Method for preparing nanometer ceramic particle dispersion enhancing copper-based composite material through multi-step ball milling and multi-step gas phase reduction

A technology of nano-ceramic particles and dispersion-strengthened copper, which is applied in the field of copper-based composite materials, can solve the problems of low volume fraction of strengthening phase, uniform distribution of unfavorable strengthening phase, and increased difficulty in process control, and achieve excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

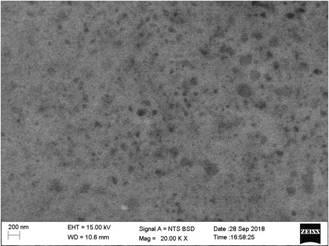

Image

Examples

Embodiment 1

[0036] 1) Simply mix 48.75g of nano-copper oxide powder with 1.25g of nano-alumina powder, and the nano-alumina powder accounts for 4% of the total volume of the mixed powder;

[0037] 2) Put the above mixed powder, cemented carbide balls, ball-to-material ratio of 20:1 and 50mL of absolute ethanol into a cemented carbide ball mill jar.

[0038] 3) Put the ball mill jar into the planetary ball mill, and perform the first high-energy ball mill with the ball mill revolution speed 300r / min and the ball mill time 2h;

[0039] 4) The ball-milled material is used as the precursor powder. Put the precursor powder into a quartz tube furnace, evacuate to 15Pa, heat up to 100°C, and then introduce reducing gas CO to reduce the precursor powder once. After 120 minutes of heat preservation, cool to room temperature with the furnace to obtain copper powder and Alumina particles are nano-scale primary copper-based composite powder;

[0040] 5) The primary copper-based composite powder in ...

Embodiment 2

[0045] The preparation method is basically the same as in Example 1, the difference is:

[0046] In step 1), it is a mixed powder of 49.49g nano-copper oxide powder and 0.51g nano-silicon carbide powder, and the nano-silicon carbide powder accounts for 2% of the total volume of the mixed powder;

[0047] In step 3), the revolution speed of the first ball mill is 250r / min, and the ball milling time is 4h;

[0048] In step 4), the primary reduction temperature is 120°C, and the reduction holding time is 70 minutes.

[0049] After spark plasma sintering, a copper-based composite material with a nano-silicon carbide volume fraction of 3.5% was obtained. The measured microhardness was HV146, the compressive yield strength was 426MPa, the maximum compressive strength was 580MPa, the compressibility was 48%, and the electrical conductivity at room temperature was 72% IACS.

Embodiment 3

[0051] The preparation method is basically the same as in Example 1, the difference is:

[0052] In step 1), it is a mixed powder of 47.59g nano-copper oxide powder and 2.41g nano-yttrium oxide powder, and the nano-yttrium oxide powder accounts for 6% of the total volume of the mixed powder;

[0053] In step 3), the revolution speed of the primary ball mill is 200r / min, the ball milling time is 6h, and the ball-to-material ratio is 15:1.

[0054] After spark plasma sintering, a copper-based composite material with a volume fraction of nanometer yttrium oxide of 10.2% was obtained. The measured microhardness was HV209, the compressive yield strength was 655MPa, the maximum compressive strength was 932MPa, the compressibility was 33.2%, and the electrical conductivity at room temperature was 55% IACS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive yield strength | aaaaa | aaaaa |

| Maximum compressive strength | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com