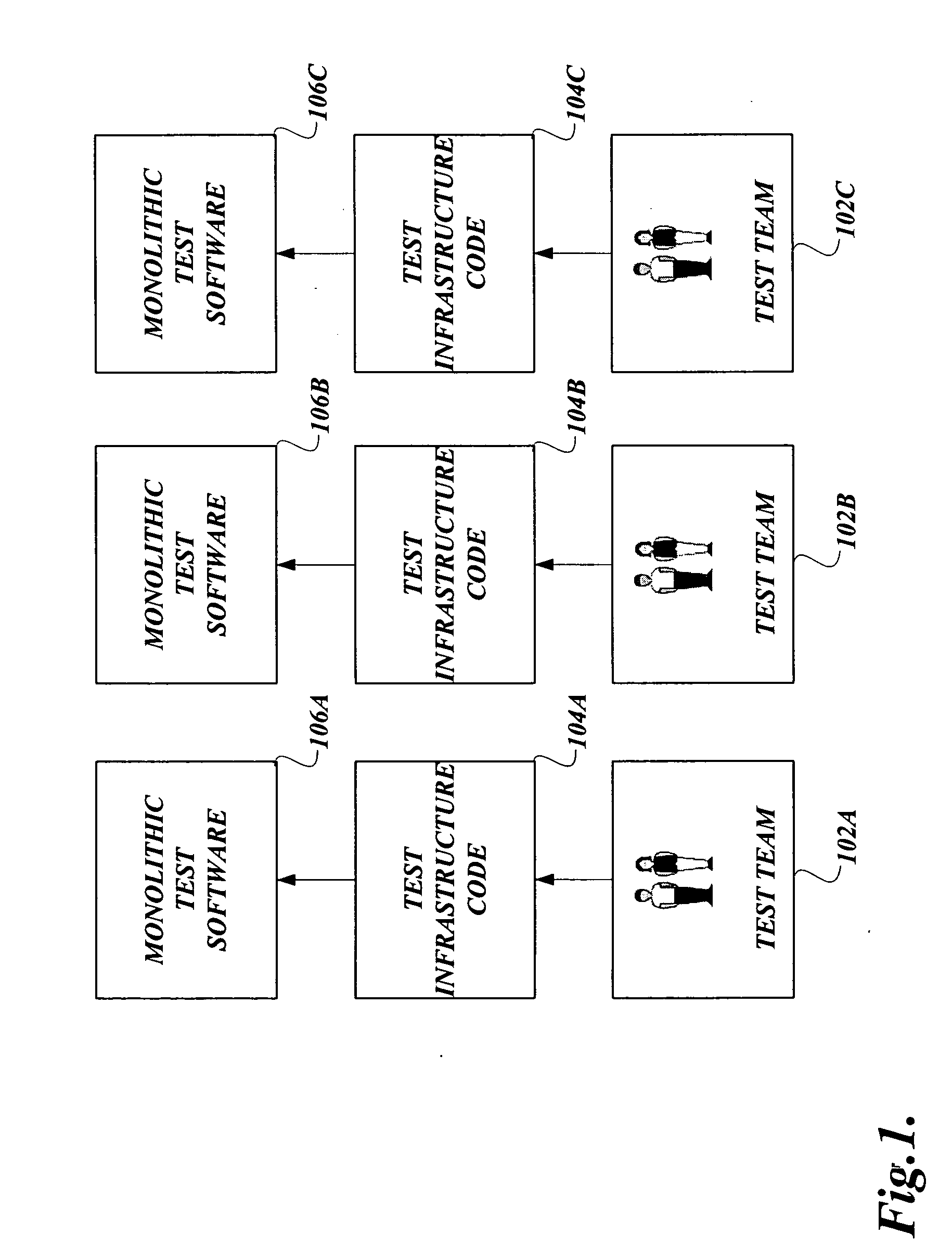

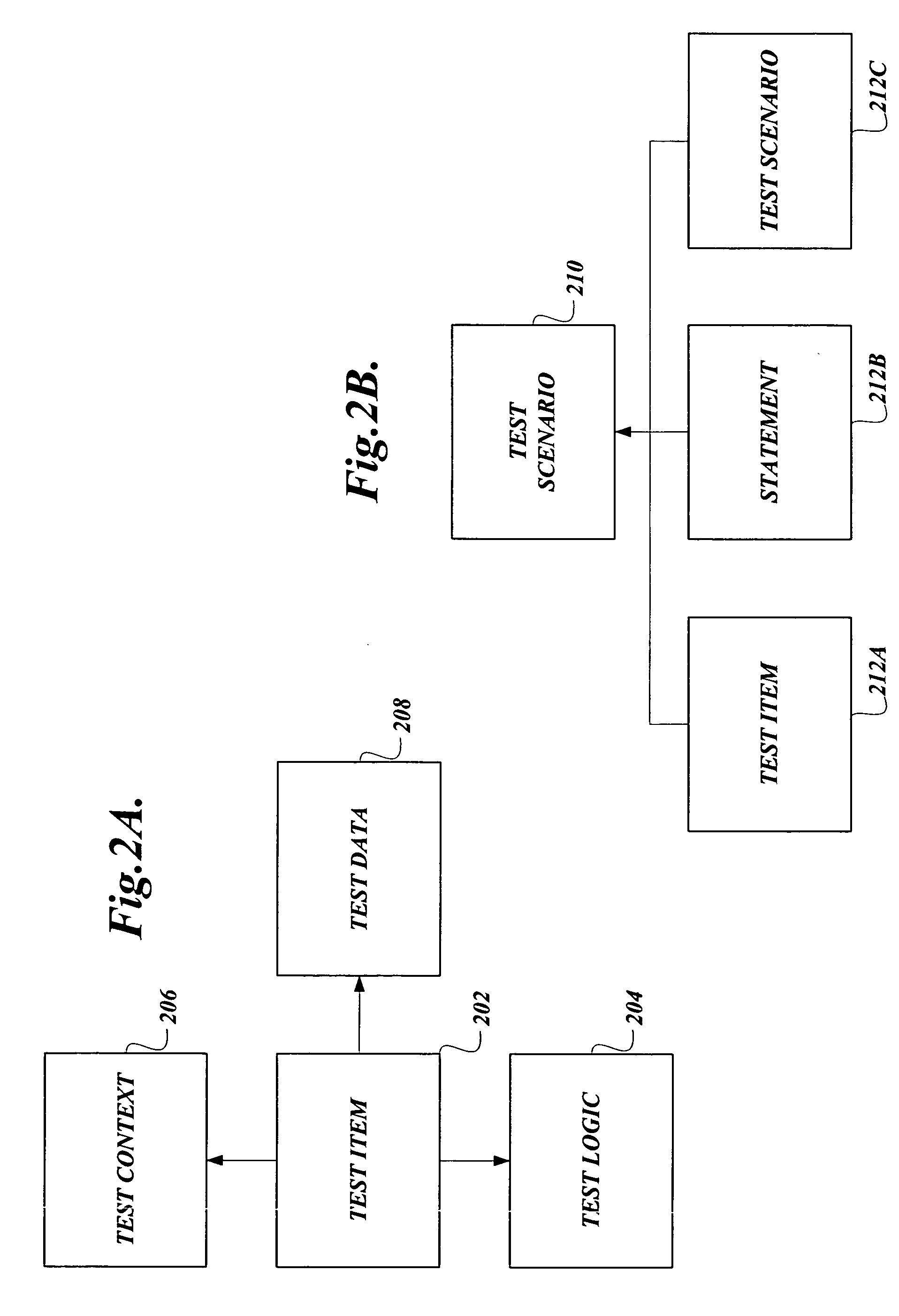

Software test framework

A reusable software test framework includes abstract and concrete classes as well as a user interface, for assisting in creating test scenarios from test items. A test item is a reusable test unit. The test item can be combined with other test items to create a test scenario that can be executed to perform a particular test for various pieces of software. Disassociated with the test item is a test context, test data, and test logic.

Owner:MICROSOFT TECH LICENSING LLC

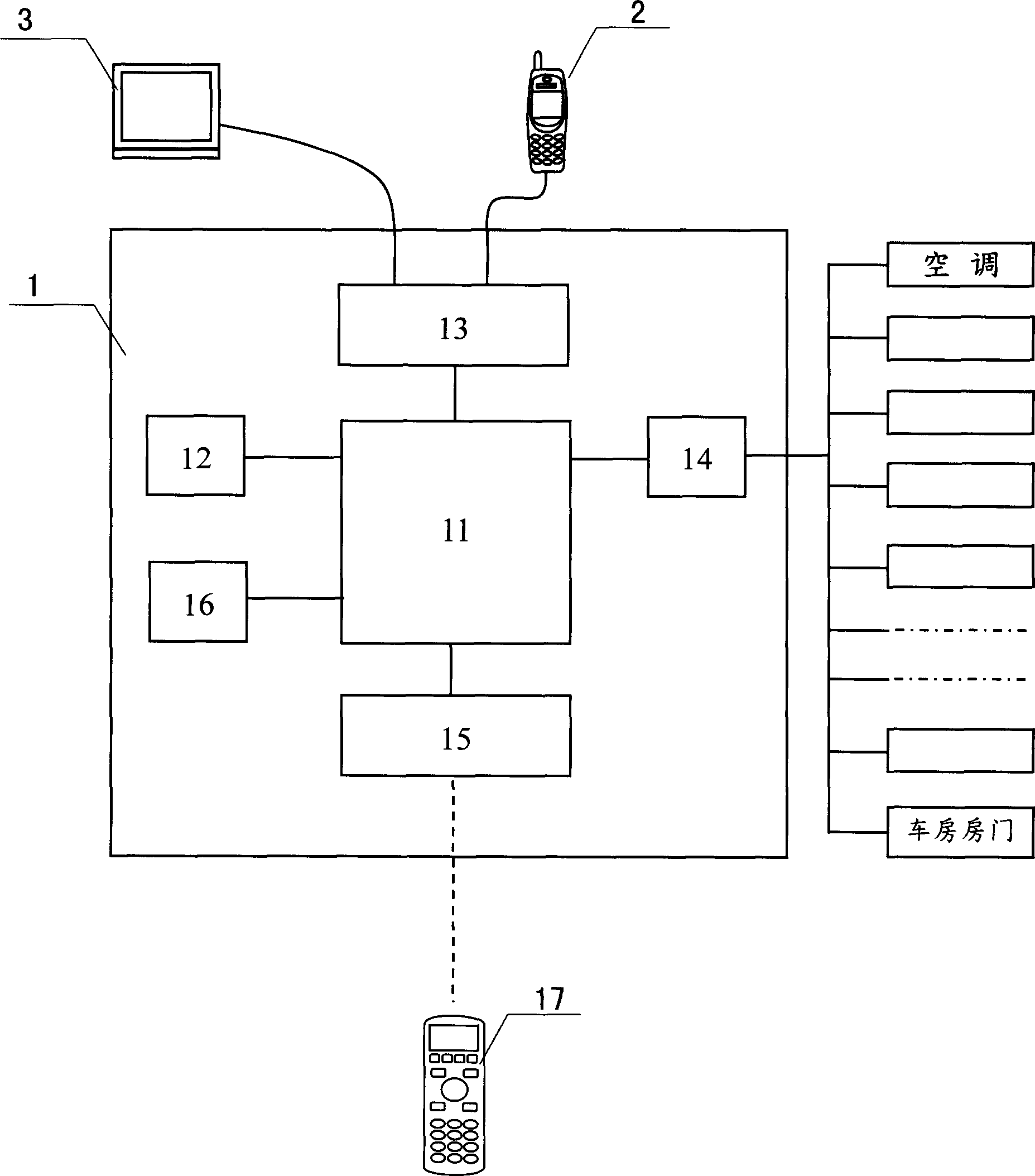

Handset remote controller and its relevant combination device

InactiveCN1801868AFacilitateImprove efficiencyNon-electrical signal transmission systemsTelephonic communicationRemote controlAgricultural engineering

present invention refers to a handset remote controller and relevant assembly, It features that said including handset remote controller handset tv set , wherein handset is connected with remote controller, tv set connected with handset remote controller. Said assembly can remote control domestic air conditioner , gate video recorder etc by handset remote controller through handset and communication network. Said invention enlarges service efficiency and raises saves equipment resource.

Owner:黄金富

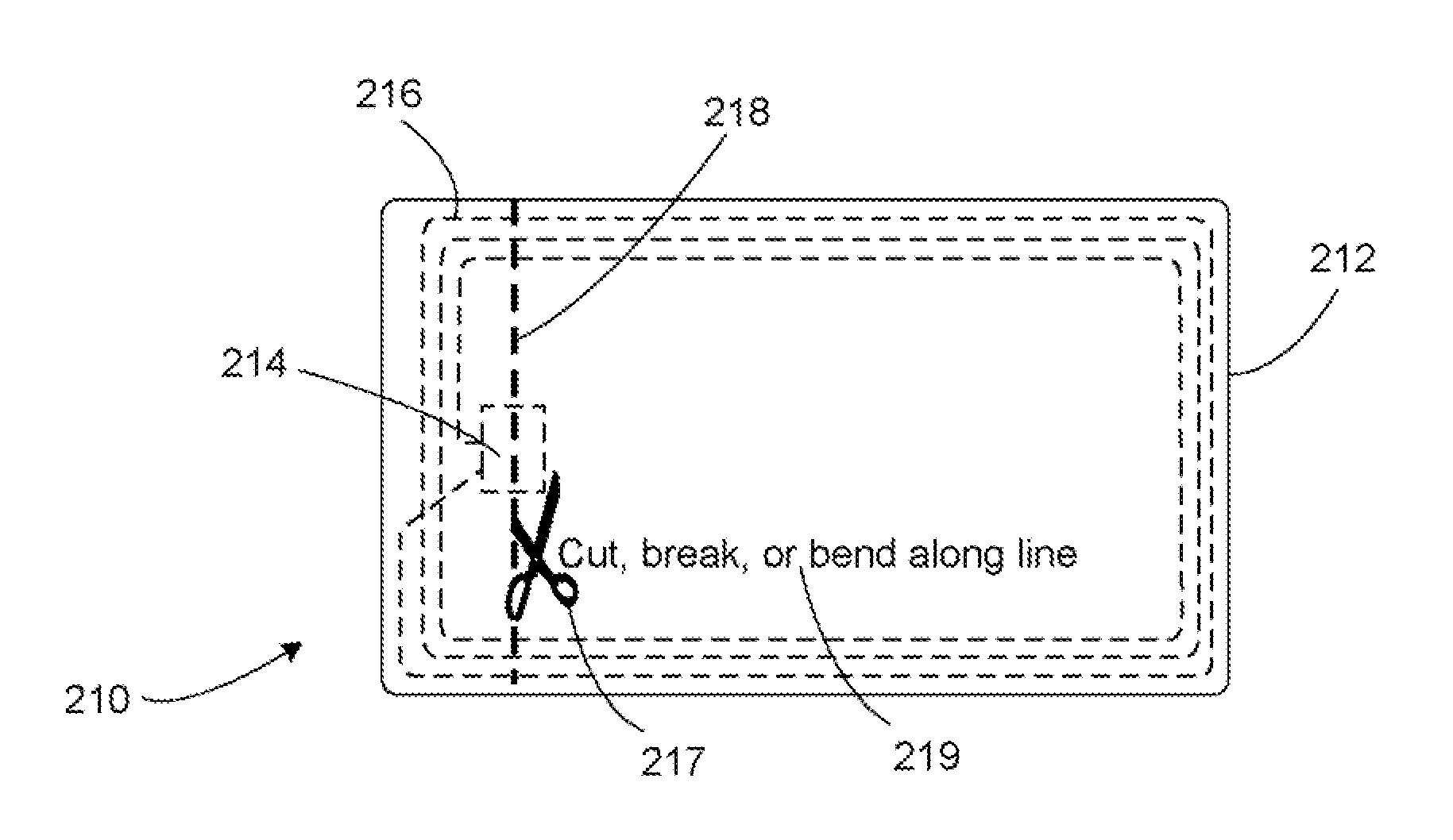

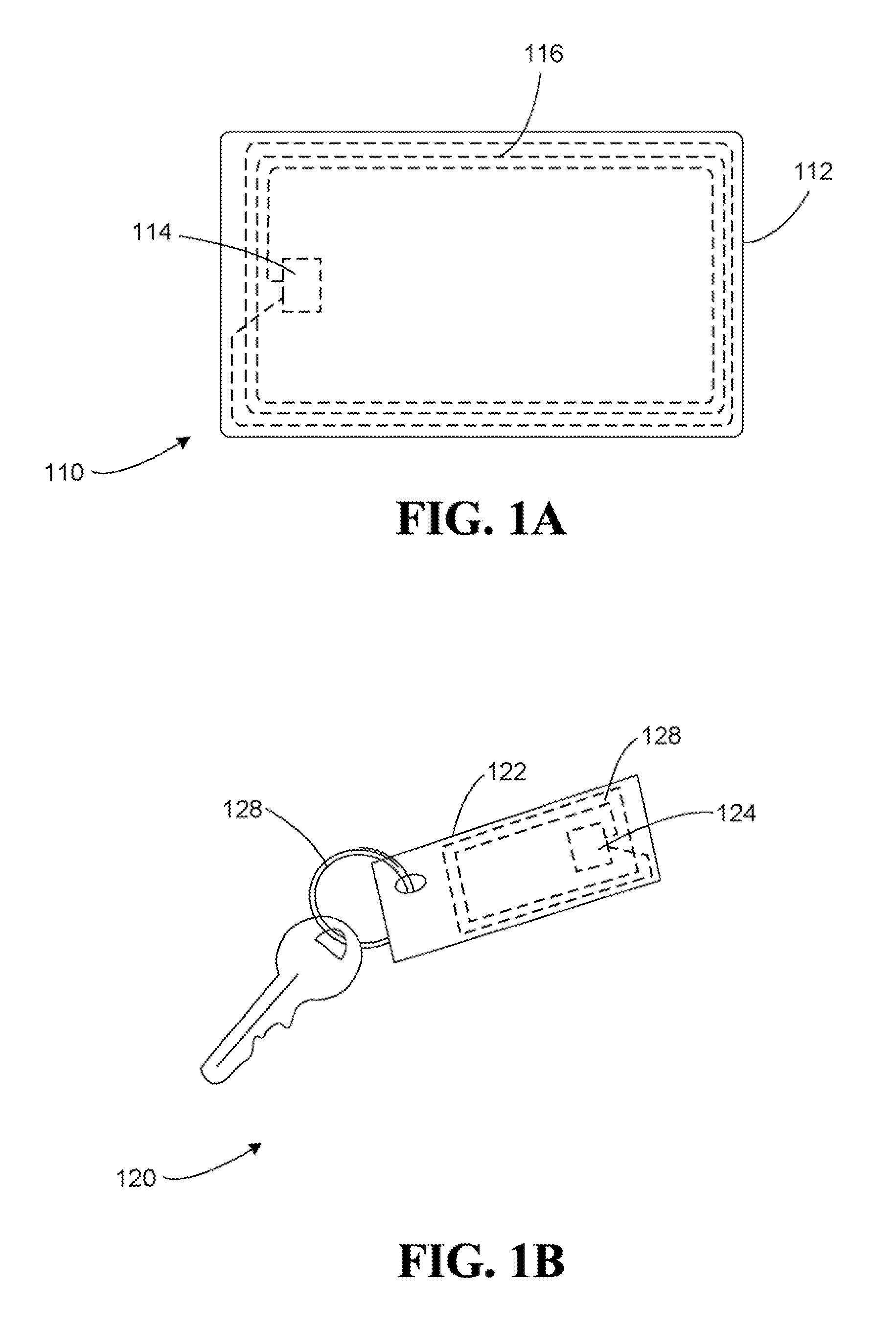

Systems and Methods for Disabling a Contactless Transaction Device

InactiveUS20100102131A1FacilitateRecord carriers used with machinesWaveguide type devicesEngineeringElectronic transaction

Certain embodiments of the invention can provide systems and methods for disabling a contactless transaction device. In one example embodiment, a contactless transaction device operable to facilitate an electronic transaction is provided. The device may include a body, a microchip integrated with the body, and an antenna integrated with the body and in communication with the microchip. The body may include destruction indicia to indicate at least one position on the body to receive a force to disable use of the contactless transaction device for facilitating an electronic transaction.

