Multipurpose spreading machine with flattening and cloth-pressing functions

A multi-purpose stretching machine technology, applied in the direction of fabric elongation, textile and paper making, fabric surface trimming, etc., can solve the problems of low degree of automation, low efficiency of cloth stretching, easy deviation of cloth, etc., and achieve a high degree of automation , the efficiency of pulling cloth is improved, and the effect of improving the accuracy of stop and reverse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

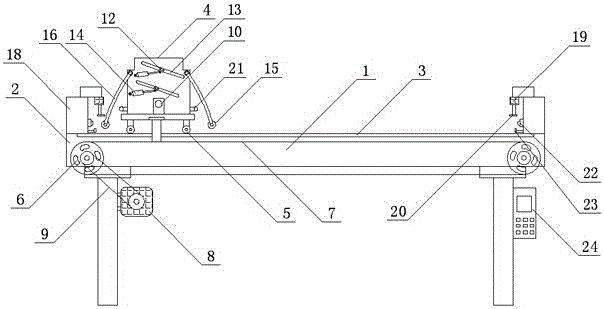

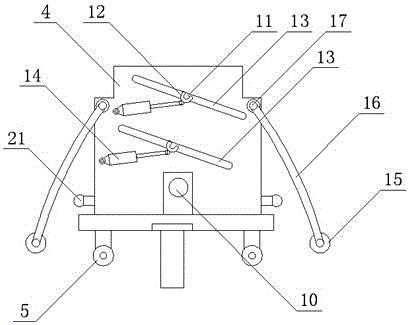

[0019] see figure 1 , figure 2 , a kind of multi-purpose stretching machine with flattening and cloth pressing function of the present invention, comprises frame 1, and frame 1 is fixed with stretching platform 2, is characterized in that: the both sides of described stretching platform 2 are respectively set There are side slide rails 3, on which there is a door-shaped movable spreader frame 4, the bottom of the movable spreader frame 4 is equipped with rollers 5 matching with the side slide rails 3, and the bottom side of the frame 1 is along the The side slide rail 3 is provided with a reciprocating drive device, and the reciprocating drive device is connected with the moving cloth frame 4 through a connecting piece, and the middle part of one side of the mobile cloth frame 4 is provided with a first-level reel storage posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com