Preparation method of high volume stability concrete

A concrete and stability technology, applied in the field of high volume stability concrete preparation, can solve the problems of increased risk of concrete cracking, poor durability of concrete structure, large concrete moisture loss, etc., to improve volume stability, autogenous shrinkage and drying shrinkage Small size, good crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

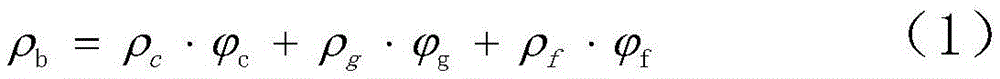

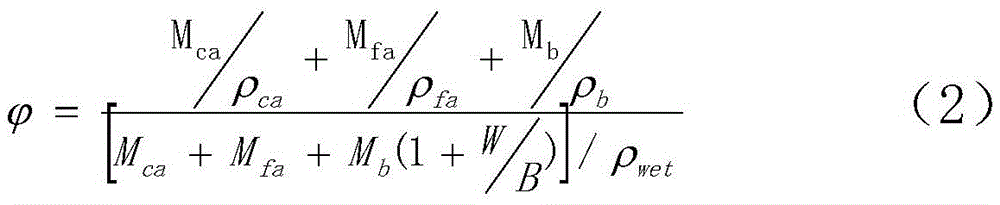

Method used

Image

Examples

Embodiment 1~5

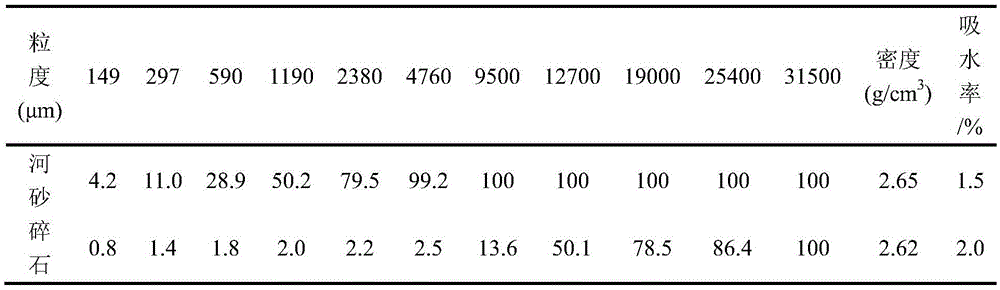

[0035] Examples 1 to 5 explore the influence of aggregate grading on concrete performance, the coarse and fine aggregate grading is shown in Table 4, and the amount of crushed stone is 1160kg / m 3 , the amount of river sand is 750kg / m 3 , the amount of cementitious material is 380kg / m 3 , the composition is Portland cement: slag powder: fly ash = 40%: 23%: 37%, the water-binder ratio is 0.35, and the concrete slump is controlled to 17±2cm by adjusting the amount of water reducing agent. Table 5 shows that by optimizing the aggregate gradation, the solid particle content in concrete can be significantly increased (from 62.3% to about 70%), and the amount of concrete cementitious material can be increased from 440kg / m 3 Reduced to 380kg / m 3 At the same time, it can still reach or even exceed the early and late strength of ordinary C40 concrete, and the crack resistance of concrete has been significantly improved, and the 28-day autogenous shrinkage and drying shrinkage have bee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com