Liquidus temperature detection oven systematic device for aluminum electrolysis

A technology of primary crystal temperature and system installation, which is applied in furnaces, furnace types, investigation stages/state changes, etc., can solve problems such as inability to detect primary crystal temperature of aluminum electrolysis, and achieve low power consumption, accurate temperature values, and reliable heating furnaces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

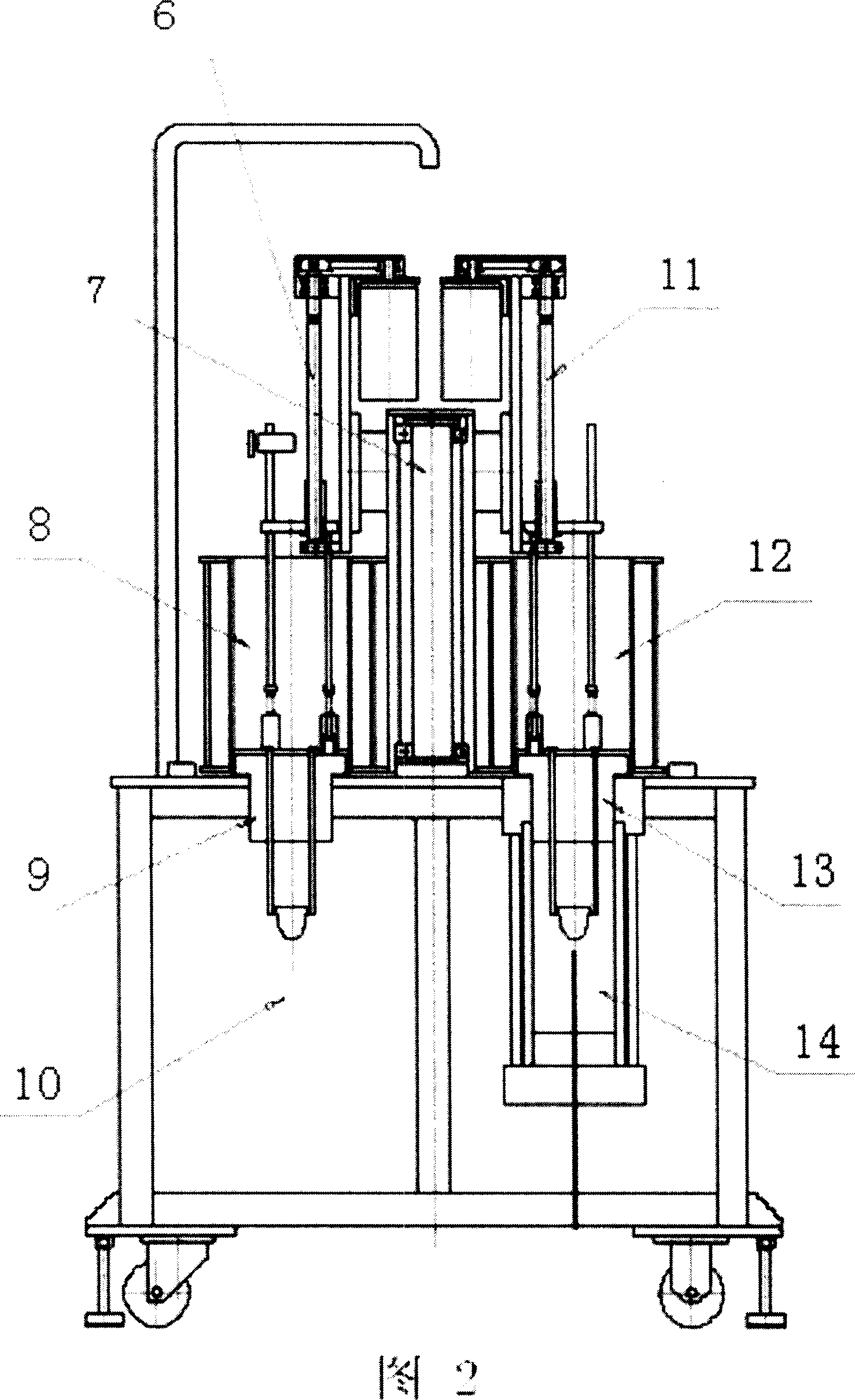

[0058] Embodiment of the present invention: the primary crystal temperature detection furnace 2 is mainly composed of manipulators 6, 11 for taking and placing samples, a rotary transposition mechanism 7, measuring chambers 8, 12, furnace covers 9, 13, cooling chamber 10, and heating chamber 14. The composition is connected as shown in Figure 2, wherein the cooling chamber 10 and the heating chamber 14 are split structures, the heating chamber 14 is located at the right bottom of the furnace body, the cooling chamber 10 is located at the left bottom of the furnace body, and the cooling chamber 10 is connected to the heating chamber. The warehouse 14 forms an included angle of 180°, the rotary transposition mechanism 7 is located in the middle of the furnace body, the main shaft coincides with the central axis of the furnace body, and the furnace covers 9 and 13 are located at the bottom of the rotary transposition mechanism 7 and above the furnace body table top, and the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com