Torque testing machine for drill rod joint

A drill pipe joint and torque detection technology, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of torque not reaching the set value, large error, low production efficiency, etc., and achieve accurate torque value, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

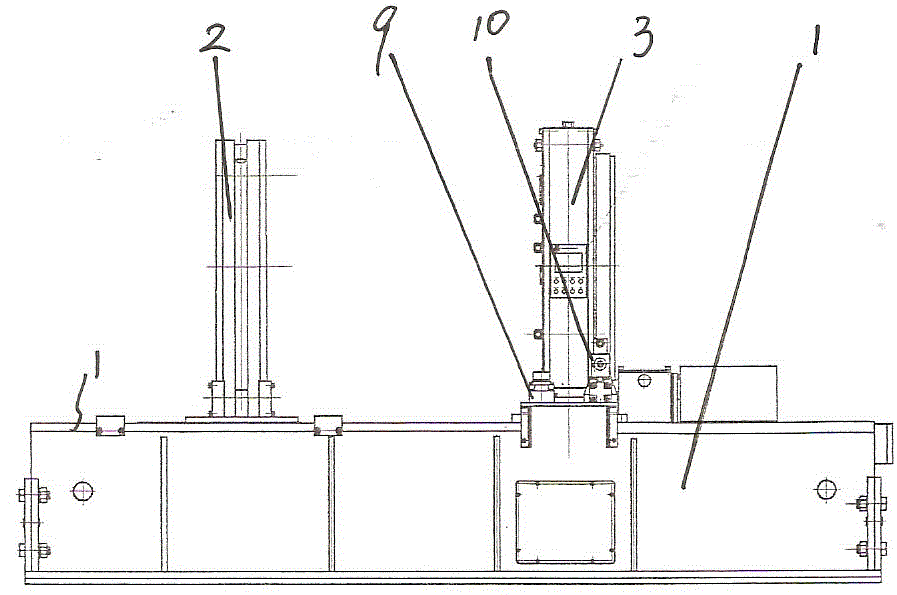

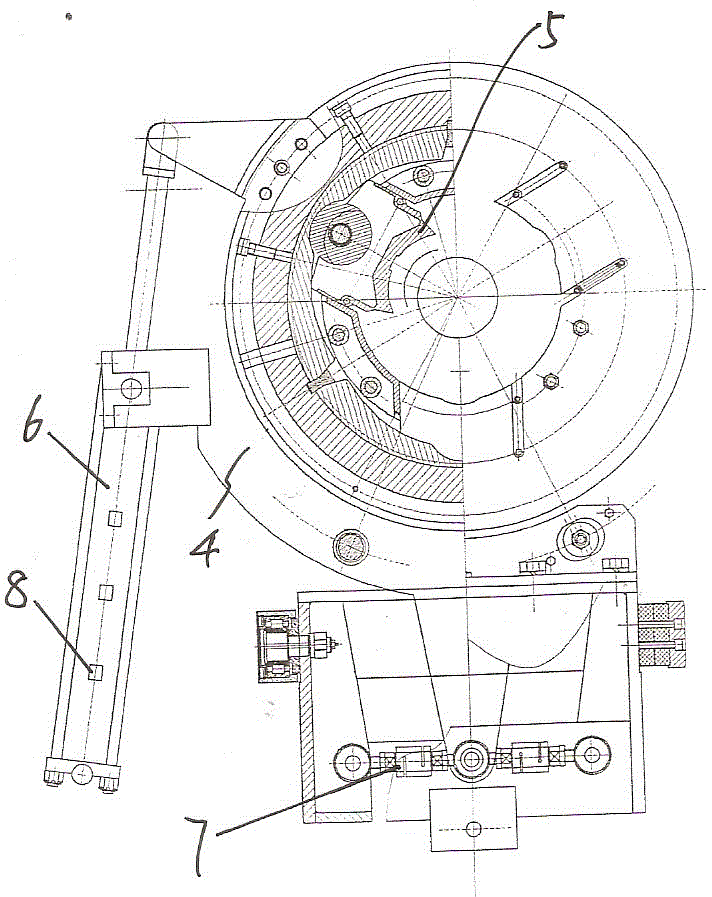

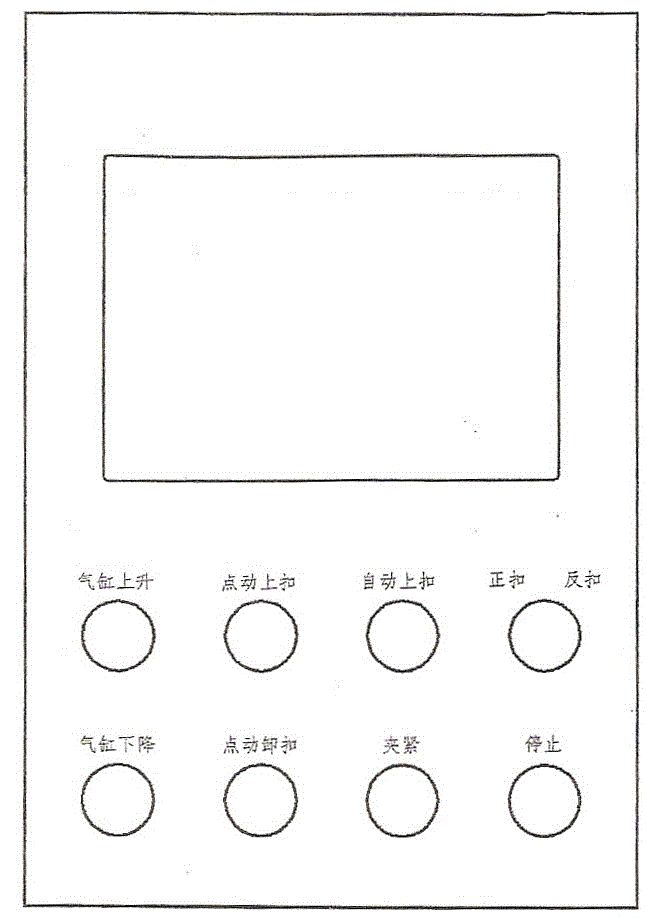

[0021] A torque testing machine for drill pipe joints, comprising a frame 1, on which are respectively mounted clamping pliers 2 and rotating pliers 3 for clamping and rotating two sections of drill pipe connected by disconnected joints; the clamping pliers include jaw plates Frame 4, the jaw plate frame is equipped with the jaw plate 5, the jaw plate frame is connected with the piston rod of the magnetic cylinder 6, the tension sensor 7 is installed on the jaw plate frame, and the magnetic cylinder is equipped with three magnetic switches 8, respectively detecting the cylinder rising in place, the cylinder middle position, The cylinder is lowered to three positions, the lifting of the magnetic cylinder is controlled by the three-position five-way double electric control slide valve 9, the rotary tong is controlled by the electro-hydraulic reversing valve 10; the torque value of the drill pipe joint and breakout is controlled by the clamp The tension sensor 7 on the tester is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com