A New Type of Building Thermal Insulation Mortar

A technology for thermal insulation mortar and construction, applied in the field of thermal insulation mortar for new construction, can solve the problems of increased mortar strength, poor frost resistance of mortar, affecting product use, etc., and achieves improved hydration speed, low hydration heat, and comprehensive performance improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

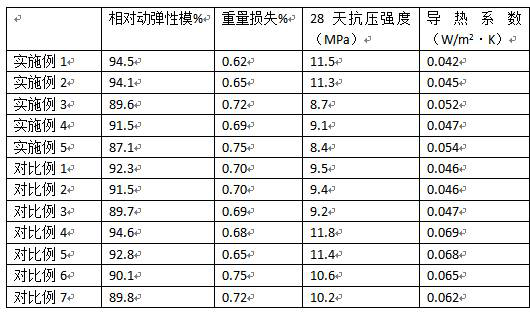

Examples

Embodiment 1

[0030] A new type of thermal insulation mortar for construction, which is made from the following raw materials by weight:

[0031] 30 parts of cement, 42 parts of fly ash, 36 parts of yellow sand, 8 parts of foamed polyurethane particles, 12 parts of raw vermiculite, 8 parts of short fiber mixture.

[0032] The short fiber mixture is made of glass fiber and nylon fiber in a weight ratio of 6.5:1 by weight.

[0033] The fly ash is modified using the following methods:

[0034] (1) Take fly ash, remove the debris in the fly ash, soak the removed fly ash in water for 2-3 days, and then filter;

[0035] (2). Bake the fly ash processed in step (1) at 100-120℃ for 1h in an oven;

[0036] (3) Fly ash treatment;

[0037] a. Soak the fly ash with 0.8mol / L oxalic acid solution for 2-3min, then wash with water and dry;

[0038] b. Raise the fly ash treated in step a to 380°C at a temperature increase rate of 10°C / min, heat preservation treatment for 5 minutes, then heat up to 650°C at a rate of 8°C / ...

Embodiment 2

[0048] A new type of thermal insulation mortar for construction, which is made from the following raw materials by weight:

[0049] 32 parts of cement, 43 parts of fly ash, 38 parts of yellow sand, 8.5 parts of foamed polyurethane particles, 13 parts of raw vermiculite, 8 parts of short fiber mixture.

[0050] The short fiber mixture is made of glass fiber and nylon fiber in a weight ratio of 7:1 by weight.

[0051] The fly ash is modified using the following methods:

[0052] (1) Take fly ash, remove the debris in the fly ash, soak the removed fly ash in water for 2 days, and then filter;

[0053] (2) Bake the fly ash processed in step (1) at 110°C for 1 hour in an oven;

[0054] (3) Fly ash treatment;

[0055] a. Soak the fly ash with 0.8mol / L oxalic acid solution for 3 minutes, then wash with water and dry;

[0056] b. Raise the fly ash treated in step a to 380°C at a temperature increase rate of 10°C / min, heat preservation treatment for 5 minutes, then heat up to 650°C at a rate of 8°C...

Embodiment 3

[0064] Compared with Example 1, the fly ash uses Grade 1 fly ash, which does not undergo the modification treatment in this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com