Measuring device for fracture speed of whole-size gas bursting test of gas conveying steel pipe

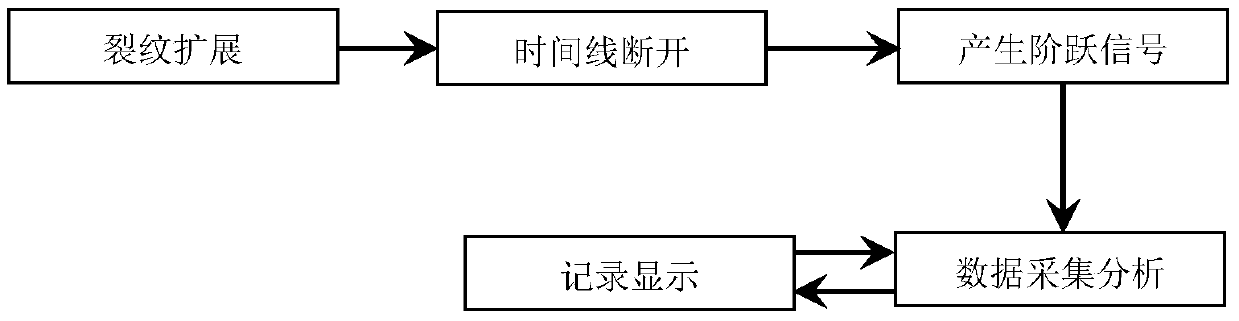

A blasting test and fracture velocity technology, applied in the field of explosion measurement, can solve problems such as failure to correctly reflect crack arrest performance, and achieve the effects of reliable test results, elimination of interference factors, and efficient and safe data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

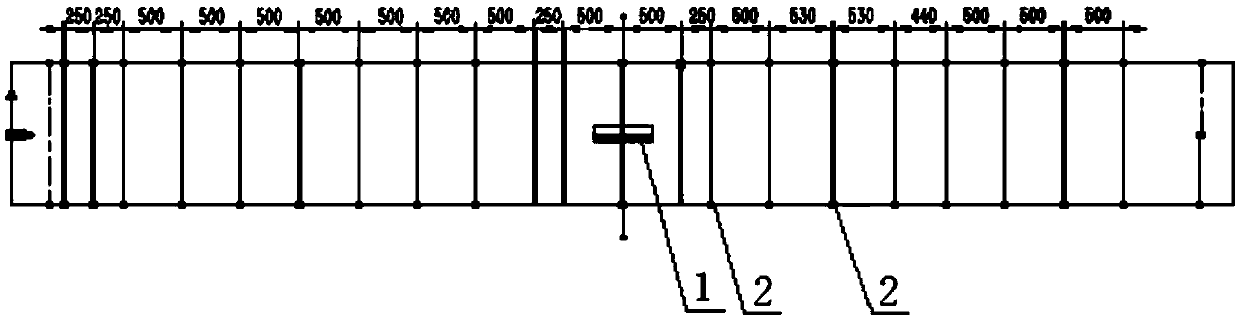

[0027] see figure 1 , the gas transmission steel pipe full-scale gas explosion test fracture velocity measuring device disclosed in the present invention comprises an explosion initiation device 1 arranged at the center of the gas transmission steel pipe to be tested, and a number of blasting devices arranged on the outer wall of the upper half of the circumference of the gas transmission steel pipe to be tested. Timeline 2; and each timeline 2 is connected in series with an external resistor and a constant voltage power supply to form a closed test circuit; signal lines for collecting voltage signals are also provided at both ends of each timeline, and the signal lines are connected to the data acquisition system , the data acquisition system is connected to the processing terminal.

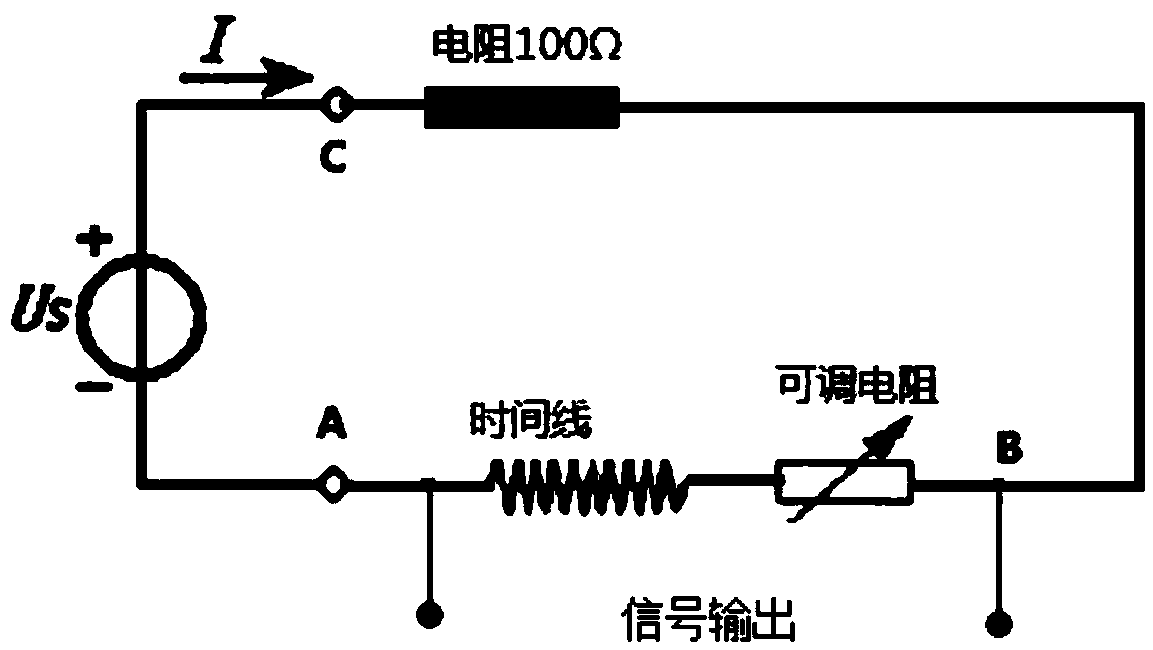

[0028] see figure 2 , is the connection structure of the timeline test circuit. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com