Metallized polypropylene film capacitor for induction cooker

A polypropylene film and metallized film technology, used in the field of capacitors, can solve problems such as limited application and inability to meet requirements, and achieve the effects of strong self-healing, low contact resistance, and strong ability to withstand effective current and impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

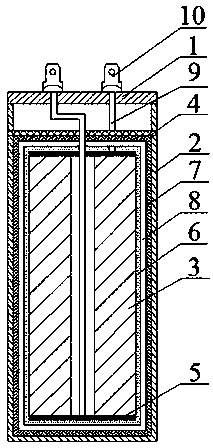

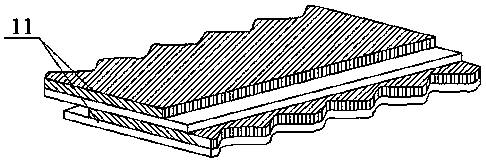

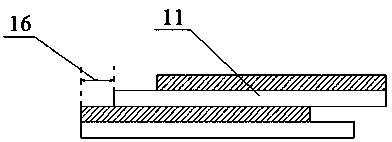

[0036] Such as figure 1 As shown, a metalized polypropylene film capacitor for an induction cooker includes an upper insulating cover 1, a lower insulating cover 2, a capacitor core 3, a gold spray layer 5, a conductive post 9 and a lead terminal 10, an upper insulating cover 1 and a lower insulating cover The surface of the cover 2 is treated with sandblasting and oxidation protection, which can increase the safety performance and service life of the capacitor. The upper insulating cover 1 and the lower insulating cover 2 are fixedly connected by the explosion-proof plate 4, the lower insulating cover 2 and the explosion-proof plate 4 are combined to house the capacitor core 3, and the gap between the lower insulating cover 2 and the explosion-proof plate 4 is provided with impregnant 6. The impregnant 6 completely impregnates the capacitor core 3. The inner surface of the lower insulating cover 2 is provided with a buffer layer 7, the thickness of the buffer layer 7 is 3~4mm,...

Embodiment 2

[0045] A metallized polypropylene film capacitor for induction cooker. The structure is roughly the same as that of Example 1, except that:

[0046] Impregnant 6 is made of the following raw materials: 31 parts by weight of monobenzyl toluene, 21 parts of 1,1-diphenylethane, 21 parts of vegetable oil, 16 parts of glycerin, 16 parts of nano powder, 0.35 parts of antioxidant, 0.6 part of silane coupling agent, 0.3 part of metal deactivator.

[0047] Among them, vegetable oil is a mixture of rapeseed oil and camellia seed oil, the weight ratio of rapeseed oil: camellia seed oil is 4.5:5.5; the nano powder is a mixture of aluminum oxide, magnesium oxide and zinc oxide, aluminum oxide, magnesium oxide and oxide The particle size of zinc is 50~80nm, the weight ratio of aluminum oxide: magnesium oxide: zinc oxide is 3:2:3; antioxidant is rosemary antioxidant; silane coupling agent KH560; metal passivator is three Azocyclohexene.

[0048] Adding a metal passivator can suppress various effe...

Embodiment 3

[0054] A metallized polypropylene film capacitor for induction cooker. The structure is roughly the same as that of Example 1, except that:

[0055] Impregnant 6 is made of the following raw materials by weight: 34 parts of monobenzyl toluene, 23 parts of 1,1-diphenylethane, 23 parts of vegetable oil, 17 parts of glycerin, 17 parts of nano powder, 0.4 part of antioxidant, 0.65 parts of silane coupling agent.

[0056] Among them, vegetable oil is a mixture of rapeseed oil and camellia seed oil, the weight ratio of rapeseed oil: camellia seed oil is 5:5; the nano powder is a mixture of aluminum oxide, magnesium oxide and zinc oxide, aluminum oxide, magnesium oxide and oxide The particle size of zinc is 50~80nm, the weight ratio of aluminum oxide: magnesium oxide: zinc oxide is 3:2:3; the antioxidant is tea polyphenol; the silane coupling agent is KH570.

[0057] The preparation method of the above-mentioned impregnant 6 includes the following steps:

[0058] (1) Dissolve the nanopowder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com