Owner:FIRST DATA

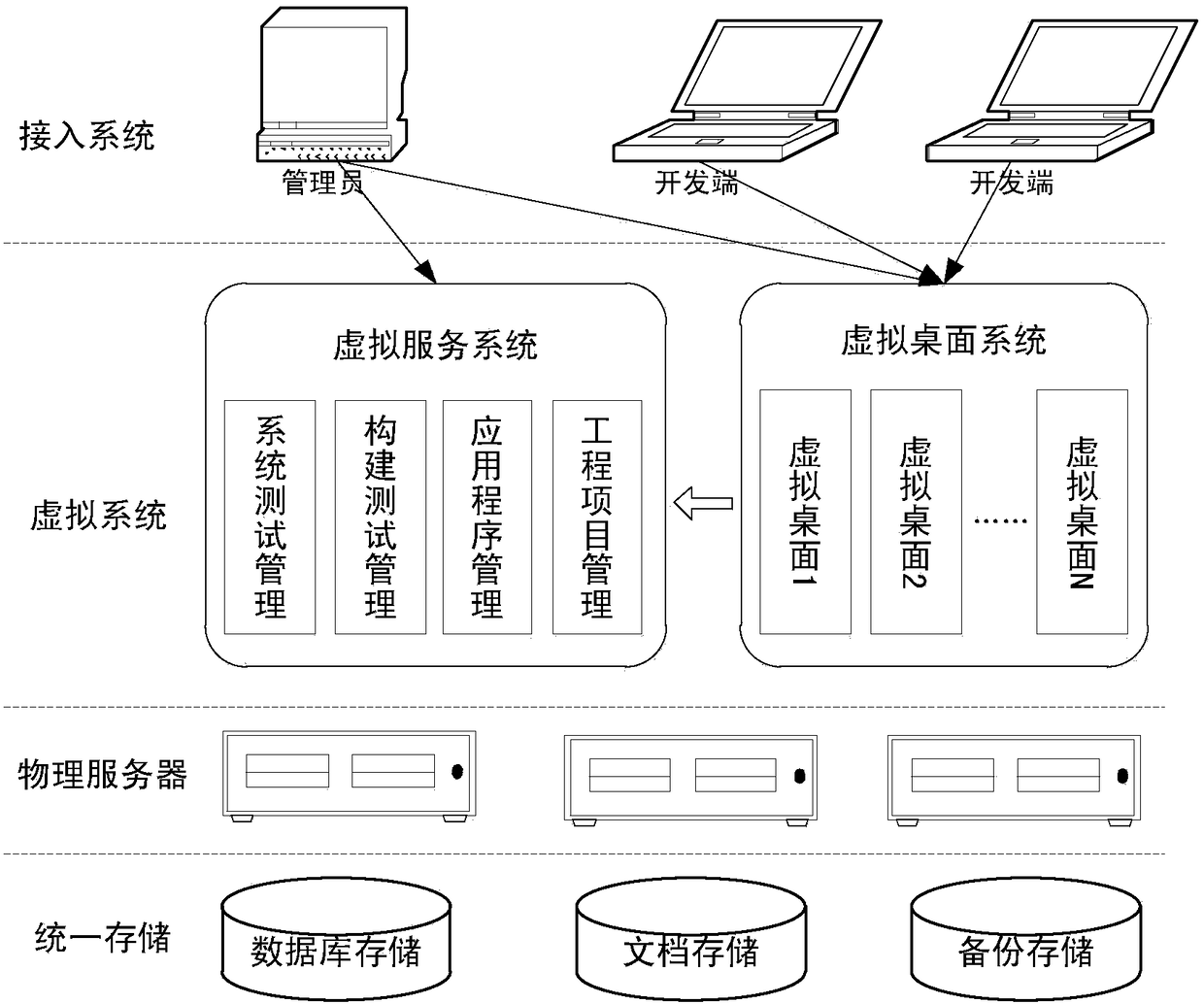

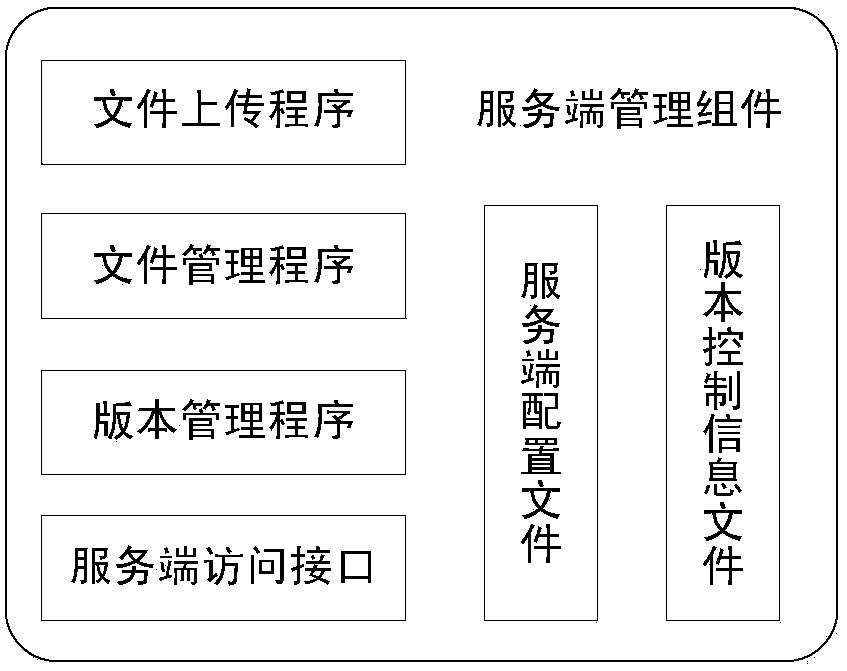

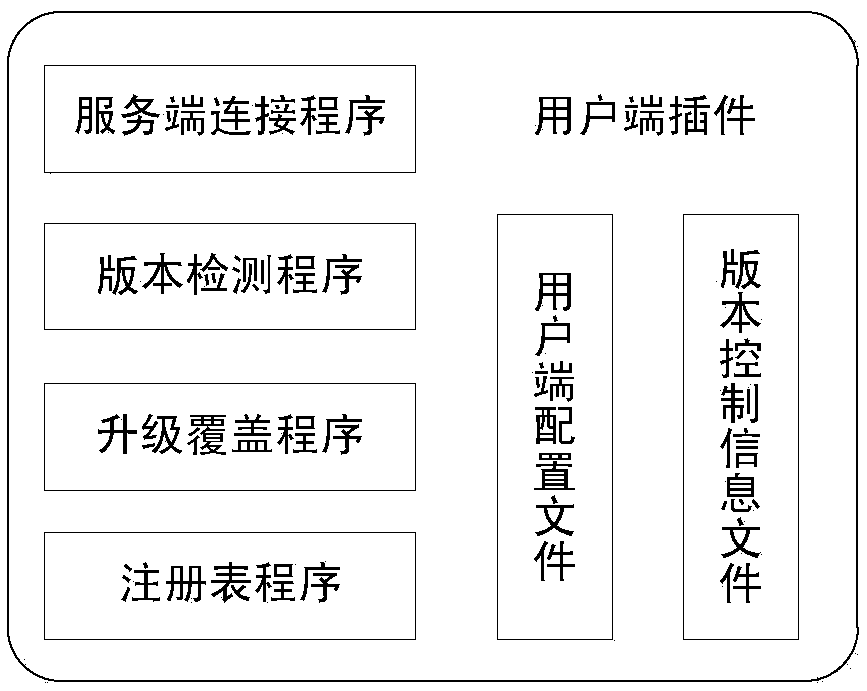

Integrated system and method for developing and deploying application program

InactiveCN108446102ASafe and efficient developmentSafe and efficient testingVersion controlSoftware testing/debuggingVirtualizationGraphics

The invention provides an integrated system and method for developing and deploying an application program, and belongs to the technical field of drilling software. The system includes a storage system, a physical server, a virtual system, an access system, and a client. The storage system is used for storing software developing tools, program codes and document data. The physical server is builton the storage system, can carry out high-speed graphics processing, and supports virtualization software. The virtual system virtualizes the physical server into a plurality of virtual machines, wherein each virtual machine is deployed with a virtual service system and a virtual desktop system. The access system is used by developers to access system service resources built by the virtual servicesystem through the virtual desktop system, and is used by a system administrator to manage and adjust the virtual service system and the virtual desktop system. The client is used for accessing the application program of the virtual service system. The integrated system and method for developing and deploying the application program greatly reduce the cost of system development, release, upgradeand maintenance.

Owner:CHINA PETROLEUM & CHEM CORP +1

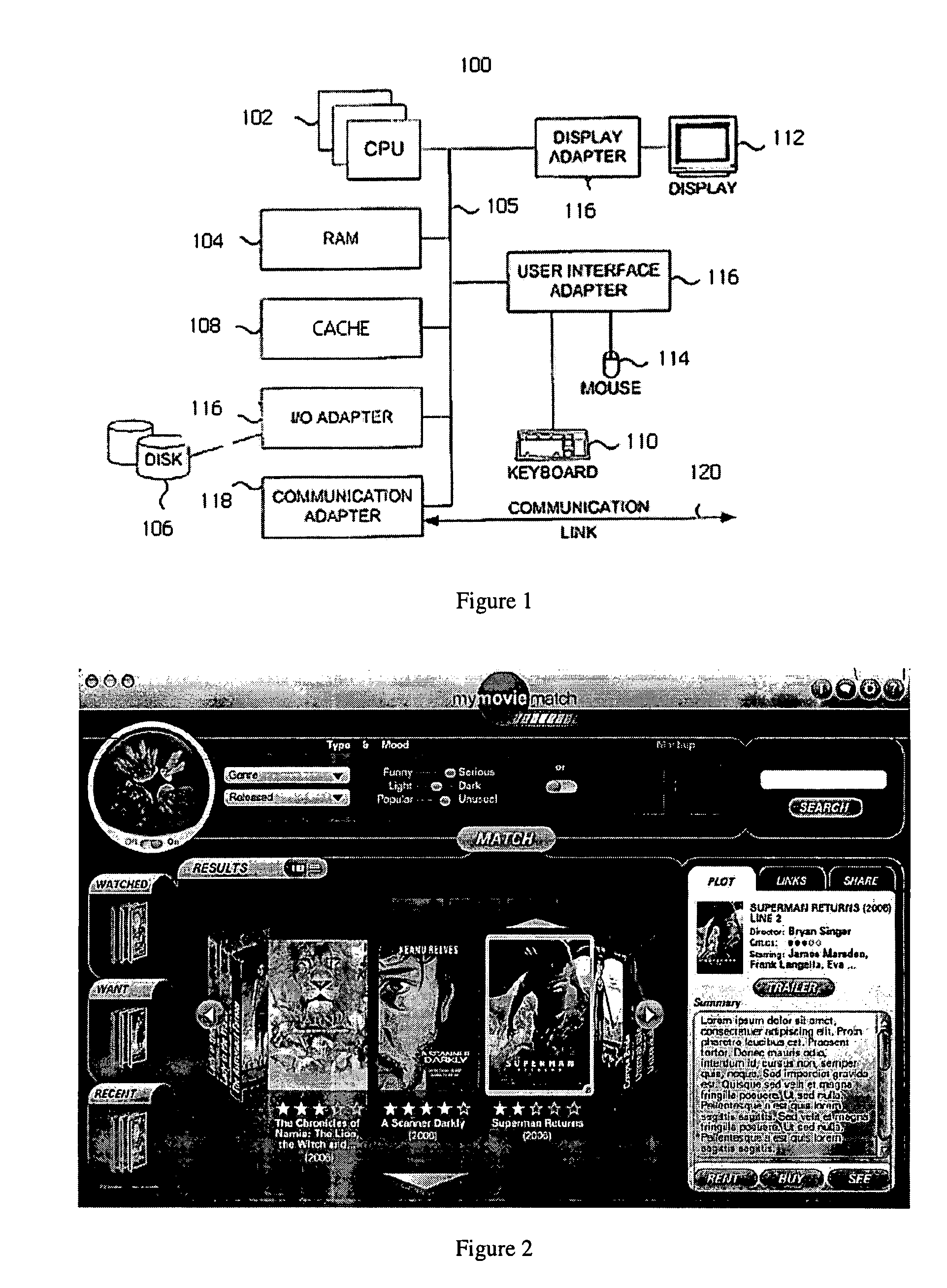

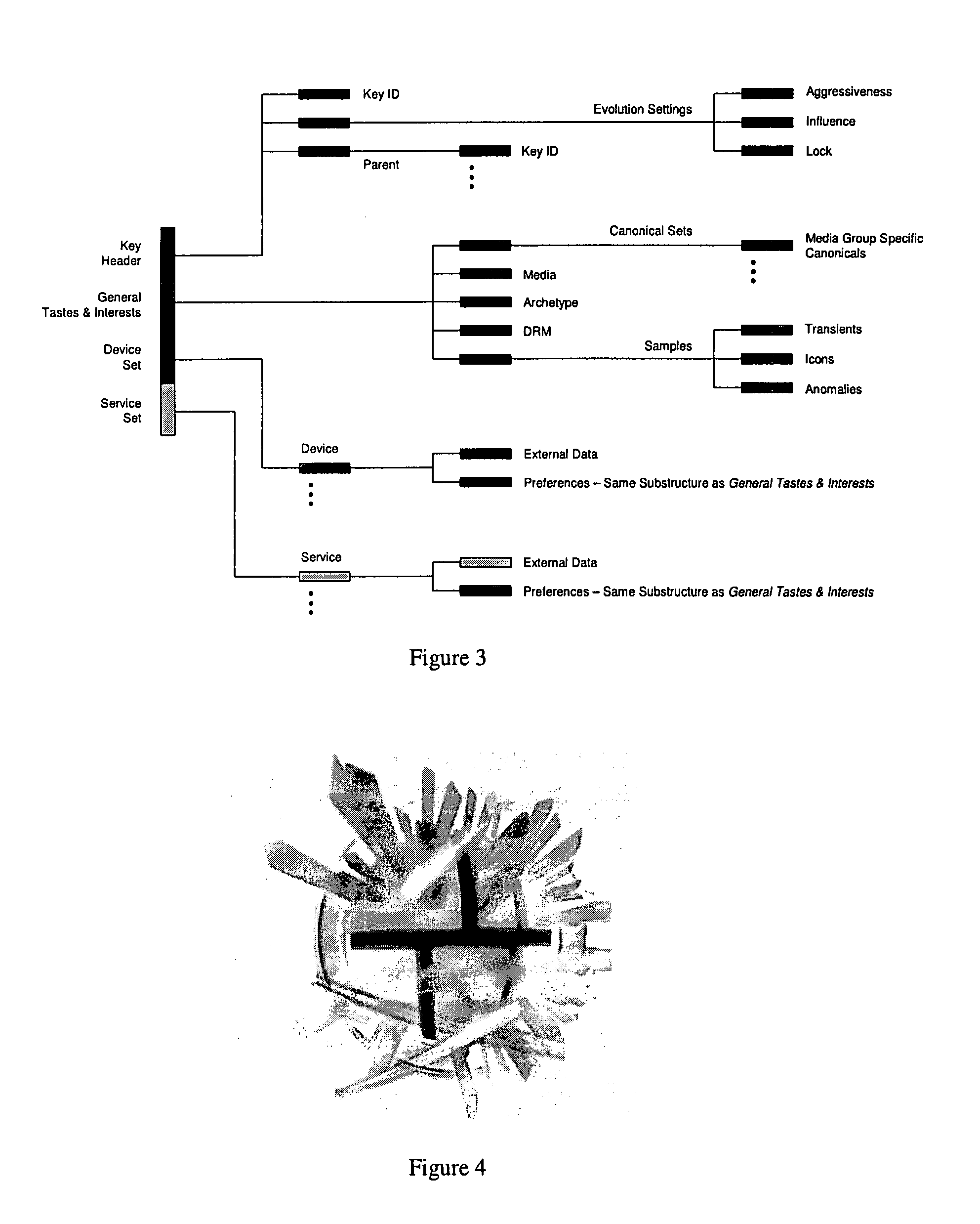

Display method and system for collecting media preference information

InactiveUS20090083320A1FacilitateEasy to findDigital data information retrievalSpecial data processing applicationsWeb siteMultiple site

An end user media preferences “key” captures an end user's personal media interests and tastes in a unique display format that is saved locally to an end user's computer. The key is forged using a display interface on a given site. As the end user later navigates to different web sites having media discovery applications and services, he or she uses the key to facilitate a media discovery process on such sites. In this manner, the key captures, carries and controls access to the end user's personal interests and tastes across multiple sites.

