Altitude adaptive soya-bean milk manufacture method and soya-bean milk machine thereof

A production method and self-adaptive technology, applied in applications, dairy products, beverage preparation devices, etc., can solve problems such as inability to successfully complete pulping, incompletely cooked pulp and undrinkable, etc., to overcome continuous detection and judgment, and judgment of boiling point value Convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] As the first embodiment of the method for making altitude-adaptive soybean milk according to the present invention, its specific pulping process is as follows:

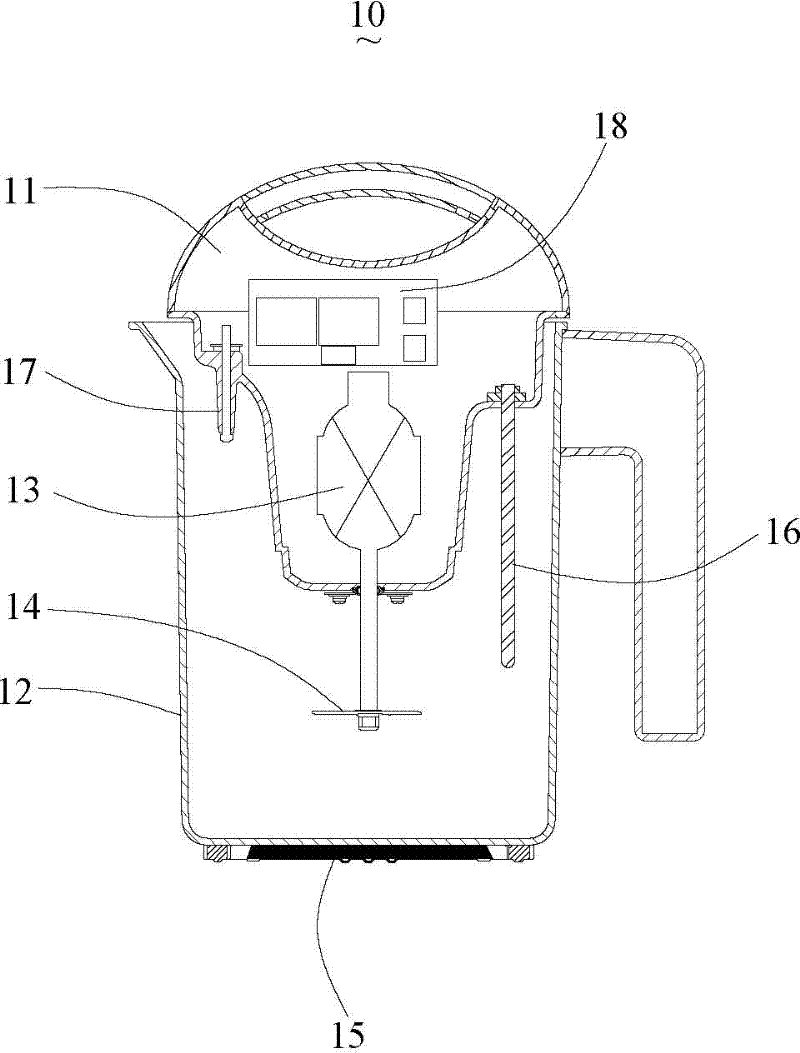

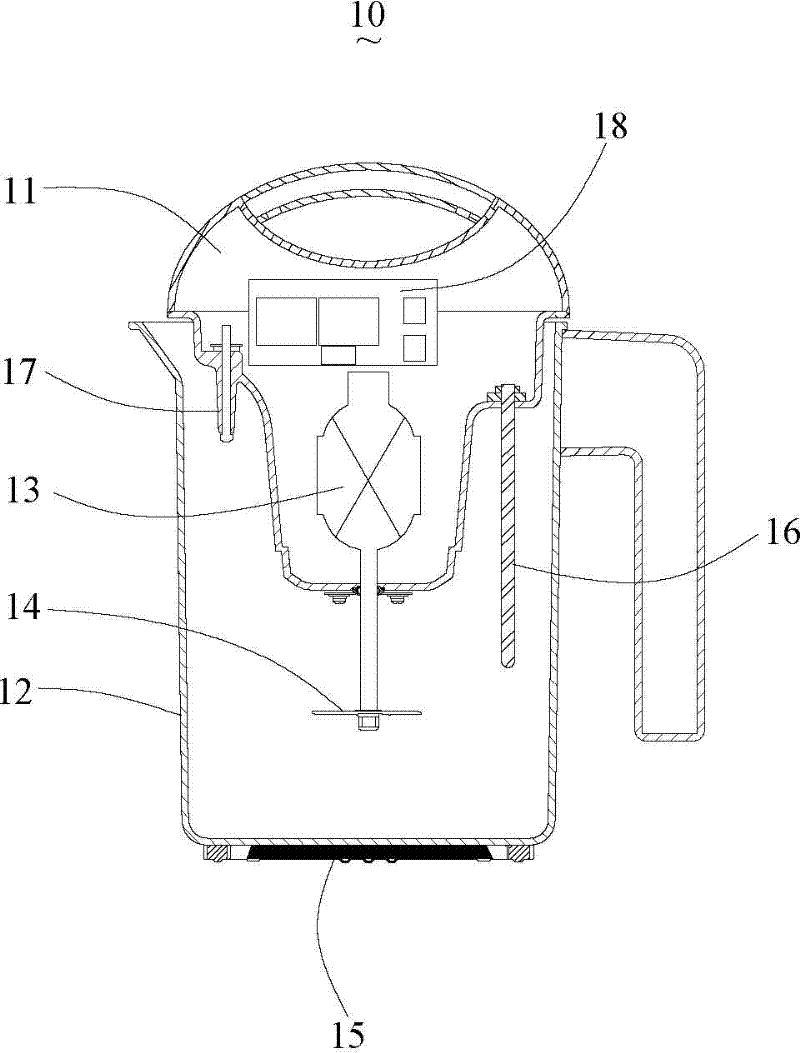

[0036] (a) In the heating stage, a cup body 12 and a heating device 15 are provided, and the heating device 15 preheats the water in the cup body 12 and the material containing soybeans.

[0037] In the said heating stage, the altitude judging step is also included, that is, the anti-overflow electrode 17, the temperature sensor 16 and the control device 18 having at least two or more pulping procedures, the anti-overflow electrode 17, the temperature sensor 16 and the control device 18 are electrically connected. connected, the temperature sensor 16 detects the actual temperature value of the preheated water and the material containing soybeans until the foam touches the anti-overflow electrode 17, and the control device 18 is preset with a temperature setting value, and the control device 18 is based on the ac...

Embodiment approach 2

[0046] As the second embodiment of the altitude-adaptive soymilk production method of the present invention, the specific pulping process differs from the pulping process in the first embodiment in that: the altitude-adaptive soymilk production method also includes a boiling stage, the heating The device circulates the heated water and the soybean milk after crushing the soybean-containing material, so as to fully inactivate the anti-nutritional factors in the soybean milk, so that the soybean milk can completely eliminate the beany smell.

[0047] When in high-altitude areas, extend the cooking time to avoid the low boiling point in high-altitude areas, which will cause the soy milk to have a strong beany smell. The control device selects a longer cooking time based on the comparison between the actual temperature value and the temperature setting value. pulping procedure.

[0048] In this implementation manner, other structures and beneficial effects are consistent with thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com