Unloading device and concrete warehousing method

A technology of unloading device and concrete, which is applied in the direction of transportation, packaging, loading/unloading, etc., and can solve problems such as easy temperature cracks, large concrete slump, and high heat of hydration of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

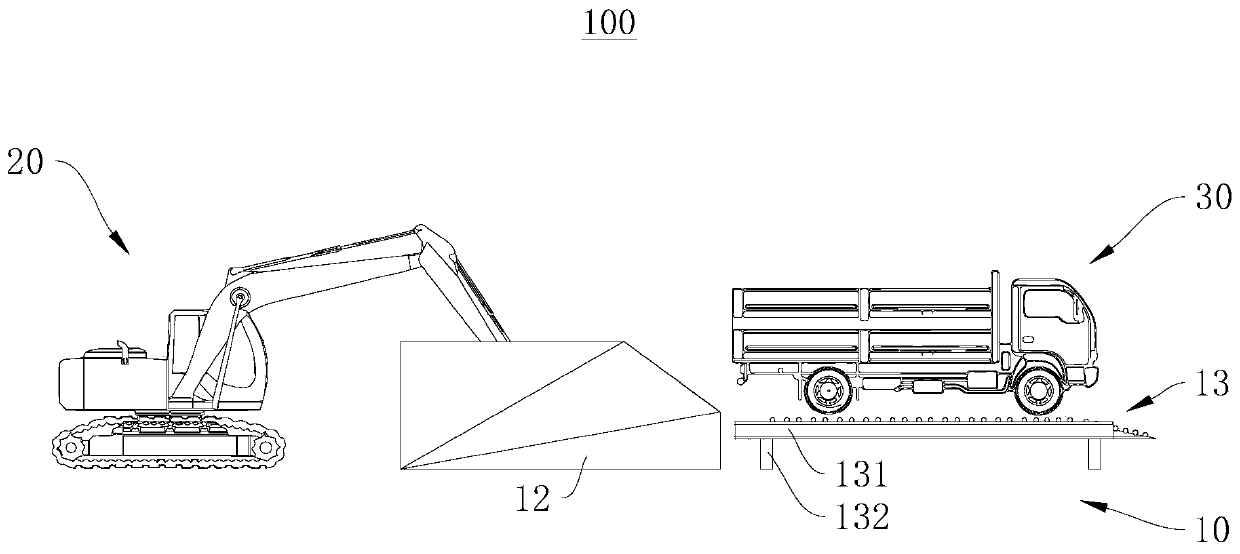

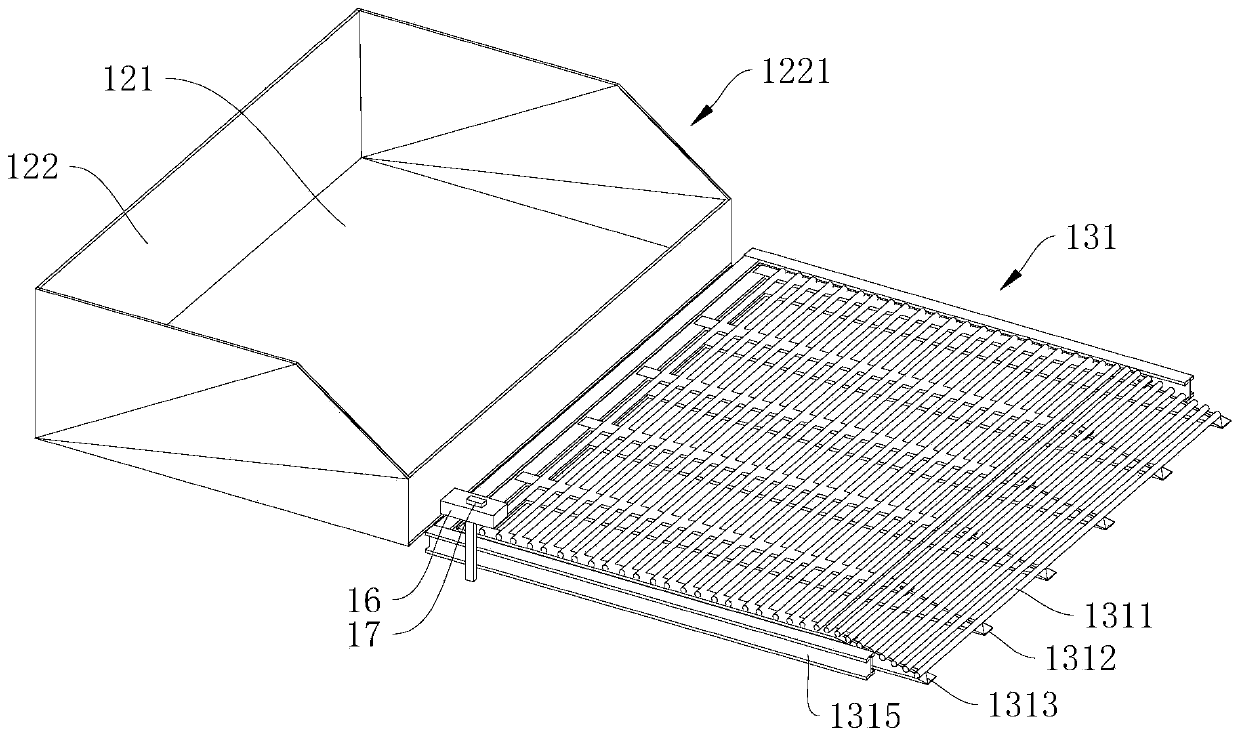

[0036] see figure 1 , figure 1 It is a structural schematic diagram of the unloading device 10 provided by the first embodiment of the present invention when it is applied to the concrete silo system 100 .

[0037] The first embodiment of the present invention provides a discharge device 10, the discharge device 10 can cooperate with the concrete transport vehicle 30 and the excavator 20, to complete the concrete silo operation of concrete, the discharge device 10 can control the slump The lower concrete is used for concrete warehousing operations, and is conducive to the temperature control of concrete. It is especially suitable for concrete warehousing operations in dry and cold valley areas at high altitudes. The unloading device 10 can be applied to a concrete storage system 100 .

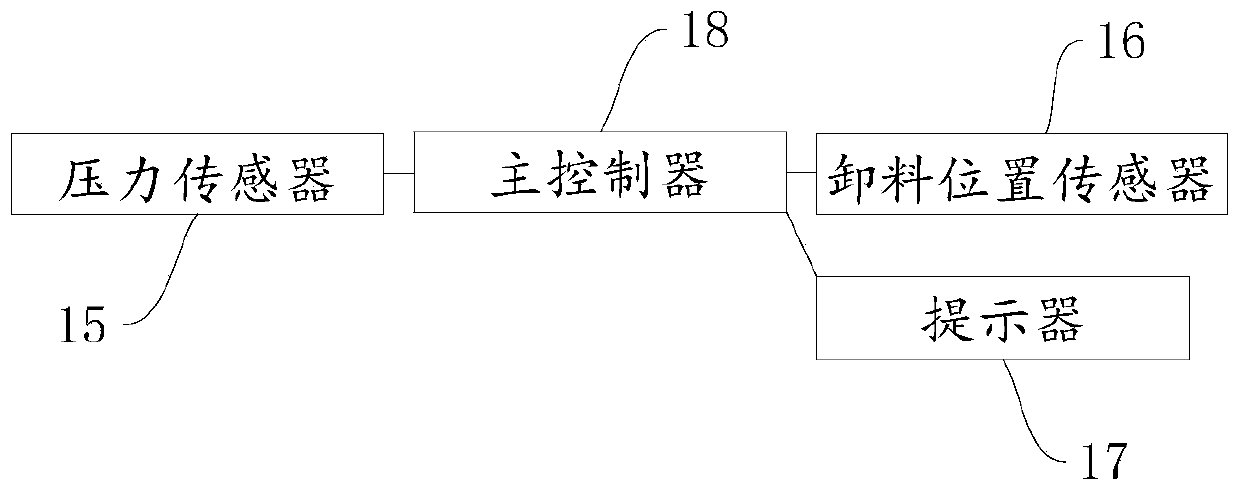

[0038] Taking the unloading device 10 that can be applied to the concrete silo system 100 as an example, the concrete silo system 100 includes the unloading device 10, which completes the au...

no. 2 example

[0065] see Figure 4 , Figure 4 It is a schematic flow chart of the method for storing concrete into silos provided by the second embodiment of the present invention.

[0066] The concrete storage method adopts the unloading device 10, the concrete transport vehicle 30 and the excavator 20, wherein, the basic principle and the technical effect produced by the unloading device 10 are the same as those of the above-mentioned embodiments, and are not mentioned in this embodiment for a brief description. For details, reference may be made to the corresponding content in the above-mentioned embodiments.

[0067] The concrete storage method includes:

[0068] Step S101 : The concrete transport vehicle 30 unloads the concrete into the collecting hopper 12 . The method of directly containing concrete through the collecting hopper 12 has lower requirements on the slump of the concrete, and the temperature control of the concrete in the collecting hopper 12 is relatively simple, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com