Automatic film pasting equipment

A film sticking equipment and automatic technology, applied in packaging and other directions, can solve the problems of inability to tighten the film, small friction, film damage, etc., and achieve the effects of reducing the probability of film defects, ensuring quality, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

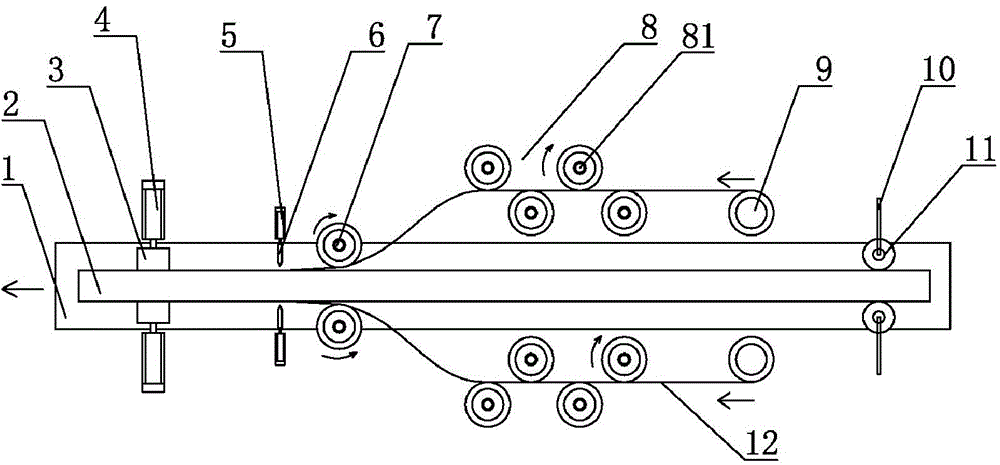

[0014] like figure 1 As shown, the present invention is an automatic film lamination equipment, an automatic film lamination equipment, including a conveying table 1, a PVC profile 2, a film pressing block 3, a first cylinder 4, a second cylinder 5, a cutter 6, and a tension roller 7. Leveling device 8, unwinding device 9, connecting bracket 10, cleaning roller 11 and packaging film 12, the PVC profiles 2 are placed on the conveying table 1, the cleaning roller 11 and the The connecting bracket 10 is fixedly connected, the cleaning roller 11 is located at the right end of the conveying table 1, the unwinding device 9 is arranged at the front end of the cleaning roller 11, and the packaging film 12 is provided On the unwinding device 9, the packaging film 12 passes through the leveling device 8 and the tension roller 7 in turn to spread on the PVC profile 2, and a cutting knife is provided at the front end of the tension roller 7 6. The cutter 6 is fixedly connected to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com