Spinning reel

A technology of reel and body, applied in the field of mechanical parts in the textile field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

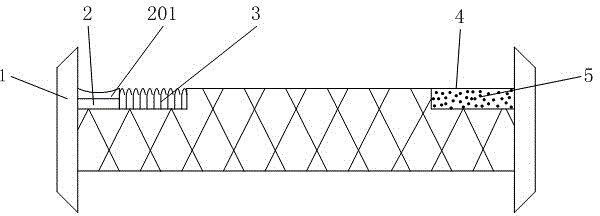

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail: as figure 1 As shown, a textile reel includes a reel body 1, wherein the front end of the reel body 1 is provided with a cut-off area 2, and a burr area 3 is provided adjacent to the cut-off area 2, and the cut-off area 2 is provided with a dedicated Blade 201, the shape of the special blade 201 is concave arc, when the probe sends down the yarn end, the reel rotates at high speed, when the yarn encounters the burr area 3, the burr catches the yarn, and the yarn end will immediately Winding on the drum body 1, when the yarn is wound, the probe moves the yarn to the cutting area 2, because the cutting area is equipped with a blade 201, so the yarn will be cut easily, and the blade 201 is set in a concave arc The shape is to prevent the yarn from being accidentally cut and cause loss. During the whole process, it can be completed without stopping the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com