Seamless paper pipe production line

A seamless paper tube and production line technology, applied in the direction of paperboard winding articles, etc., can solve the problems of winding layer wrinkles, poor appearance of paper tubes, material waste, etc., and achieve good comprehensive performance and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

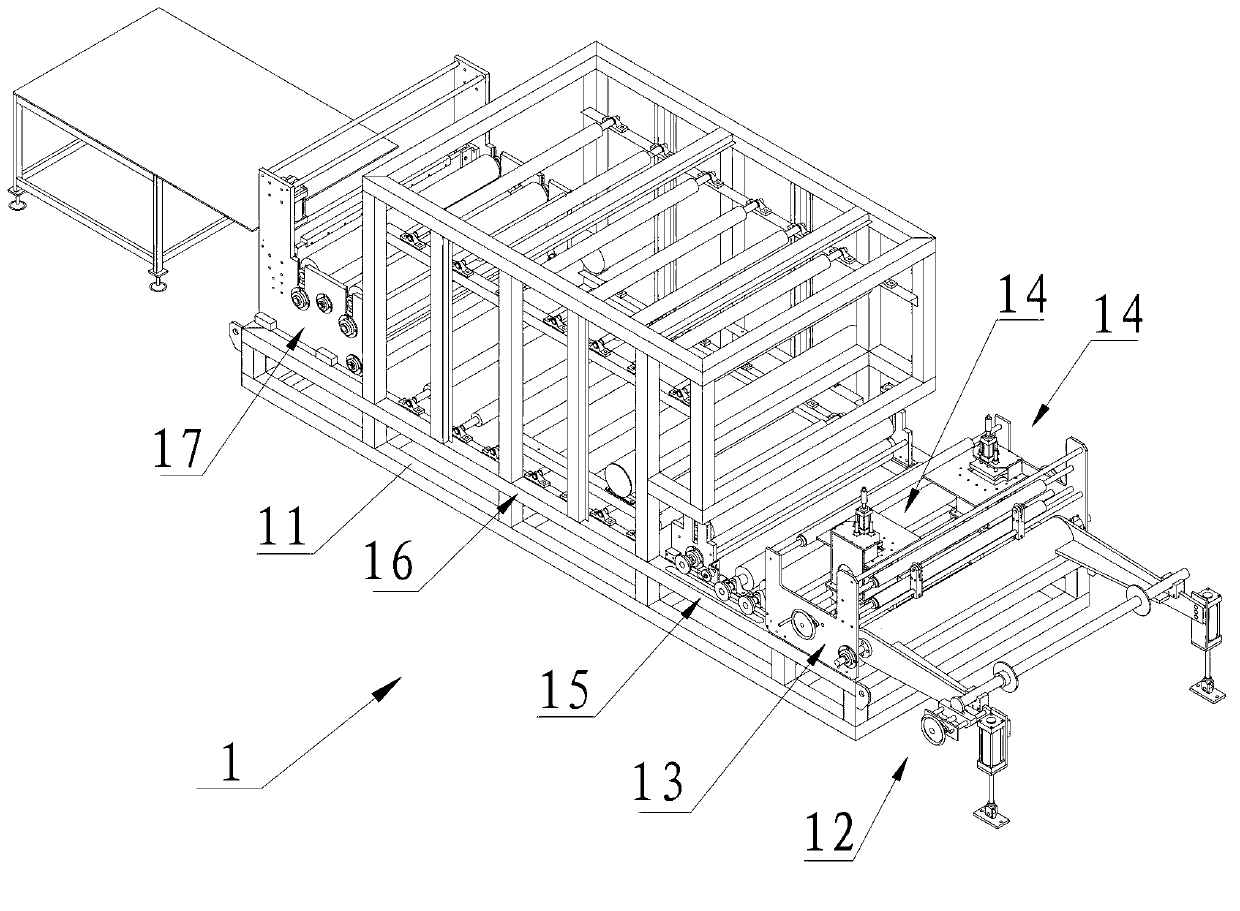

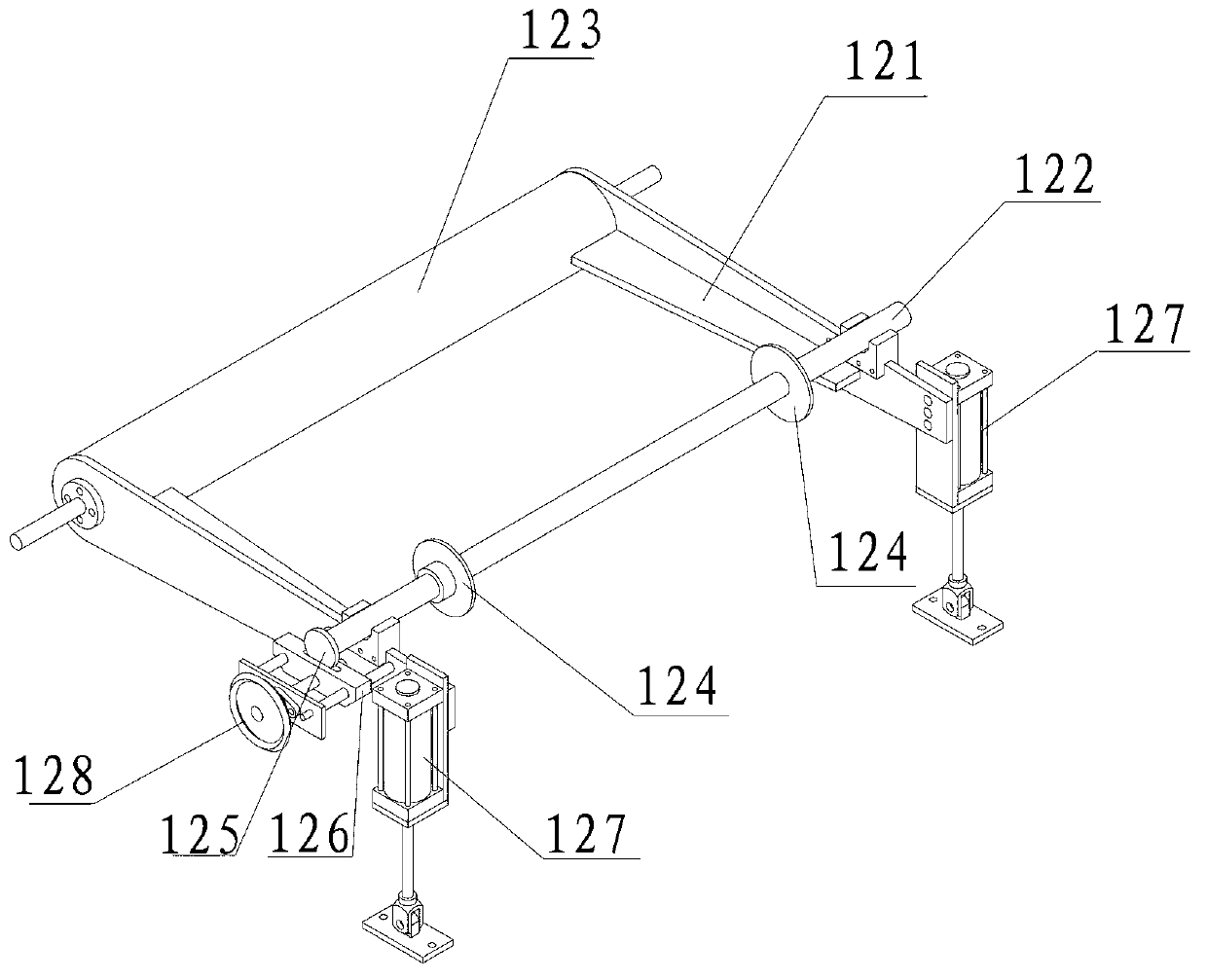

