Phase-change mass concrete and preparation method thereof

A mass concrete and phase change technology, applied in the field of concrete materials, can solve the problems such as the difficulty of precise control of the water passage time and water passage rate, the water pipe layout method, the extension of the construction period by the pre-buried cooling water pipe method, and the influence on the continuity of concrete pouring. The effect of reducing construction cost, reducing construction period and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

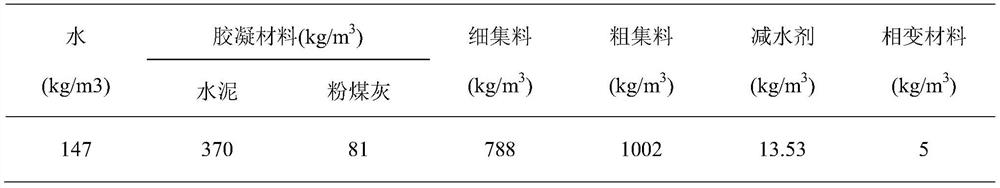

[0043] Table 1

[0044]

[0045] The water fine aggregate is machine-made sand and river sand, the blending mass ratio is 1:1, and the fineness modulus is 1.6-3.0; the coarse aggregate is 5-31.5mm continuous graded gravel, and the apparent density 2700~3100kg / m 3 ; The phase change material is a microcapsule phase change material, and the machine-made sand of equal volume is replaced by a volume sand substitution method.

[0046] Pour the cementitious material, fine aggregate, coarse aggregate and phase change material into the concrete mixer according to the proportions in Table 1 and dry mix for 30-60 seconds, then add water reducer and water, and continue mixing for 50-120 seconds to obtain the product based on Phase change concrete made of phase change materials. Its physical performance technical indicators are listed in Table 5.

Embodiment 2

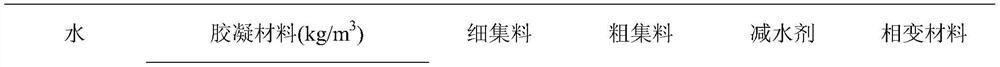

[0048] Table 2

[0049]

[0050]

[0051] The water fine aggregate is machine-made sand and river sand, the blending mass ratio is 1.2:1, the fineness modulus is 1.6-3.0; the coarse aggregate is 5-31.5mm continuous graded crushed stone, the apparent density 2700~3100kg / m 3 ; The phase change material is a microcapsule phase change material, and the machine-made sand of equal volume is replaced by a volume sand substitution method.

[0052] Pour the cementitious material, fine aggregate, coarse aggregate and phase change material into the concrete mixer according to the ratio in Table 2 and dry mix for 30-60 seconds, then add water reducer and water, and continue mixing for 50-120 seconds to obtain the Phase change concrete made of phase change materials. Its physical performance technical indicators are listed in Table 5.

Embodiment 3

[0054] table 3

[0055]

[0056] The water fine aggregate is machine-made sand and river sand, the blending mass ratio is 1.5:1, the fineness modulus is 1.6-3.0; the coarse aggregate is 5-31.5mm continuous graded crushed stone, the apparent density 2700~3100kg / m 3 ; The phase change material is a microcapsule phase change material, and the machine-made sand of equal volume is replaced by a volume sand substitution method.

[0057] Pour the cementitious material, fine aggregate, coarse aggregate and phase change material into the concrete mixer according to the ratio in Table 3 and dry mix for 30-60 seconds, then add water reducer and water, and continue mixing for 50-120 seconds to obtain the Phase change concrete made of phase change materials. Its physical performance technical indicators are listed in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com