Activate micro powder prepared through wind quenching method steel slag and directly-discharged pulverized fuel ash and method

A technology of fly ash and steel slag, which is applied in chemical instruments and methods, climate sustainability, and filtering and screening, and can solve the problems of difficult and effective crushing of steel slag, uneven particle size, and poor actual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

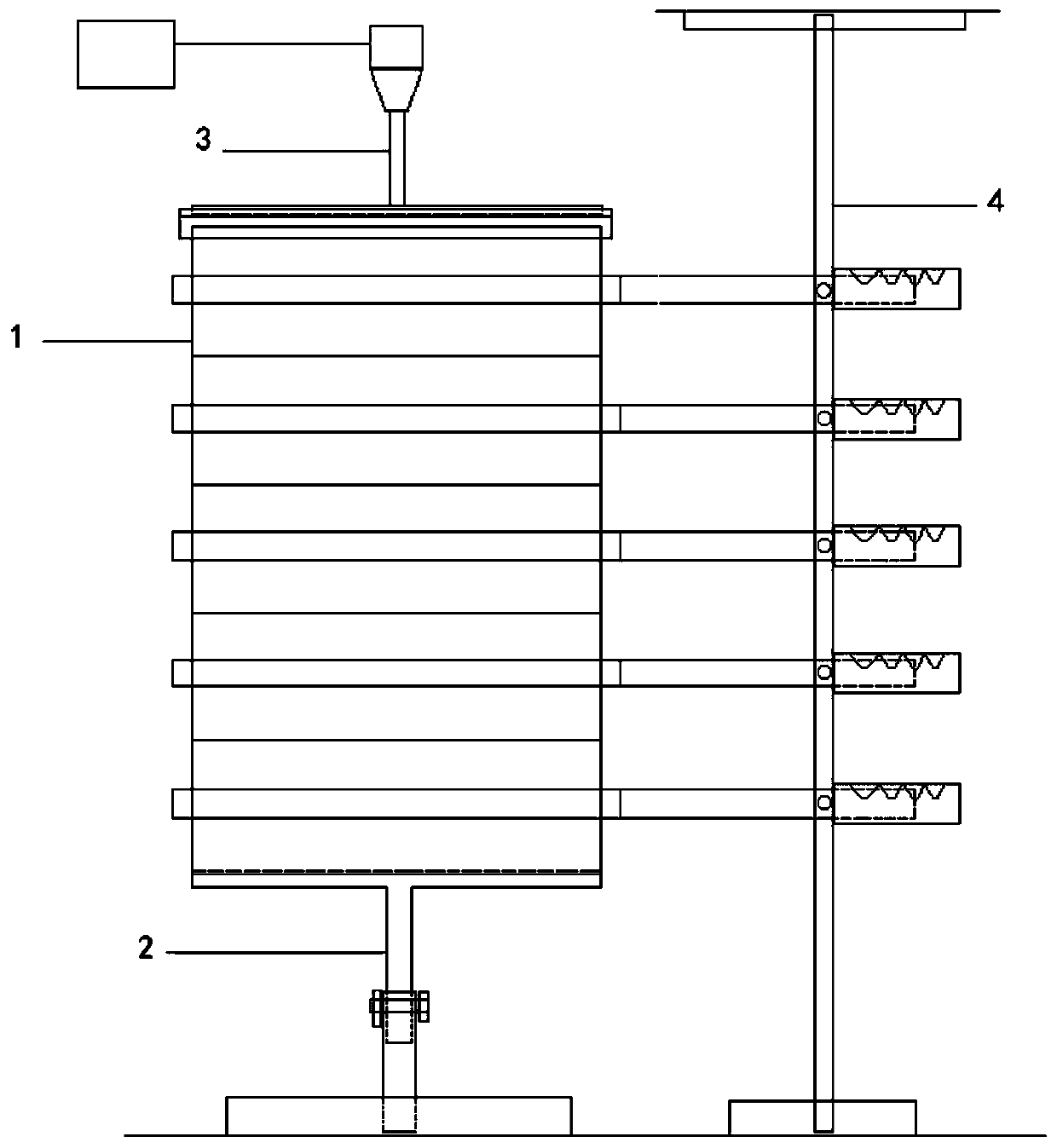

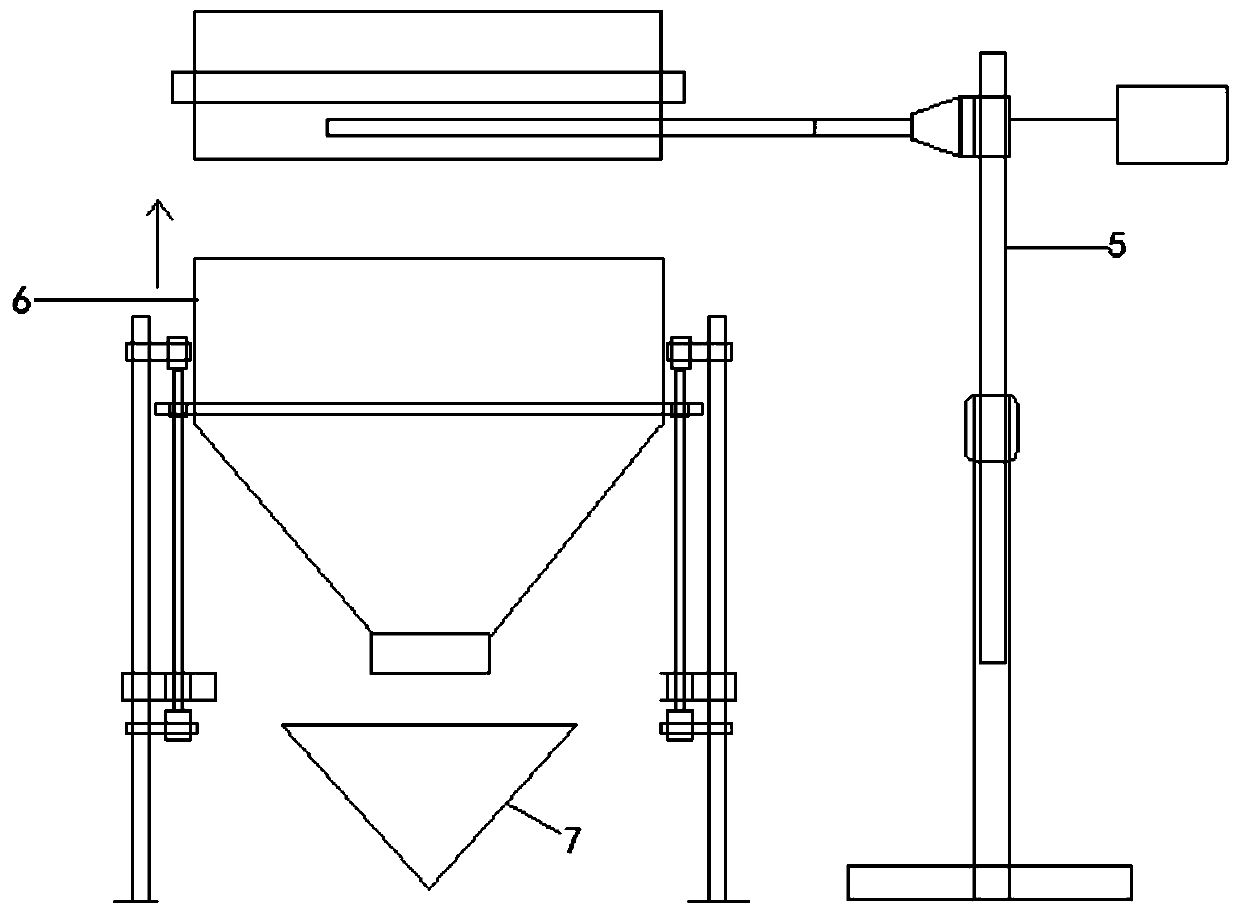

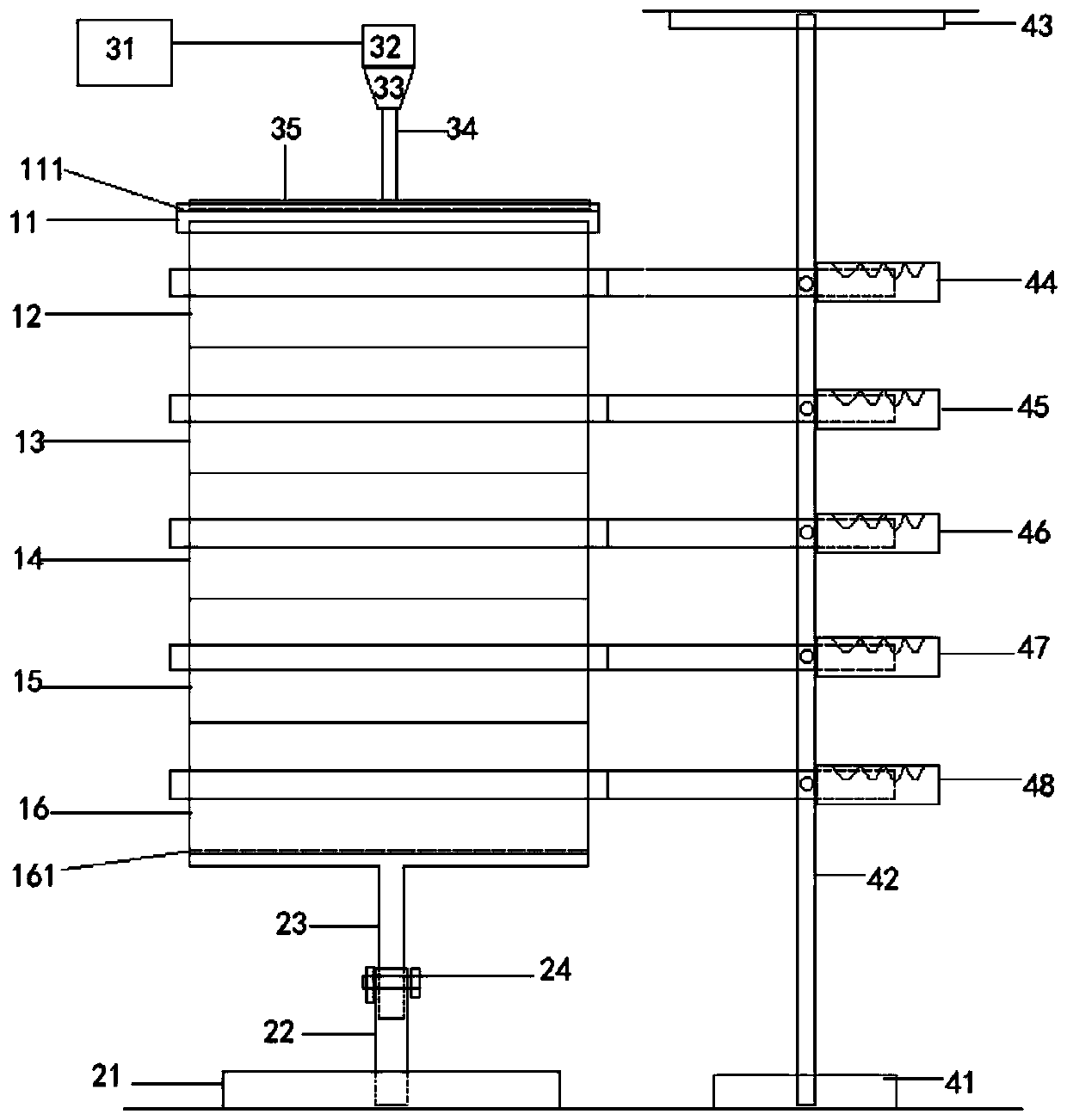

[0042] see Figure 1-7 , the present invention provides a technical solution: a steel slag crushing auxiliary device, which is characterized in that it includes a vibrating screen group 1, a support frame 2, a first vibrator 3, a side frame 4, an ultrasonic clamping frame 5, a funnel portion 6, Grinder Hopper7. The vibrating screen group 1 has a top cover 11 , a first vibrating screen 12 , a second vibrating screen 13 , a third vibrating screen 14 , a fourth vibrating screen 15 , and a bottom tank 16 sequentially from top to bottom.

