Airless tires with built-in tube rings and hoops

A technology of non-pneumatic tires and round tubes, applied in the direction of wheels, wheel covers, transportation and packaging, etc., can solve the problems of uneven ground contact of tires, permanent reduction of foam cells, unsuitable for heavy-duty driving, etc., to improve the bearing capacity and elasticity, reducing the internal temperature rise, reducing the effect of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

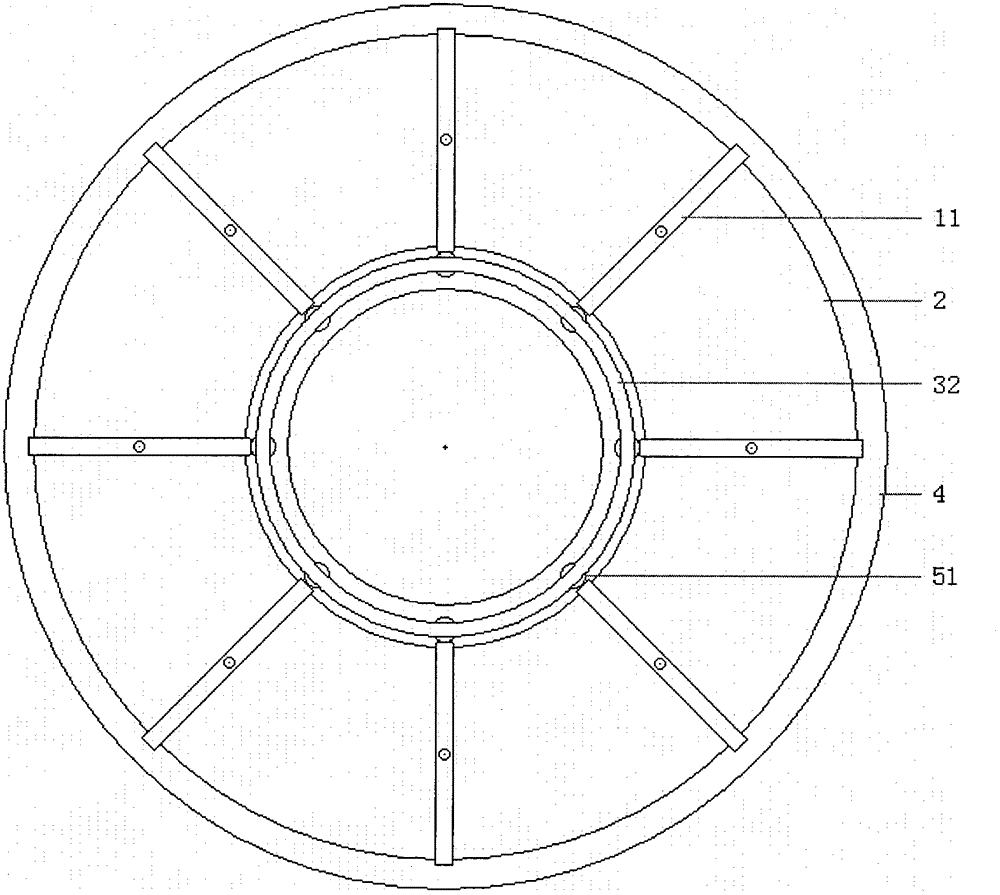

[0008] Embodiment one, such as Figure 1 to Figure 3.1 , Figure 4.1 , Figure 5 , Figure 6 As shown: eight closed connecting cylinders 11 or open connecting cylinders 12 with two outer walls connected to reverse columns are equally spaced on the pipe surface of a circular pipe ring 2, and the reverse columns of the connecting cylinders are all parallel to The rotating shaft of the circular tube ring (that is, the opposite column supports the two side walls of the circumference of Ω, so that the circular tube ring does not produce axial displacement in the mold cavity), together with a spring hoop 41, is placed in the cavity of the two-petal mold Inside, the cavity wall above the lower part of the cross section of the mold cavity 4 forms an Ω circle, and the lower wall is provided with eight groups of equally spaced, two-to-two facing single-end support ring column groups 51 whose length direction is perpendicular to the rotation axis of the Ω ring. The coincidence of the ...

Embodiment 2

[0009] Embodiment two, such as Figure 1 to Figure 3.1 , Figure 4.1 , Figure 7 , Figure 8 Shown: Figure 7 , Figure 9 The connecting cylinder shown is the slotted connecting cylinder 12 and the open connecting cylinder 13, and the two single steel wire rings 70 are symmetrically embedded in the top inner wall groove of the open connecting cylinder or the inner peripheral wall of the slotted connecting cylinder The end of the single steel wire ring is welded or pipe-connected. According to the embedding method, it can also be placed in the two-part mold of the special-shaped circular pipe ring with a conjoined reverse column or reverse ring rib to achieve plastic bonding. The ends of the single-piece steel wire ring are welded or piped. Others are the same as in Embodiment 1.

Embodiment 3

[0010] Embodiment three, such as Figures 1 to 4.2 , Figure 9 to Figure 13 Shown: Figure 10 , Figure 11 The hoop shown is that the elastic tube hoop 32 is embedded in the groove of the single-ended groove support ring column group 51. The elastic tube hoop is formed by placing a long-pitch coil spring in a plastic tube and then connecting the two ends of the spring. Figure 12 , Figure 13 The spacer posts shown are double groove spacer post sets 52, Figure 12 A spring hoop 31 is respectively embedded in each opposite groove of the double-slot support ring post group, Figure 13 A bomb tube hoop 32 is respectively embedded in each opposite groove of the double groove support ring post group, Figure 9 The top ring side formed by the top surface of the peripheral wall of the opening connected to the cylinder 13 is provided with a composite ring 71 of this material, Figure 10 The top ring side formed by the top surface of the peripheral wall of the slit connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com