High voltage control and power integrated cable and preparation method thereof

A high-voltage control and control cable technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, insulated cables, etc., can solve the problem of poor ability of cables to resist external electromagnetic interference, great difficulty in cable fault detection, construction and detection Inconvenience and other problems, to achieve the effect of preventing interference, good resistance to external electromagnetic interference, and saving wiring space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

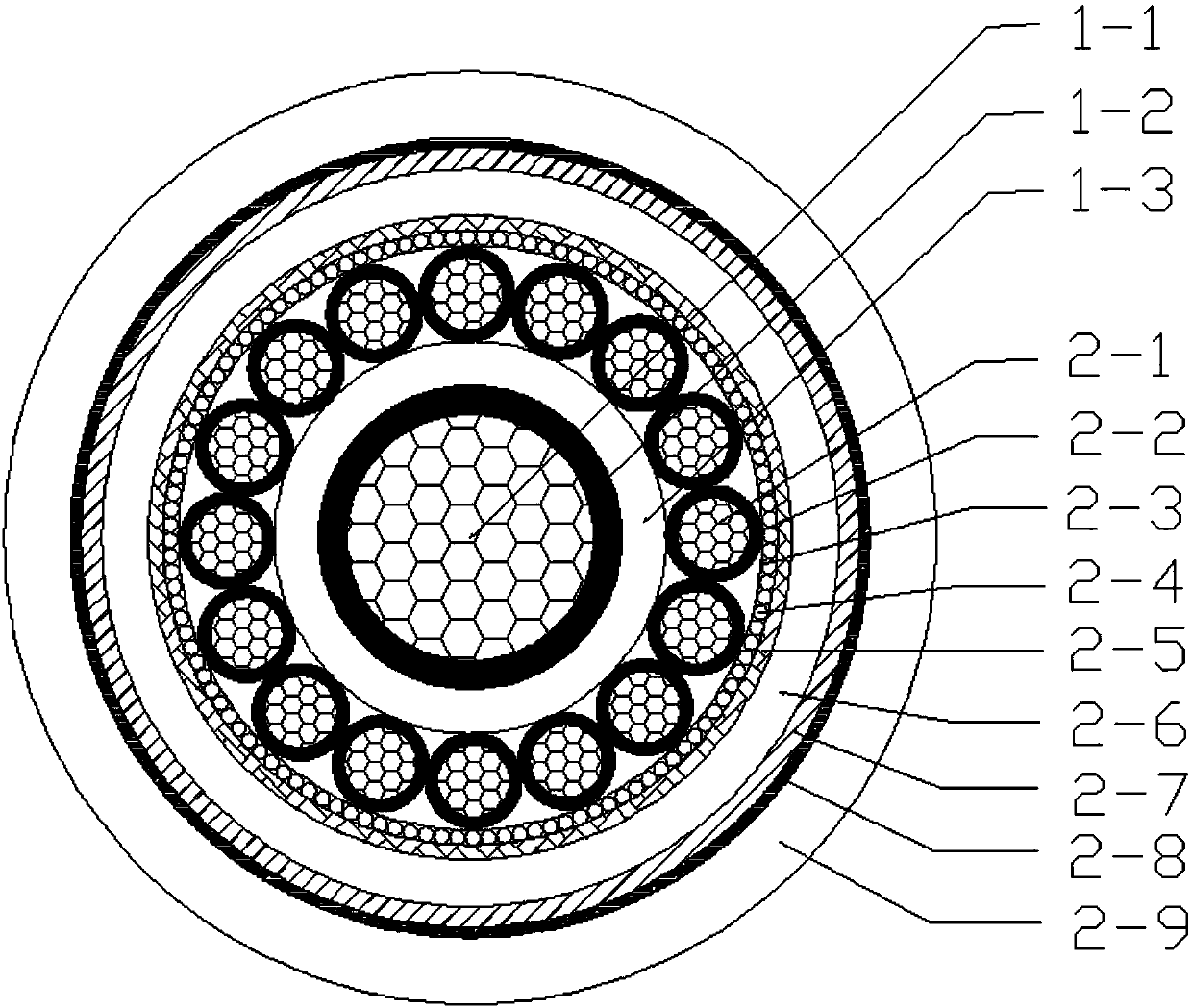

[0039] A high-voltage control and power integrated cable, comprising two parts: a control cable and a power cable, the power cable is located at the center of the cable, the outer side of the power cable surrounds the control cable, and the power cable is composed of conductors, insulation layers and sheath layers from inside to outside. The control cable is conductor and insulating layer from inside to outside. The outer side of the control cable is the shielding layer, the outer side of the shielding layer is the inner lining layer, the outer side of the inner lining layer is the armoring layer, the outer side of the armoring layer is the oxygen barrier layer, the outer side of the oxygen barrier layer is It is the sheath layer; the conductors are all made of copper wire stranded structure, and the insulating layers are all made of insulating materials with a temperature resistance level of -40°C to 105°C.

