A ground rail type automatic wire rope take-up machine without lifting device

A lifting device and wire rope technology, applied in the field of mechanical devices, can solve problems such as low work efficiency, complex structure, and affecting the clamping hole of the rope reel, and achieve the effects of simplifying the overall structure, overcoming easy deformation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

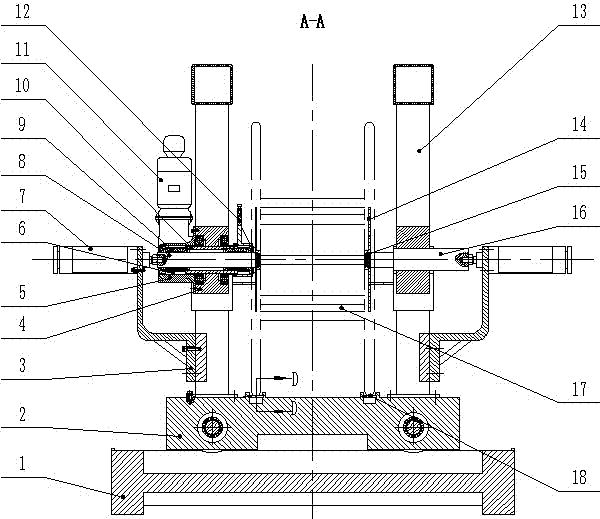

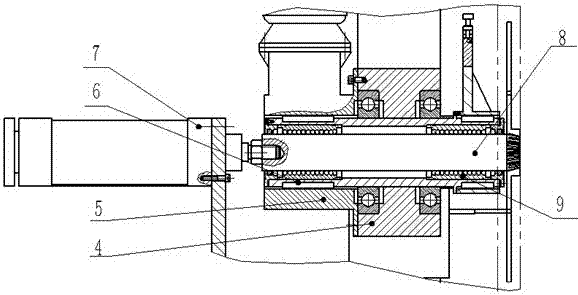

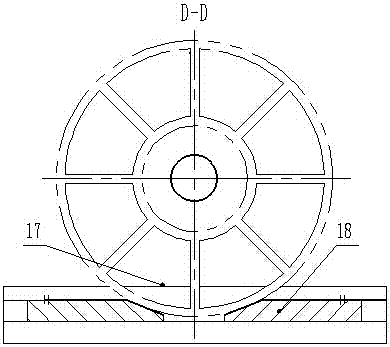

[0020] Below in conjunction with the accompanying drawings, the specific implementation of the present invention will be further introduced: as shown in the figure, a ground rail type automatic wire take-up machine without a lifting device, including: a rope reel clamping device, the rope reel clamping device Including support frame 3, flat key 6, hydraulic cylinder 7, active thimble shaft 8, linear bearing 9, drive shaft outer shaft 10, column 13, roller 15, passive thimble shaft 16; rope reel winding device, the rope reel The winding device includes a fixed plate 4, a motor support plate 5, a linear bearing 9, a drive shaft outer shaft 10, a motor with a reducer 11, a dial 12, a cross chuck 14, a roller 15, a rope reel 17, and a shaft frame 21; Wiring device, described wiring device comprises ground rail 1, base 2, roller 19, drive shaft 20, planetary cycloid pinwheel reducer, small sprocket 23, large sprocket 24; Guide rail device, described guide rail device comprises groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com