Light energy-saving heat-insulating wall material

A heat-insulating wall and lightweight technology, applied in the field of building materials, can solve problems such as difficult surface bonding, soft materials, improper dosage, etc., and achieve the effects of reducing early hydration heat, improving permeability resistance, and reducing temperature cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

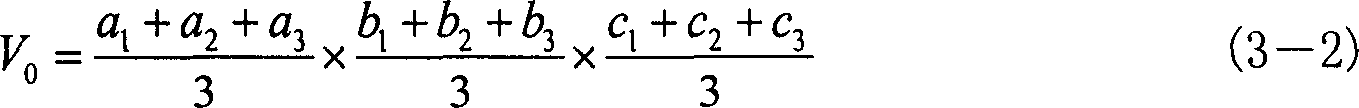

Method used

Image

Examples

Embodiment Construction

[0079] The following examples describe the present invention in more detail:

[0080] 1. Polystyrene with a weight ratio of 1.2-2.6% is used as lightweight aggregate, 72-76% of Portland cement is used as cementitious material, 22-26% of sand is used as aggregate, and 35% of polystyrene weight -88% water, expansion agent accounting for 13% by weight of Portland cement, and water reducing agent accounting for 1% by weight of Portland cement as raw materials. First, crush the polystyrene into particles with a radius of 1-6mm with a pulverizer, add water to make the polystyrene wet, then add Portland cement, sand, and expansion agent and stir evenly, and dilute the water reducer with water Add it together with the rest of the water, stir it, and shape it into a product.

[0081] 2. Polystyrene and perlite with a weight ratio of 1.2-2.6% are used as lightweight aggregates, 72-76% of Portland cement and fly ash are used as cementitious materials, and 22-26% of sand is used as aggre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com