Owner:MATCHMINE

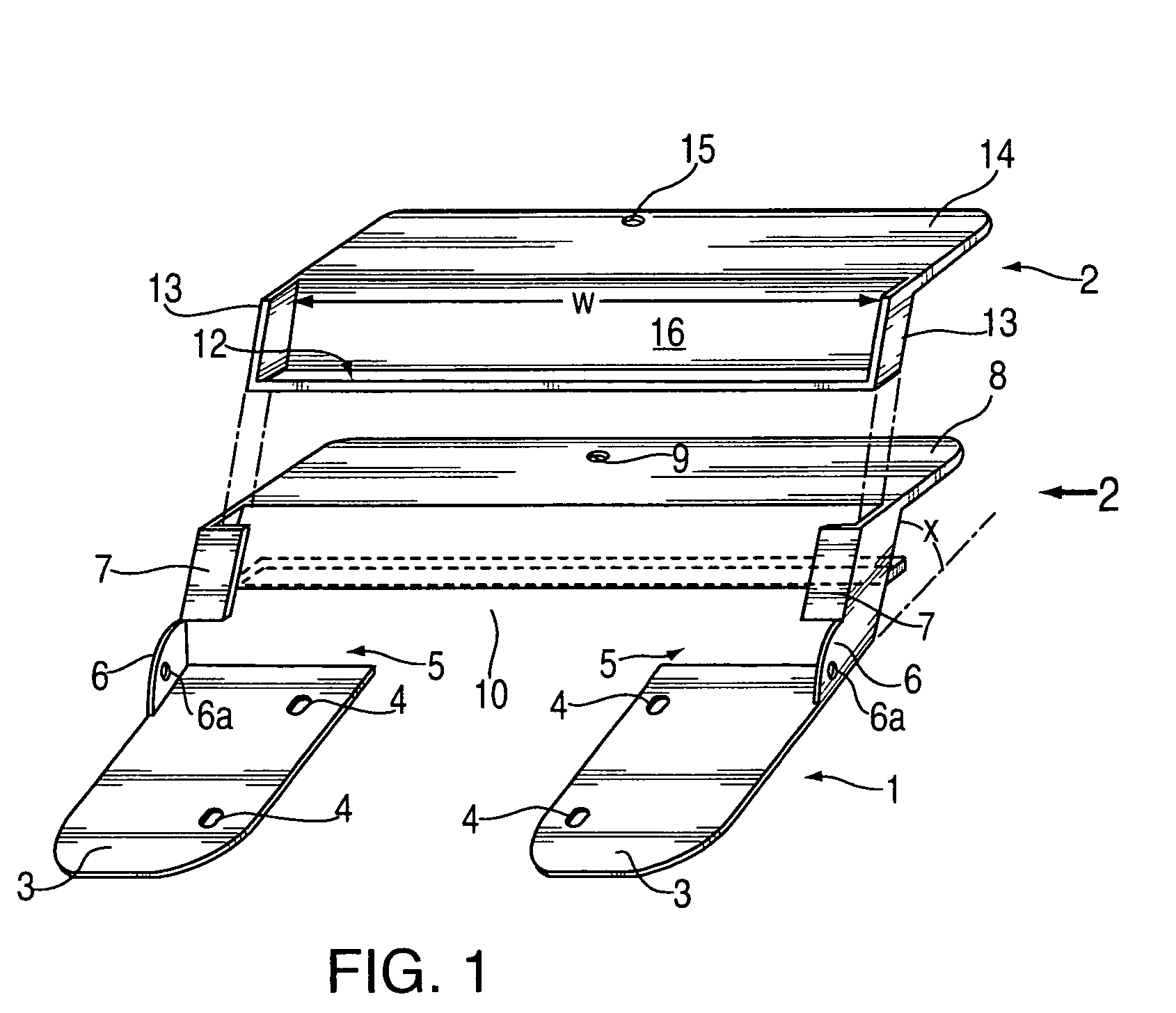

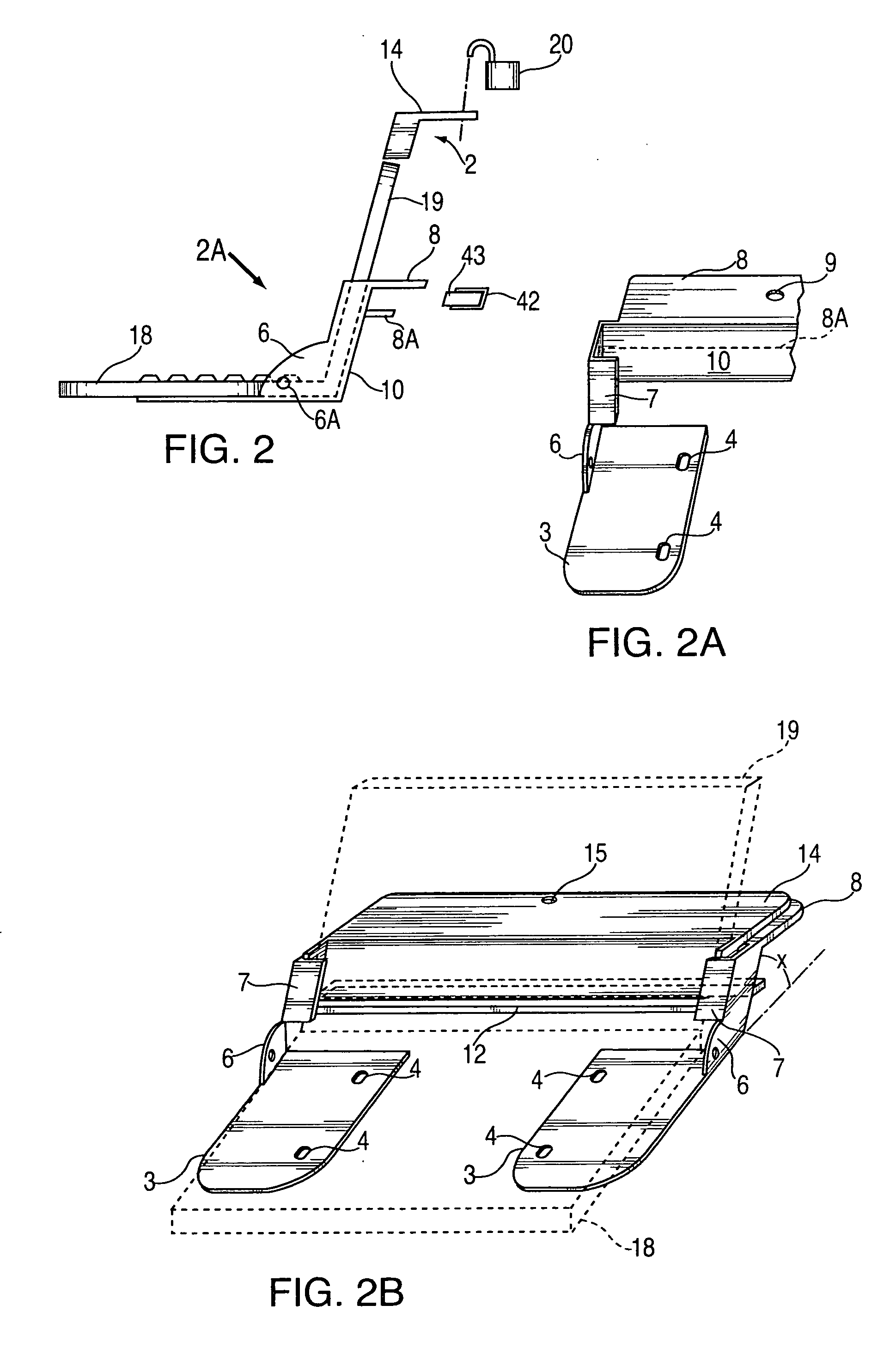

Notebook computer locking base

ActiveUS20050248914A1FacilitateAvoid spreadingLocks for portable objectsDigital data processing detailsLaptopMechanical engineering

A notebook / laptop computer locking assembly includes a locking base secured to a working surface. The locking base has a first rear wall to receive a keyboard portion of the notebook computer, with a screen portion of the notebook computer in the open position resting against the rear wall. A locking bar is adapted to pivot over the notebook computer screen in the open position, extending across a front surface of the screen portion. This locking bar has a rearwardly extending locking plug insertable within a locking receptacle of a lock. The locking bar is deployed on the notebook computer, thereby preventing removal of the notebook computer from the locking base. Additionally, locking holes are aligned with each other to receive a padlock to lock the locking bar to the locking base.

Owner:THINK PROD

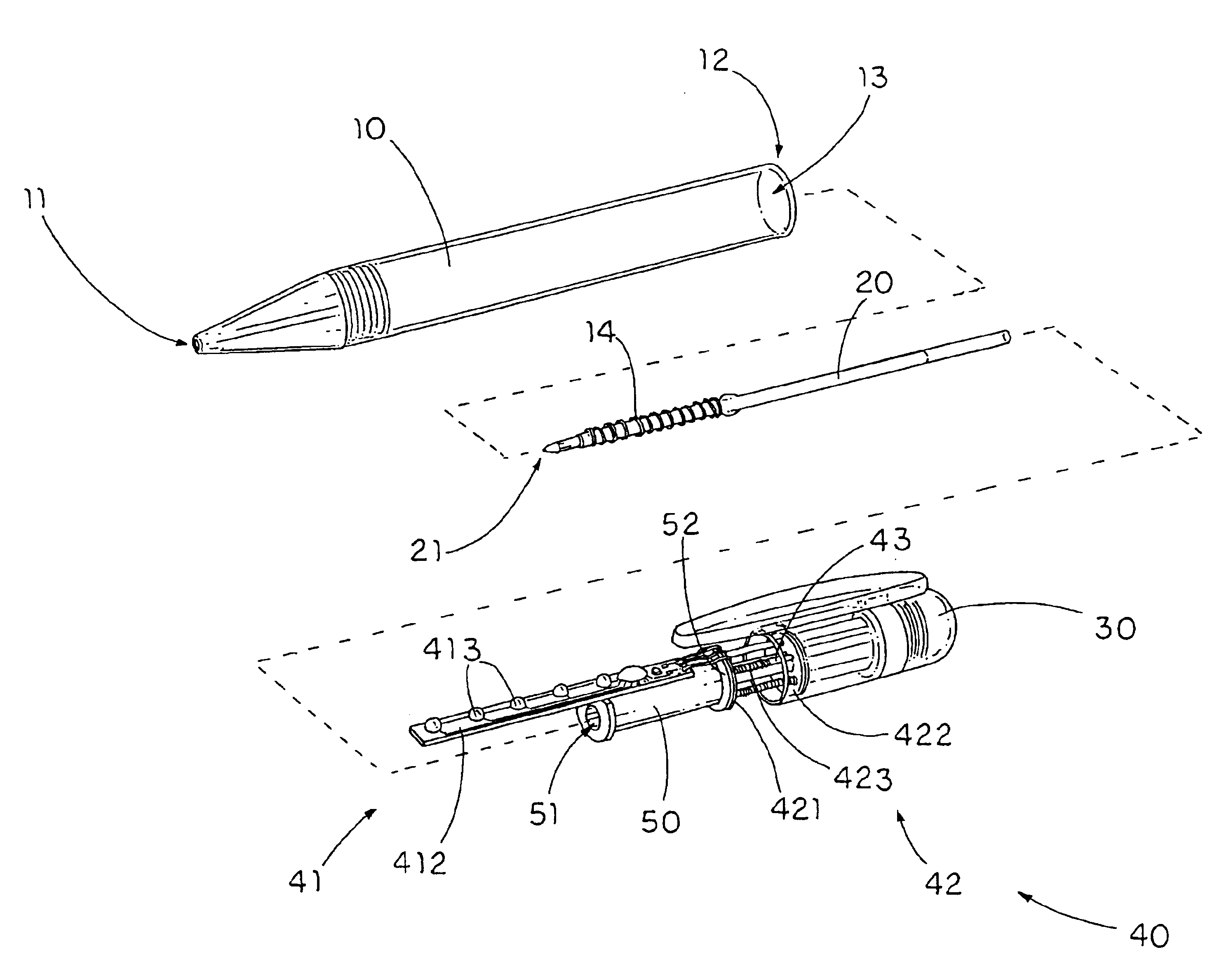

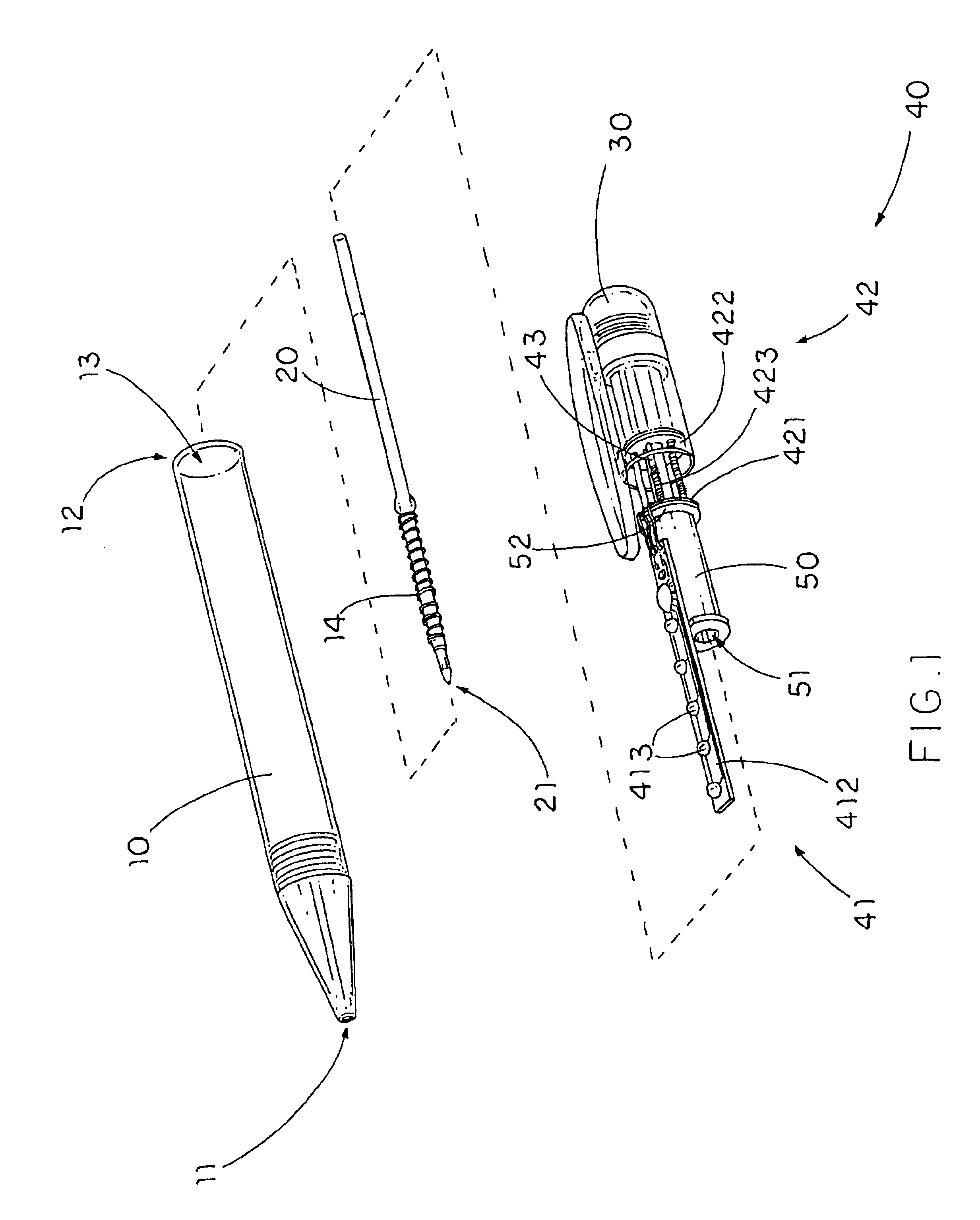

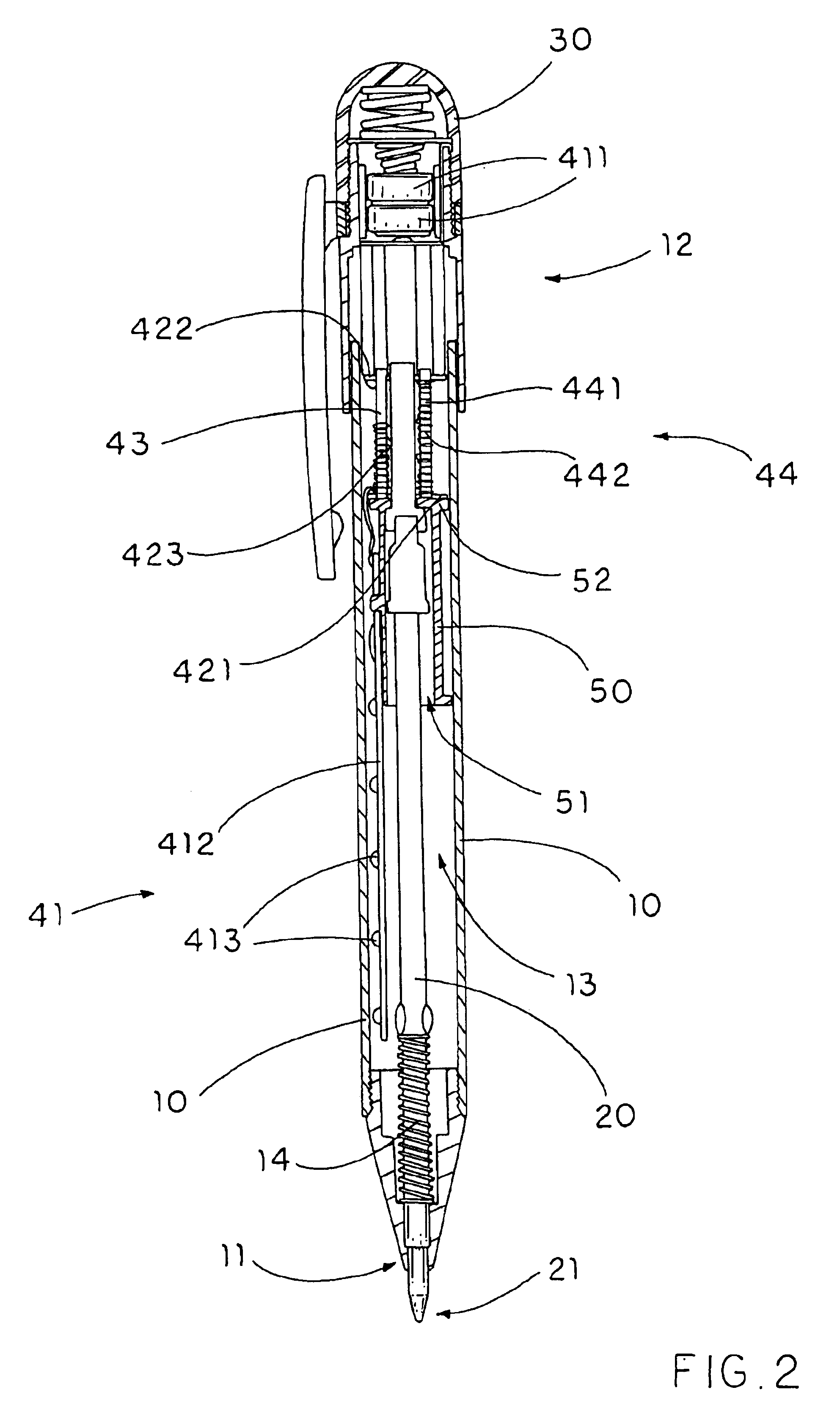

Illuminable writing instrument

InactiveUS6837639B2Improved aesthetic appearanceFacilitateBall-point pensInk reservoir pensEngineeringElectrical and Electronics engineering

An illuminable writing instrument includes a hollow elongated body having a first end, an opposed second end, and a receiving cavity, wherein the elongated body is adapted for a light passing from the receiving cavity to outside, a writing unit, having a writing tip, disposed in the receiving cavity, an actuator mounted at the second end of the elongated body to move the writing unit from a normal unemployed position to an operation position, and an illumination arrangement including an illuminating unit supported within the receiving cavity of the elongated body and a switch control which is electrically connected to the illuminator and is arranged to activate the illuminating unit for providing a lighting effect throughout the elongated body while actuating the writing unit via the actuator.