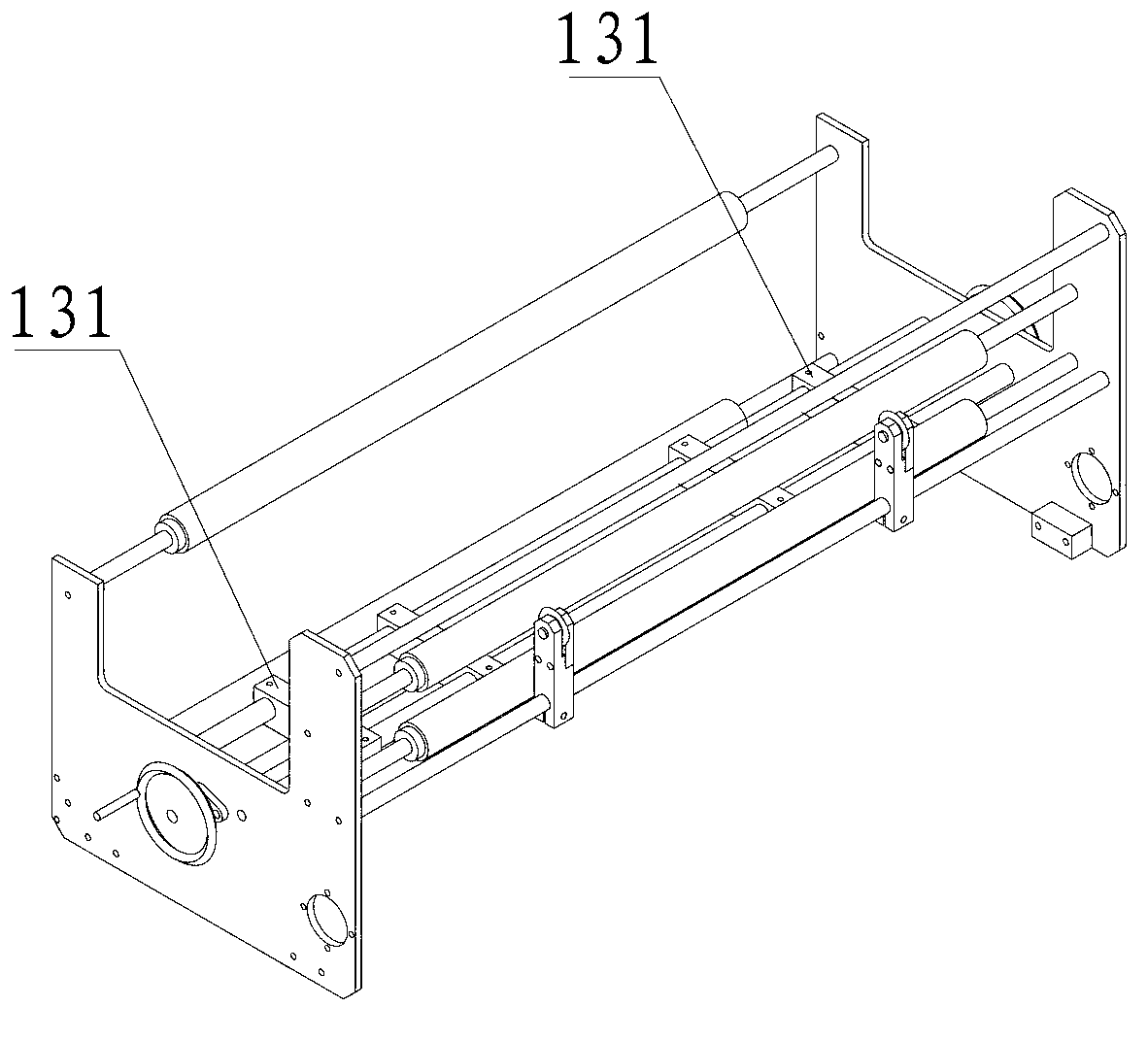

[0039] Referring to the seamless paper tube production line shown in the drawings, the seamless paper tube is formed by covering the outer circumference of the paper tube with paper, and the paper tube has a central through hole penetrating in the axial direction. The production line includes paper processing equipment 1 , paper gluing device 2 , paper tube wrapping device 3 , paper tube waxing device 4 , and paper tube calendering device 5 from front to back. The structure of each device is introduced in detail as follows:

[0040] The following definitions of direction are defined according to the front and rear directions of paper, paper roll-in and receiving. The front-back direction refers to the left-right direction when the observer observes each drawing, and the right side is the front side. , correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com