Energy saving type control method of composite switch and energy saving type composite switch

A composite switch, energy-saving control technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation and other directions, can solve the problems of large heat generation of relay coils, waste of electric energy, and shortened service life of relays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

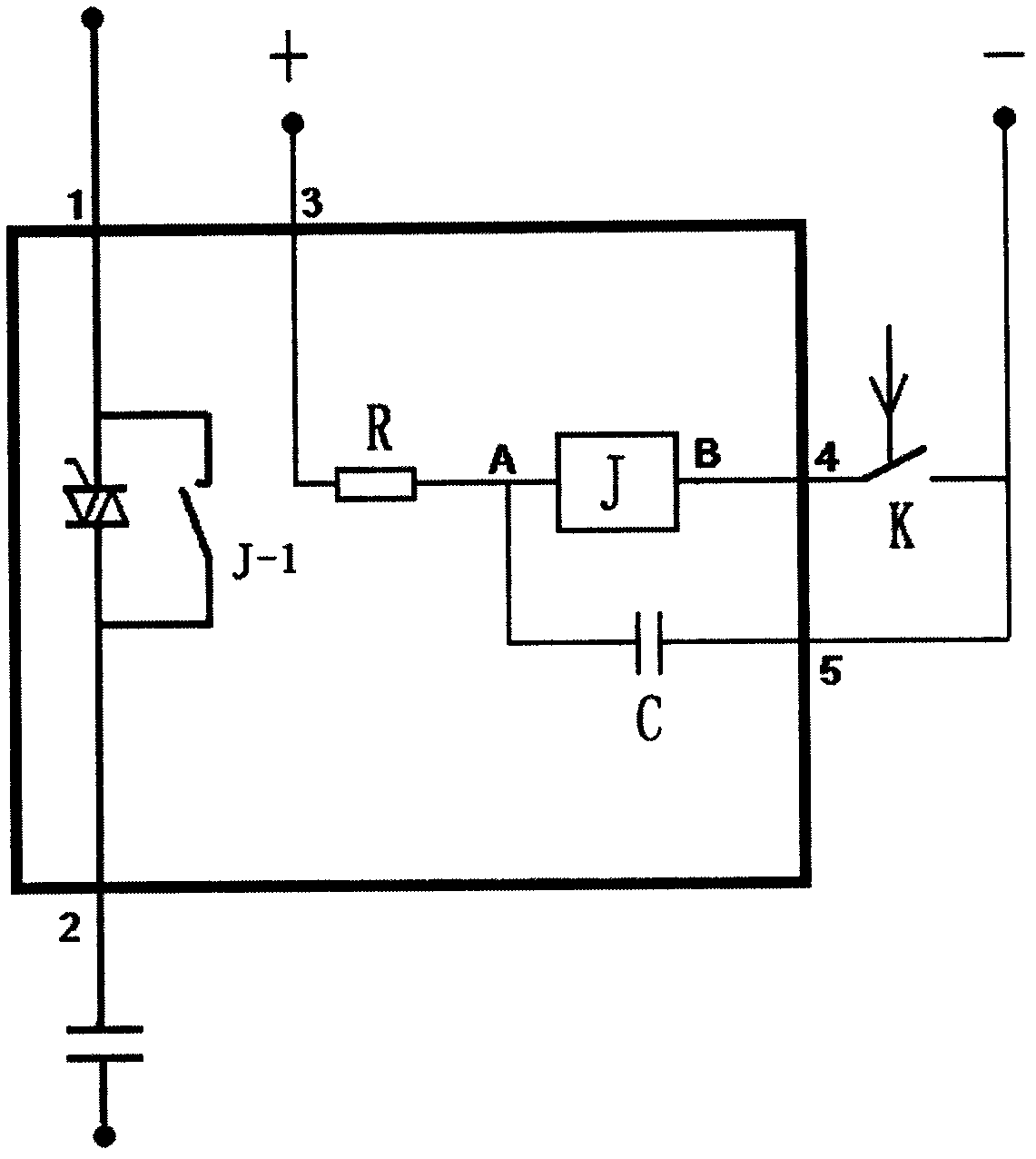

[0033] Figure 1 The energy-saving composite switch shown includes five external terminals: the first terminal 1 is used to connect to the power grid, the second terminal 2 is used to connect to the power capacitor, the third terminal 3 is used to connect the positive pole of the relay DC power supply, and the second terminal 3 is used to connect to the positive pole of the relay DC power supply. The four terminals 4 are connected in series with the relay control switch K to the negative pole of the relay DC power supply, and the fifth terminal 5 is directly connected to the negative pole of the relay DC power supply. The internal circuit connection relationship of the energy-saving composite switch is: between the first terminal 1 and the second terminal 2 is a parallel circuit of a bidirectional thyristor switch and a normally open contact of a relay; The output terminals of the silicon-controlled switching control circuit are connected; the third terminal and the fourth ter...