[0043] Among the first vibrating screen 12, the second vibrating screen 13, the third vibrating screen 14, and the fourth vibrating screen 15, the first screen cloth 123 of 120-240 purpose, the second screen cloth 133 of 600-800 purpose, The third mesh 143 of 1200-1500 mesh, the fourth mesh 153 of 2200-3800 mesh, the above four meshes are all in a horizontal state.

[0044] The outer side of the top cover 11 has a downward flange, and is fasten...

Embodiment 2

[0063] A method for preparing active micropowder containing steel slag and fly ash by wind-quenching method is carried out by using the device of the aforementioned embodiment 1, and specifically includes the following steps.

[0064] (1) Weighing raw materials: Weigh 60-70% steel slag, 20-30% fly ash, 0.7-2% steel slag grinding aid, 16-20% lime, 0.1-0.3% Polycarboxylate superplasticizer powder, 0.2-0.6% activator, 0.1-0.3% silicon oxide, and 0.1-0.3% reinforcing fiber.

[0065] (2) Classification and screening: use the steel slag crushing auxiliary device as claimed in claim 3, pour the steel slag, steel slag grinding aid and fly ash taken in step 1 on the first vibrating screen 12, buckle the top cover, Align the first vibrating screen 12, the second vibrating screen 13, the third vibrating screen 14, the fourth vibrating screen 15, and the bottom groove 16 in the vertical direction, and use the vibrating top bolt 35 and the upper frame 23 of the vibrating screen group 1 up ...

Embodiment 3

[0071] Same as the implementation of Example 2, the difference is: (1) raw materials are taken by weighing: take by weight respectively 62% steel slag, 20.8% fly ash, 0.7% steel slag grinding aid, 16% lime, 0.1% polycarboxylate superplasticizer powder, 0.2% activator, 0.1% silicon oxide, and 0.1% reinforcing fiber.

[0072] (2) Hierarchical screening: Vibrate for at least 1.5 hours by alternating low and high frequencies.

[0073] (3) Multiple grinding steps: the second generator vibrates for five times, the second generator 51 is turned on to vibrate at 15000-16000 Hz for 10 minutes, and the grinder is turned on to grind for at least 1.5 hours to obtain the product of step 3.

[0074] (4) Ultra-fine grinding step: in a gravity-free mixing mixer, stir for 30 minutes to obtain the active micropowder composite material.

[0075] Preferably, the repeated alternation of low and high frequencies refers to repeated alternation of 8000-9000 Hz vibration for 20 s and 24000-26000 Hz v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com