Owner:TUNG YIK INT

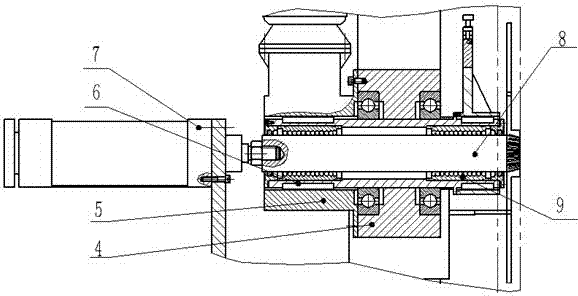

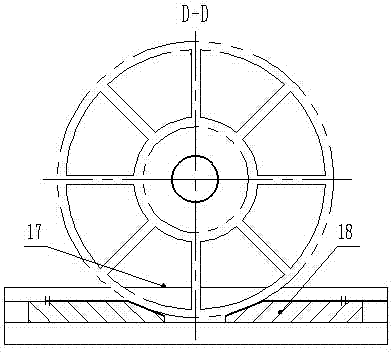

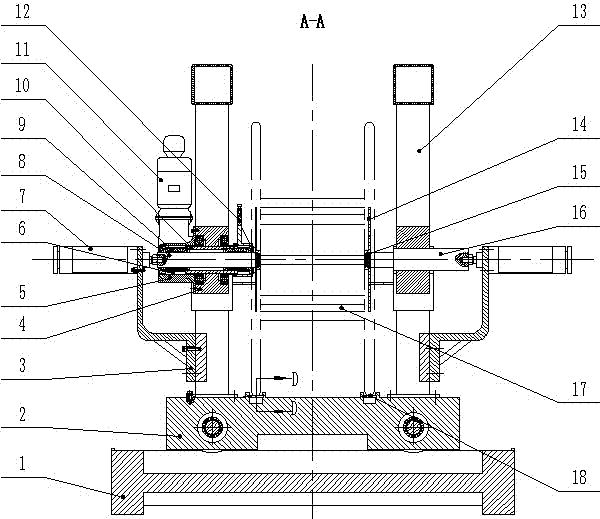

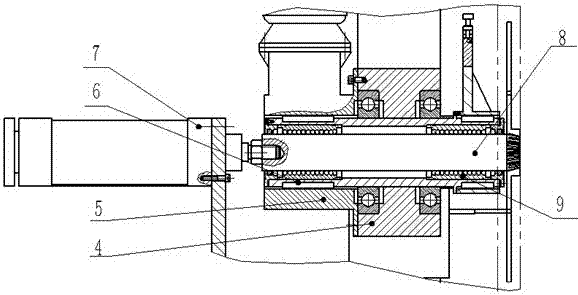

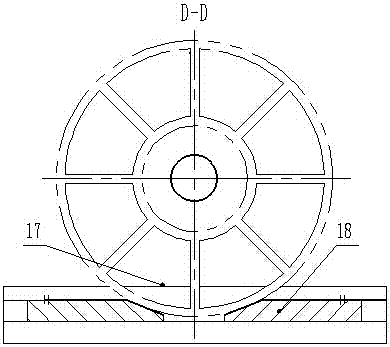

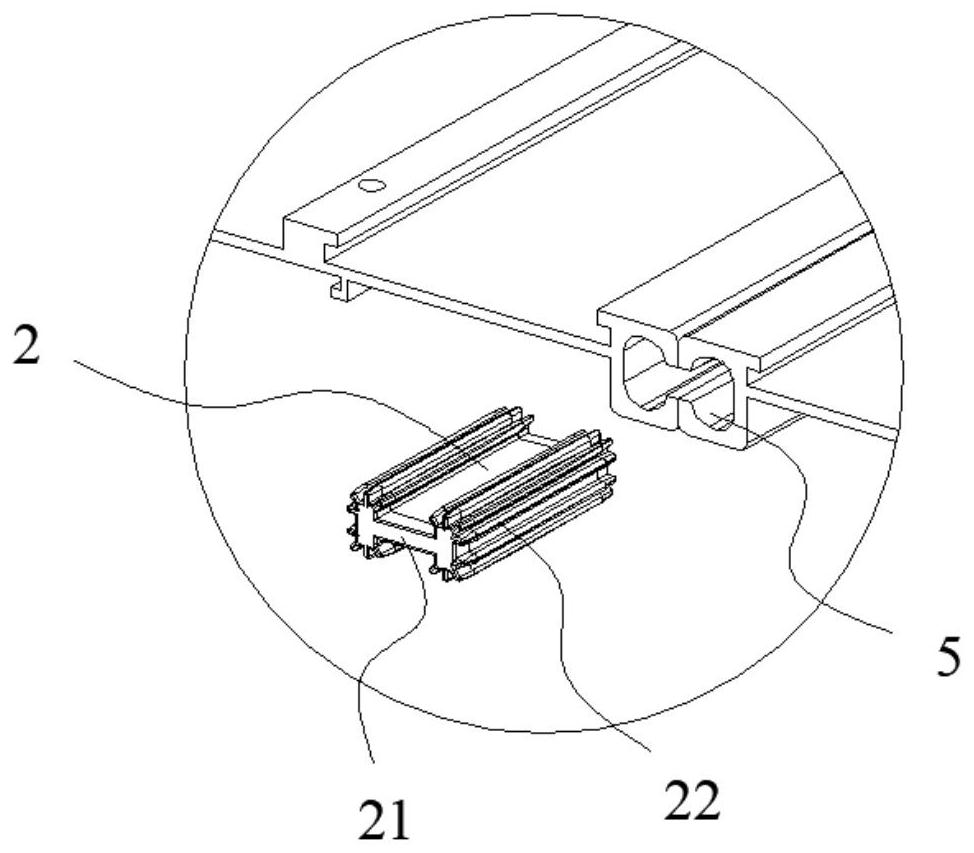

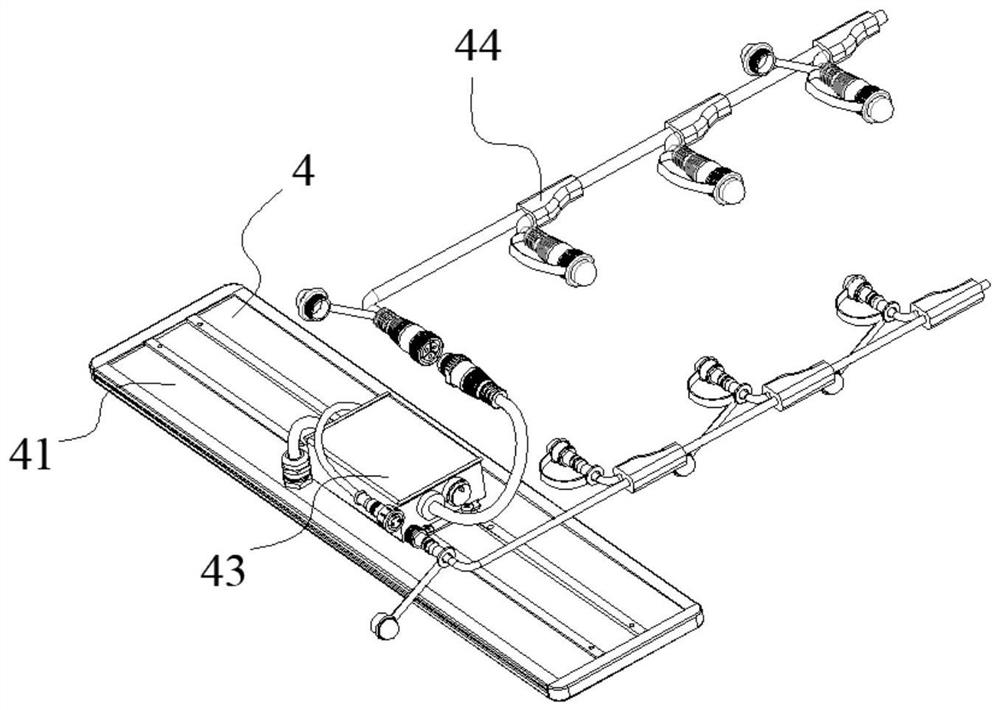

Automatic ground rail type steel wire rope winding machine without lifting device

InactiveCN104773606AThe overall structure is simpleReduce the incidence of complete machine failureFilament handlingWinding machineEngineering

Owner:UNIV OF JINAN

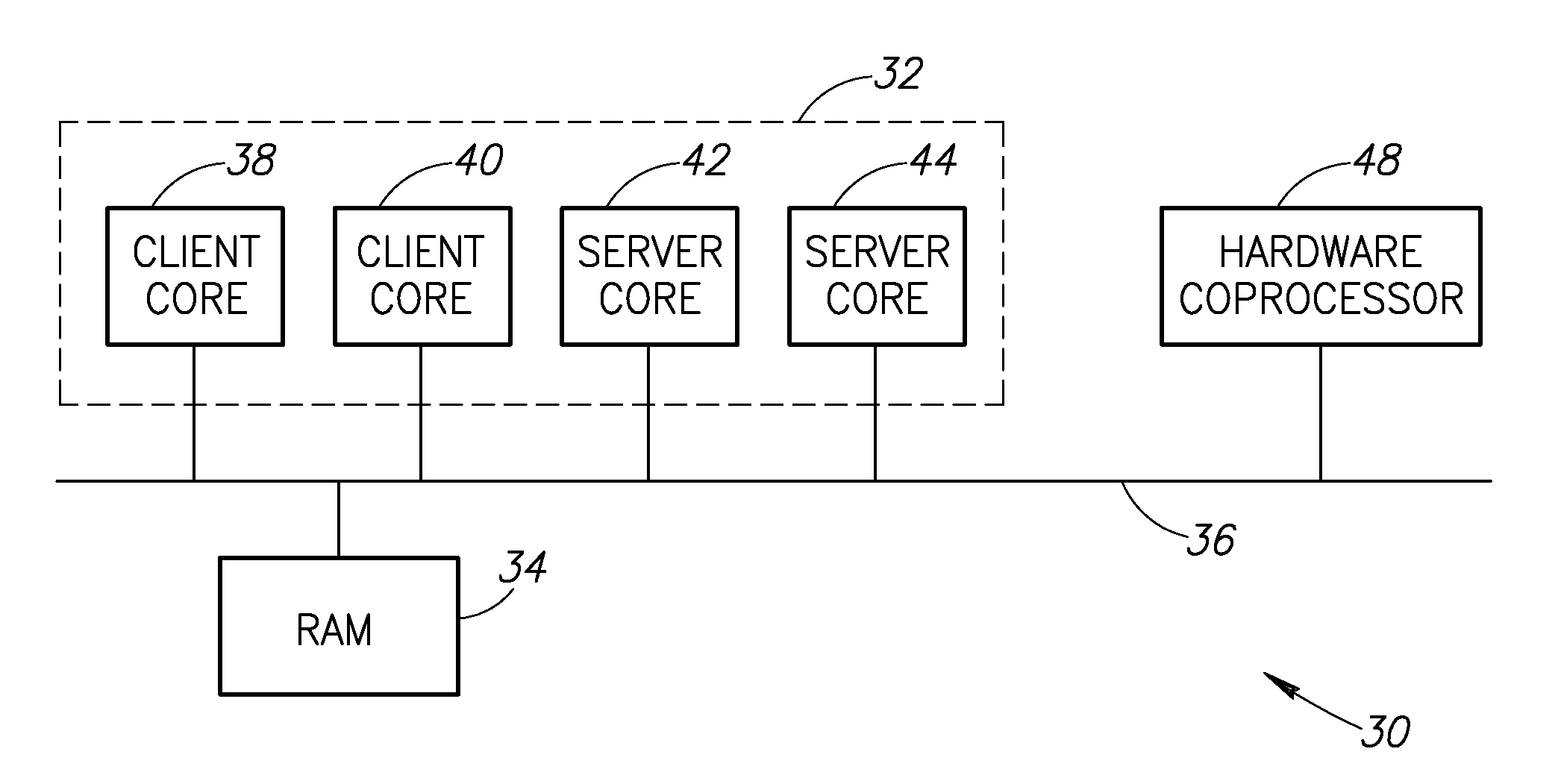

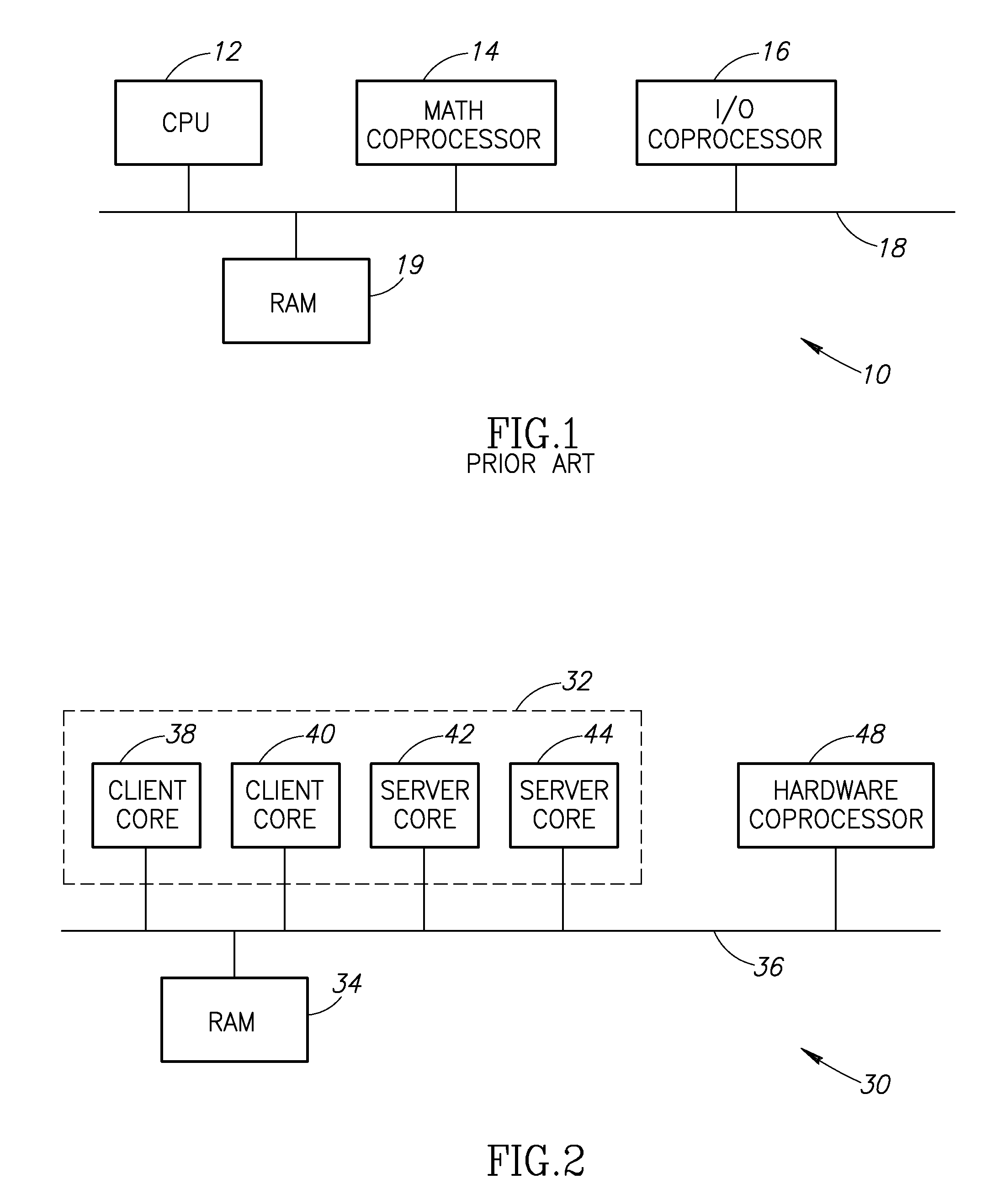

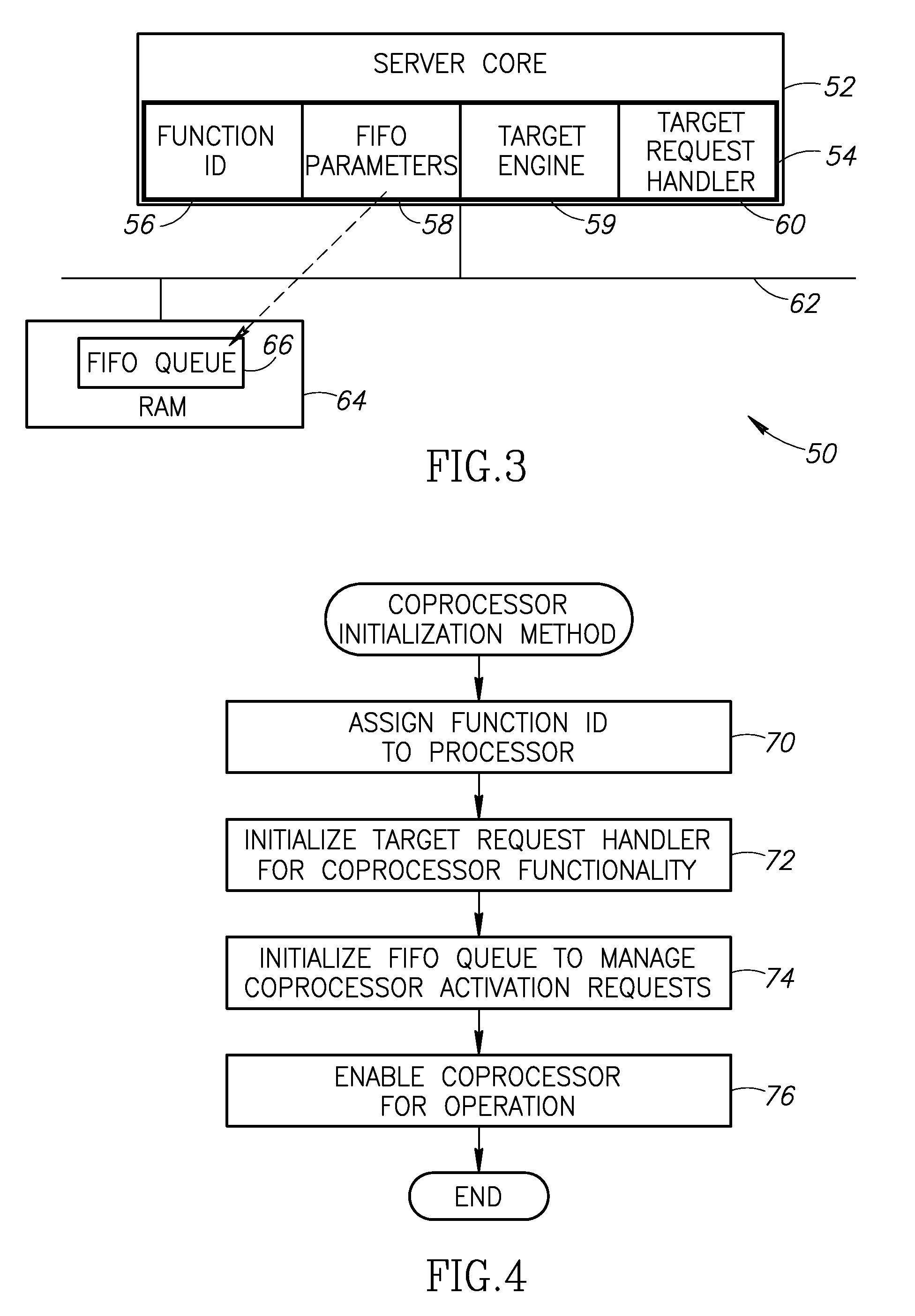

Apparatus for and Method of Processor to Processor Communication for Coprocessor Functionality Activation

InactiveUS20090216998A1FacilitateImproved processor performanceGeneral purpose stored program computerMachine execution arrangementsSpecific functionOperating system

A novel and useful mechanism enabling a processor in a multiprocessor complex to function as a coprocessor to execute a specific function. The method includes a mechanism for activating a coprocessor to function as a coprocessor as well as a mechanism to execute a coprocessor request on the system. The present invention also provides a mechanism for efficient processor to processor communication for processors coupled to a common bus. Overall system performance is enhanced by significantly reducing the use of hardware interrupts for processor to processor communication.

