Pneumatic tube clamping valve

A pneumatic tube and pinch valve technology, applied in the direction of diaphragm valves, valve devices, valve details, etc., can solve the problems of short service life and high cost, and achieve the effect of long service life, large diameter and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

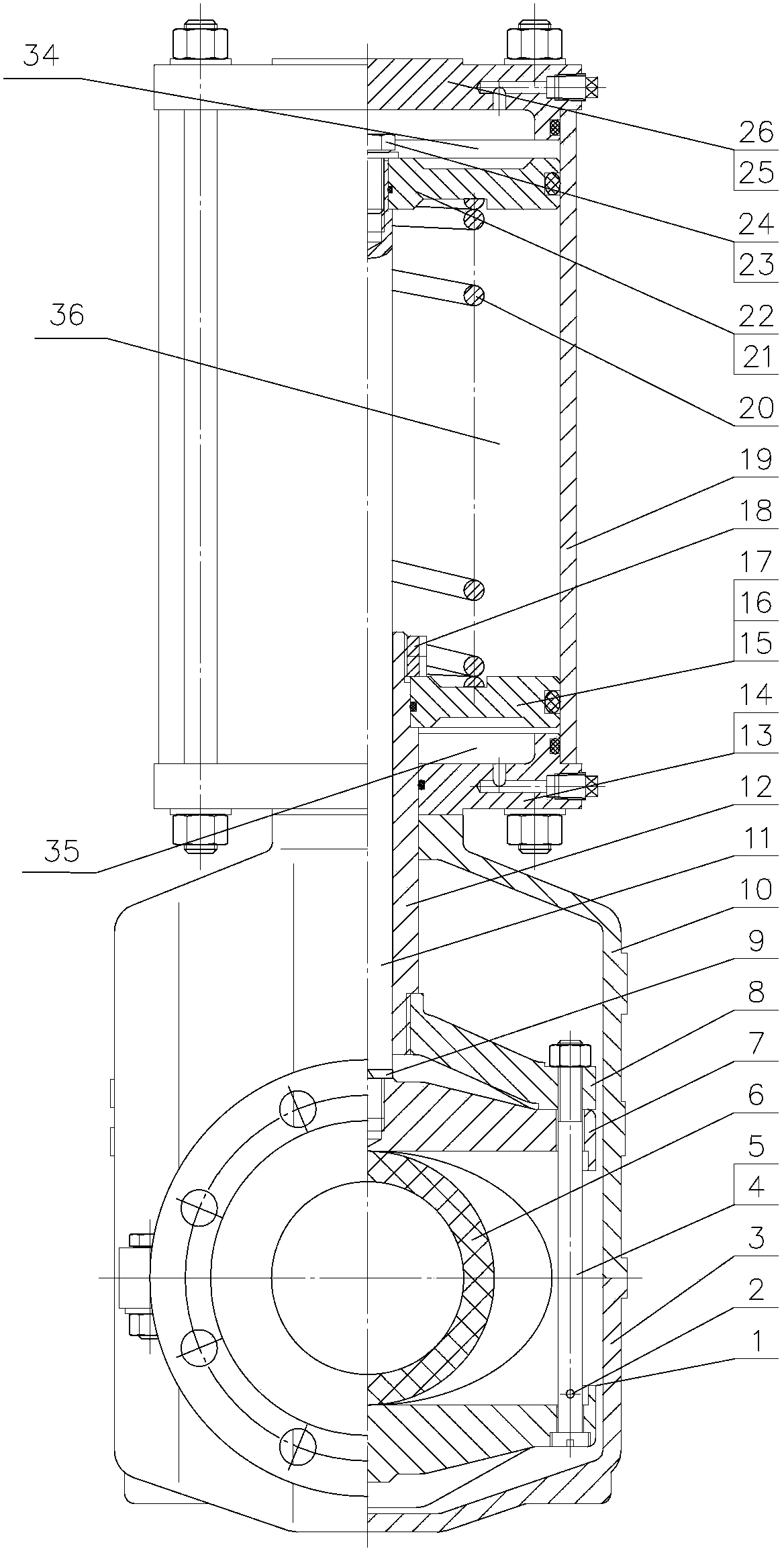

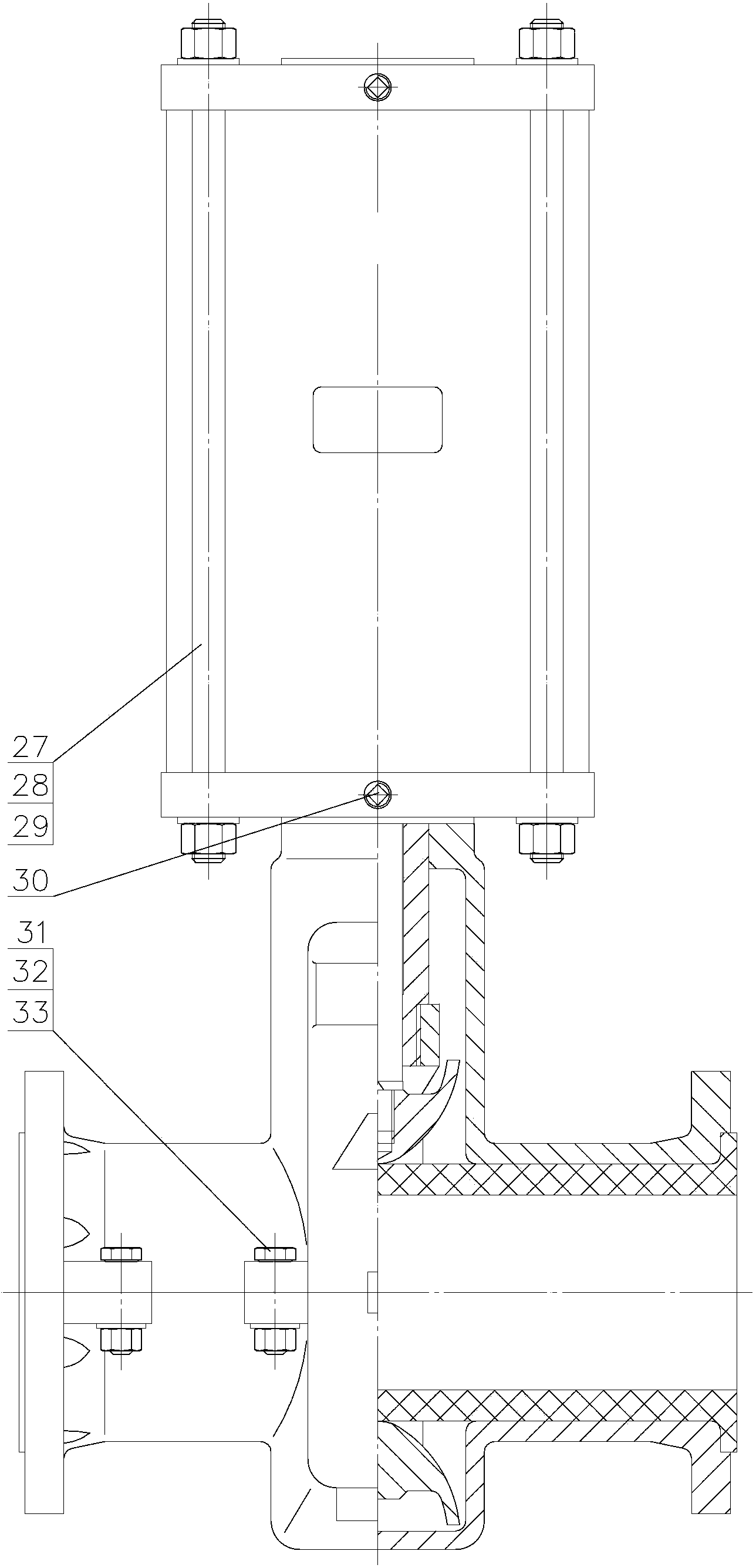

[0020] like figure 1 As shown, a pneumatic pipe pinch valve, the main components include three parts: valve body, clamping assembly and pneumatic assembly.

[0021] The valve body is composed of upper valve body 10 and lower valve body 3, which are connected by bolt II 31 and nut V33. There is also a washer IV here to enhance the locking torque of the upper and lower valve bodies. This detachable The split design makes the maintenance of the valve more convenient. The inside of the valve body is provided with a sleeve 6 as a medium flow channel.

[0022] The clamping assembly includes a small valve stem 11, a large valve stem 12, a bracket 8, a pull rod 4, an upper pressing rod 7 and a lower pressing rod 1. The small valve stem 11 is movably installed in the large valve stem 12, and is connected with the large valve stem. Rod 12 constitutes a threaded pair to facilitate the relative movement of the two. The upper pressing rod 7 is arranged at the lower end of the small valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com