Treatment method of assembled-type prefabricated component wallboard joints

A technology of prefabricated components and processing methods, applied in building components, building structures, building thermal insulation materials, etc., can solve the problems of increased construction costs, increased post-defect processing costs, and inability to effectively control the generation and spread of cracks. Economical value, easy operation, effect of reducing temperature cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

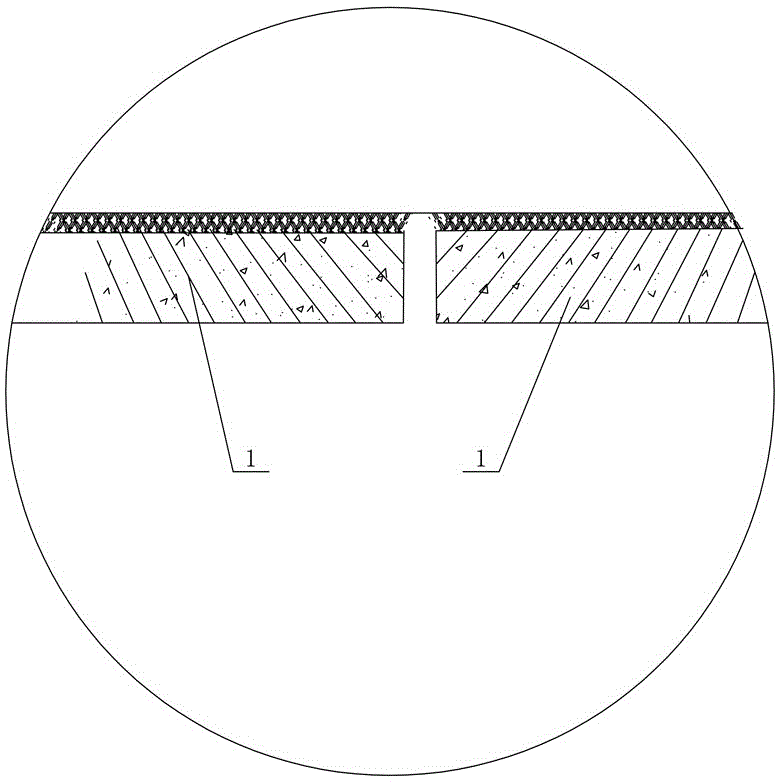

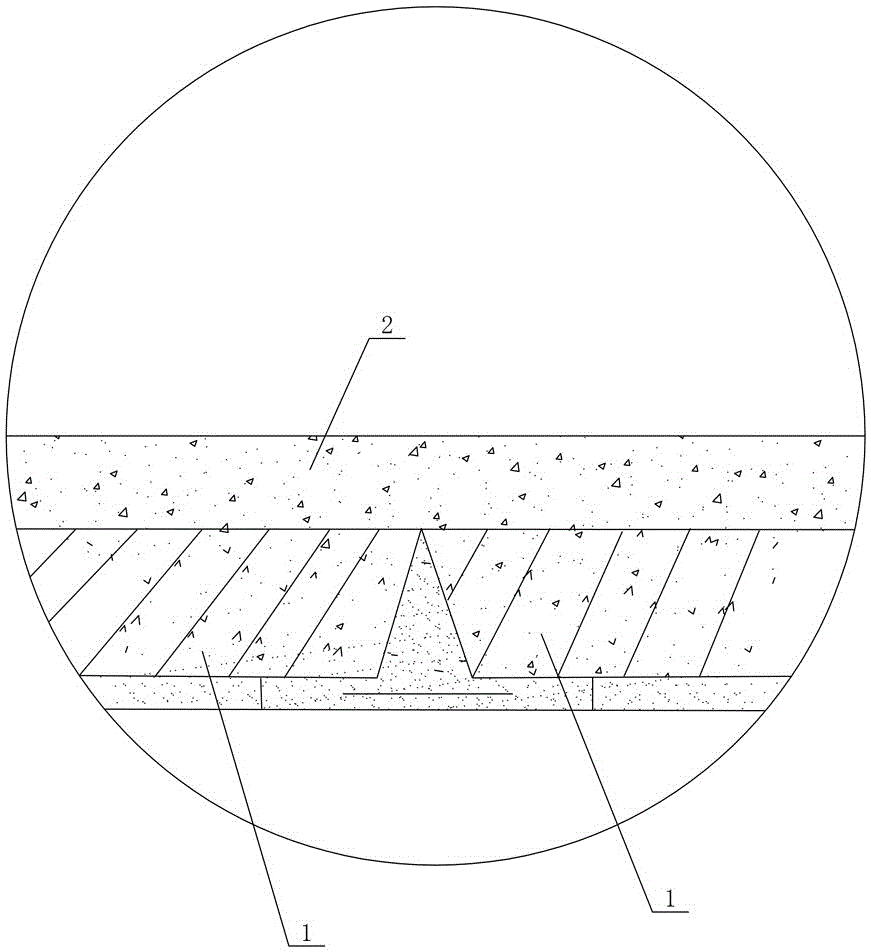

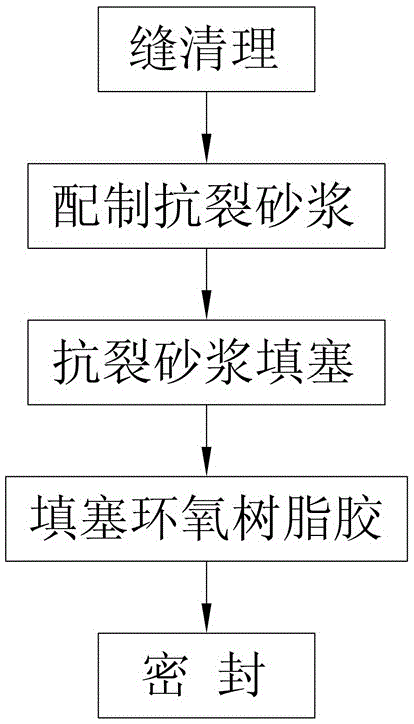

[0041] Figure 1 to Figure 5 It shows an embodiment of the method for processing the wall panel seams of assembled prefabricated components of the present invention. When processing the vertical joints between prefabricated components 1 and the top horizontal panel seams, the following steps are included:

[0042] S1: Seam cleaning: Remove concrete blocks, scum and other sundries in or around the seam with iron chisels and gray knives. If there is oil on the surface, use cleaning agent and water to clean it, and then use a brown brush to remove the dust on the surface after drying. clean up;

[0043] S2: Preparation of anti-cracking mortar: Use a low-speed electric drill with stirring blades to mechanically stir until it is uniform and free of lumps. After standing for 5 minutes, it can be used after a little stirring;

[0044] S3: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com