Owner:IBM CORP

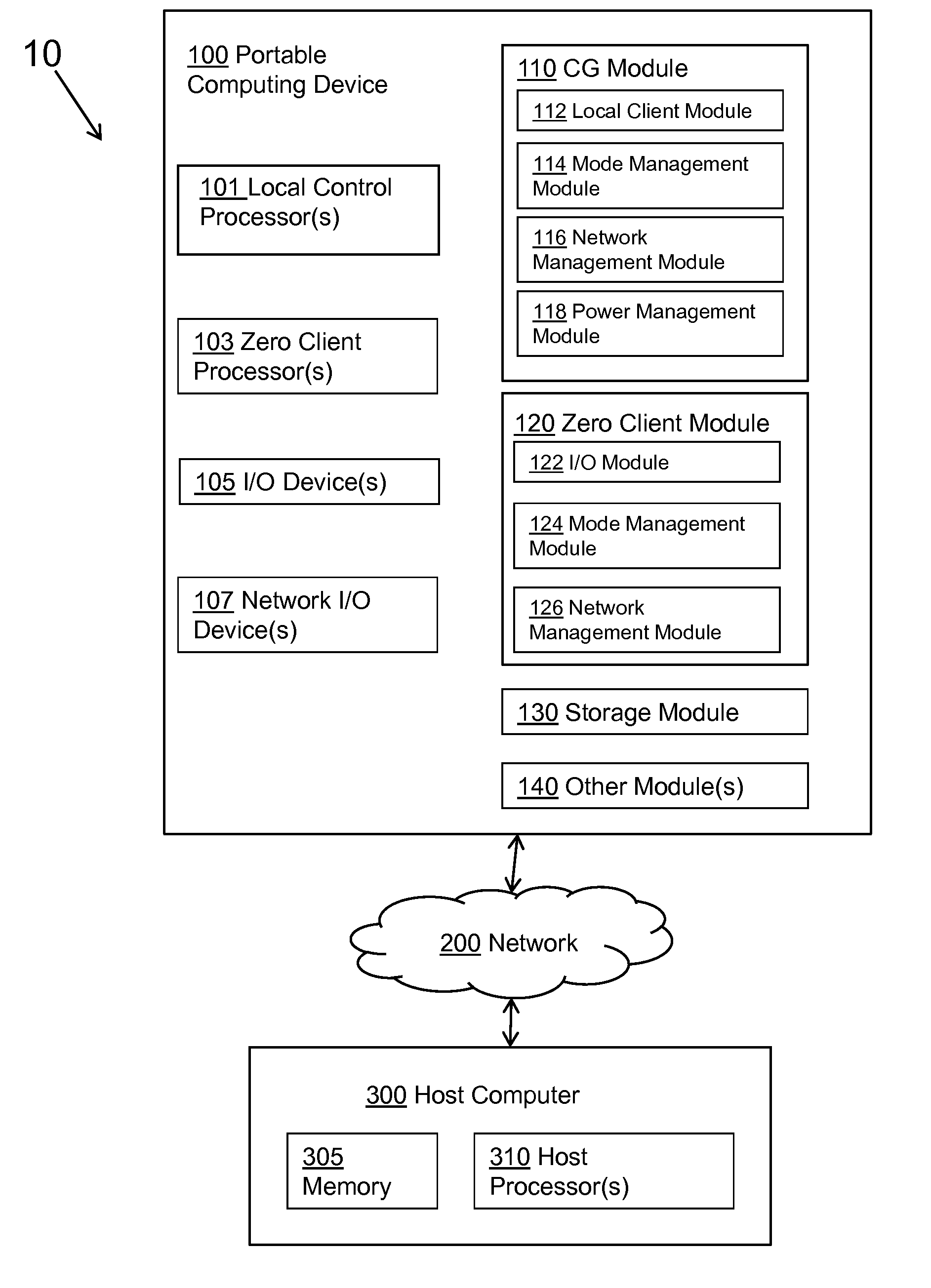

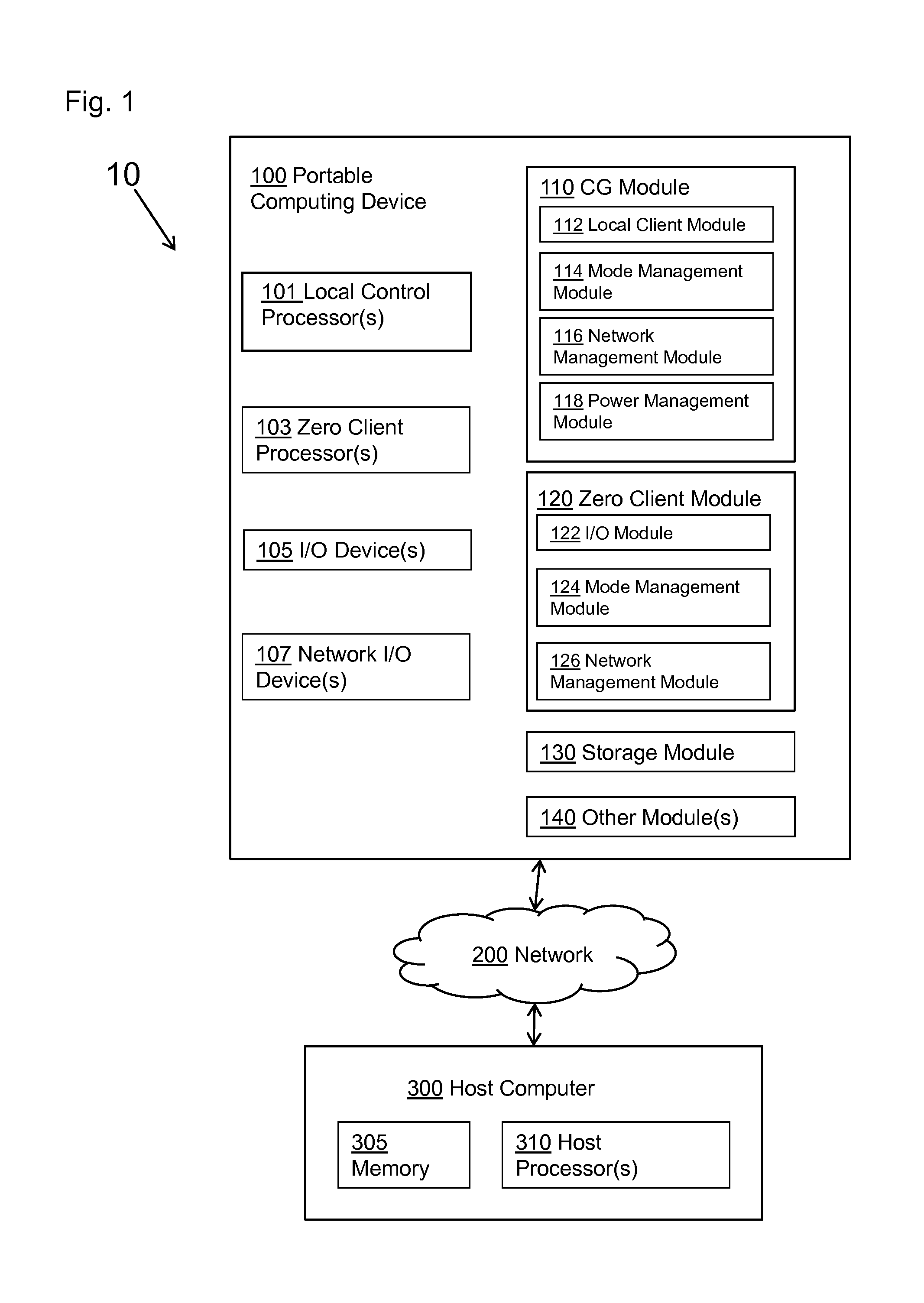

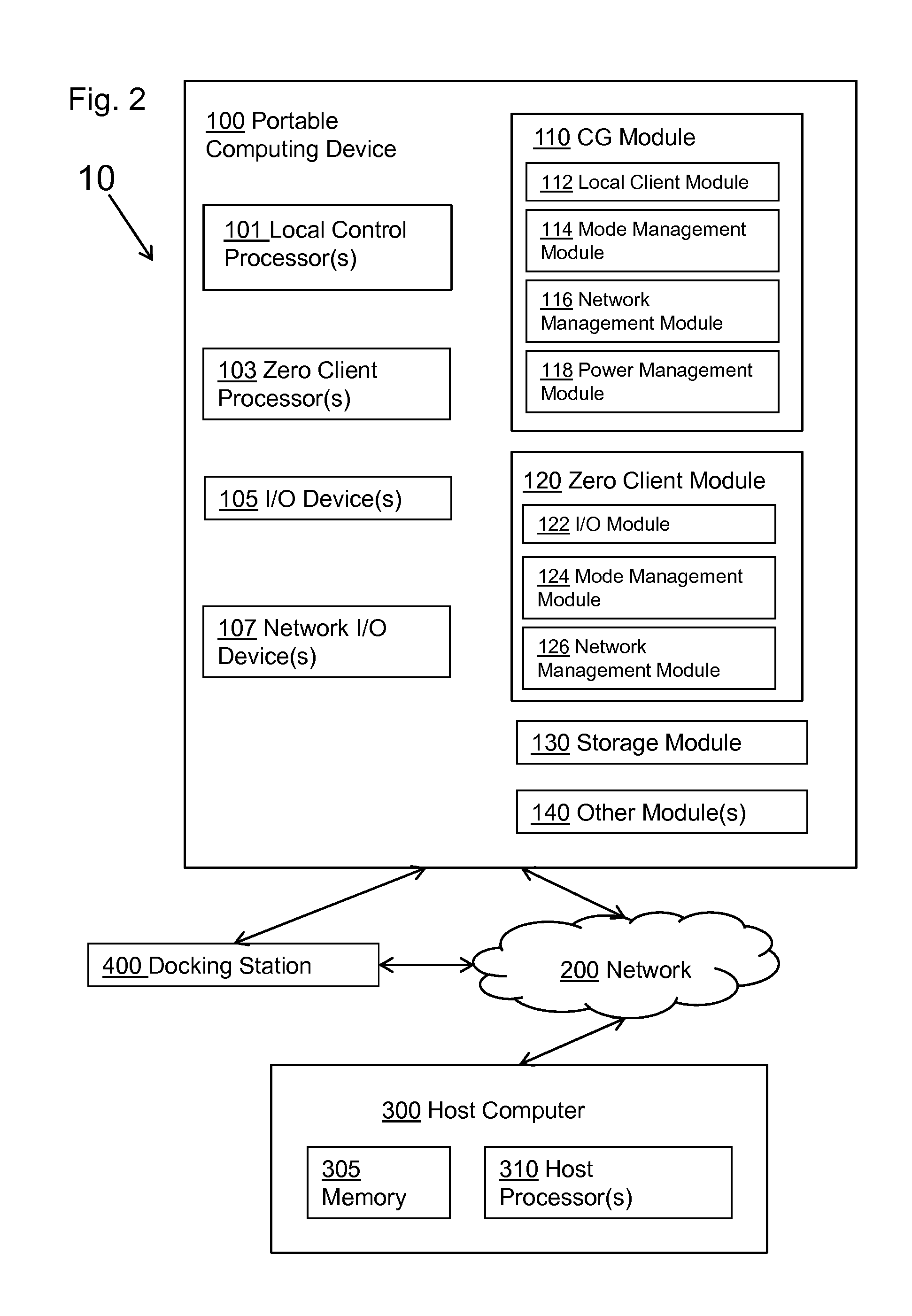

Systems and methods providing a mobile zero client

ActiveUS8682999B1FacilitateMultiple digital computer combinationsWireless network protocolsClient-sideInput device

The disclosure relates to a portable computing device configured to selectably switch between a wired zero client mode in which the portable computing device operates as a terminal for a host computer via a wired communication channel, a wireless zero client mode in which the portable computing device operates as a terminal for the host computer via a wireless communication channel, and a local mode in which the portable computing device operates independently from the host computer. The portable computing device may include one or more zero client processors that facilitate operation in the wired or wireless zero client mode and one or more local control processors that facilitate operation in the local mode. The portable computing device may include input devices used to receive inputs for the host computer during the wireless or wired zero client modes or for the local control processors during the local mode.

Owner:NCS TECH

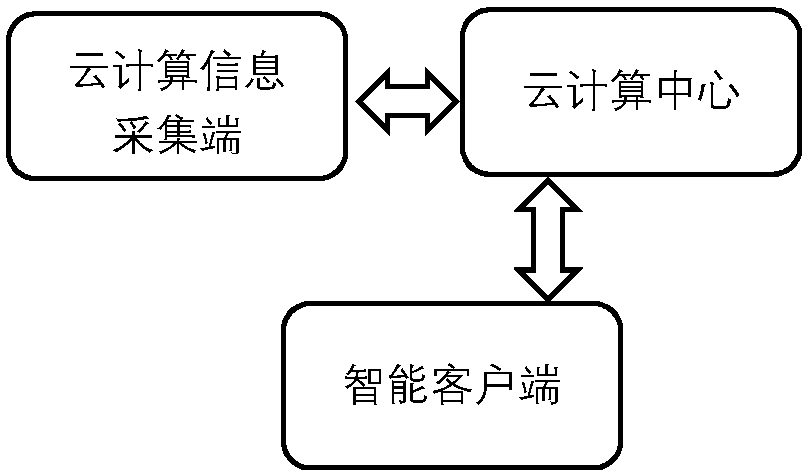

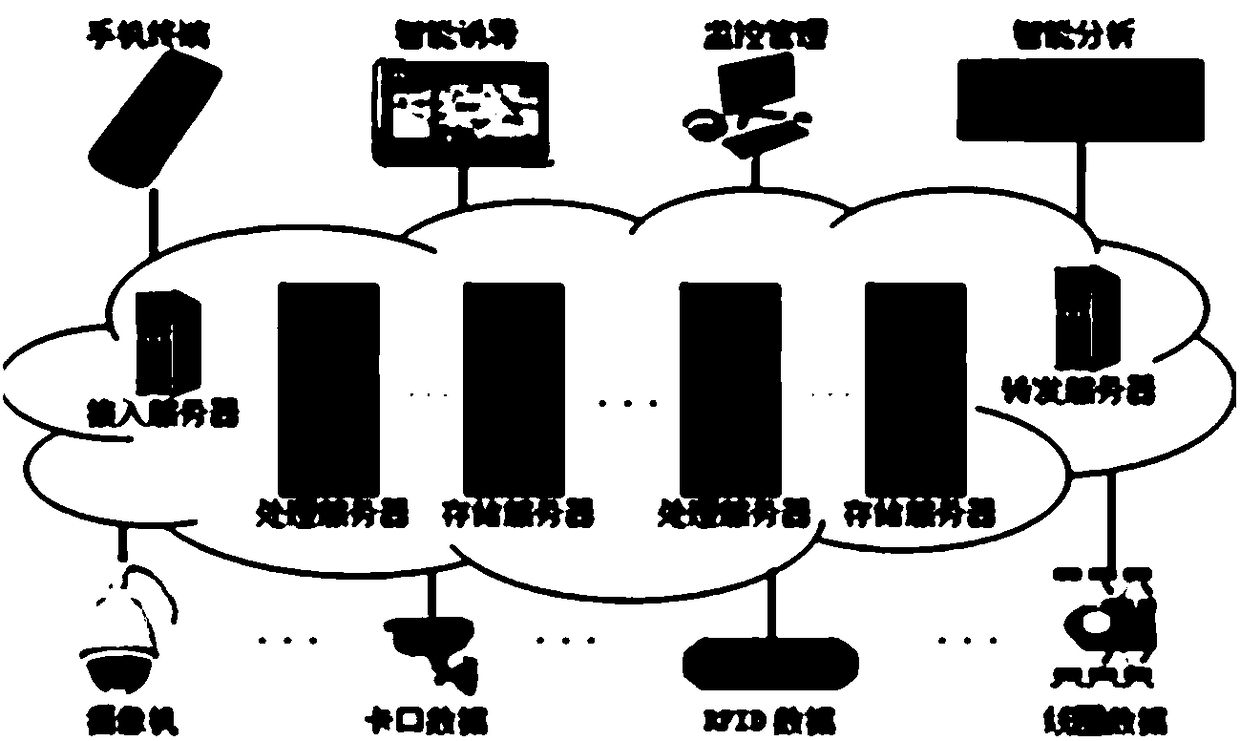

Intelligent traffic plan based on cloud computing

InactiveCN108090611AFacilitateReduce resource usageForecastingTransmissionRelevant informationClient-side

The invention relates to the field of computers, in particular to an intelligent traffic method and system based on cloud computing. The intelligent traffic system is composed of a cloud computing information collecting terminal, a cloud computing center and a user smart client. A user visits the cloud computing center by the smart client; the cloud computing information collecting terminal obtains related information and map information of various transport tools in real time and feeds back the information to the cloud computing center; and the cloud computing center provides travel plans based on travel needs, transmitted by the smart client, of the user. Therefore, resource occupation of the mobile phone of the user is reduced and the public service is realized conveniently.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

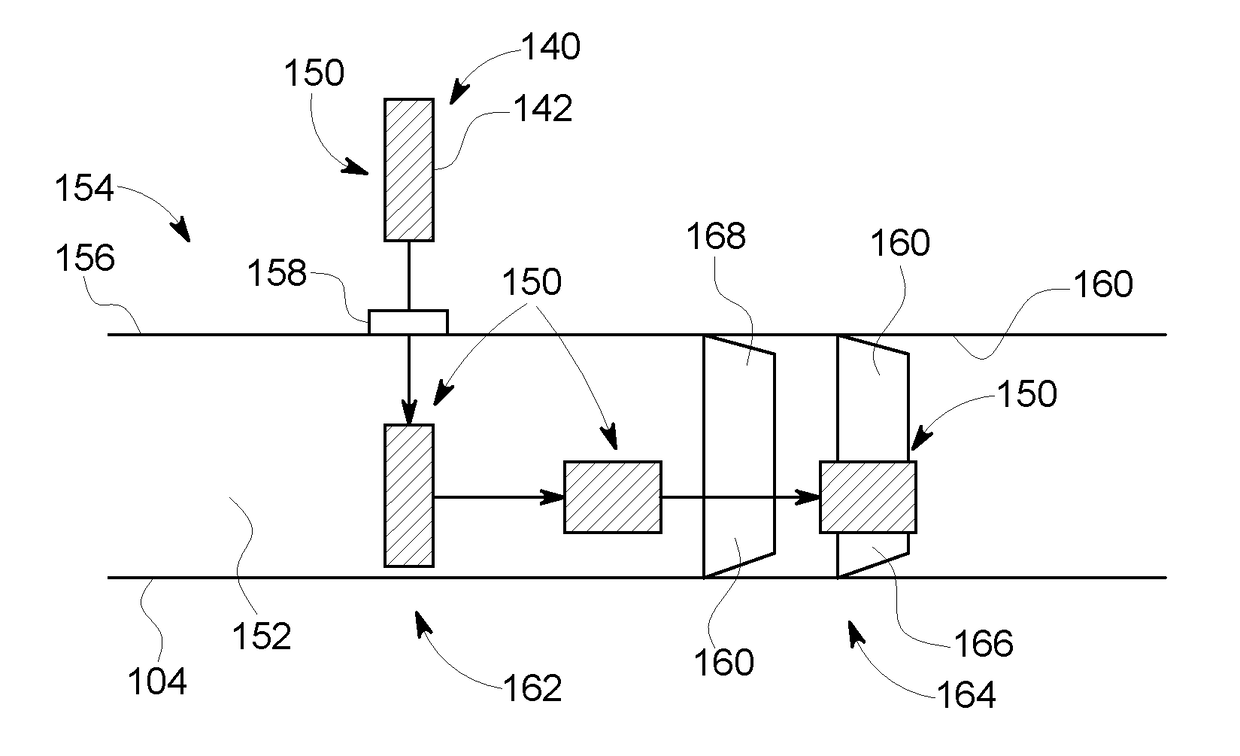

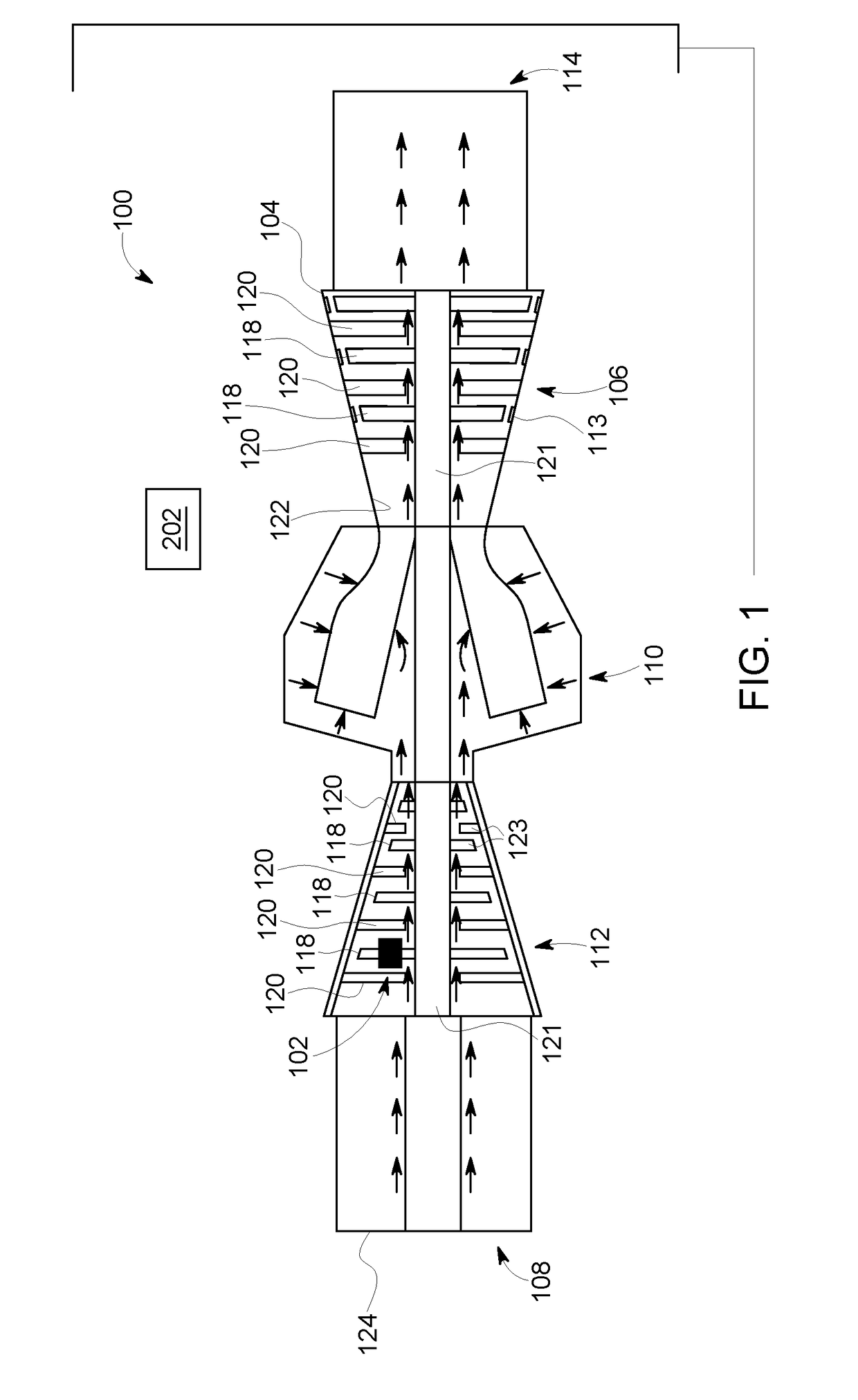

Reconfigurable maintenance apparatus

ActiveUS20180223667A1FacilitateEasy accessPump componentsBlade accessoriesEmbedded systemSystem configuration

Owner:GENERAL ELECTRIC CO

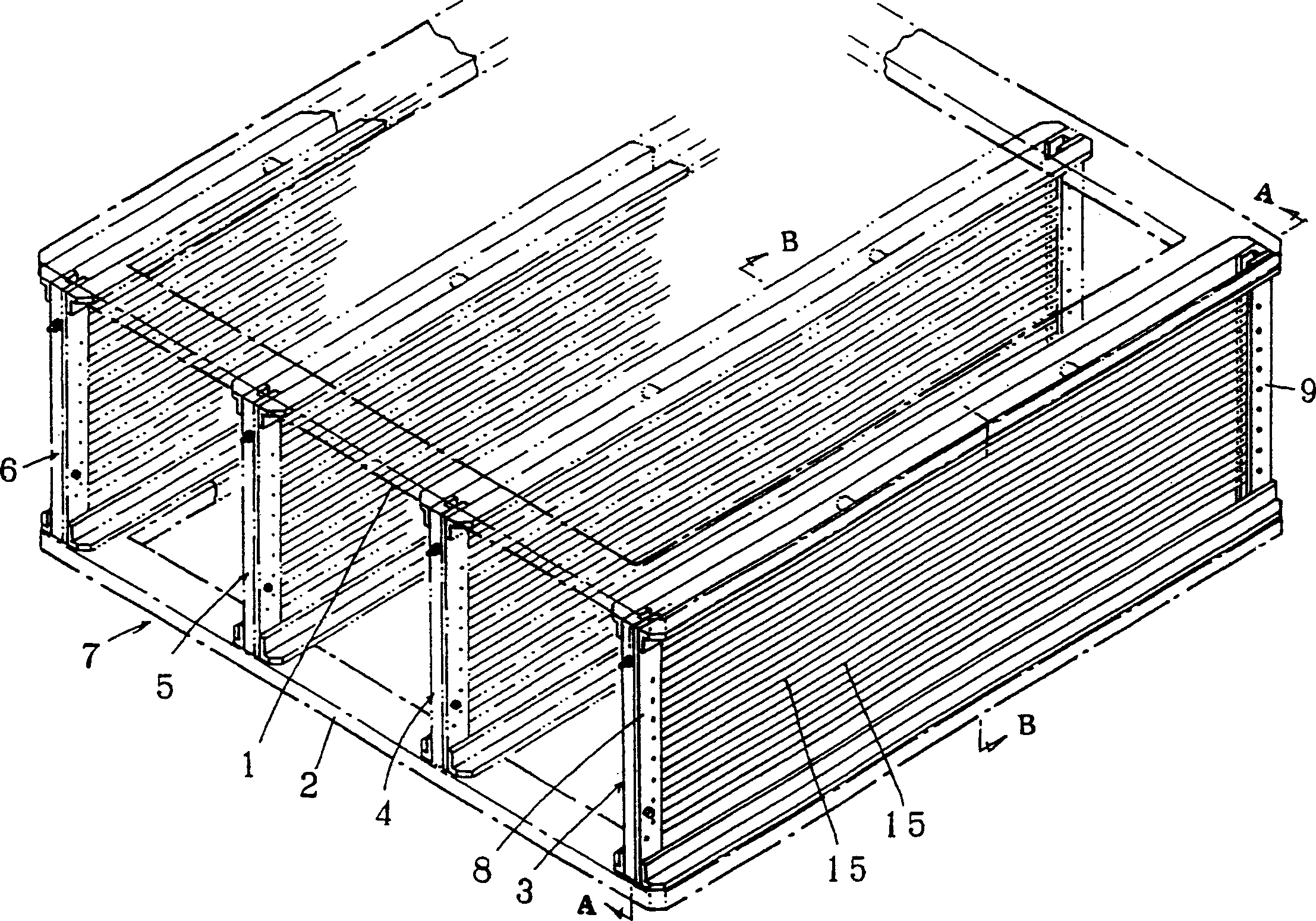

Container for lamellate articles

The invention relates to a sheet staff counter, which comprises a cubic framework group. The framework group comprises a top framework set on the top and a framework between the top framework and bottom framework; on each framework is set a cross holder for carrying sheet staffs. The cross holder is set on the supporting wire of each framework. The supporting wire is coated with engineering plastics pipes.