Embodiment 2

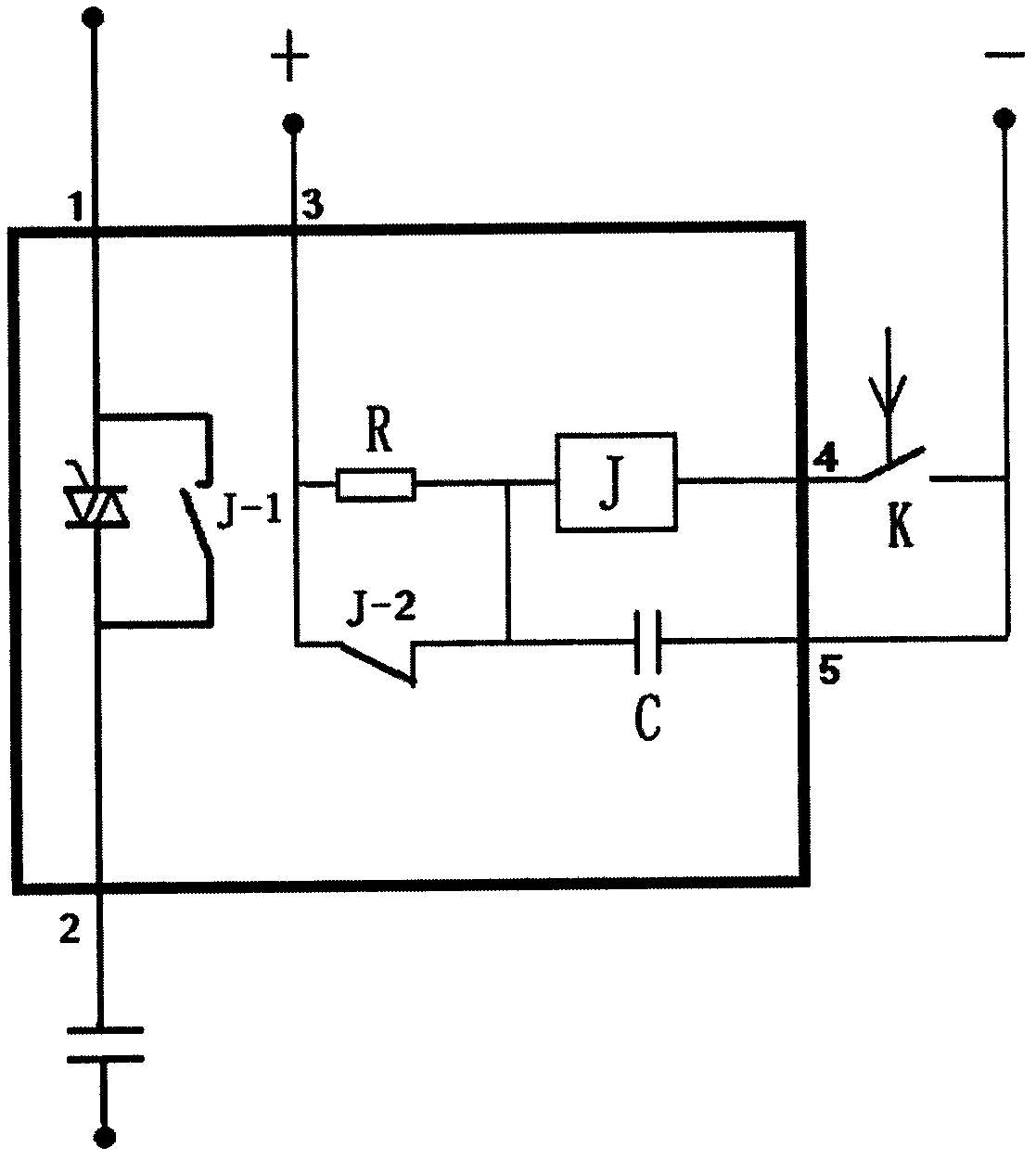

[0058] figure 2 It is a schematic diagram of the circuit principle of another embodiment of the energy-saving composite switch of the present invention. and figure 1 In comparison, the difference is that a pair of normally closed contacts of the relay are also connected in parallel at both ends of the resistor R.