[0040] The outer side of the control cable is wrapped with an isolat...

Embodiment 2

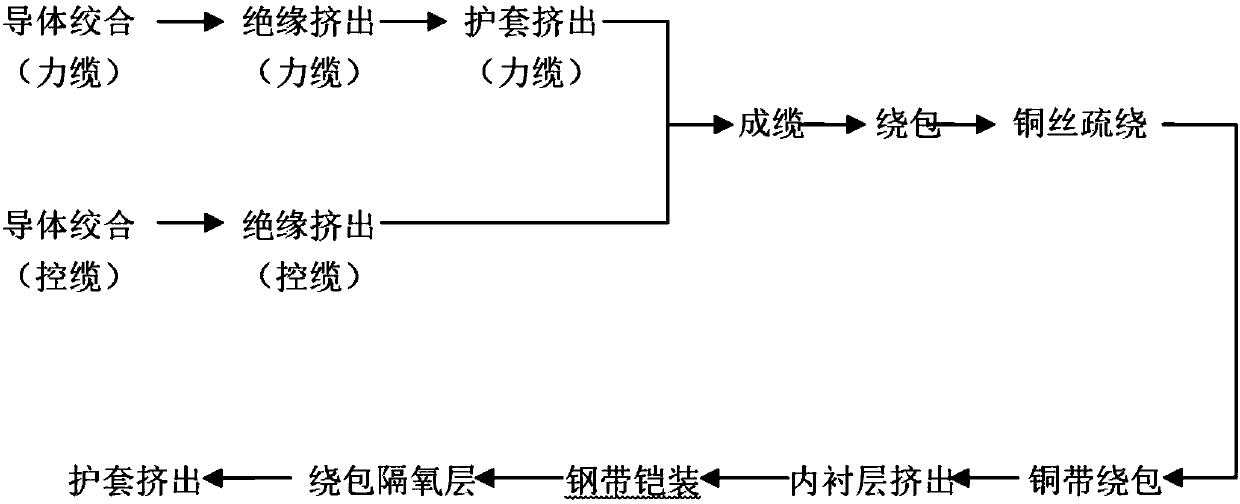

[0044] A preparation method of a high-voltage control and power integrated cable, comprising the following process steps:

[0045] 1) Conductor stranded: The conductor is made of copper conductors stranded;

[0046] 2) Extruded insulation layer: The insulation of control wires and power cables is produced by extrusion of low-smoke halogen-free materials with a temperature grade of -45°C to 105°C; the outer side of the power cable insulation layer is extruded with a sheath layer;

[0047] 3) Cable formation: the power cable is placed in the middle, and the control cable is arranged in one or more layers outside the power cable from the inside to the outside;

[0048] 4) Wrapping isolation layer: The isolation layer is formed by double-layer overlapping and wrapping of polyester film, and the wrapping rate is greater than 30%;

[0049]5) Shielding: the cable is shielded with copper wire sparse winding and copper tape wrapping shielding, the pitch ratio of the sparse winding is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com