Owner:IWASAKISEISAKUSHO

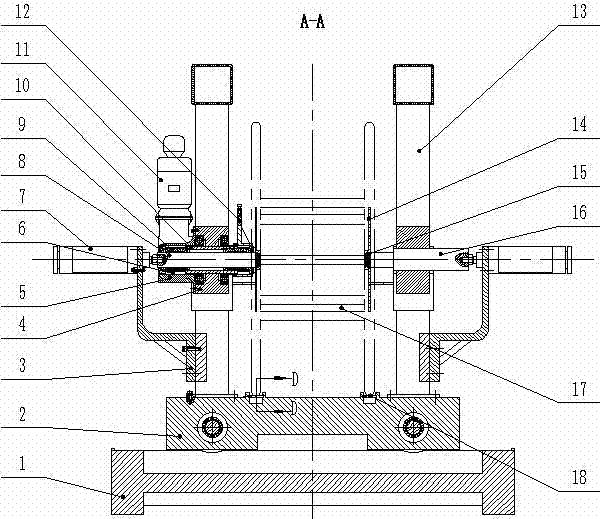

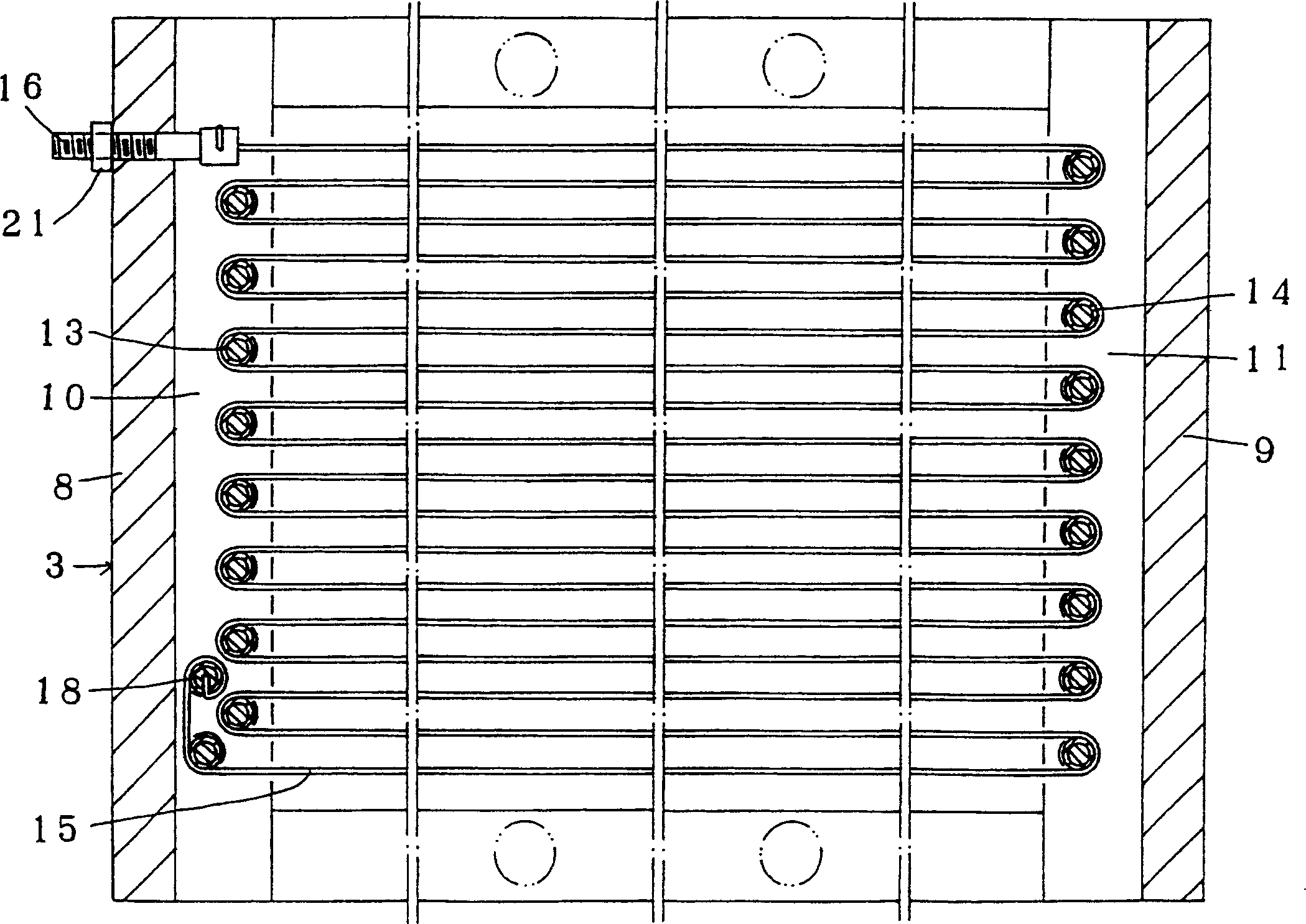

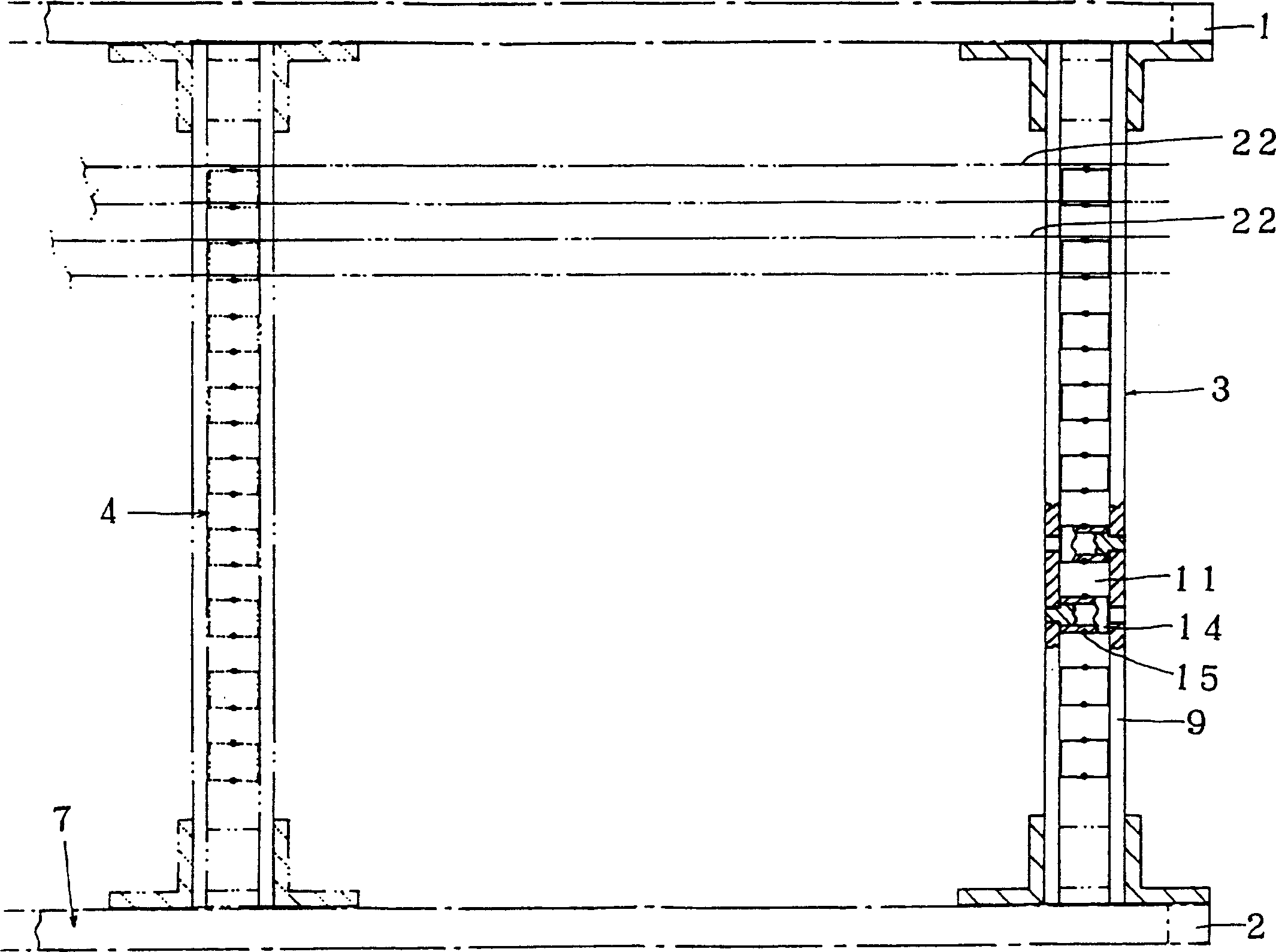

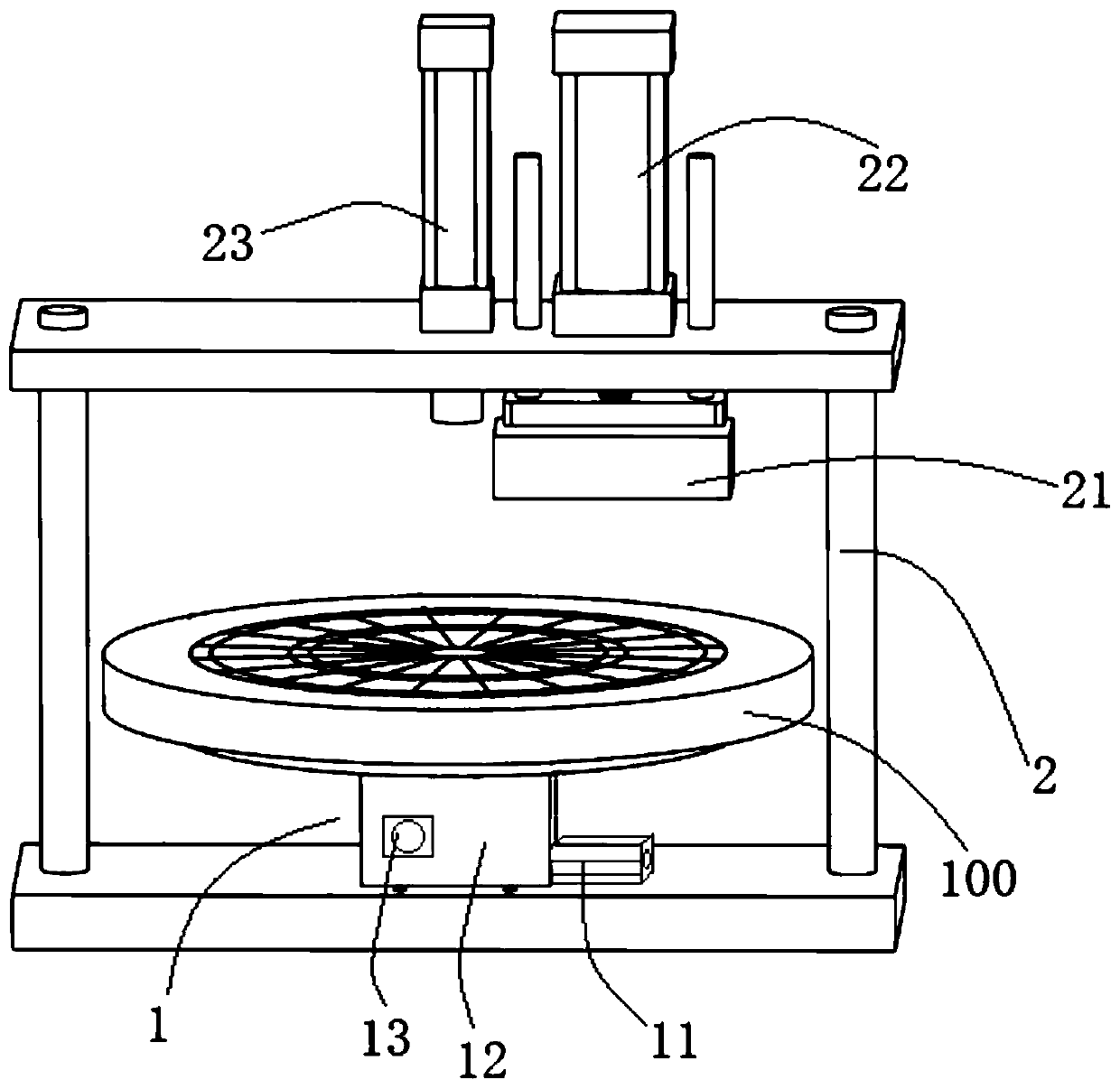

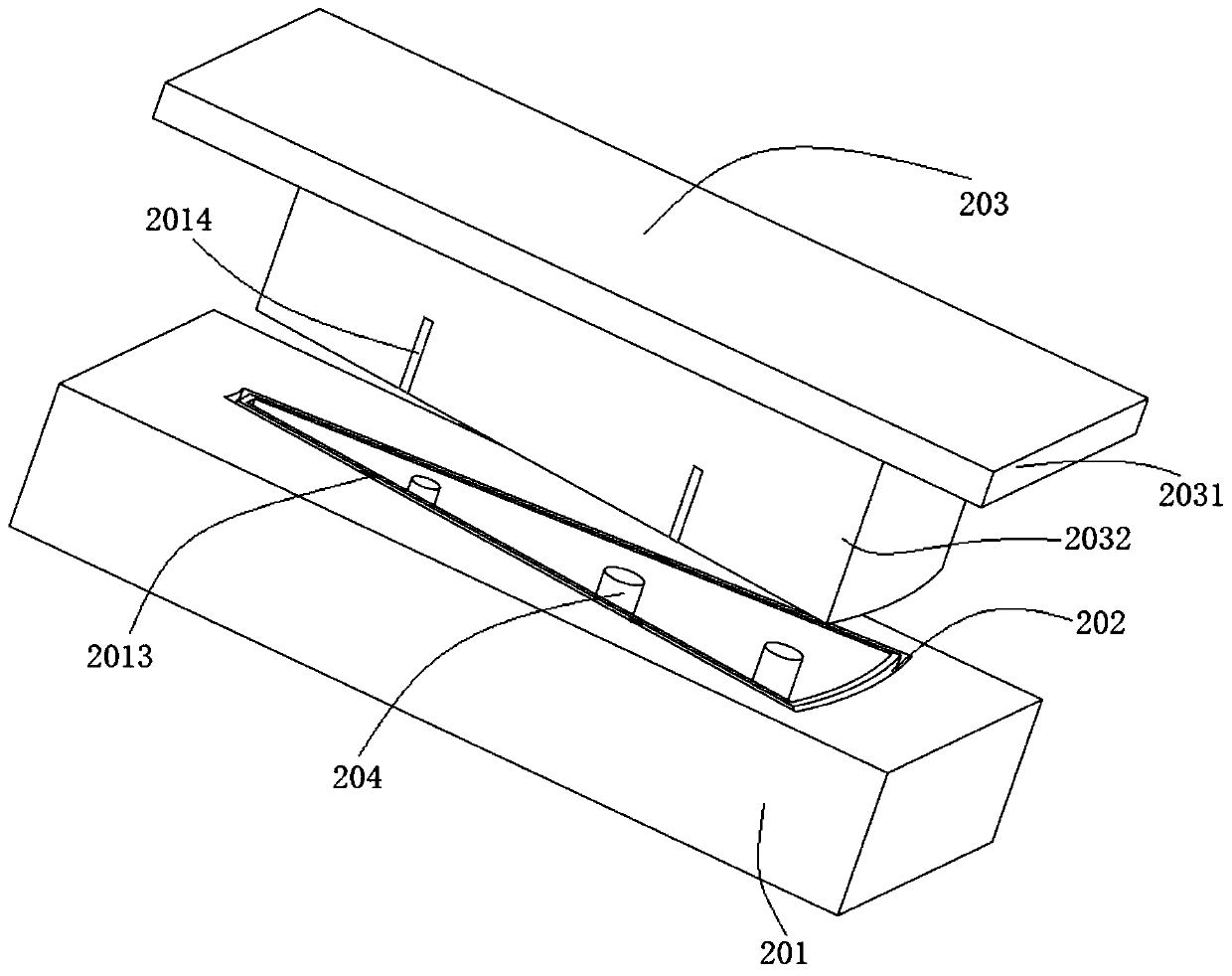

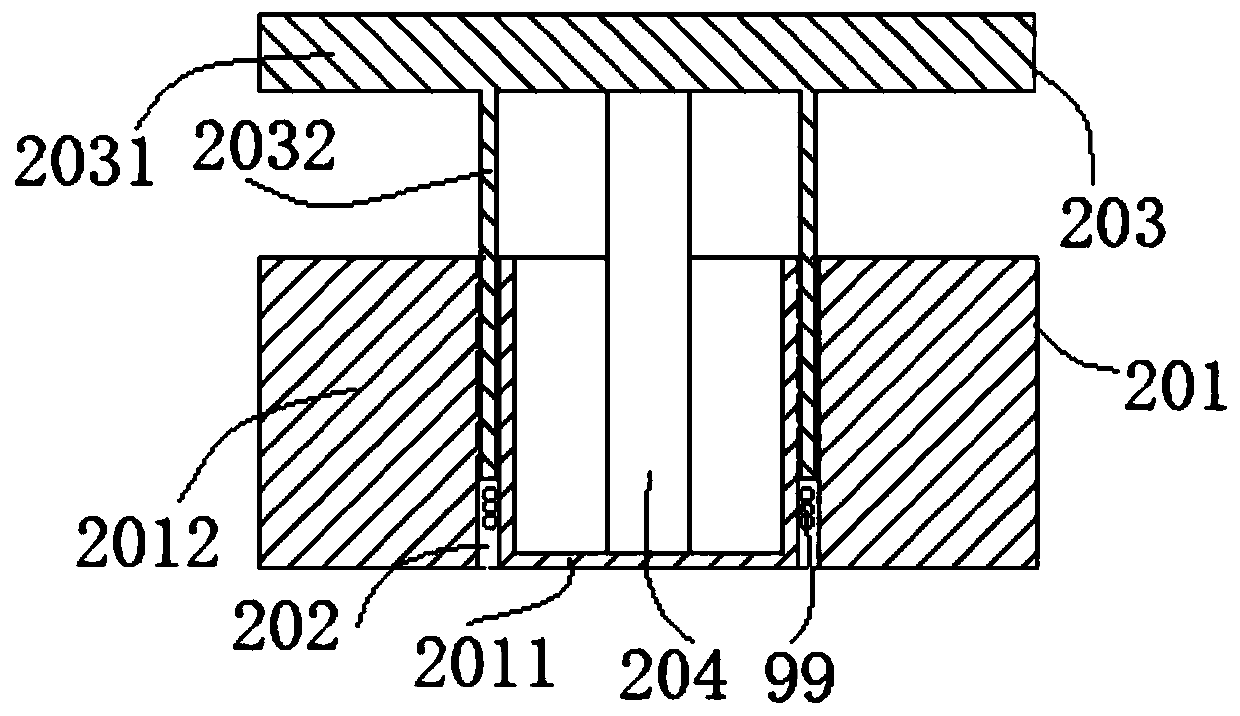

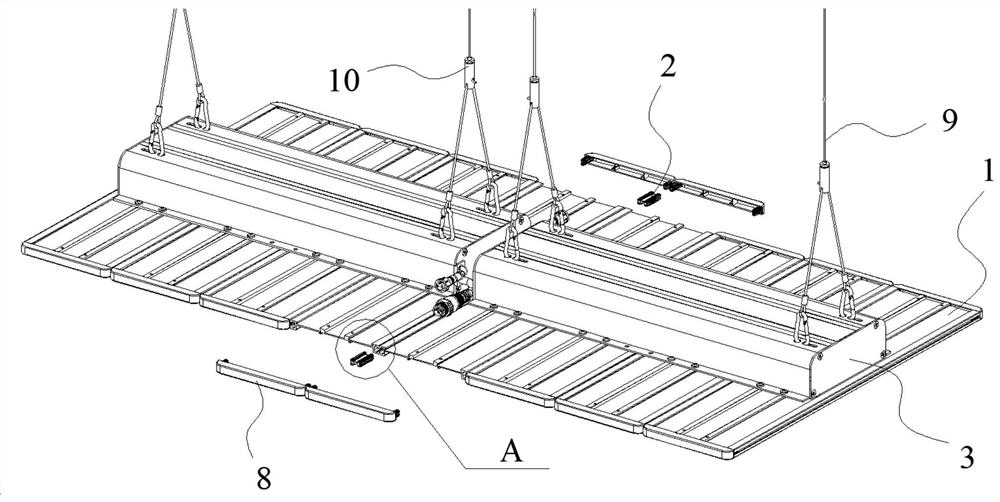

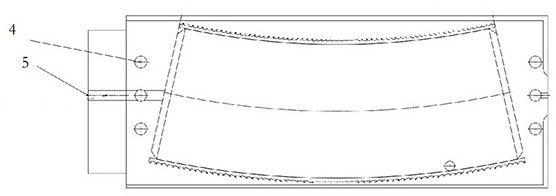

Equipment for mounting dart target coil and burying method for dart target coil

ActiveCN110108167AAchieve simplicityFacilitateMetal working apparatusDartboardsComputer moduleElectromagnetic valve

The invention relates to equipment for mounting a dart target coil and a burying method for the dart target coil. The equipment comprises a first power mechanism, a rotary platform and a first electromagnetic valve; the first power mechanism, the rotary platform and the first electromagnetic valve form an equal-angle rotating device; a wire feeding module is arranged above the rotary platform; a wire storage groove, in which a coil is stored, of the wire feeding module is arranged right above a groove position of a to-be-implanted coil of a dart target; a second power mechanism is fixedly connected with the wire feeding module and is used for pushing the wire feeding module to place the coil into the groove position of the dart target; and a second electromagnetic valve is electrically connected with the second power mechanism and is used for controlling the second power mechanism to drive the wire feeding module to place a preset coil on the dart target. The equipment has the beneficial effects that 1) through automatic equipment, simplification and convenience in the burying process of the dart target coil are realized, operation is convenient, and the production efficiency is high; and 2) the structure of the wire feeding module is ingenious in design, the coil can be accurately placed in the dart target, and wiring is neat.

Owner:浙江众和科技有限公司

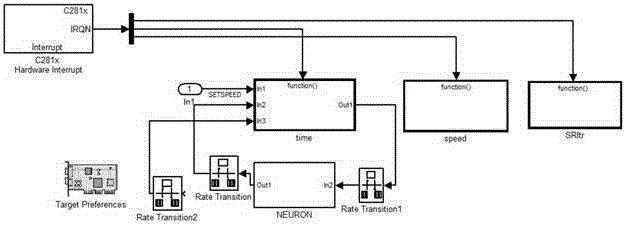

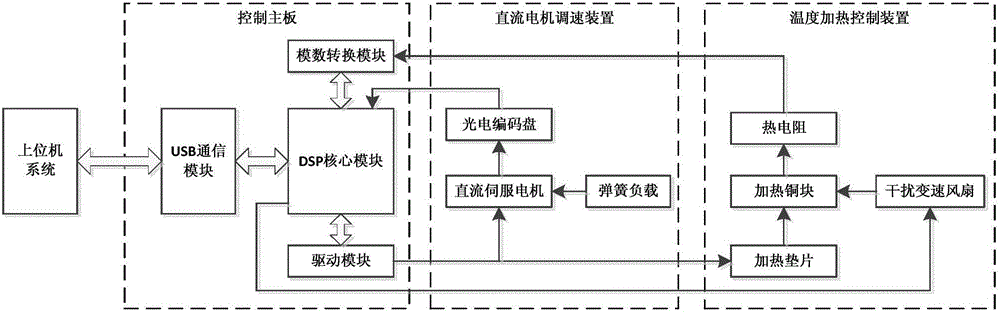

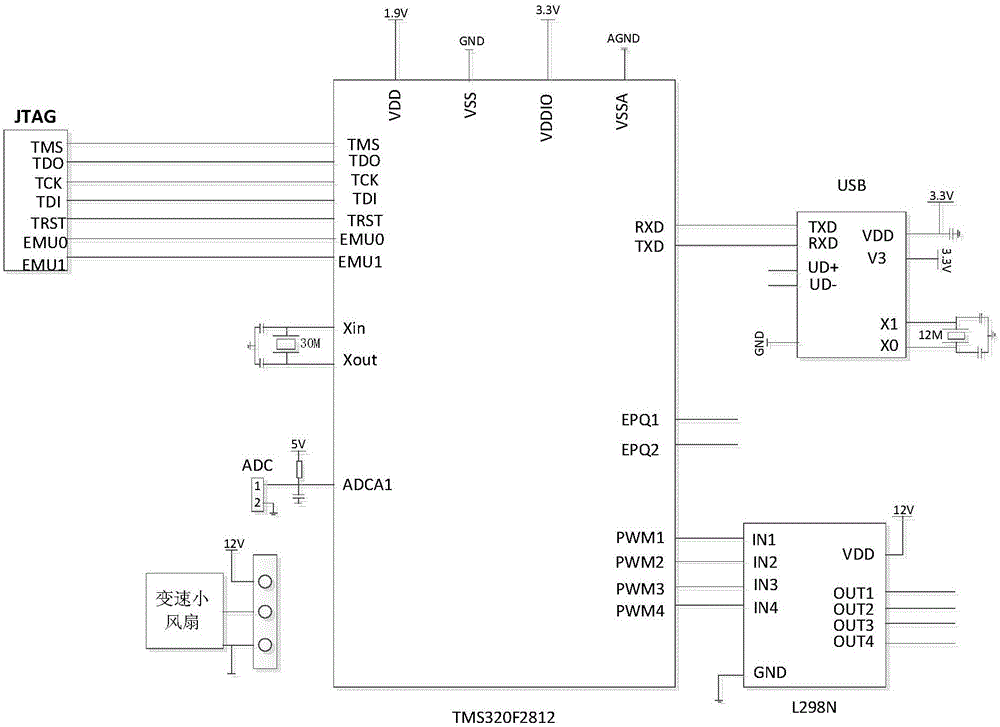

Portable computer control experiment system

