Steel slag composite material for 3D printing as well as preparation method and application of steel slag composite material

A composite material and steel slag technology, applied in the field of steel slag composite material and preparation, can solve problems such as steel slag occupying land, polluting the environment, and steel slag cannot be disposed of in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

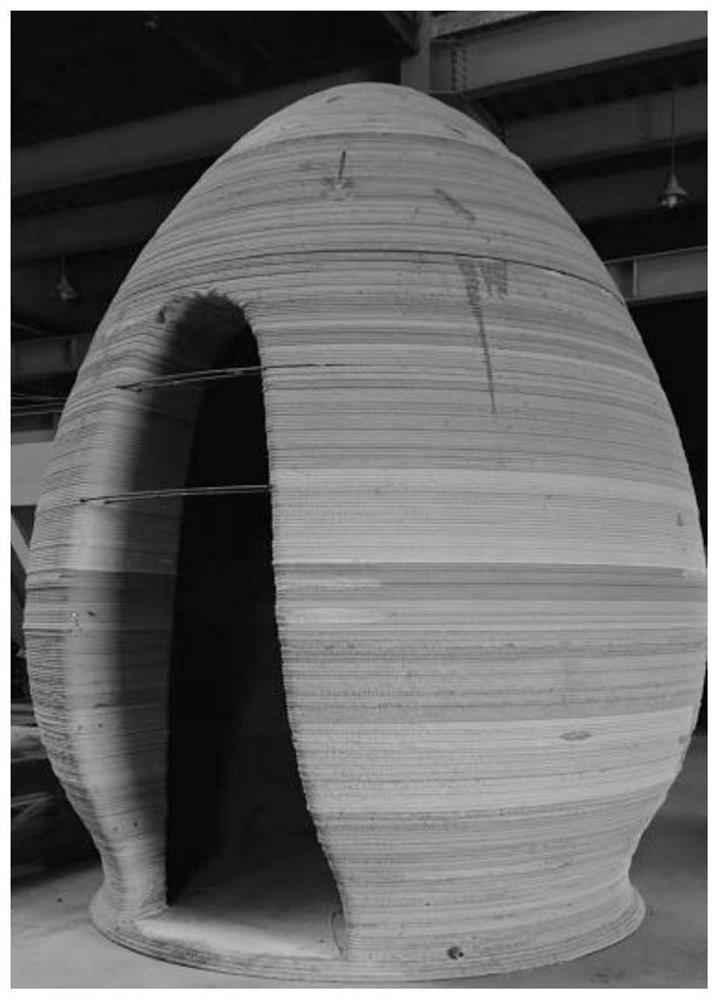

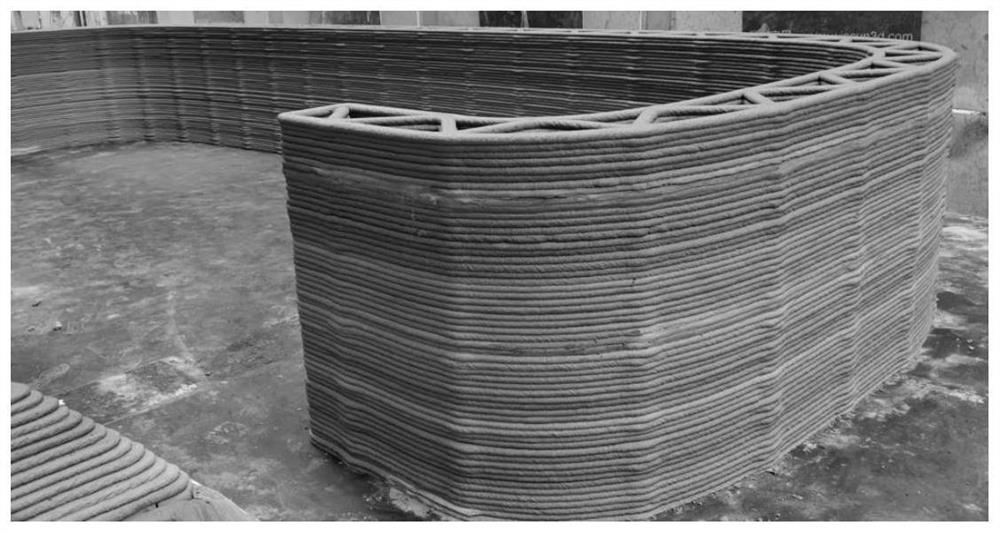

Image

Examples

Embodiment 1

[0047] The steel slag composite material for 3D printing provided in this embodiment has the following raw material ratios:

[0048]

[0049]

[0050] The preparation method of the steel slag composite material is as follows:

[0051] Take the above fixed components and mix and stir for 3-5 minutes, add the liquid ingredients and stir for 5-8 minutes, stir evenly and then use for 3D printing.

Embodiment 2

[0053] The steel slag composite material for 3D printing provided in this embodiment has the following raw material ratios:

[0054]

[0055]

[0056] The preparation method is the same as in Example 1.

Embodiment 3

[0058] The steel slag composite material for 3D printing provided in this embodiment has the following raw material ratios:

[0059]

[0060]

[0061] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com