Embodiment 3

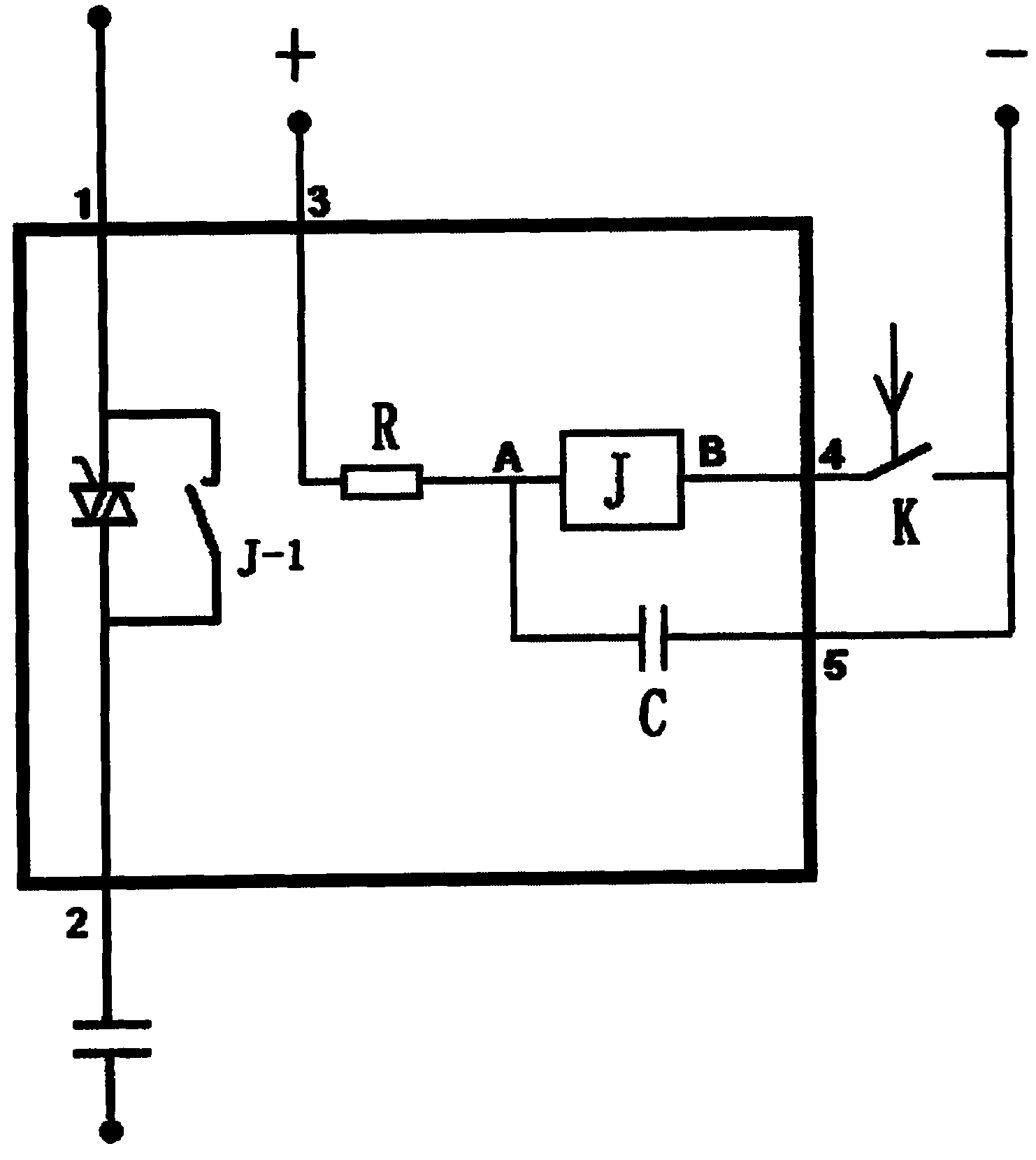

[0060] refer to figure 1 , the compound switch energy-saving control method of the present invention is:

[0061] 1) Before the composite switch receives the power capacitor input command: the relay DC power supply in the composite switch charges the capacitor C through the resistor R;

[0062] 2) After the composite switch receives the input command of the power capacitor, it controls the thyristor in the composite switch to trigger conduction at the moment when the voltage crosses zero;

[0063] 3) After the power capacitor is put into stable operation, by controlling the closing of the switch K, the capacitor C is instantly discharged to the relay coil and the contacts of the relay are pulled in place;

[0064] 4) After the contacts of the relay are pulled in place, control the thyristor in the composite switch to be removed from the circuit;

[0065] During the stable operation of the power capacitor, the relay coil is connected in series with the resistor R to the DC po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com