The invention provides a portable computer control experiment system, which belongs to the technical field of control experiments. A typical object control device for the system comprises a controlled device, a signal acquisition device for acquiring signals outputted by the controlled device and a load device for interfering the signals outputted by the controlled device. The typical object control device adopts a DC motor speed regulation device and a temperature heating control device, MATLAB / Simulink is adopted for modeling in a control system and simulation research on a control algorithm, a control code after simulation verification is directly used for being converted to an actual system control code, the software of an upper computer is written also by adopting MATLAB, and the whole development work is completed in the same working environment. The DC motor speed regulation device adopts a vertical motor base as a device for fixing the motor, the appearance is delicate but the mass is large, and jitter generated during the motor rotation process can be prevented. A copper block of the temperature heating control device is fixed in the middle position of a heating cushion, and uniform heating is ensured. a heating copper block adopts a vertical placement mode, and temperature control is facilitated.

Owner:NORTHEASTERN UNIV

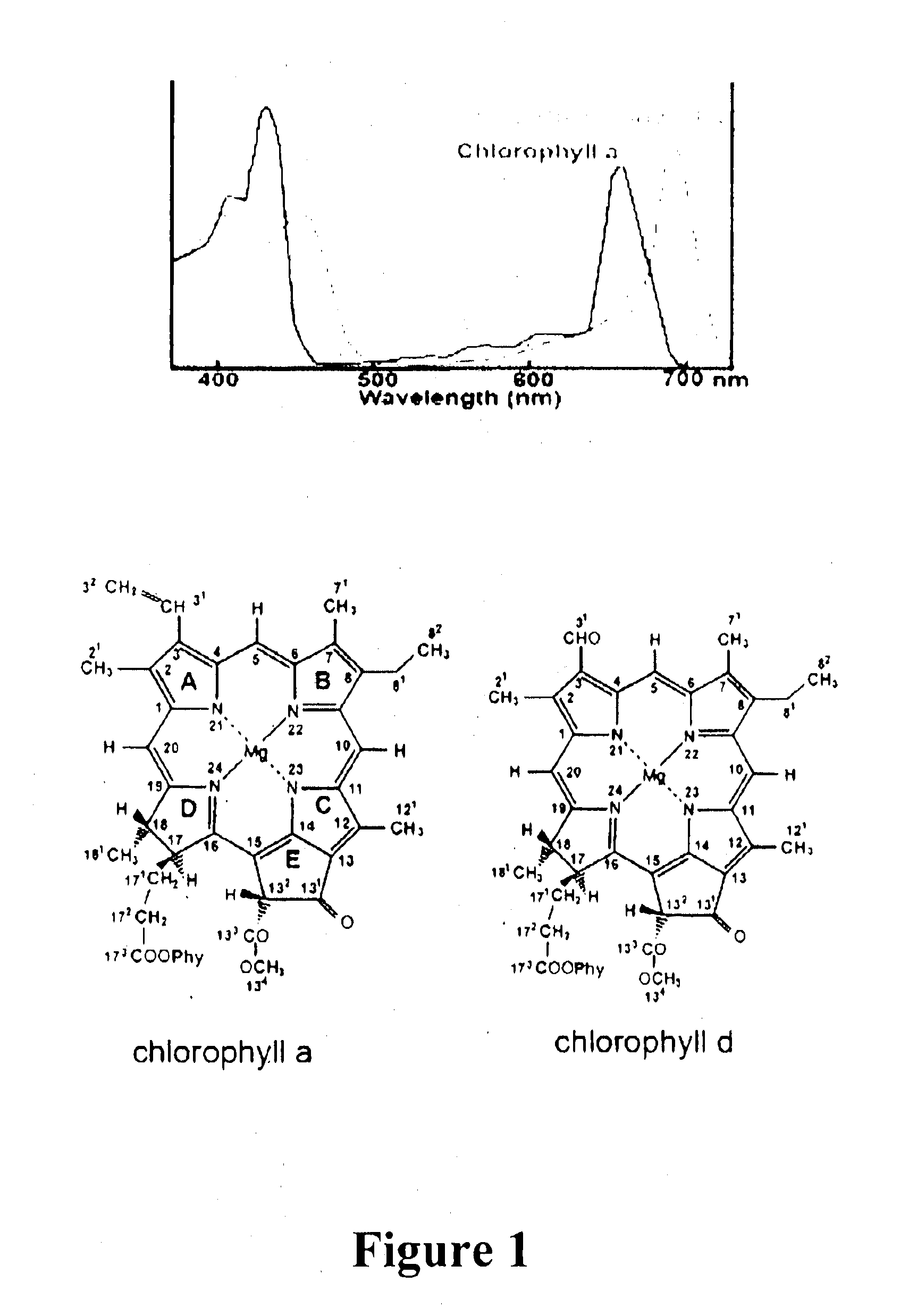

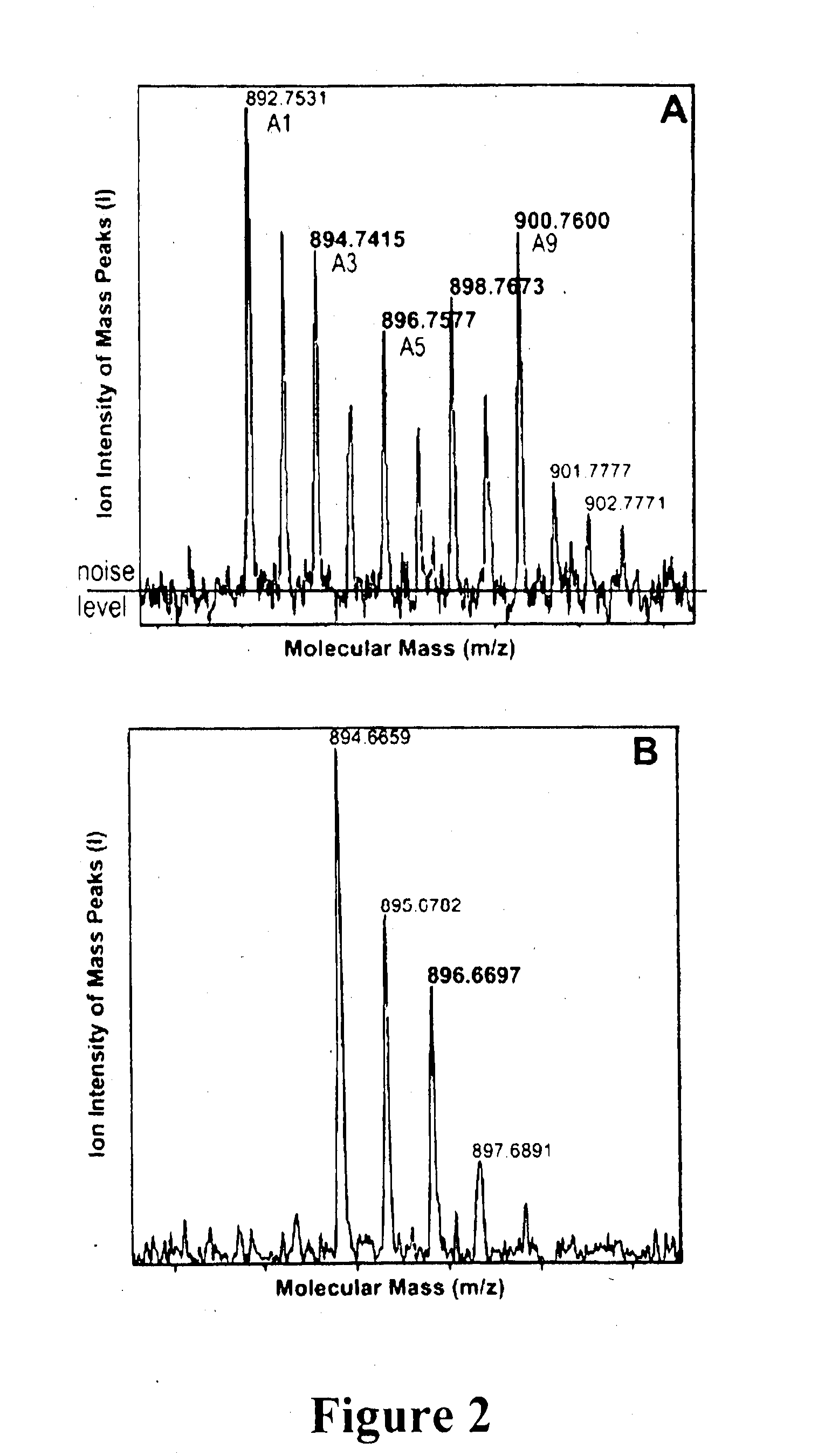

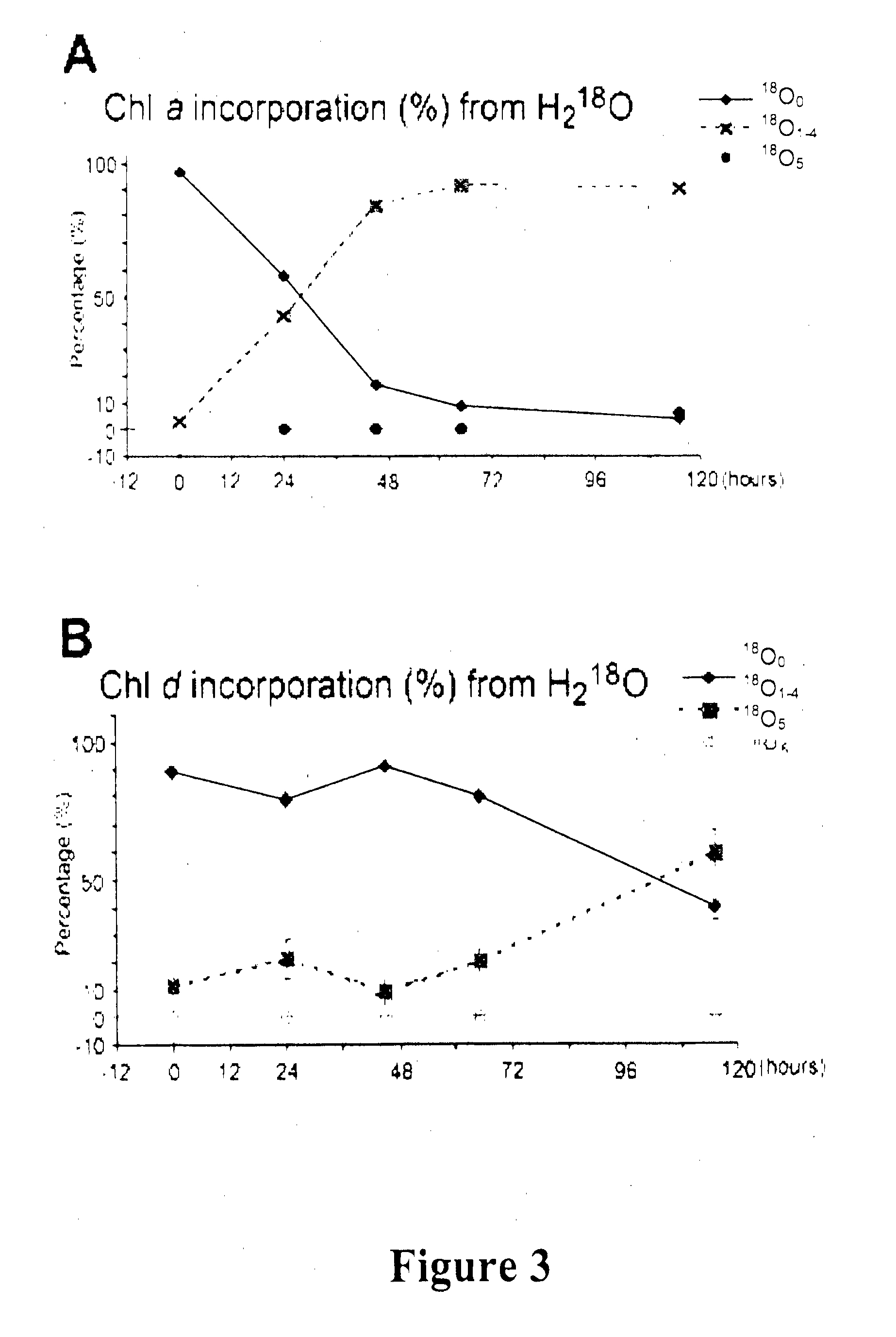

Gene Constructs Comprising Nucleic Acids That Modulate Chlorophyll Biosynthesis And Uses Thereof

InactiveUS20130276162A1Facilitate Agrobacterium-mediated integrationImprove abilitiesMicroorganismsClimate change adaptationBiological bodyPlant tissue

The present invention provides isolated nucleic acids encoding Ch1 d synthase, gene constructs comprising the isolated nucleic acids and cells, chloroplasts, plant tissue and whole plants ectopically expressing cyanobacterial Ch1 d synthase. The invention also provides isolated antibodies prepared using recombinant Ch1 d synthase. The antibodies and gene constructs of the invention are used to produce Ch1 d in organisms that do not normally produce Ch1 d, and to modify Ch1 d level in cyanobacterial cells, such as for modifying environmental host range and photosynthetic capacity of organisms in low light and / or red or far-red or near far-red light environments.

