Detachable gravity dam and construction and dismounting method thereof

A gravity dam and dismantling technology, which is applied in gravity dams, dams, etc., can solve the problems of temperature cracks, no consideration of how to disassemble the dam body, and low dam construction speed, so as to reduce temperature cracks, increase construction efficiency, and reduce engineering costs. volume and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

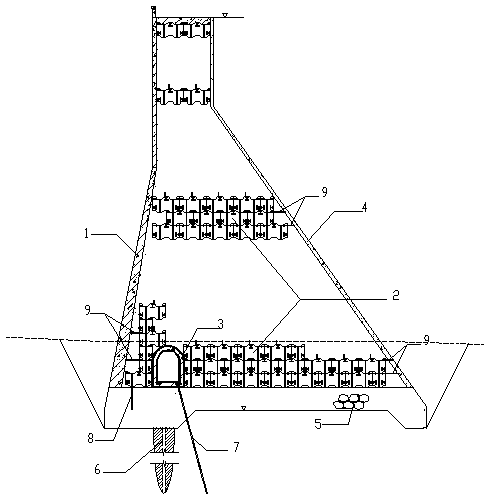

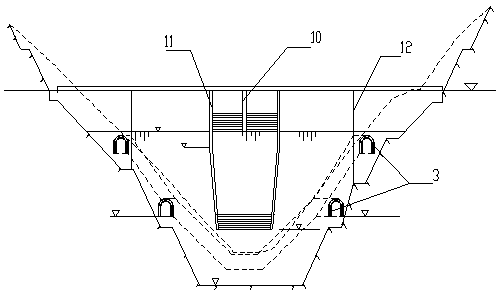

[0054] Embodiment 1: as Figure 1-11 As shown, a detachable gravity dam includes drainage grouting corridor 3, anti-seepage curtain 6, dam foundation drainage hole 7, middle pier 10, side pier 11, transverse joint 12, and upstream concrete panel 1, block concrete 2 , downstream concrete face plate 4, plain concrete cushion 5, dam foundation anchor bar 8;

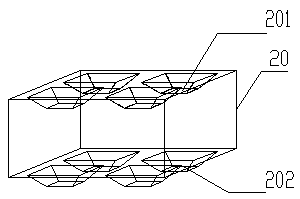

[0055] The upstream concrete panel 1 and the downstream concrete panel 4 are respectively poured on the upstream and downstream sides of the dam body, a plain concrete cushion 5 is laid on the dam foundation, and a detachable block concrete 2 is built on the plain concrete cushion 5, and the dam foundation is anchored The ribs 8 are arranged in the hoisting holes 205 of the block concrete 2 at the bottom.

[0056] Further, it can be set that the block concrete is made of prefabricated blocks connected by bolts in a certain order; specifically, it can be set that: the block concrete 2 is constructed row by row from upstream ...

Embodiment 2

[0081] Embodiment 2: as Figure 1-11 As shown, a detachable gravity dam includes drainage grouting corridor 3, anti-seepage curtain 6, dam foundation drainage hole 7, middle pier 10, side pier 11, transverse joint 12, and upstream concrete panel 1, block concrete 2 , downstream concrete face 4, plain concrete cushion 5, dam foundation anchor bar 8; described upstream concrete face 1, downstream concrete face 4 are respectively poured on the upper and lower reaches of the dam body, plain concrete cushion 5 is paved on the dam foundation, plain Detachable block concrete 2 is built on the concrete cushion 5 , and the dam foundation anchor bar 8 is arranged in the hoisting hole 205 of the bottom block concrete 2 .

[0082] Further, it can be set that the block concrete is made of prefabricated blocks connected by bolts in a certain order; specifically, it can be set that: the block concrete 2 is constructed row by row from upstream to downstream. The block concrete 2 is assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com