Paper money processing device

A processing device and paper money technology, applied in metal processing, etc., can solve the problems of excessive loss of raw material paper, slow processing speed, and inability to meet production needs, and achieve the effect of preventing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

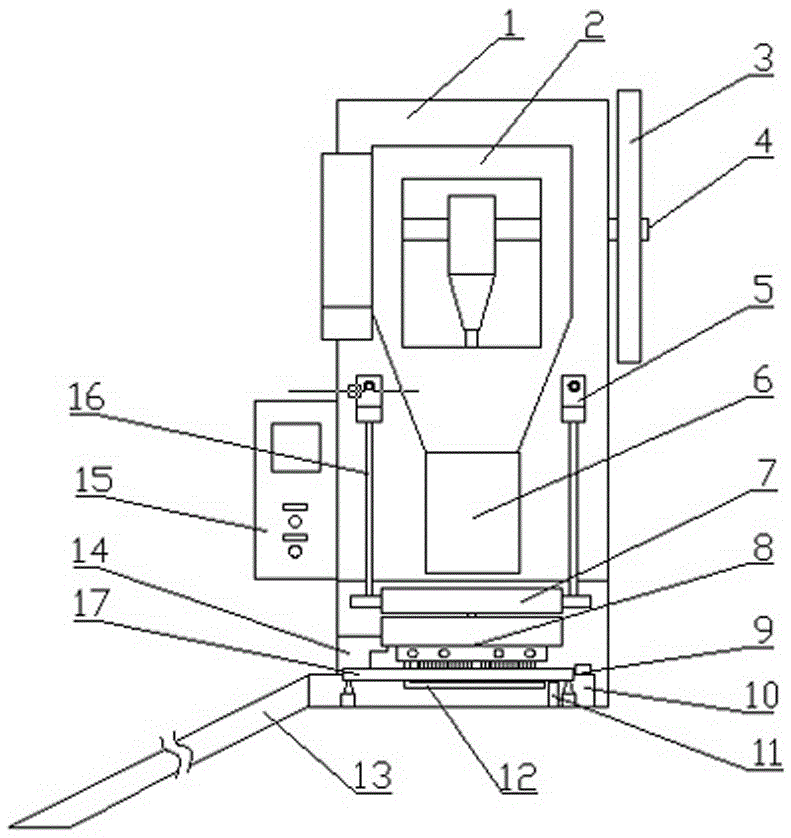

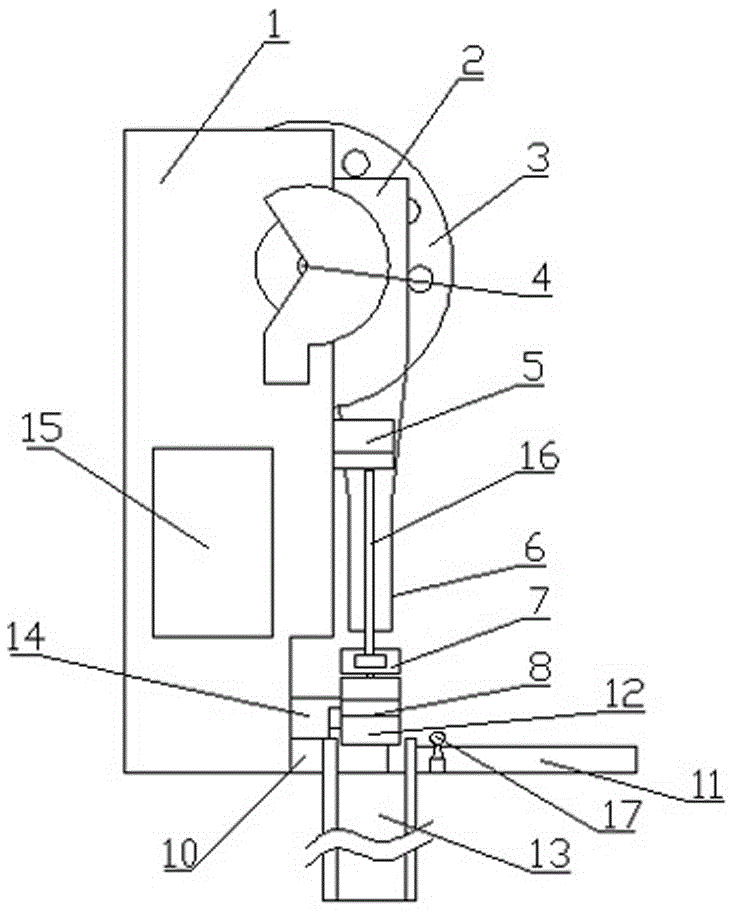

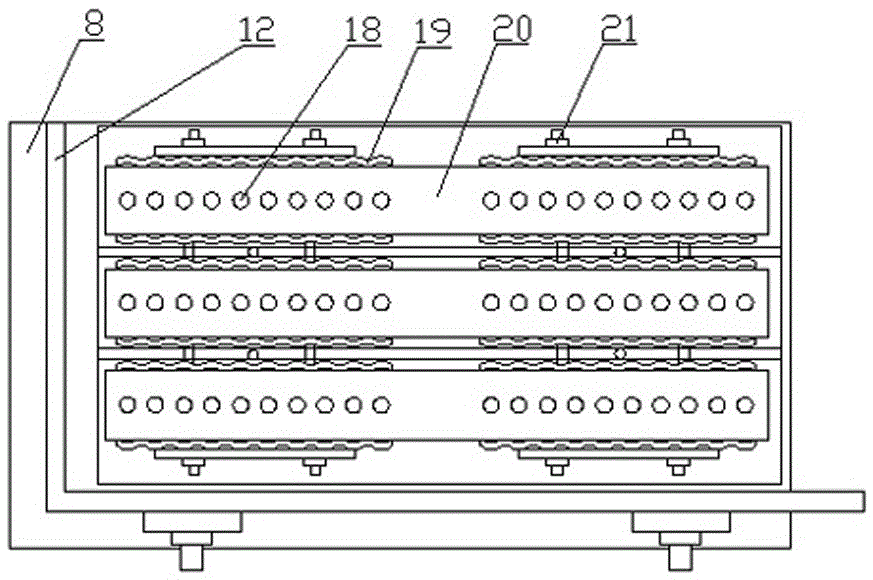

[0022] The specific implementation, structure, features and functions of the paper money processing device according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0023] see Figure 1 to Figure 4 , the paper money processing device of the present invention includes a body 1, a blade assembly 8, and a transmission tank 13, wherein: a pressure regulating body 2 is installed at the front of the body 1, an electric control box 15 is installed on the side of the body 1, and the bottom of the pressure regulating body 2 is connected with The lifting pressure head 6, one end of the pressure regulating body 2 is provided with a transmission wheel 3 through the rotating shaft 4, a mounting frame 7 is installed directly below the lifting pressure head 6, a blade assembly 8 is installed under the mounting frame 7, and a blade assembly 8 is connected directly below the blade assembly 8 The unloading pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com