Owner:BLANKENSHIP ROBERT +2

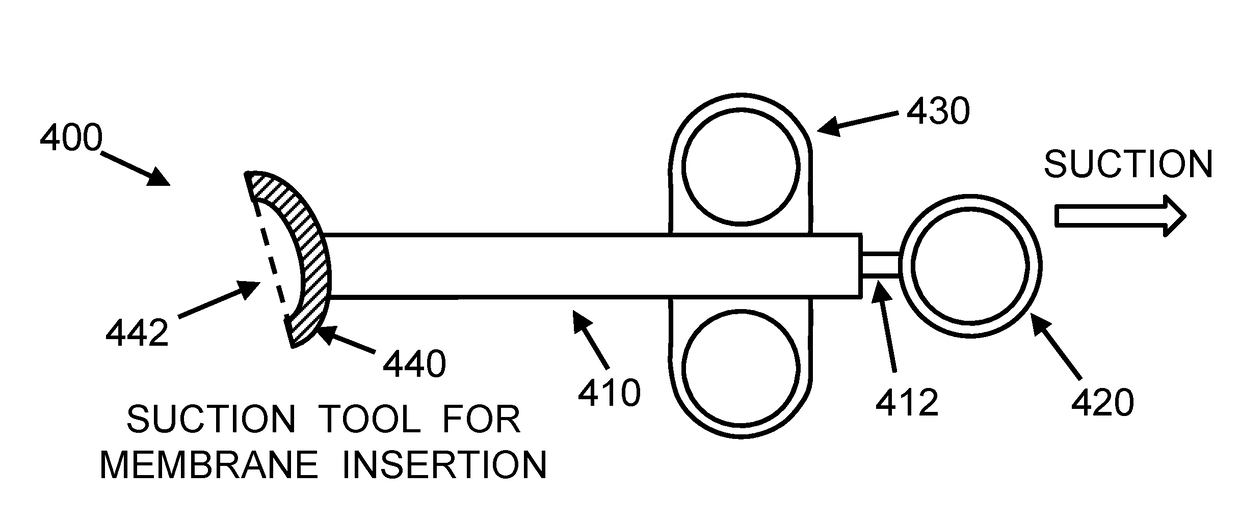

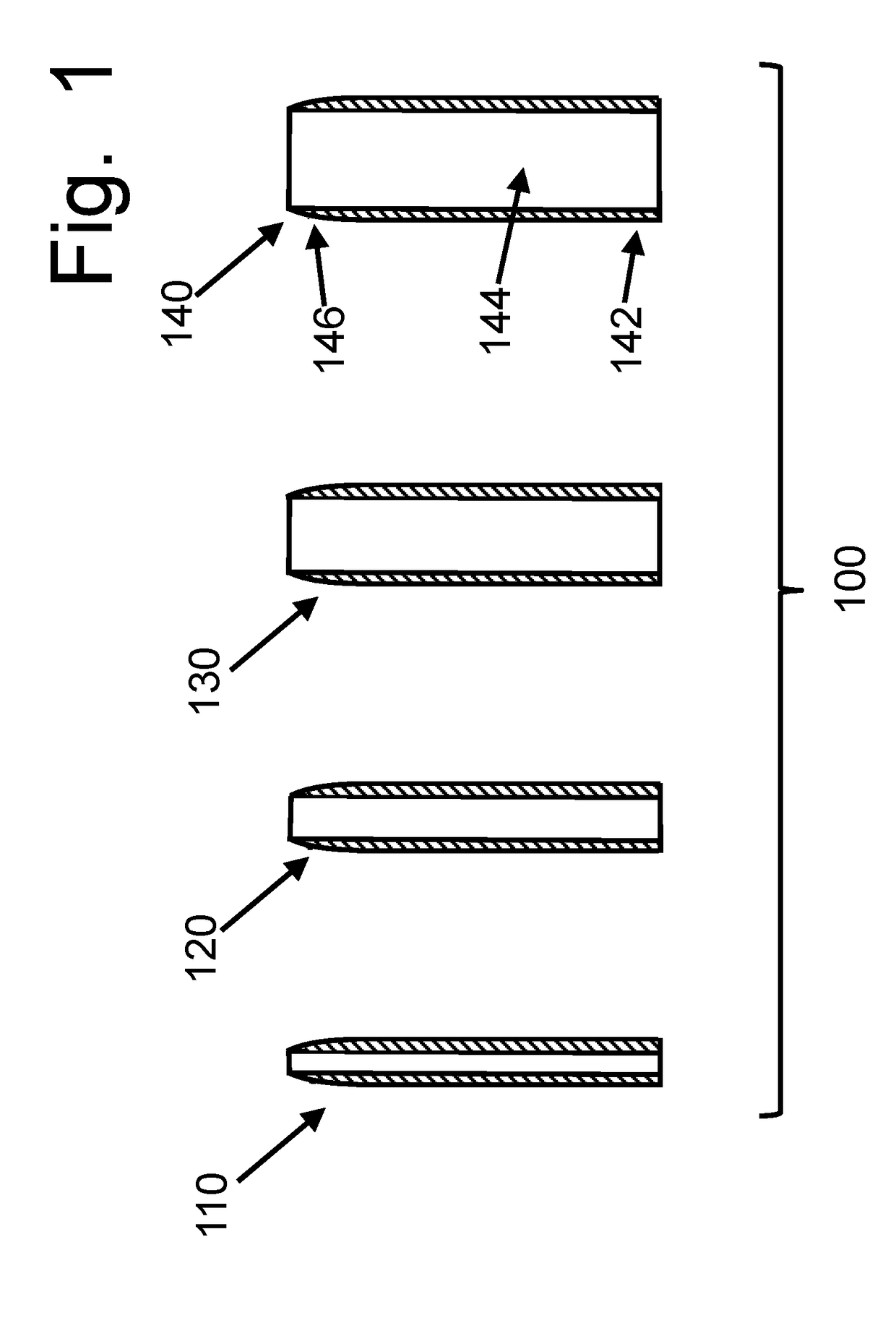

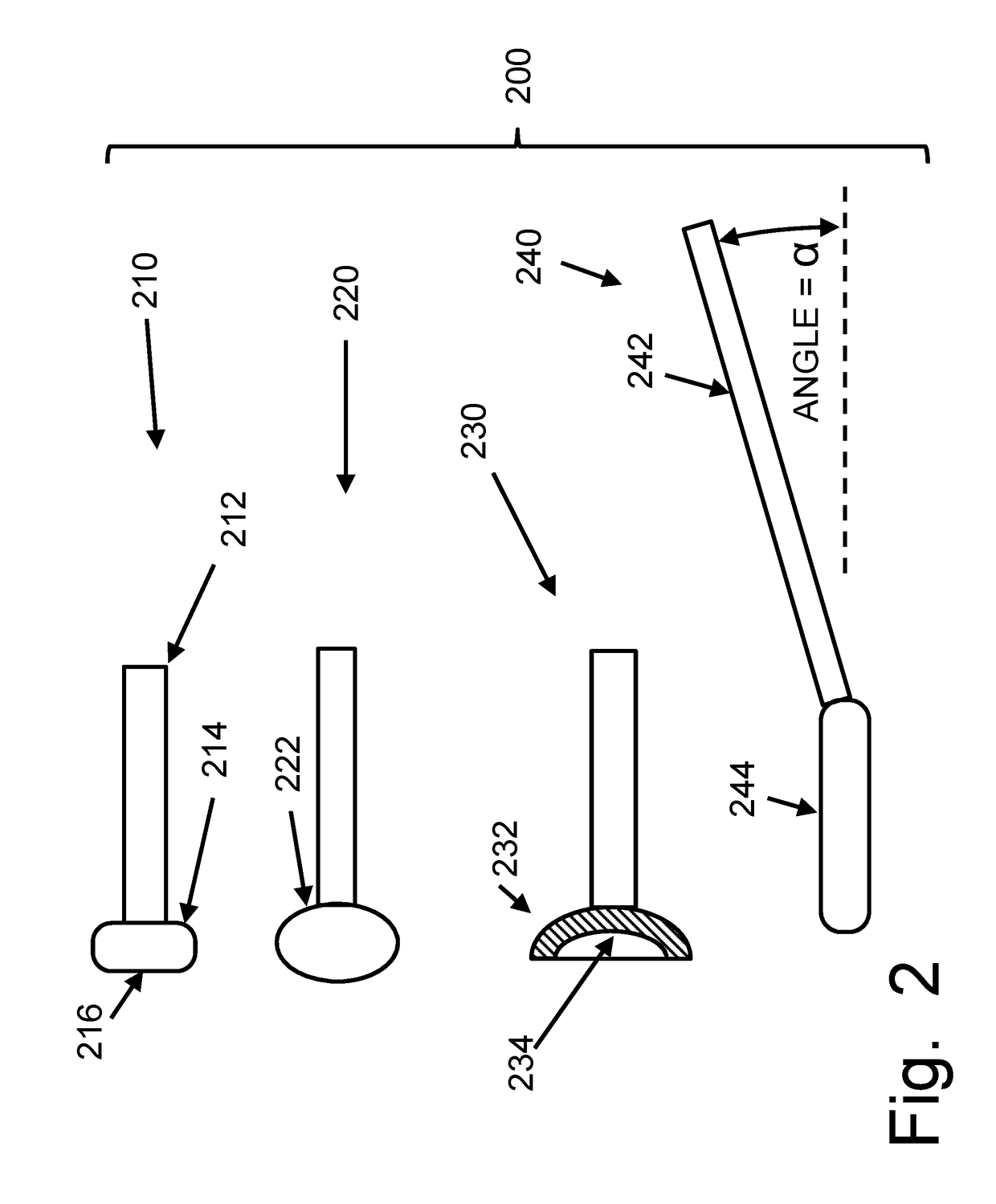

Surgical tools and kits for cartilage repair using placental, amniotic, or similar membranes

Surgical tools and kits are disclosed for repairing hyaline or meniscal cartilage, using membrane segments to protect and promote the growth and activity of cartilage-generating cells. These kits include: (i) a set of dilator tubes, adapted from similar tubes used in spinal surgery except shorter, that will allow a surgeon to progressively enlarge an insertion tunnel for inserting a membrane segment into an articulating joint that is being repaired; and, (ii) an assortment of membrane “tamping” devices, with smooth rounded “tamping heads” (or tips, etc.), and with a size and length that allow the tool tip to pass through the longest dilator tube while being held by the surgeon. Additional components (including disposable supplies) that can help facilitate these types of surgery can be included in any such kit, or in “supplemental” kits that can be bundled and shipped with these “primary” kits.

Owner:NEXT GENERATION REGENERATIVE MEDICINE DEV LLC

A ground rail type automatic wire rope take-up machine without lifting device

The invention discloses an automatic ground rail type steel wire rope winding machine without a lifting device. The automatic ground rail type steel wire rope winding machine comprises a guide rail device, a rope coil clamping device, a rope coil winding device and a wiring device. According to the automatic ground rail type steel wire rope winding machine disclosed by the invention, a lifting mechanism in a traditional wire winding machine is replaced by mainly utilizing the guide rail device of which a bottom plate can be pulled out, a space is reserved for the rotation of a rope coil by pulling out the bottom plate after the rope coil is clamped, the convenience of disassembling the rope coil and the steel wire rope winding without a lifting mechanism are realized, and the problems that the lifting position of a rope coil clamping shaft is inaccurate and the centering efficiency and the working efficiency of a rope coil clamping hole are low are solved; a hydraulic cylinder symmetrically pushes a driving ejector pin shaft and a driven ejector pin shaft to move transversely in the axial direction, a force application point and a pressing point of the hydraulic cylinder are positioned in the same axis, the clamping and the winding of the rope coil are realized through a design that an inner shaft and an outer shaft are arranged in a nesting and isolating way and a series of rolling posts which are uniformly arranged at a clamping cone end along the circumferential direction, the problem that a whole framework is easy to deform is solved, the structure is compact, and safety and reliability are realized.

Owner:UNIV OF JINAN

A splicing led lamp

ActiveCN112879847BFacilitateEnsure safetyLighting support devicesElectric circuit arrangementsLED lampMaterials science

Owner:XIAMEN GUANGPU ELECTRONICS

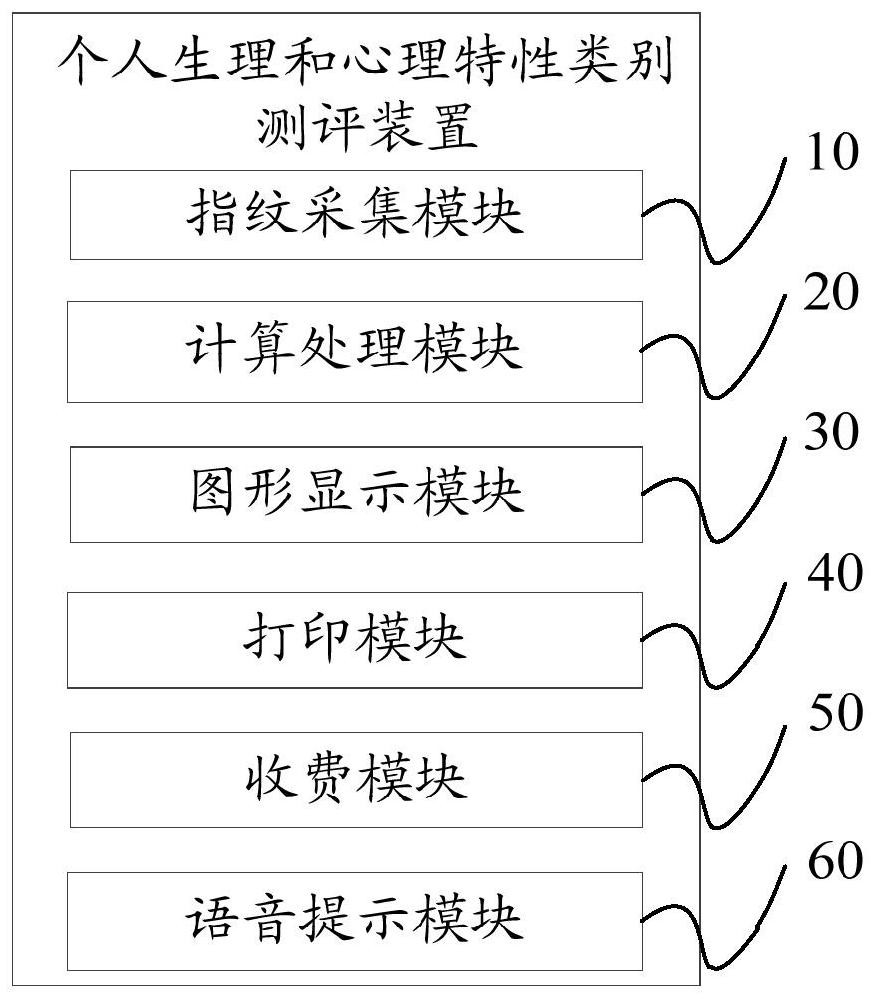

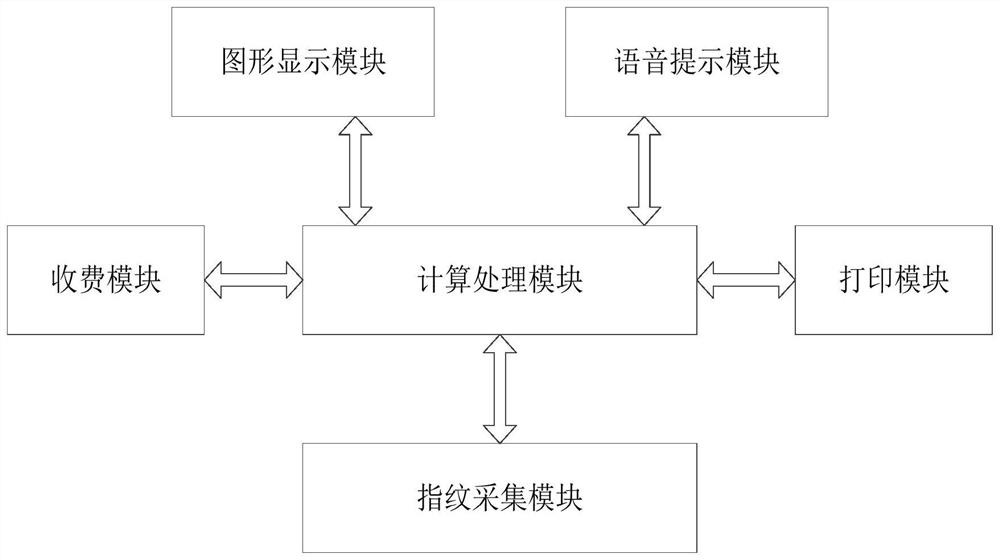

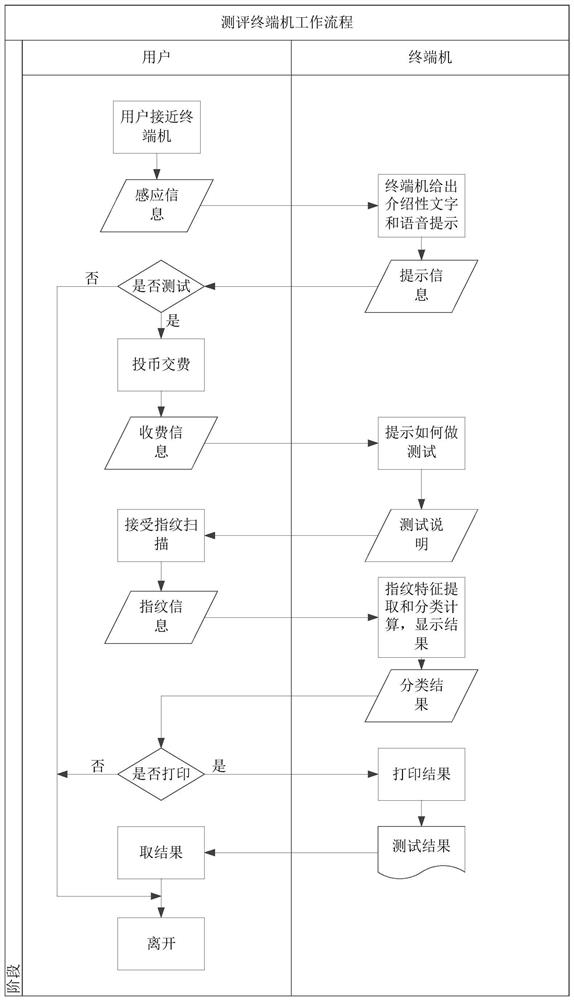

Personal physiological and psychological characteristic category evaluation device and method

PendingCN114708961AFacilitatePopularizeMedical automated diagnosisSensorsPublic placeKnowledge management

The invention discloses a personal physiological and psychological characteristic category evaluation device and method, and belongs to the technical field of computers. According to the invention, fingerprint scanning is carried out on a user to obtain fingerprint information of the user; extracting fingerprint features from the fingerprint information; according to the method, the personal physiological and psychological characteristic category evaluation can be deployed in various public places, so that personal physiological and psychological characteristic category evaluation services are easy to obtain and low in price, and convenience and popularization of personal physiological and psychological characteristic category evaluation can be realized.

Owner:BEIJING INST OF TECH ZHUHAI CAMPUS

A processing method of curved oblique helix skeleton

ActiveCN110181232BFacilitateAvoid stress deformationMagnetsPositioning apparatusUltimate tensile strengthSpiral line

Owner:兰州科近泰基新技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com