Anti-cracking large-size early-strength, high-strength and micro-expansion M grouting material and construction method thereof

A construction method and technology of grouting materials, which are applied in basic structure engineering, construction, etc., can solve problems such as the impact of structural durability and the inconvenience of construction of large-volume grouting materials, and achieve the effect of preventing cracking, simple and practical preparation, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The anti-cracking large-volume early-strength, high-strength, micro-expansion M grouting material of the present invention,

[0059] Including cement, sand, early strength agent, water reducer and expansion agent, characterized in that:

[0060] The cement, P.Ⅱ52.5R, the amount of M grouting material per ton is 440Kg, and the mix ratio is 1;

[0061] The sand, medium sand, the amount of M grouting material per ton is 492Kg, the mix ratio is 1.12; the medium sand is medium sand (Zone II), fineness modulus > 2.6, mud content ≤ 2.0%, mud content > 0.5 %;

[0062] The early strength agent: calcium formate, the amount of per ton of M grouting material is 10Kg, and the mixing ratio is 0.02;

[0063] The water reducing agent: polyacid, the amount of M grouting material per ton is 5Kg, and the mixing ratio is 0.01;

[0064] The expansion agent: calcium sulfoaluminate expansion agent for concrete (UEA Yinge brand), the dosage per ton of M grouting material is 53Kg, and the mixi...

Embodiment 2

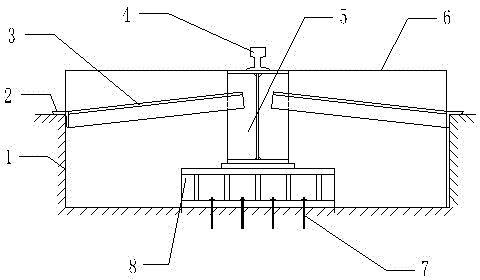

[0076] see now figure 1 , figure 1 It is a schematic diagram of on-line reconstruction grouting construction of the track according to the embodiment of the present invention.

[0077] The construction method of anti-cracking large-volume early strength, high strength, micro-expansion M grouting material of the present invention comprises the following steps:

[0078] a. On-site preparation of grouting material for construction immediately

[0079] Add crushed stone and water to the prefabricated M grouting material, the ratio is:

[0080] Prefabricated M grouting material: the amount of grouting material for immediate construction per ton is 512Kg, and the mix ratio is 1;

[0081] Coarse aggregate crushed stone: gradation 5-25mm, the amount of grouting material for construction immediately per ton is 419Kg, and the mix ratio is 0.82;

[0082] Water: tap water, the amount of grouting material for construction immediately per ton is 70Kg, and the mix ratio is 0.14;

[0083...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com